Multi-source laser multi-channel integrated repair method for metal surface

A technology of metal surface and repair method, applied in the direction of metal material coating process, coating, etc., can solve the problem of low efficiency of laser repair technology step-by-step implementation, improve laser repair efficiency, reduce secondary damage, and facilitate automated production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

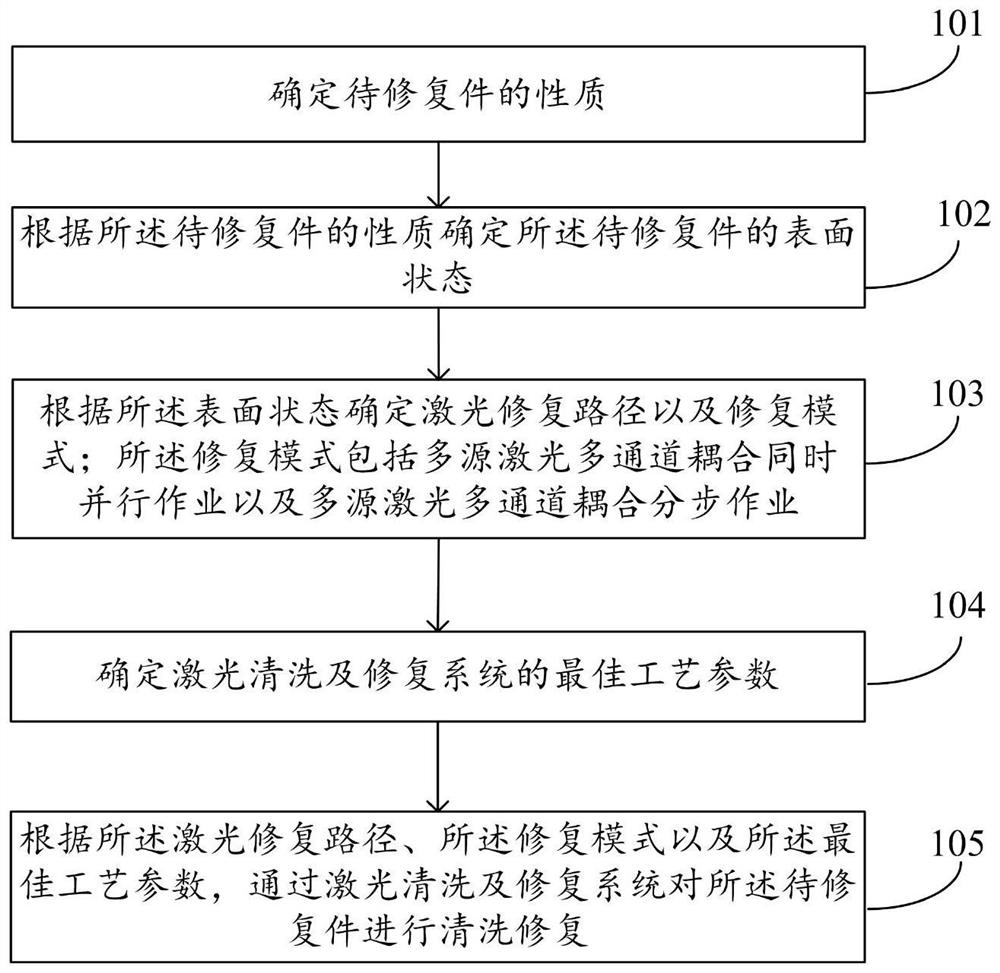

Embodiment 1

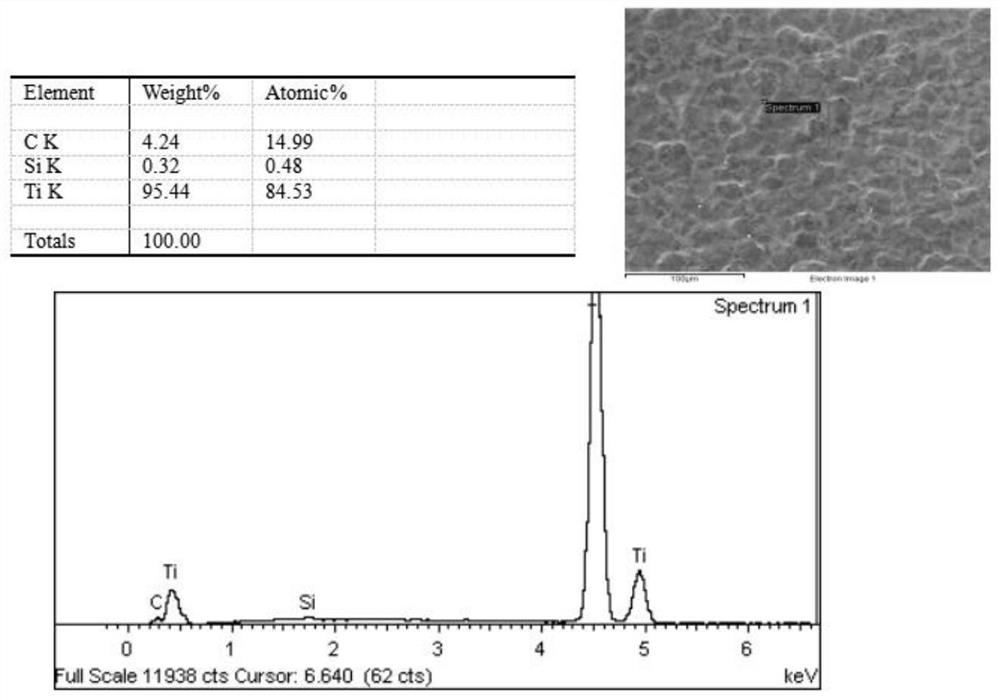

[0073] According to the method disclosed in the present invention, the oil stain on the surface of the titanium alloy is laser cleaned, and the microscopic appearance and composition of the cleaned titanium alloy surface are tested by using a scanning electron microscope and an energy spectrometer. distributed as figure 2 shown.

Embodiment 2

[0075] According to the method disclosed in the present invention, "laser cleaning-laser polishing" is carried out on the surface of the 316L iron-based alloy for parallel and integrated repair, that is, two laser light sources are used to emit from different lasers, and the surface of the 316L iron-based alloy is respectively treated one after the other. Carry out cleaning and polishing treatment, the cleaning laser is in the front, and the laser polishing is in the back; the average power of the cleaning laser is 300W, the average power of the laser polishing is 500W, the spot distance between the two laser beams is 5mm, and the spot moving speed of the two laser beams is 10mm / s , the sequential scanning time interval of the two laser beams is 1s. The three-dimensional micro-morphology and roughness of the polished 316L iron-based alloy surface are as follows: image 3 As shown, the energy density is 9.43J / cm 2 The roughness is the smallest, indicating that laser polishing ...

Embodiment 3

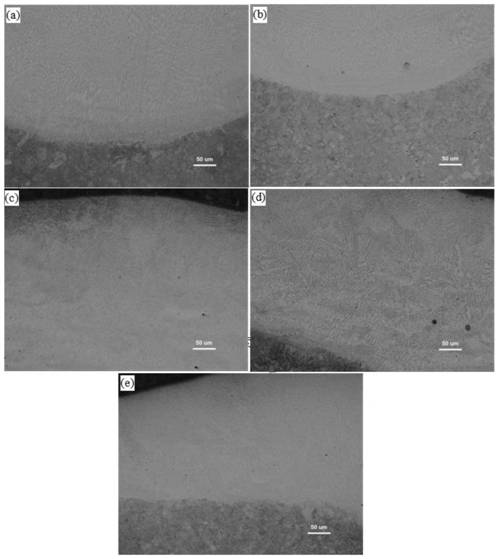

[0077] According to the method disclosed in the present invention, "carbon deposit cleaning-surface strengthening" is carried out on the surface oil stains of 316L iron-based alloy in parallel and simultaneous integrated repair, that is, two laser light sources are used to emit from different lasers, and the 316L iron-based alloy is treated one after the other. The surface is cleaned and strengthened, the cleaning laser is in front, and the laser shock strengthening is behind; the average power of the cleaning laser is 300W, and the average power of laser shock strengthening is 500W. 5mm / s, the sequential scanning time interval of the two laser beams is 1s; the wavelength of the laser shock intensified laser is 1064nm, the repetition frequency is 6kHz, the laser pulse width is 80ns, the output power is 500W, and the square spot size is 4mm×4mm; The surface micro-morphology and surface stress state of the 316L iron-based alloy after strengthening and repairing are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com