Rotary swatting fire extinguisher

A fire extinguisher and rotating shaft technology, applied in the field of fire extinguishers, can solve the problems of increased labor, equipment and cost, slow fire extinguishing speed, unsatisfactory effect, etc., to achieve the effect of easy carrying on the back, fast fire extinguishing speed, and reduced physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

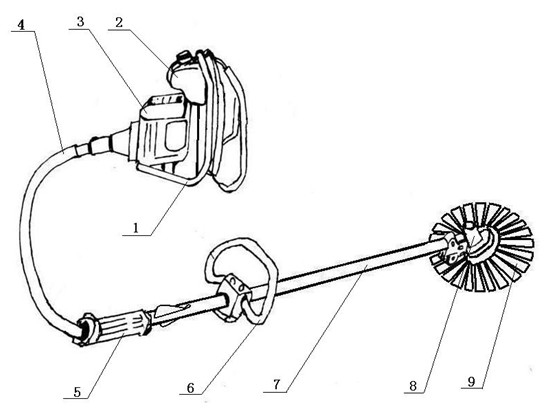

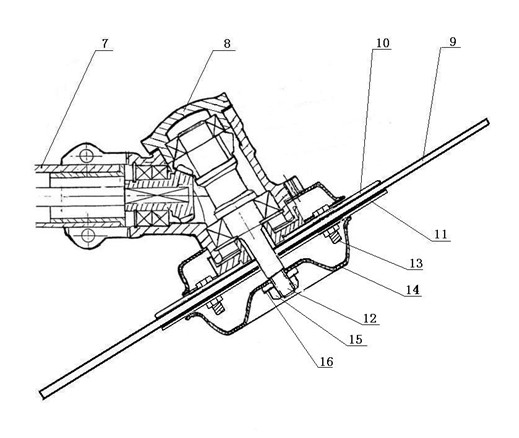

[0025] like figure 1 and figure 2 As shown, the oil pot 2 is installed on the top of the gasoline engine 3, so that gasoline can flow into the gasoline engine 3 under its own gravity, and the oil pot 2 and the gasoline engine 3 are installed on the back frame 1 as a power source, and the back frame 1 has straps for convenience. The staff carries the power source on their shoulders, the transmission shaft of the gasoline engine 3 is connected to one end of the flexible shaft 4, and the other end of the flexible shaft 4 passes through the working rod 7 with the switch 5 and is connected to the rotating shaft 12 of the working head 8 at the front end of the working rod 7 , the switch 5 on the working rod 7 can control the speed and power of the gasoline engine 3, the handle 6 is convenient for the operator to hold, the front end of the working rod 7 is the working head 8, and the upper splint 10 is fixed on the rotating shaft 12 of the working head 8. Four holes are evenly ope...

Embodiment 2

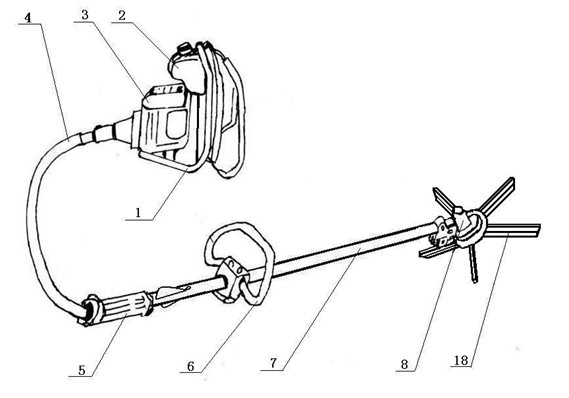

[0027] like image 3 and Figure 4 As shown, the power transmission and control part of the working head 8 of the rotary swat fire extinguisher is the same as that of Embodiment 1. The protective cover 17 is fixed on the rotating shaft 12, and the five mounting plates 22 are evenly arranged and welded on the circumference of the bottom end of the rotating shaft 12 under the protective cover 17. , the angle between every two mounting plates 22 is 72°, the mounting plates 22 are arranged parallel to the rotating shaft 12, and there are two mounting holes for installing strip type fire extinguishing soft belts 18 on the mounting plate 22, the distance between the two holes is 2cm, each Strip type fire extinguishing belt 18 is 2cm wide and 60cm long. There is also a mounting hole in the middle of the installation end of strip type fire extinguishing belt 18. Use bolt 21, nut 20 and gasket 19 to fix strip type fire extinguishing belt 18 on the mounting plate On the 22, two strip t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com