Hard-soft multipoint follow-up supporting head used for image processing

A technology of mirror image processing and support head, which is applied in the direction of metal processing equipment, metal processing machinery parts, support, etc., can solve the problems of precise positioning of difficult thin-walled parts, poor rolling performance, etc., to increase the support area, reduce control difficulty, Reduce the effect of flutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

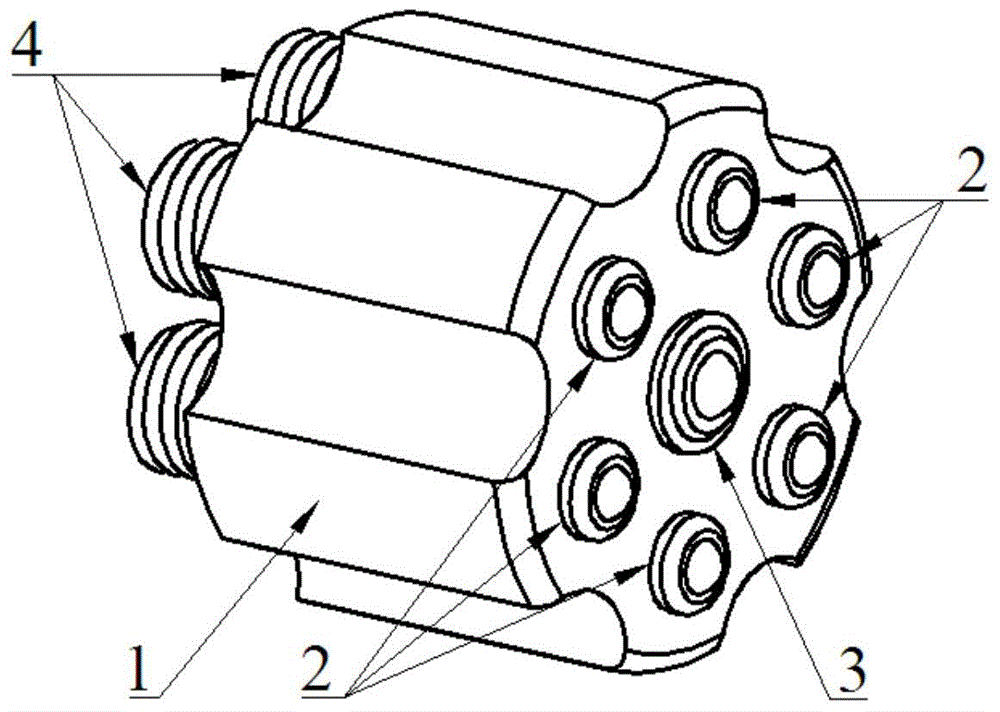

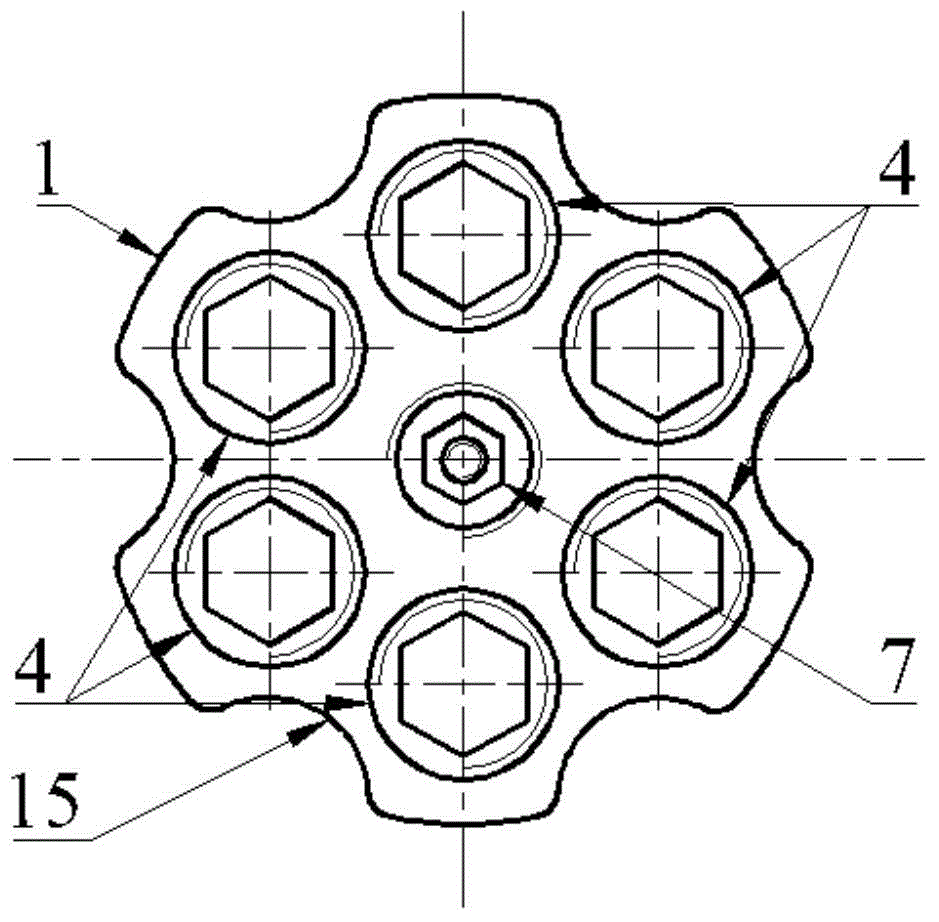

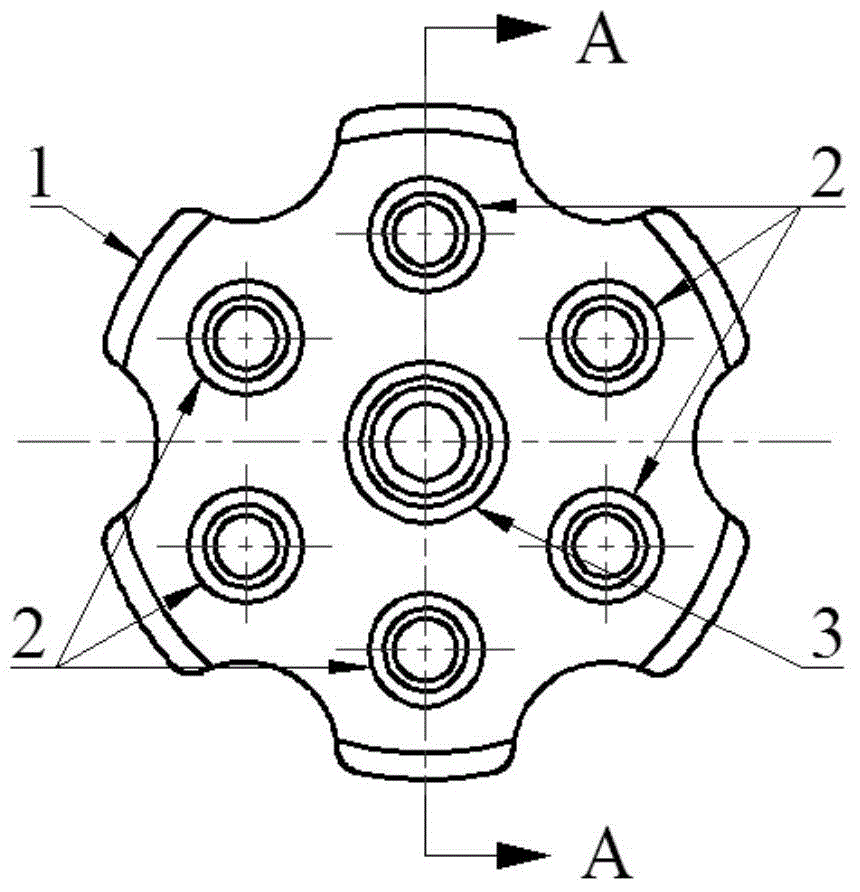

[0014] As shown in the accompanying drawings, the rigid-flexible multi-point follow-up support head for mirror image processing of the present invention includes a base 1 on which a plurality of axes are uniformly arranged along the circumferential direction and arranged parallel to each other. Circumferential step through hole 10, in the middle position of the base, there is a central step through hole 12 arranged parallel to the axis of the circumferential step through hole, on the left side of the plurality of circumferential step through holes and the center step through hole Internal threads are provided, and threaded connectors 4, left springs 5, and support rods 7 covered with right spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com