Sucking supporting head provided with rigid and flexible supports and used for machining grids of thin-walled workpiece

A technology of thin-walled parts and support heads, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of reduced processing accuracy, inability to locate thin-walled parts, and suppress chatter, so as to reduce chatter, The effect of increasing rigidity and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

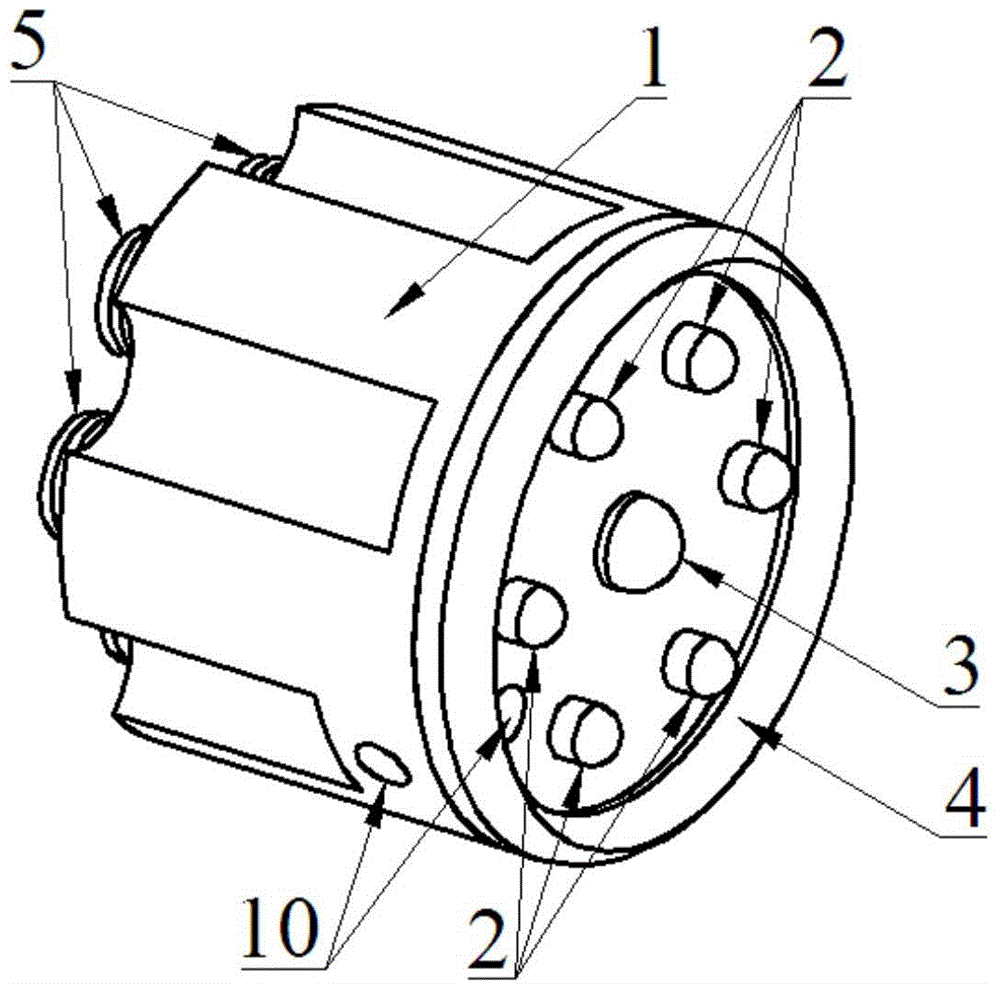

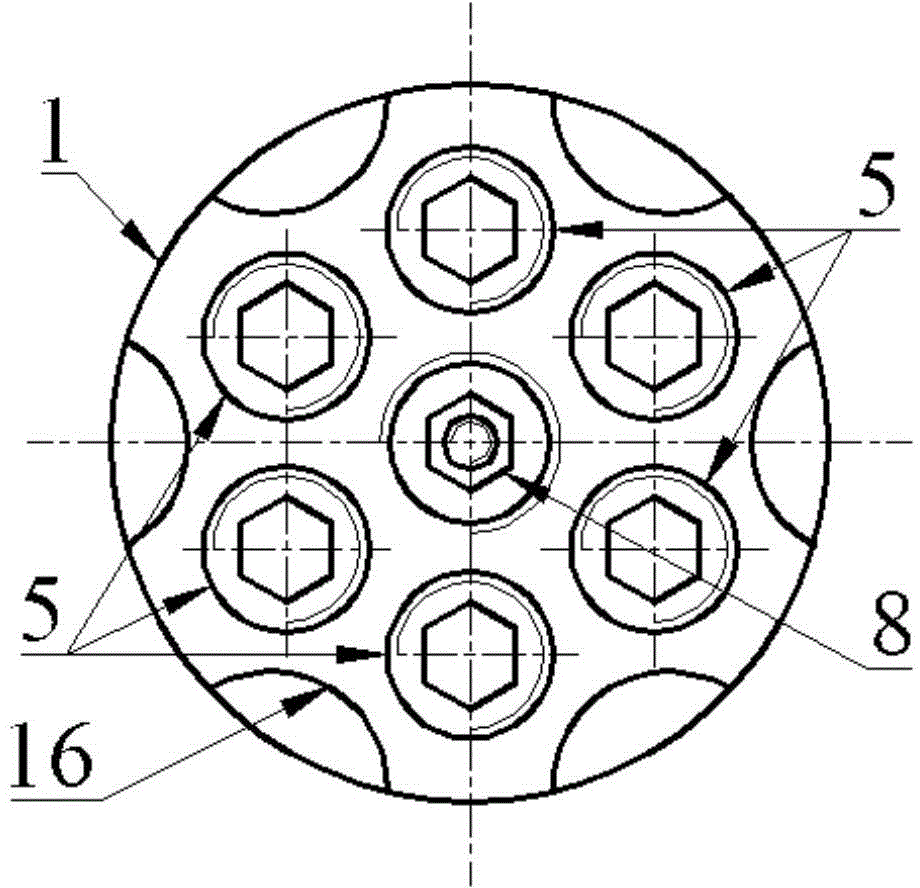

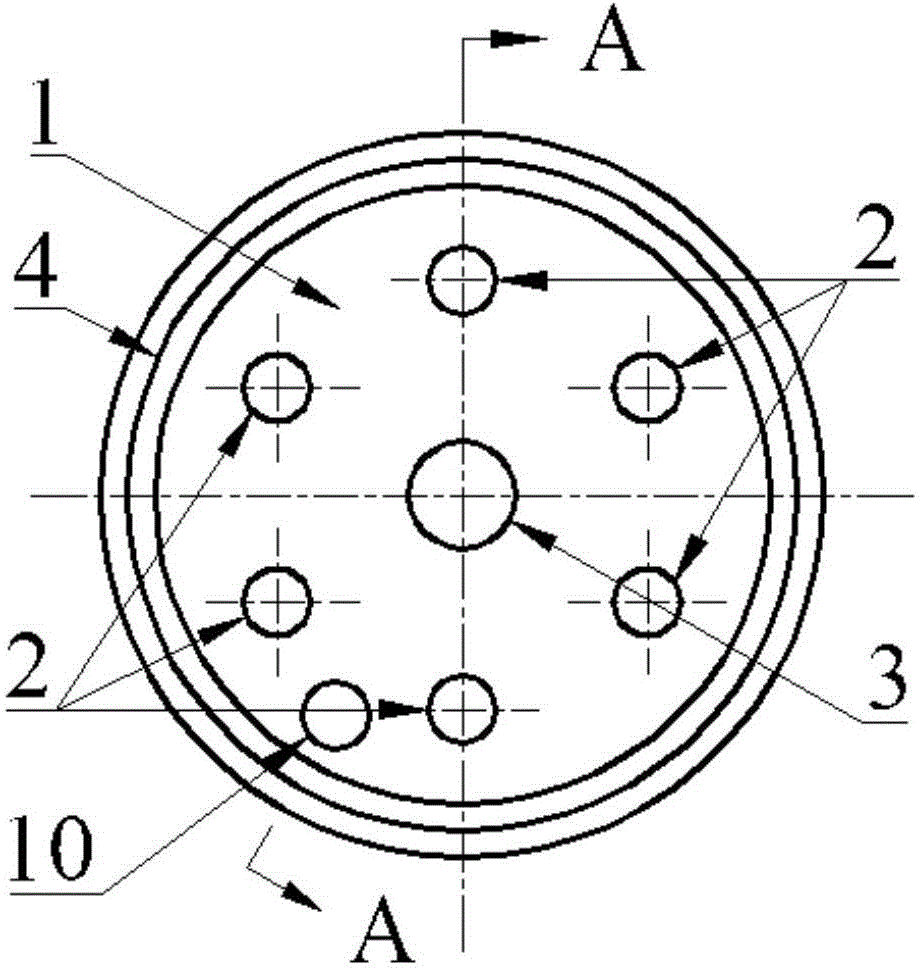

[0014] As shown in the accompanying drawings, the adsorption support head with rigid and flexible support for grid processing of thin-walled parts of the present invention includes a base 1, which is used to connect a negative pressure pump on the right end surface and side of the base. The ventilation holes 10 are uniformly opened on the base along the circumferential direction with a plurality of circumferential stepped through holes 11 whose axes are parallel to each other, and in the middle of the base are opened with the circumferential stepped through holes parallel to the axes The central stepped through hole 13 of the above-mentioned multiple circumferential stepped through holes and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com