Auxiliary device for machining of oil supply crossed hole of turbine pump and machining and detecting method

An auxiliary device and turbo pump technology, which is applied in the direction of drilling molds for workpieces, mechanical devices, measuring devices, etc., can solve problems such as high cost and difficult processing, and achieve efficiency improvement, tool breakage avoidance, and flexible process control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

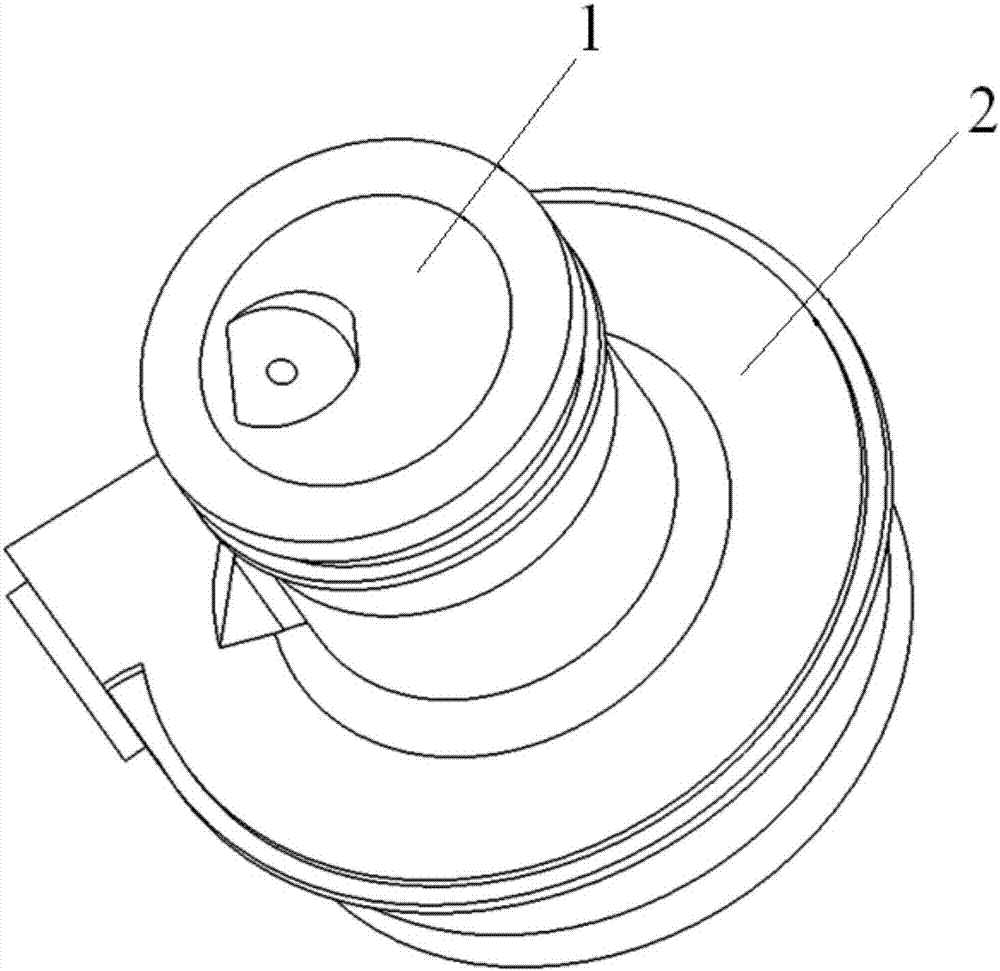

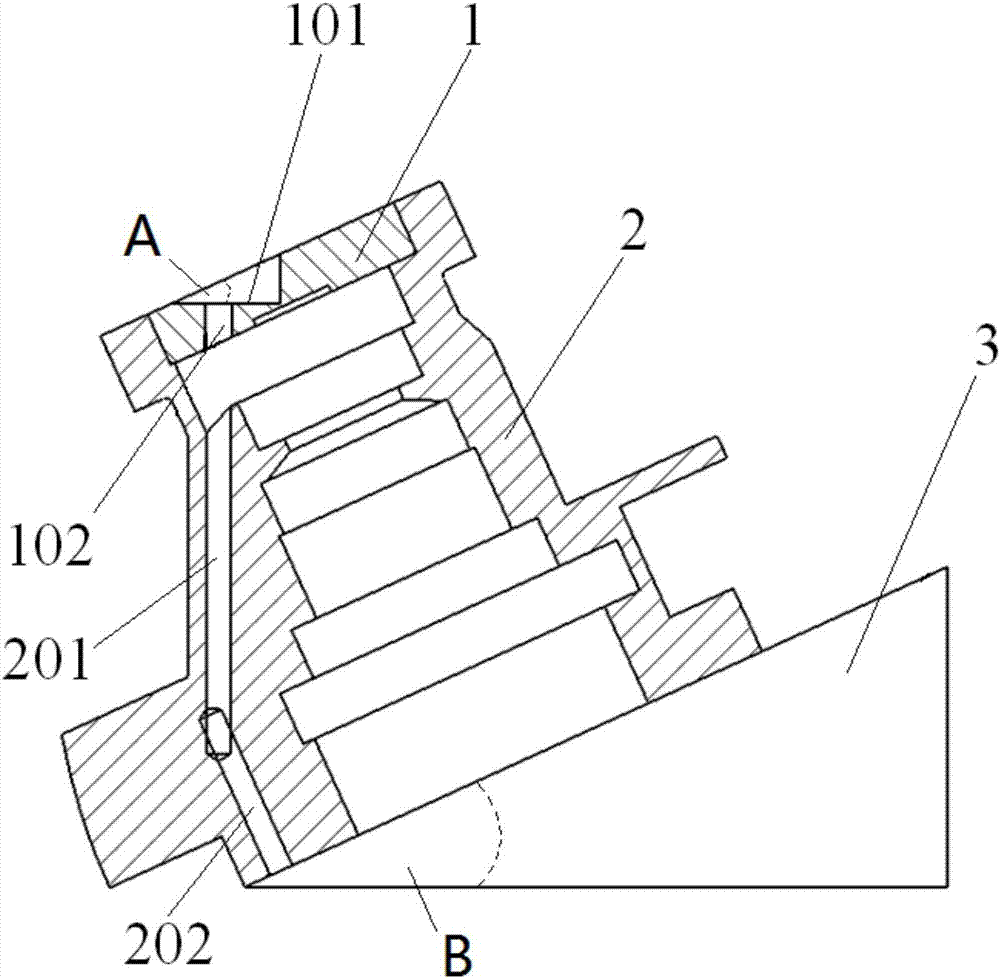

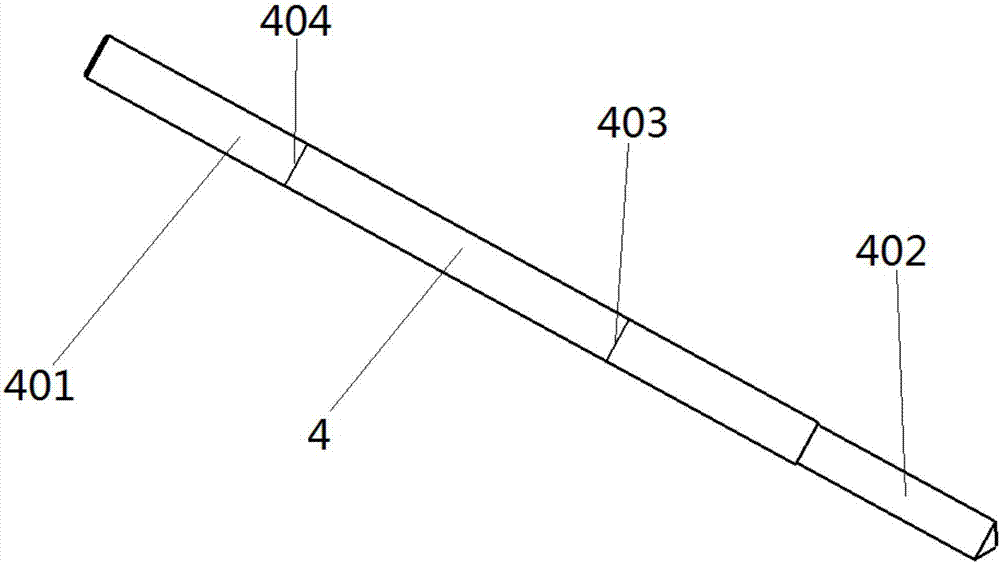

[0032] Such as Figure 1 to Figure 5 As shown, an auxiliary device for turbo pump oil supply cross hole machining according to the present invention includes a slanted hole machining limit block 1 and an angle positioning pad 3;

[0033] The processing limit block 1 is installed in the stepped hole at the upper end of the turbo pump housing 2, and the turbo pump housing 2 is placed on the inclined end surface of the angle positioning pad 3;

[0034] The upper end face of described processing limit block 1 is provided with processing groove, and the bottom end face of processing groove is processing platform 101, has the limit hole 102 that runs through on the process platform 101; The extension line of axis of described limit hole 102 and The axes of the straight holes 202 on the turbo pump casing 2 intersect;

[0035] The angle A formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com