Manufacturing process of silicon solar cell

A solar cell and manufacturing process technology, applied in sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve the problems that MWT solar cells cannot further improve conversion efficiency, and cannot cover uniformly perforated side walls, so as to improve photoelectric conversion Efficiency, improvement of battery conversion efficiency, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

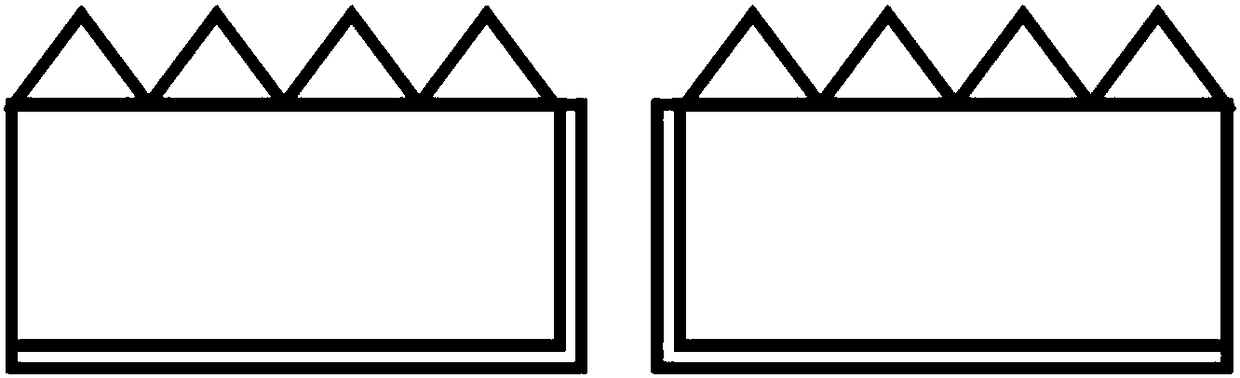

[0052] Such as figure 1 As shown, the ALD film is prepared on the perforated inner wall and the back of the battery, and the back of the battery and the perforated inner wall (reaction in figure 1 Among them, the inner wall of the perforation (the gap in the middle of the battery) has a uniform coating, which can effectively passivate the back of the p-type crystalline silicon battery, and at the same time protect the hole wall and insulate the front and back electrodes.

[0053] process such as Figure 4 Shown are: Laser Drilling, Texturing, Diffusion, Reverse Etching, ALD or PEALD passivation, Front AR, Printing, Sintering.

[0054] (1) Laser drilling: use a P-type single crystal silicon wafer with a resistivity of 1 to 3Ω.cm as the substrate, and use a laser to drill several columns from the back of the silicon wafer with a diameter of 1.2 to 2.2mm. The spacing is 8-20mm;

[0055] (2) Texturing: Texturing the silicon wafer, and making a P-N junction with a square resista...

Embodiment 2

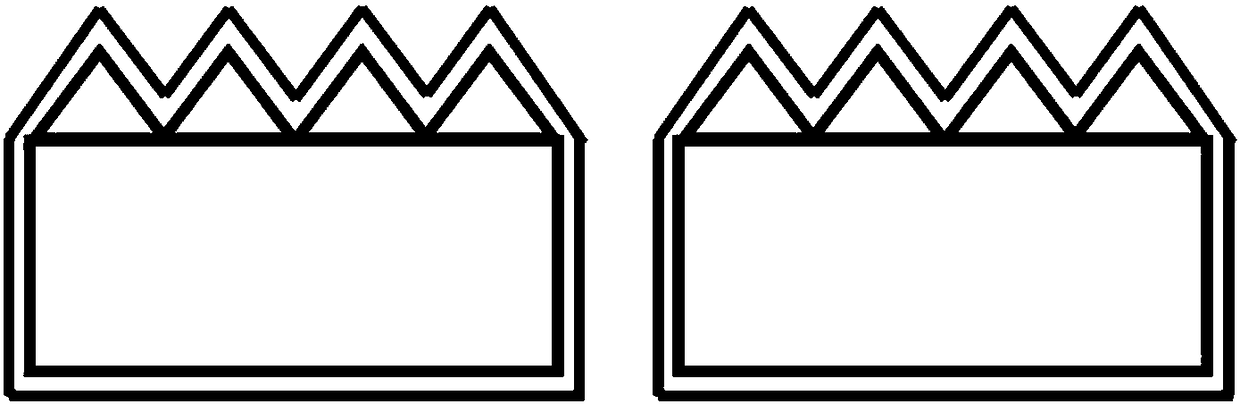

[0063] Such as figure 2 As shown, the ALD film was prepared by perforating the inner wall and the front and back of the battery (reaction in figure 2 Among them, the inner wall of the perforation is the gap in the middle of the battery), which can effectively passivate the back of the p-type crystalline silicon battery, and at the same time protect the wall and front of the hole and insulate the front and back electrodes.

[0064] process such as Figure 5 Shown: laser drilling, texturing, diffusion, back etching, front anti-reflection layer, ALD or PEALD passivation film, printing, sintering.

[0065] (1) Laser drilling: use a P-type single crystal silicon wafer with a resistivity of 1 to 3Ω.cm as the substrate, and use a laser to drill several columns from the back of the silicon wafer with a diameter of 1.2 to 2.2mm. The spacing is 8-20mm;

[0066] (2) Texturing: Texturing the silicon wafer, and making a P-N junction with a square resistance value of 85-95Ω / port on the...

Embodiment 3

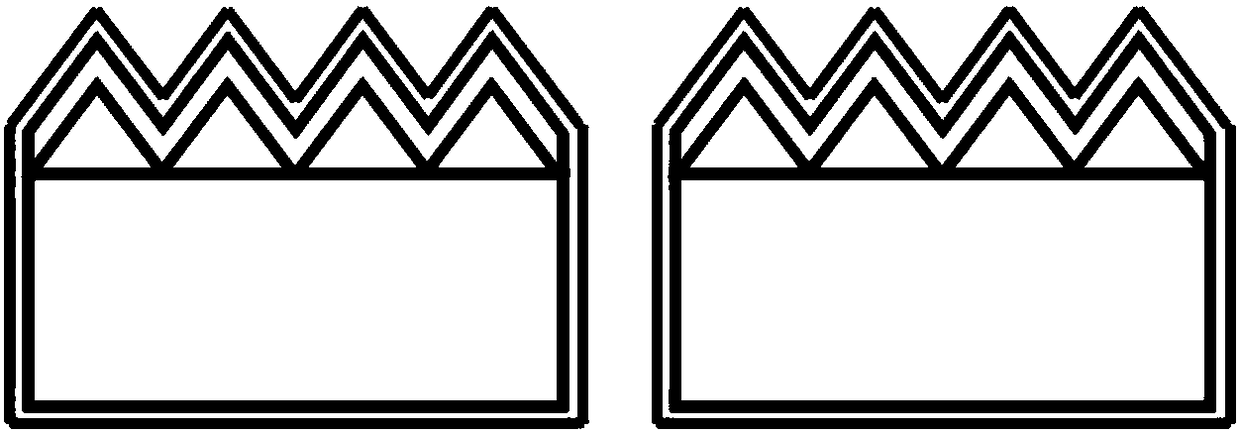

[0074] Such as image 3 As shown, ALD film is prepared on the front and back of the perforated inner wall and coated with oxide film or anti-reflection film battery (reaction in image 3 Among them, the inner wall of the perforated hole is the gap in the middle of the battery), which can effectively passivate the back of the p-type crystalline silicon battery, and at the same time protect the hole wall and front side and insulate the front and back electrodes.

[0075] process such as Figure 6 Shown: laser drilling, texturing, diffusion, back etching, oxide layer, front anti-reflection layer, ALD or PEALD passivation film, printing, sintering.

[0076] (1) Laser drilling: A P-type single crystal silicon wafer with a resistivity of 1-3Ω.cm is selected as the substrate, and a laser is used to open several rows of holes from the back of the silicon wafer. The diameter of the holes is 1.2-2.2mm. The spacing is 8-20mm;

[0077] (2) Texturing: Texturing the silicon wafer, and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com