Integral blisk grooving special variable cutting width three-sided milling cutter

An integral blisk, three-sided edge technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of unadjustable blade position, difficult tool manufacturing, and inconvenient tool installation, saving installation time and reducing processing costs. , Improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

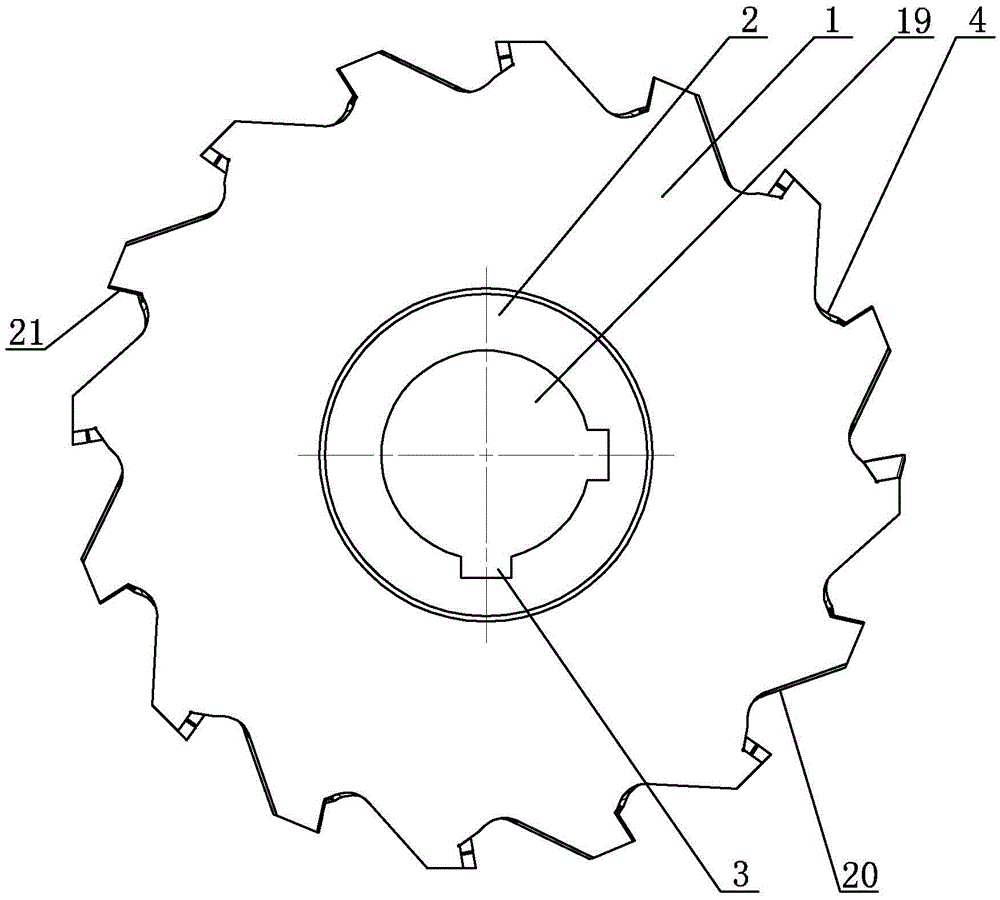

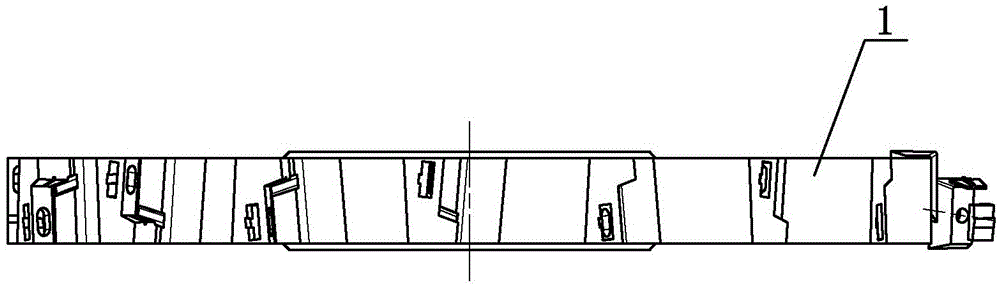

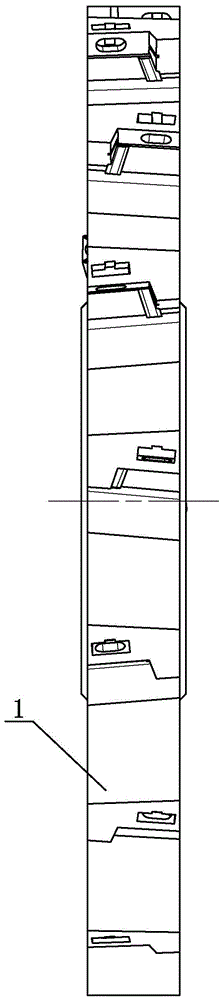

[0020] Specific implementation mode one: combine Figure 1-Figure 10 Illustrates that the variable-cut-width three-sided edge milling cutter dedicated to slotting integral blisks in this embodiment includes a cutter body 1, a central bushing 2 and N blades 6, the center of the cutter body 1 is provided with a central through hole 19, and the center The bushing 2 is located at the central through hole 19 of the cutter body 1, and the inner wall of the central through hole 19 is axially processed with at least one keyway 3, (for connecting and positioning with the drive shaft, and the milling key is installed in the keyway 3 through the key. The knife is fixed on the drive shaft and positioned through the keyway 3), and N chip removal grooves 4 are uniformly processed on the outer peripheral surface of the cutter body 1, and the N chip removal grooves 4 are opened through the thickness of the cutter body 1, and N is an even number , and 16≤N≤22; the special variable-cut width th...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 4 and Image 6 Note that the sipes 12 in this embodiment have preinstalled angles: that is, the axial relief angle is 24° to 26°, the radial relief angle is 14° to 16°, the axial rake angle is 4° to 6°, and the radial relief angle is 4° to 6°. The forward angle is 9°~11°. After the pre-installed angle is set, the size of the rake angle and rear angle of the blade can be reduced, and the strength and service life of the blade are increased. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: The radial rake angle of the special variable-cut width three-sided edge milling cutter for slotting the integral blisk described in this embodiment is 9-11°, the radial relief angle is 14-16°, and the axial rake angle is 4°. ~6°, and the axial relief angle is 9~11°. The angle after installing the blade with a front angle of 0° is the optimal angle range for processing the blisk of difficult-to-machine materials, which can effectively improve the service life of the tool. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com