Circuit board processing method

A processing method and circuit board technology, applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of easy milling sawtooth, high temperature of milling cutters, poor milling accuracy or stability, etc. Chips, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

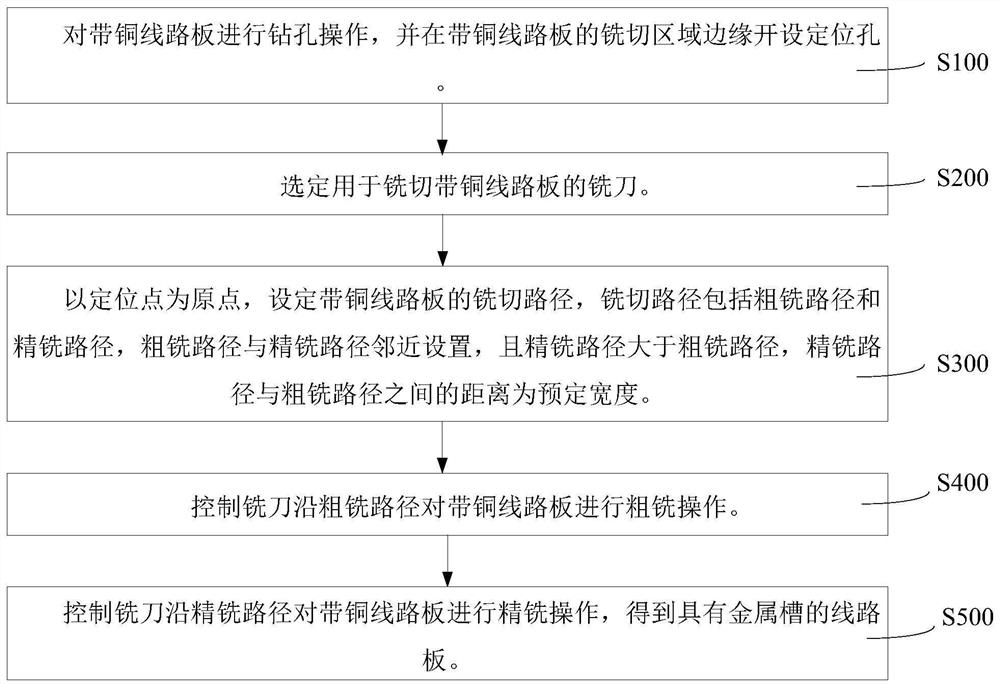

Embodiment 1

[0055] Drill the copper circuit board and make pilot holes on the edge of the milled area of the copper circuit board. Transport the copper circuit board with the positioning hole to the CNC gong machine, and select the milling cutter for milling the copper circuit board, wherein the diameter of the rough milling cutter is 0.8mm, and the diameter of the fine milling cutter is 0.5mm. With the positioning point as the origin, set the milling path with copper circuit board in the CNC gong machine. The milling path includes rough milling path and fine milling path, and there is a reserved part of 0.1mm between the rough milling path and the fine milling path . After the rough milling path is set, the milling cutter is controlled by the CNC machine to carry out the rough milling operation along the rough milling path in the circuit board with copper and the relevant parameters are set. The speed of the rough milling cutter is 0.25m / min. The lower tool position is located at the...

Embodiment 2

[0057] Drill the copper circuit board and make pilot holes on the edge of the milled area of the copper circuit board. Transport the copper circuit board with the positioning holes to the CNC gong machine, and select the milling cutter for milling the copper circuit board, wherein the diameter of the rough milling cutter is 3.0 mm, and the diameter of the fine milling cutter is 3.0 mm. 2.5mm. Taking the positioning point as the origin, set the milling path with copper circuit board in the CNC gong machine. The milling path includes rough milling path and fine milling path, and there is a reserved part of 0.3mm between the rough milling path and the fine milling path . After the rough milling path is set, the milling cutter is controlled by the CNC machine to carry out the rough milling operation along the rough milling path in the copper circuit board and the relevant parameters are set. The speed of the rough milling cutter is 0.5m / min. The lower tool position is located ...

Embodiment 3

[0059] Drill the copper circuit board and make pilot holes on the edge of the milled area of the copper circuit board. Transport the copper circuit board with the positioning hole to the CNC gong machine, and select the milling cutter for milling the copper circuit board, wherein the diameter of the rough milling cutter is 2.0 mm, and the diameter of the fine milling cutter is 2.0 mm. 1.5mm. Taking the positioning point as the origin, set the milling path with copper circuit board in the CNC gong machine. The milling path includes rough milling path and fine milling path, and there is a reserved part of 0.2mm between the rough milling path and the fine milling path . After the rough milling path is set, the milling cutter is controlled by the CNC machine to carry out the rough milling operation along the rough milling path in the copper circuit board and the relevant parameters are set. The speed of the rough milling cutter is 0.35m / min. The lower tool position is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com