Feed device for processing deep holes

A feeding device and deep hole technology, which is applied in the field of feeding device and deep hole processing, can solve the problems of complex structure of the feeding system, affecting processing stability, high manufacturing cost, etc., to improve safety and structure Simple, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

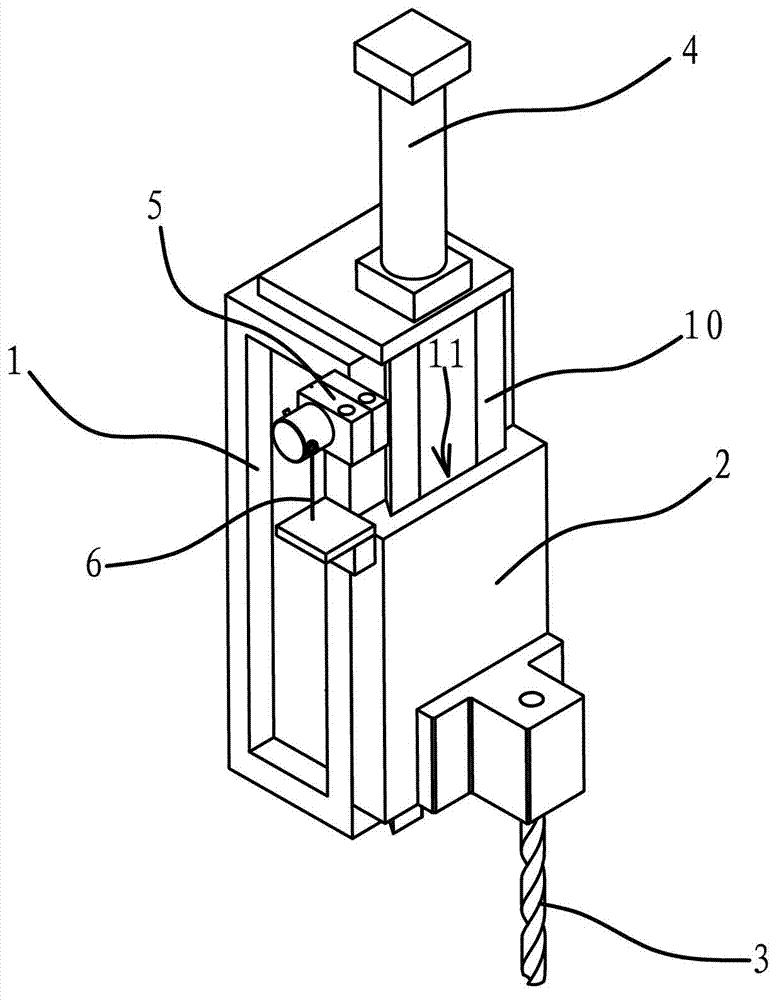

[0038] like figure 1 , 2 , shown in 8, a kind of feeding device of deep hole machining, comprises frame 1, is provided with motion slide block 2 and oil cylinder 4 on frame 1, and one end of motion slide block 2 is fixedly connected with the piston rod of oil cylinder 4, The other end of the moving slider 2 is connected with a cutting tool 3; the frame 1 is also provided with a guide rail-10, the cross-sectional shape of the guide rail-10 is a dovetail groove shape, and the inner end surface of the moving slider 2 has a matching guide rail-10. Chute one 11, guide rail one 10 and chute one 11 are embedded.

[0039] The feeding device also includes a control device, the control device includes a controller, an encoder 5 and a wire rope 6, the encoder 5 is fixed on the frame 1, and one end of the wire rope 6 is connected with the moving slider 2, and on the rotating shaft of the encoder 5 A spring is provided, and the other end of the wire rope 6 is connected with the spring on...

Embodiment 2

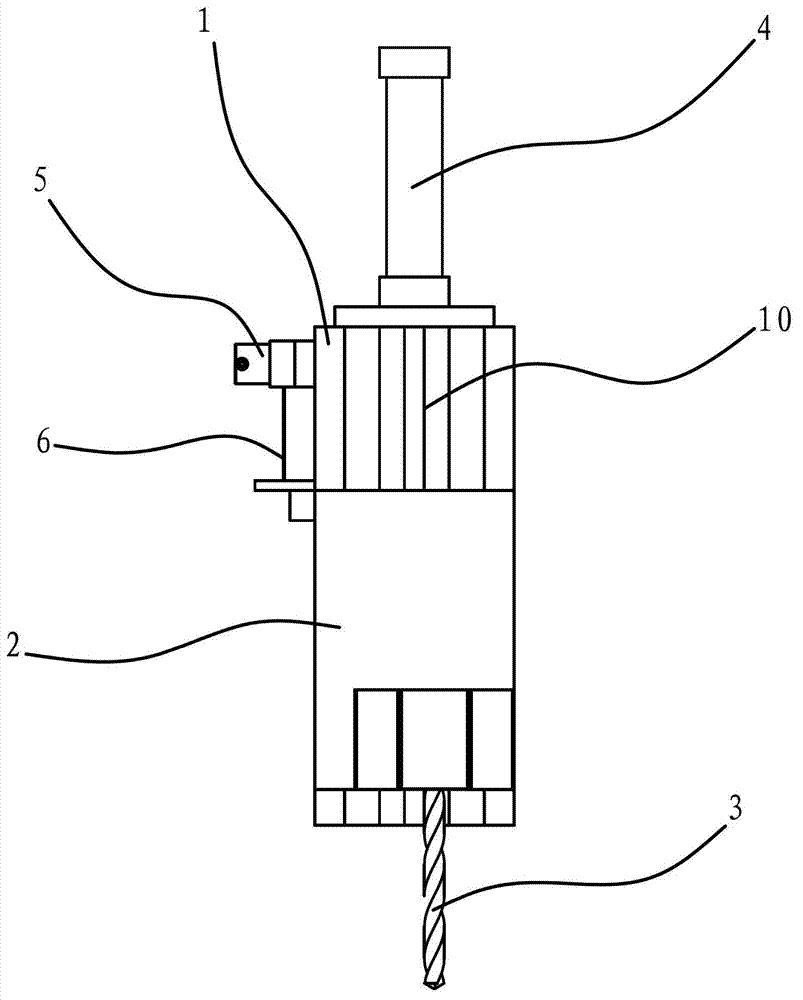

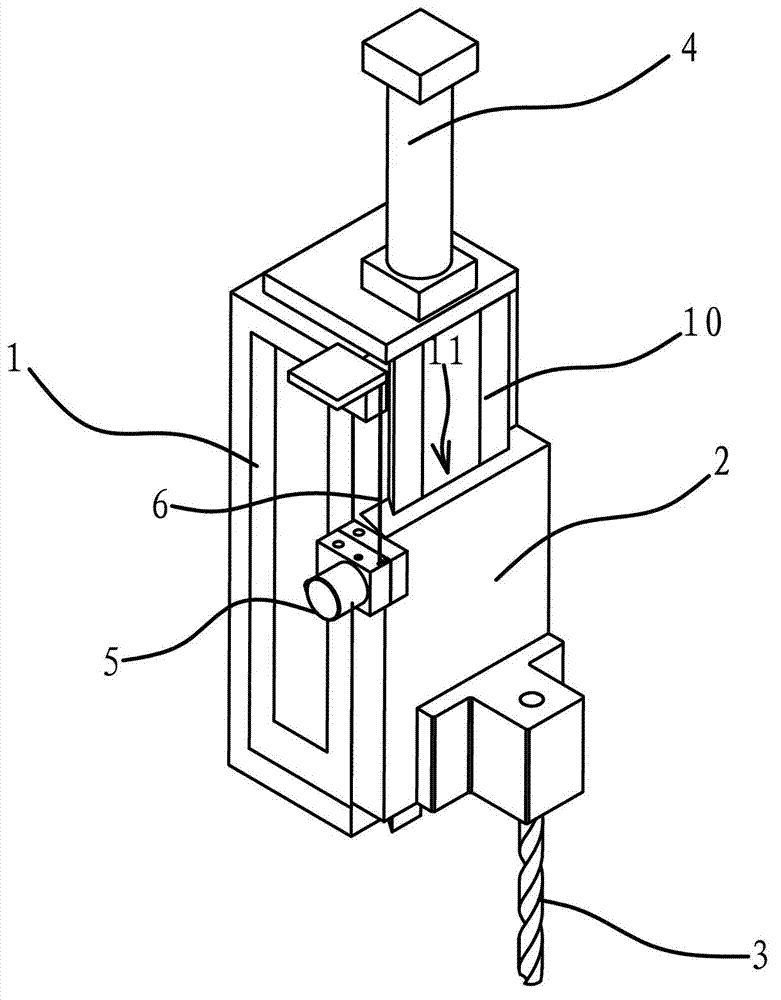

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: image 3 As shown, the control device includes a controller, an encoder 5 and a wire rope 6, the encoder 5 is fixed on the moving slider 2, one end of the wire rope 6 is connected with the frame 1, and the rotating shaft of the encoder 5 is provided with a The other end of the wire rope 6 is connected with the spring on the rotating shaft, the encoder 5 is installed on the motion slider 2, and one end of the wire rope 6 is connected with the frame 1, and the exit position is recorded by the wire rope 6 and the encoder 5. The withdrawal position of the moving slider 2 can be read out with relatively high accuracy, and the movement of the moving slider 2 to any position can be read and the position can be read, which has the advantage of more convenient installation.

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 4 As shown, the control device includes a controller, an encoder 5 and a steel bar 7, the encoder 5 is fixed on the frame 1, the rotating shaft of the encoder 5 is fixedly connected with a turntable-8, and on the frame 1 Also be provided with rotating disk two 9, one end of steel bar 7 links to each other with described motion slide block 2, and rotating disk one 8 and rotating disk two 9 are symmetrically arranged on the both sides of steel bar 7 and all abut against steel bar 7, in motion slide During the translation process of the block 2, the rigid bar 7 can be driven to move. Since the first turntable 8 and the second turntable 9 are symmetrically arranged on both sides of the steel bar 7 and are all abutted against the rigid bar 7, through the rigid bar 7 and the turntable one 8 and the The friction between the two turntables 9 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com