Numerical control gear grinding machine

A gear grinding machine and grinding wheel technology, applied in the direction of gear cutting machines, gear teeth, mechanical equipment, etc., can solve problems such as difficulty in ensuring machining accuracy, affecting loading and unloading of workpieces, and easy dripping of grinding fluid, so as to achieve easy chip removal and reduce Ease of waste, observation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

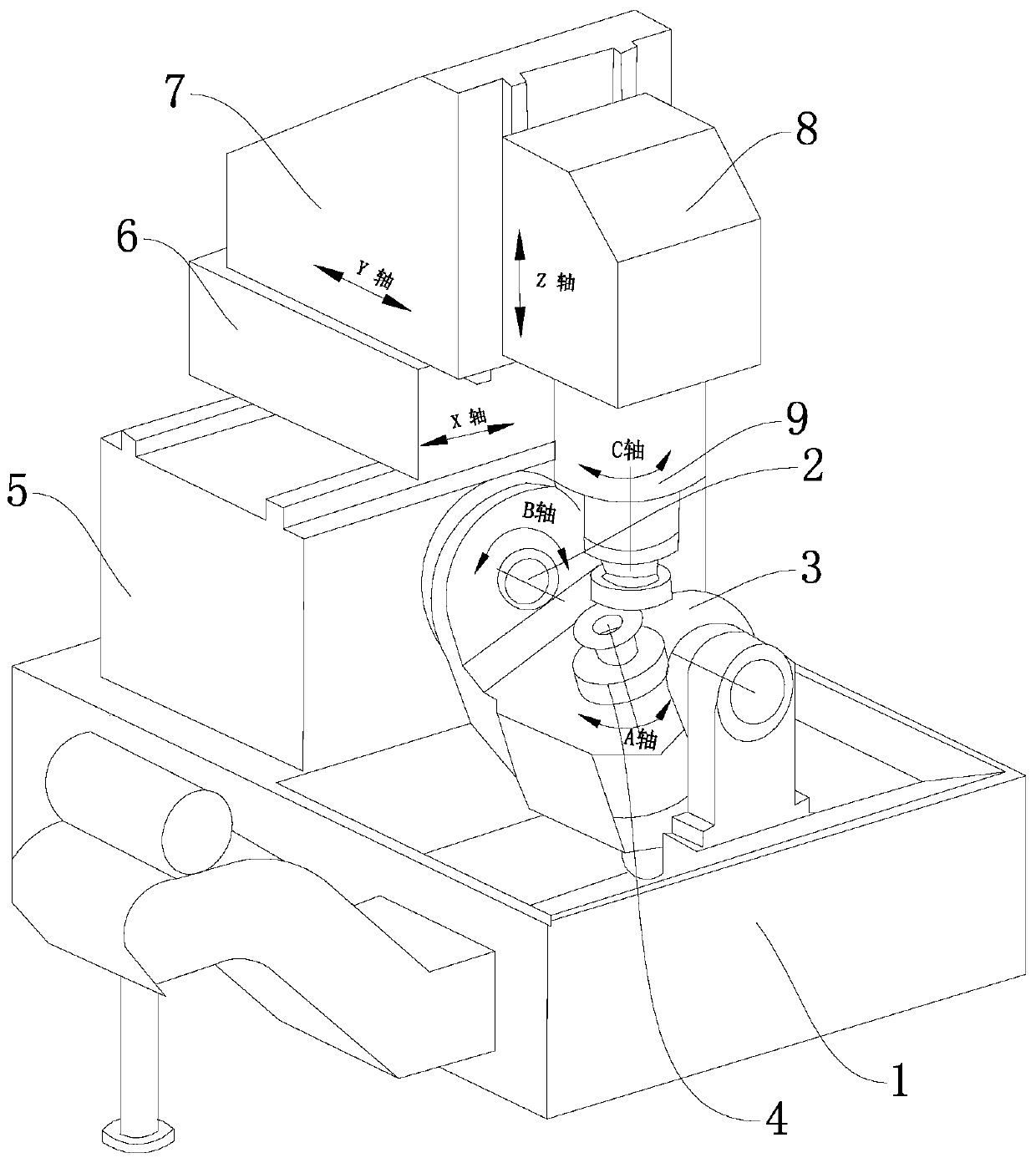

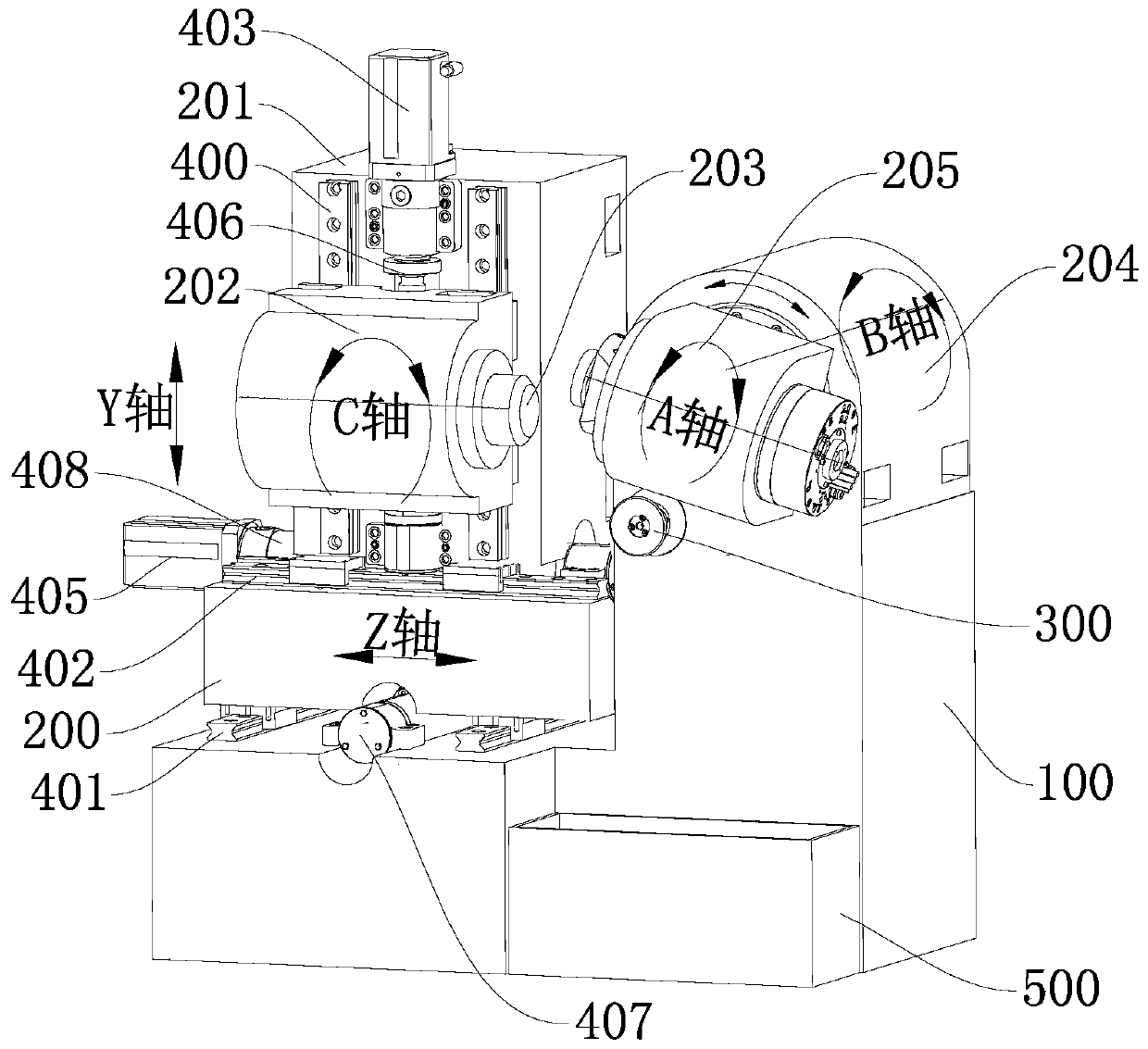

[0032] Such as Figure 2 to Figure 4 As shown, a numerically controlled gear grinding machine of the present invention includes a bed 100, on which a slide table 200 is movably arranged along the horizontal axis X-axis, and on the slide table 200 is movably arranged along the horizontal axis Z-axis A column 201 is provided, and a grinding wheel box 202 is movably arranged on the side wall of the column 201 along the vertical axis Y axis, and a grinding wheel spindle C axis is rotatably arranged in the grinding wheel box 202, and the C axis of the grinding wheel spindle is in the direction of the Z axis. Parallel, one end of the C-axis of the grinding wheel spindle is equipped with a grinding wheel 203 for processing workpieces, and the bed 100 is also provided with a rotary shaft box 204, which is located on one side of the slide table 200 along the Z-axis direction, and the rotary shaft box The body 204 is rotatably provided with a rotary shaft B shaft, the rotary shaft B sha...

Embodiment 2

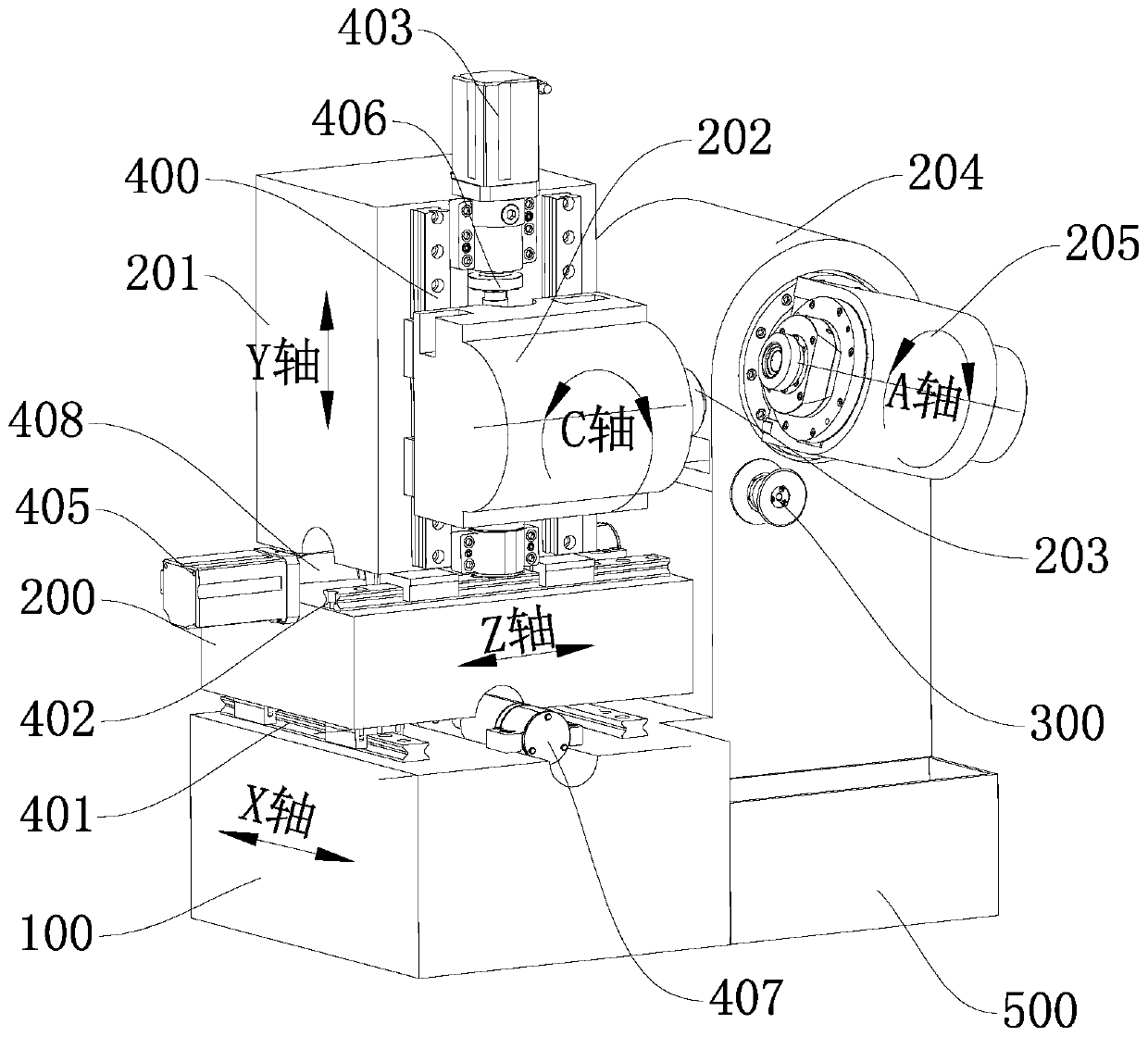

[0048] Such as Figure 5 to Figure 7 As shown, the CNC gear grinding machine provided by this embodiment is basically the same as that of Embodiment 1, the main difference lies in the connection method between the column 201 and the slide table 200 and the installation position of the grinding wheel dresser 300 in this embodiment. One makes a difference. In the first embodiment, two third guide rails 402 are horizontally arranged on the upper surface of the slide table 200, and the upright column 201 is slidably arranged on the third guide rails 402. In this embodiment, there are at least two third guide rails 402 respectively provided on the slide table On the upper surface of 200 and the side close to the tool box 202, the lower end of the column 201 and the side wall away from the tool box 202 are provided with a first opening along the Z-axis direction, so that the cross-section of the column 201 along the Z-axis direction is inverted. The ladder-like structure is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com