Diamond grinding wheel applied to grinding of inner wall of cast pipe

A diamond and grinding wheel technology, used in abrasives, bonded grinding wheels, metal processing equipment, etc., can solve the problems of complex grinding process, difficult waste recycling, low grinding efficiency, etc., to improve the recycling rate of debris, easy to operate and The effect of high maintenance and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

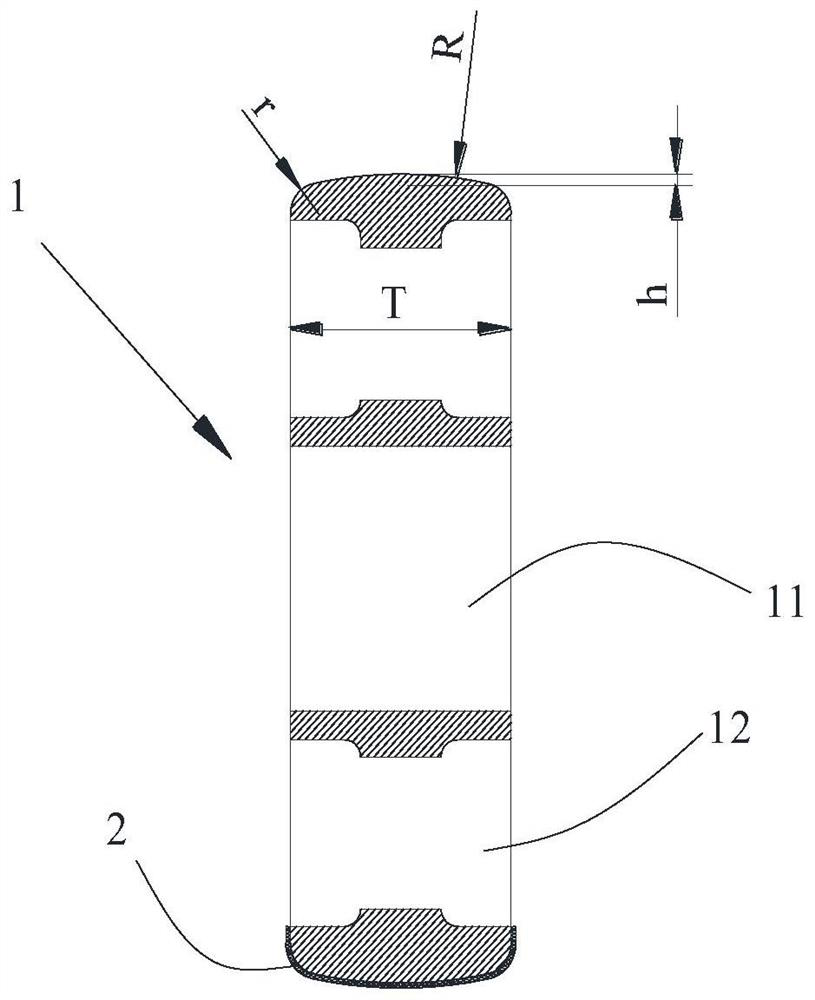

[0043] In the present embodiment, the outer diameter of the grinding wheel substrate in the diamond grinding wheel is 590 mm, the diameter of the mounting inner hole is 305 mm, the thickness of the diamond grinding wheel (i.e. the width of the wheel surface) is 100 mm, and the radius R of the grinding arc section is 626mm, the height difference h of the grinding arc section is 2mm, and the fillet size of the connecting arc section is r10.

[0044] The diamond for brazing is SMD45 grade synthetic diamond provided by Jiangyin Juxin Diamond Tool Factory with a particle size of 25 / 35 mesh, its compressive strength is not less than 400N, and the cold impact crushing rate is not less than 85%.

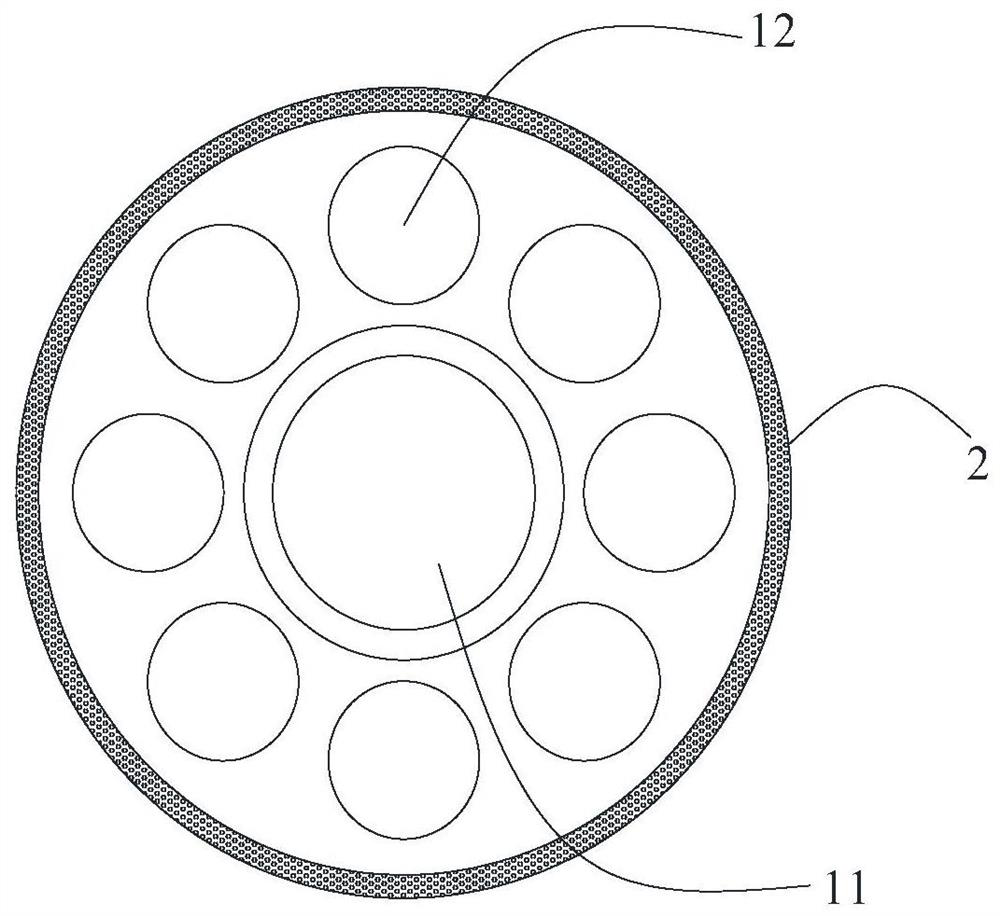

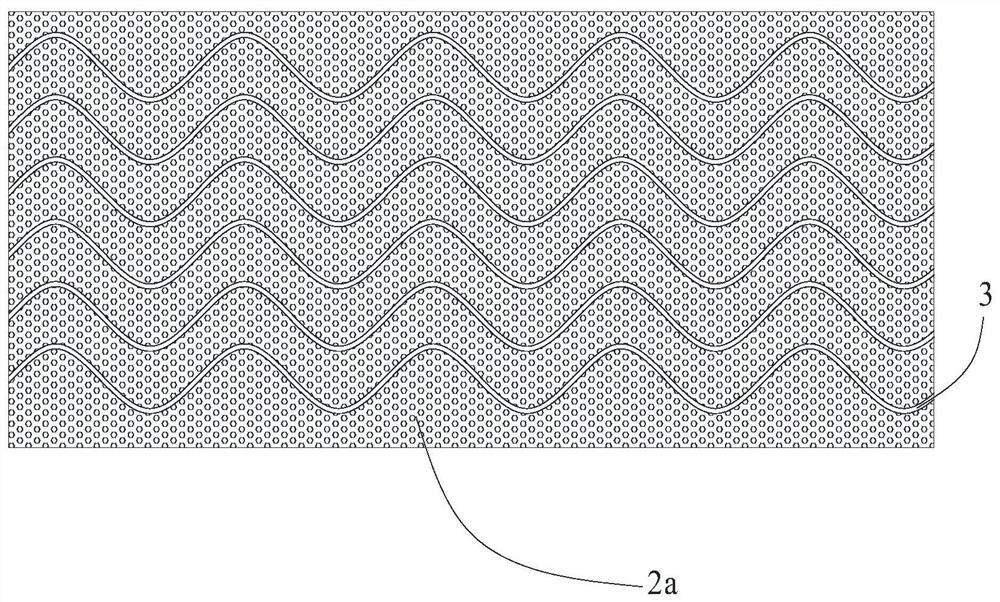

[0045] The six-segment curved spacer bar is used as the curve segment to separate the diamond cloth area on the wheel surface of the grinding wheel base to form seven diamond belts. Except for the outermost two diamond belts, the width of each diamond belt in the middle is 18mm.

[0046] The...

Embodiment 2

[0049] In the present embodiment, the outer diameter of the grinding wheel substrate in the diamond grinding wheel is 280 mm, the diameter of the mounting inner hole is 75 mm, the thickness of the diamond grinding wheel (i.e. the width of the wheel surface) is 150 mm, and the radius R of the grinding arc section is 2813mm, the height difference h of the grinding arc section is 1mm, and the fillet size of the connecting arc section is r8.

[0050] The brazing diamond adopts HSD90 grade artificial diamond with a particle size of 30 / 35 mesh Yellow River Cyclone, its compressive strength is not less than 400N, and the cold impact crushing rate is not less than 85%.

[0051] The nine-segment curve spacer is used as the curve segment to separate the diamond cloth area on the wheel surface of the grinding wheel base to form ten diamond belts. Except for the outermost two diamond belts, the width of each diamond belt in the middle is 18mm.

[0052] The diamond grinding wheel provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com