Auxiliary supporting device, system and method for thin-walled barrel piece machining

A thin-walled cylinder and support device technology, applied in the direction of support, positioning device, clamping device, etc., can solve the problem of unsuitable support surface unevenness for single-layer airbags, and achieve the effects of increased rigidity, simple structure, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

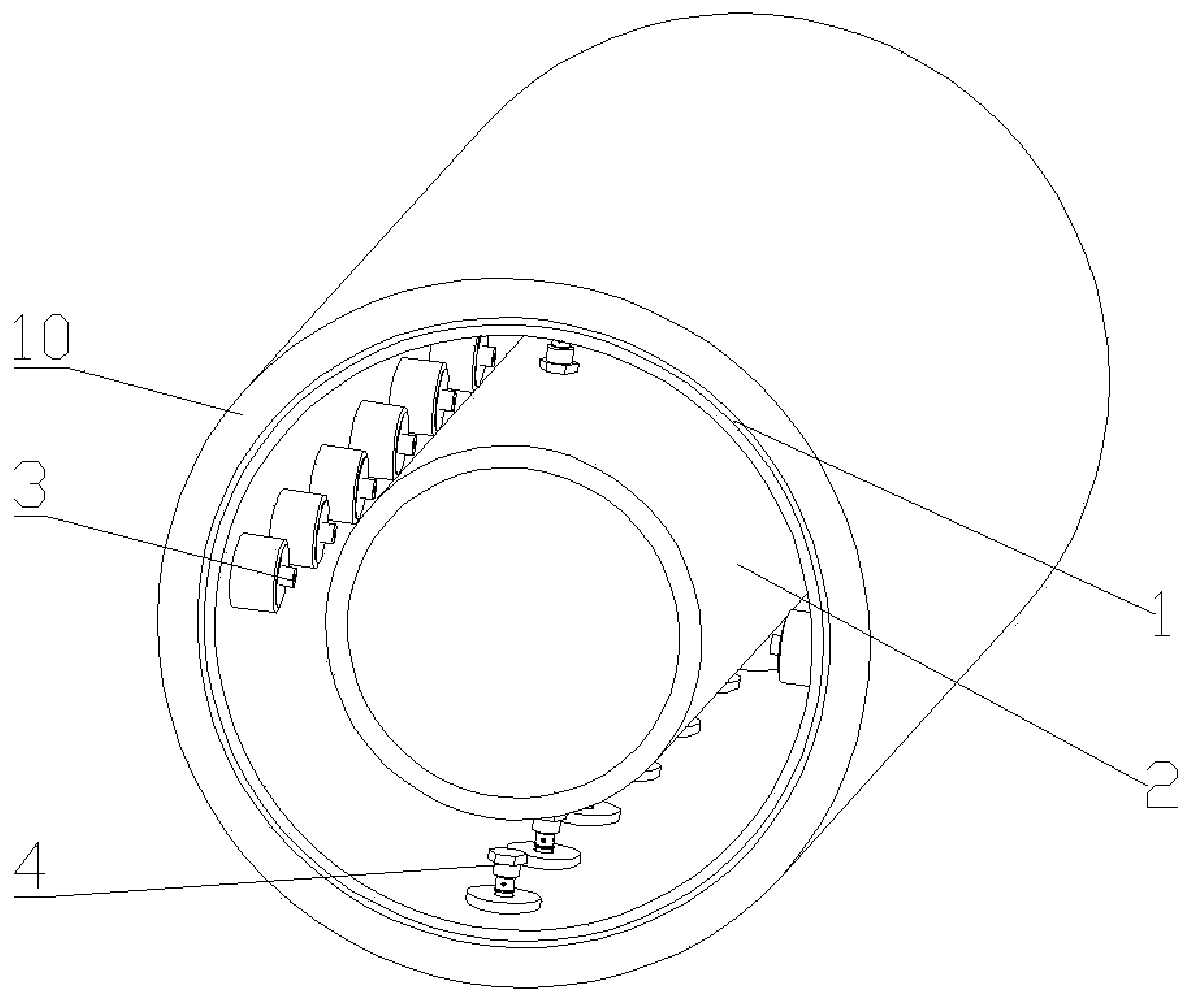

[0040] Attached below Figure 1-Figure 4 The present invention is described in detail, specifically, the structure is as follows:

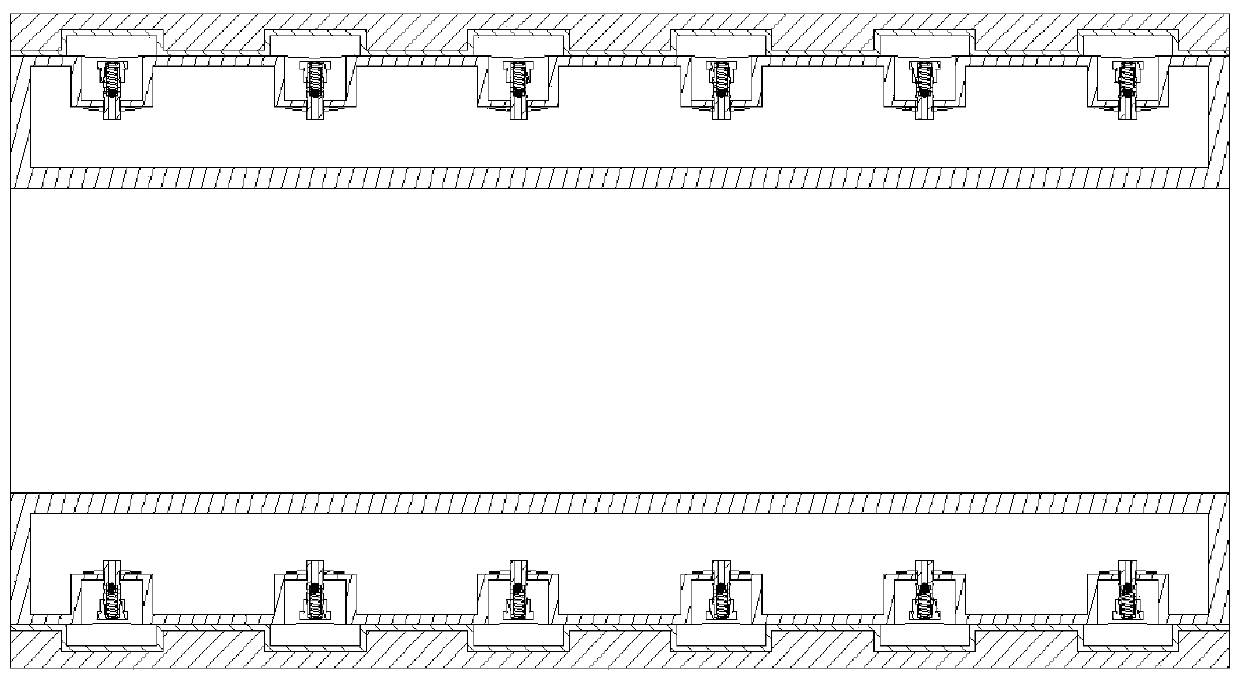

[0041] This embodiment provides an auxiliary supporting device for processing thin-walled cylindrical parts, including an outer airbag 1, an inner airbag 2, an intake valve 3, and an exhaust valve 4, wherein the inner airbag 2 is arranged on the outer airbag 1 interior. Both the outer layer airbag 1 and the inner layer airbag 2 are annular airbags whose length is compatible with the thin-walled cylindrical part 10 to be processed. In the initial state, the supporting device corresponding to the size of the thin-walled cylindrical part 10 is placed on the thin-walled cylindrical part in an uninflated state. In the inner cavity structure of the barrel 10.

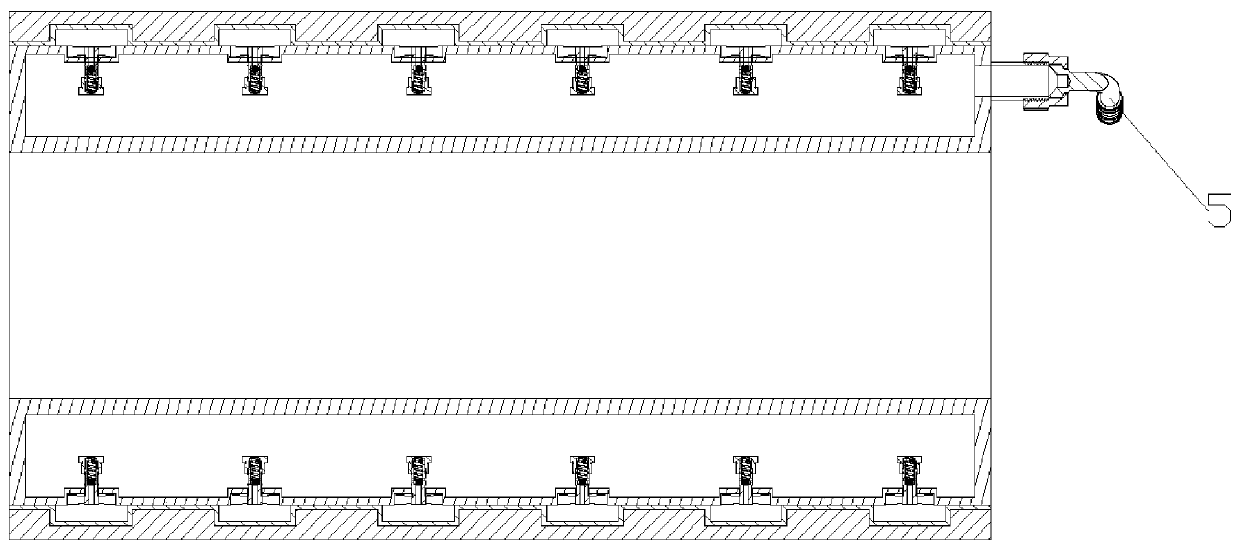

[0042] The outer wall of the inner layer airbag 2 is equipped with a valve core 5 for connecting with an inflation and deflation and air pressure detection device. An intake valve 3 and an exh...

Embodiment 2

[0049] This embodiment provides an auxiliary support system for processing thin-walled cylindrical parts, such as Figure 5 As shown, it includes the auxiliary supporting device described in Embodiment 1, the inflation nozzle 6, the hose 7, the air pressure control valve 8, the pumping dual-purpose vacuum pump 9, the air gauge 11, and the computer 12. One end of the inflation nozzle 6 is connected to the valve core 5 The other end of the inflation nozzle 6 is connected to the pumping dual-purpose vacuum pump 9 through the hose 7. The hose 7 is equipped with an air pressure control valve 8 and an air gauge 11. The air gauge 11 is connected to a computer 12 for real-time data transmission. In this embodiment, the hose 7 is a high-pressure hose.

[0050] The air pressure control valve 8 can independently set a suitable upper air pressure value. When the pressure of the filling medium in the support device reaches the upper limit of the set air pressure, the air pressure control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com