A console with can interface

A console and interface technology, applied in the control, program control, computer control and other directions using feedback, can solve the problems of easy interference, loss of power supply accuracy, affecting the output accuracy of the console, so that the shooting accuracy is not affected and reduced. The effect of calculating workload and reducing debugging workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

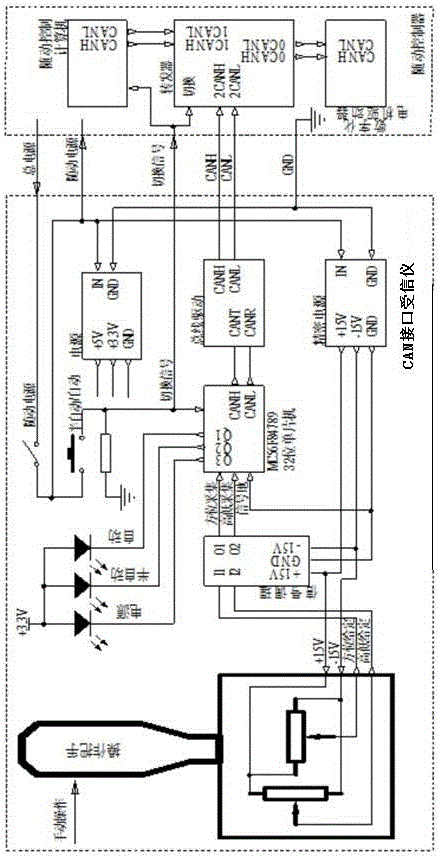

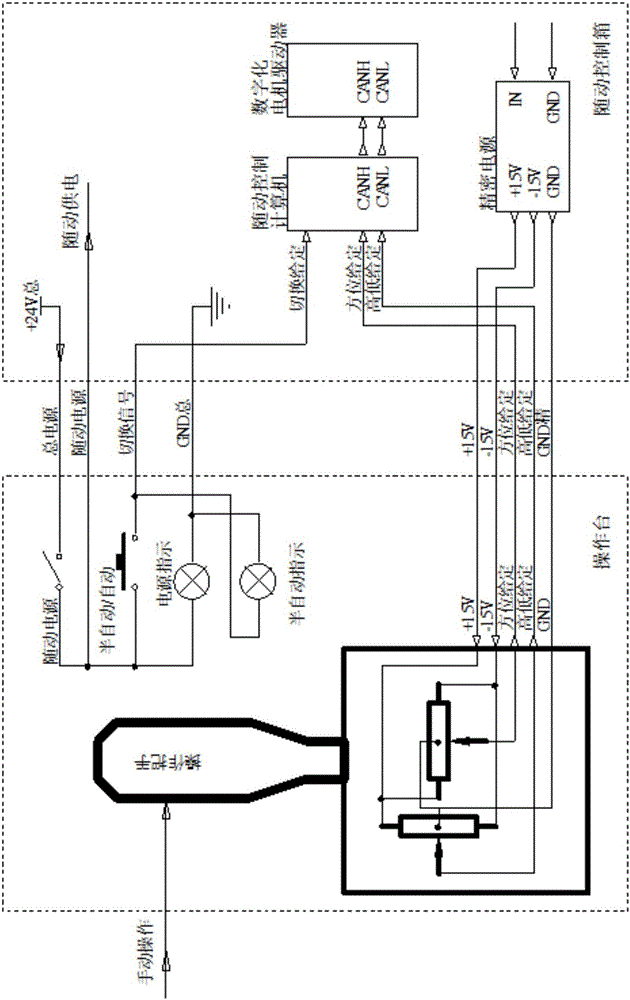

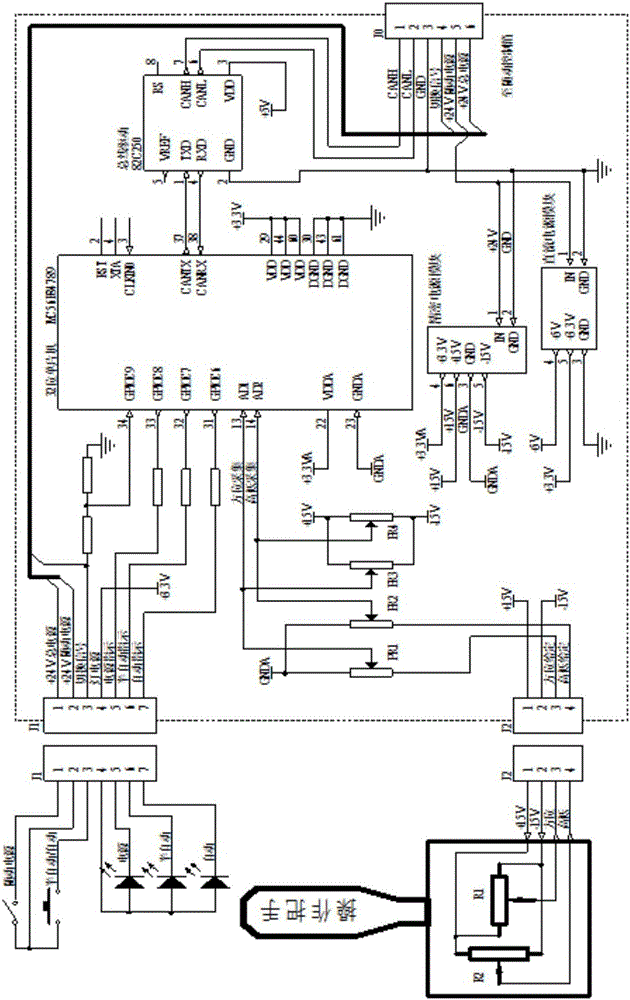

[0037] The present invention adopts the CAN field bus technology, and on the basis of the original traditional console technology, develops a digital console with a CAN interface. The principle block diagram is as follows figure 2 shown. The technical solution of the present invention is to integrate the precision power supply module, signal conditioning circuit, single-chip microcomputer with high-precision AD conversion module, and CAN driver module into the console, adopt ordinary precision DC power supply, and use CAN between the console and the servo control box Data bus communication.

[0038] The system consists of the mechanical structure of the console, two goniometer potentiometers for height and azimuth, the circuit board of the console, switches, and indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com