Rapid laser repair method and device for defect of aluminum alloy guide blade

A technology of guide vanes and repair methods, applied in laser welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of low repair reliability, low repair efficiency, poor quality stability of repair parts, etc., to improve the efficiency of laser repair , the effect of saving time and cost, saving repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

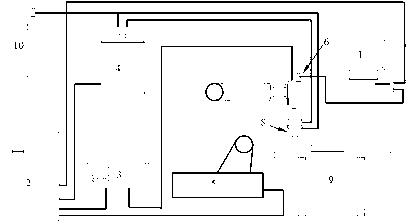

[0040] like figure 1 As shown, a laser rapid repair method and equipment for aluminum alloy guide vane defects, industrial computer 1, robot control cabinet 2, fiber laser 3, powder feeder 4, robot body 5, camera and laser ranging sensor 6, laser light path Unit 7, coaxial powder feeding nozzle 8, workbench 9, and argon gas cylinder 10, among which, the industrial control computer 1 is connected with the camera and the laser distance measuring sensor 6 through cables, and the defect pictures of aluminum alloy guide vanes taken by the camera will pass through the cables The defect position and distance information measured by the laser ranging sensor is transmitted to the industrial control computer 1 through the cable; the industrial control computer 1 is connected to the robot control cabinet 2 through the Ethernet line, and the industrial control computer 1 can realize the control of the robot through the Ethernet line. Acquisition and modification of the internal informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com