A kind of thin film transistor and its manufacturing method

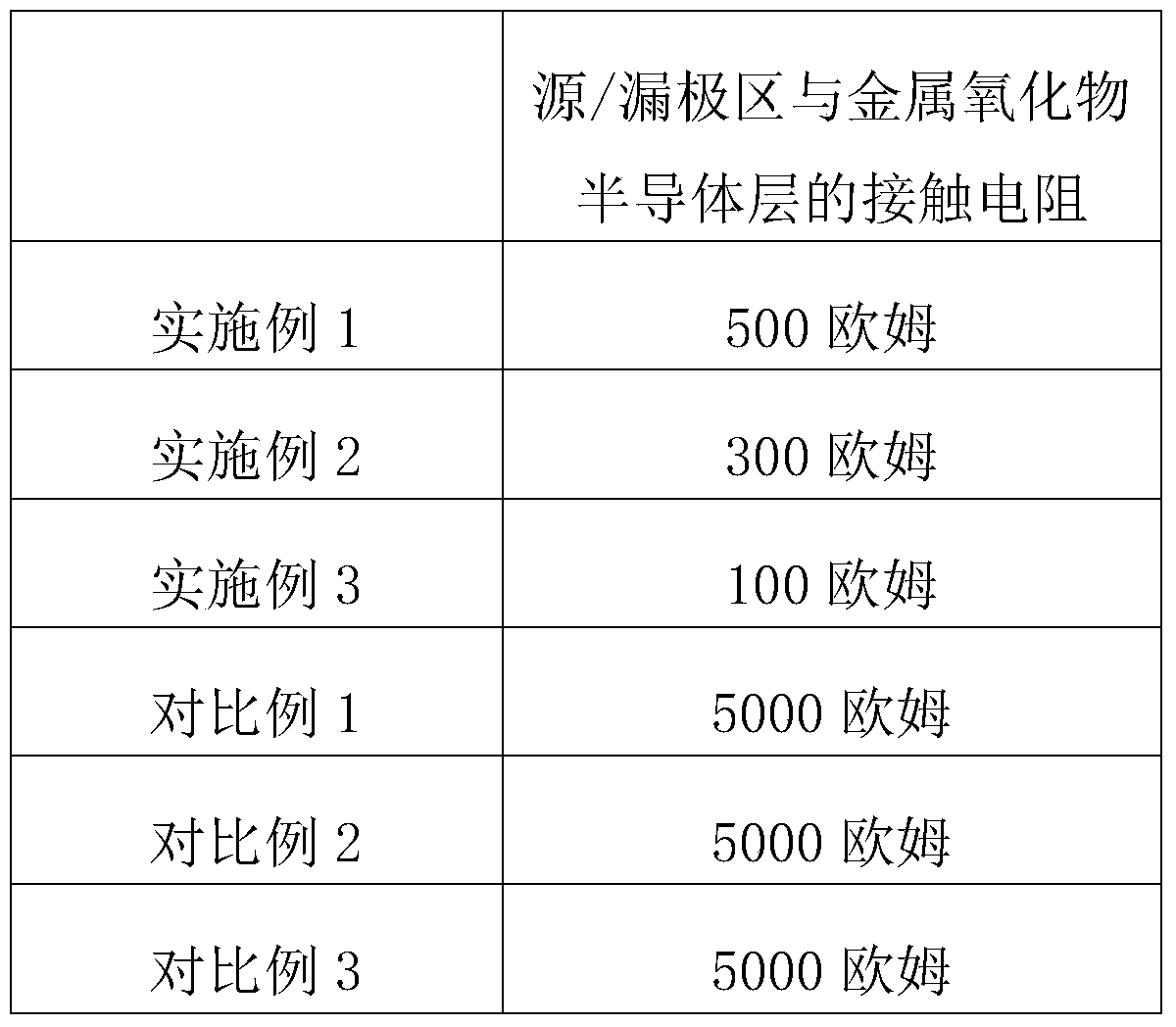

A technology of thin film transistors and manufacturing methods, which is applied in the field of organic light-emitting display devices, can solve the problems of large contact resistance and small contact resistance of semiconductor layers and source/drain electrode layers, and reduce contact resistance, save machine time and cost, and reduce The effect of one-time film forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

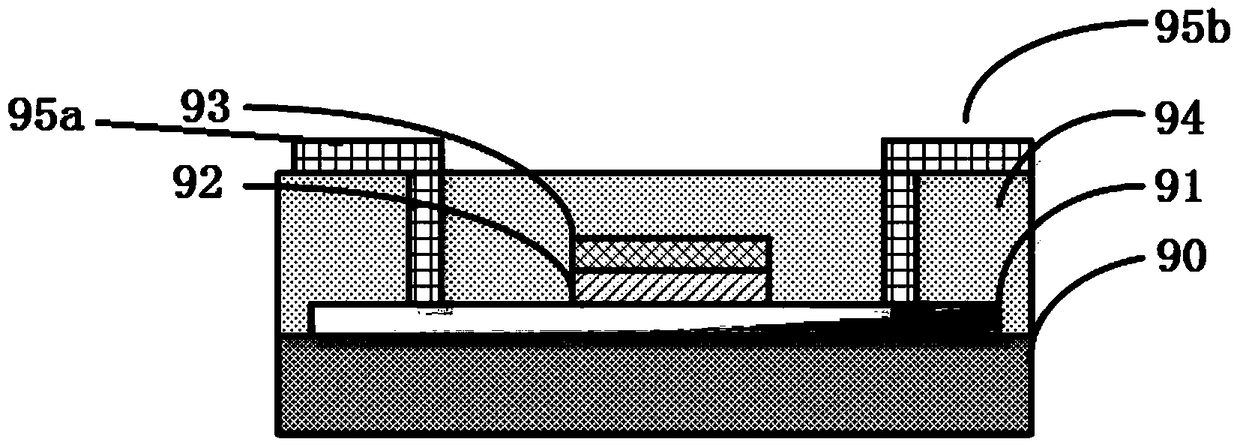

[0043] This embodiment provides a thin film transistor, such as figure 2As shown, it includes a metal oxide semiconductor layer 91, a first insulating layer 92, a gate layer 93, a second insulating layer 94 stacked on a substrate 90 in sequence, and a source electrode 95a and a drain electrode arranged at both ends of the second insulating layer. Pole 95b.

[0044] The metal oxide semiconductor layer 91 can be selected from but not limited to indium gallium zinc oxide (Indium Gallium Zinc Oxide referred to as IGZO), indium zinc oxide (Indium Zinc Oxide referred to as IZO), aluminum doped indium zinc oxide (Al-IZO ) and other materials, this embodiment is preferably IGZO material, its thickness can be 20nm-400nm, this embodiment is preferably 300nm.

[0045] The first insulating layer 92 is a metal oxide layer obtained after oxidation of a metal layer. The metal oxide layer has insulating properties. The metal layer can be selected from but not limited to one of Al, Zn, Fe, a...

Embodiment 2

[0055] On the basis of Embodiment 1, the structure of the thin film transistor in this embodiment is as follows figure 2 shown.

[0056] Wherein, the first insulating layer 92 can be selected from one or more stacked layers of directly formed insulating metal oxide layer, silicon nitride layer or silicon oxide layer. In this embodiment, Al 2 o 3 The thickness of the layer may be 50nm-350nm, preferably 150nm in this embodiment.

[0057] The second insulating layer 94 is a metal oxide layer obtained after oxidation of the metal layer. The metal oxide layer has insulating properties. The metal layer can be selected from but not limited to Al, Zn, Fe, Cu. One or more combinations, this embodiment is preferably Al obtained by oxidation of the Al layer 2 o 3 The thickness of the layer may be 100nm-500nm, preferably 400nm in this embodiment. The second insulating layer 94 is directly formed on the first insulating layer 92 and covers the gate layer 93; the second insulating lay...

Embodiment 3

[0066] On the basis of Embodiment 1 or Embodiment 2, the structure of the thin film transistor in this embodiment is as follows figure 2 shown.

[0067] Wherein, the first insulating layer 92 is a metal oxide layer obtained after the metal layer is oxidized. The metal oxide layer has insulating properties. The metal layer can be selected from but not limited to one of Al, Zn, Fe, and Cu. A combination of one or more, this embodiment is preferably Al obtained by oxidation of the Al layer 2 o 3 The thickness of the layer may be 50nm-350nm, preferably 150nm in this embodiment.

[0068] The second insulating layer 94 is a metal oxide layer obtained after oxidation of the metal layer. The metal oxide layer has insulating properties. The metal layer can be selected from but not limited to one of Al, Zn, Fe, Cu, or A variety of combinations, this embodiment is preferably Al obtained by oxidation of the Al layer 2 o 3 The thickness of the layer may be 100nm-500nm, preferably 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com