Milling tool for processing inter cavity of level bubble

A level bubble and inner cavity technology, which is applied in the direction of milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of not using special-shaped surfaces, short tool life, and difficult chip removal in the inner cavity of the workpiece, so as to facilitate the processing of special-shaped surfaces , long tool life and easy chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

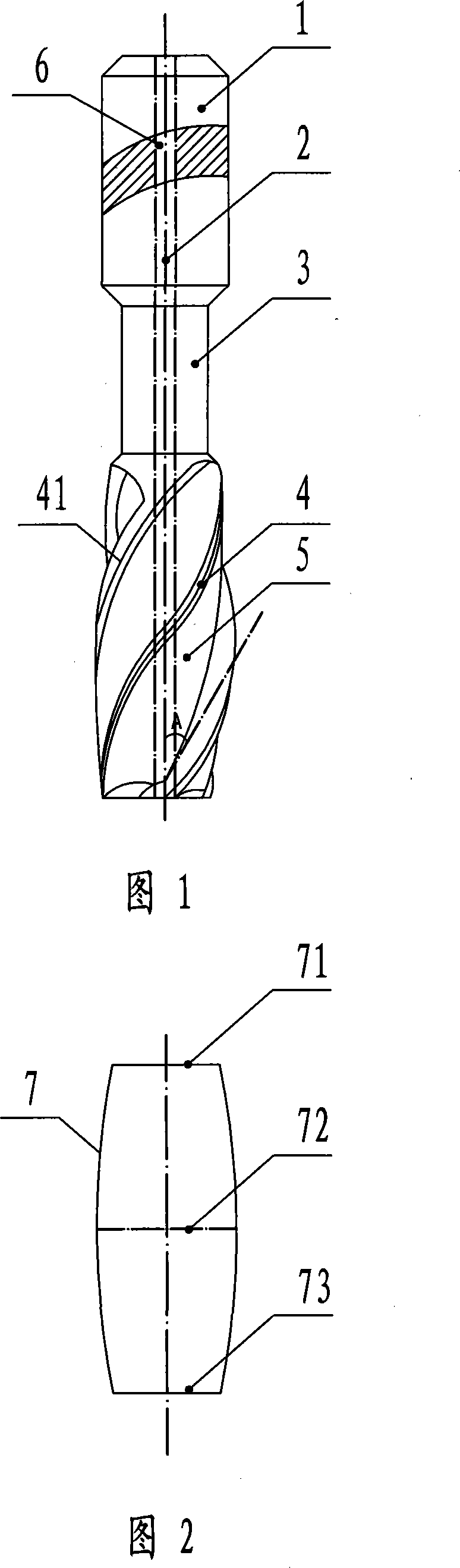

[0013] Embodiment 1. A milling cutter for machining the inner cavity of a vial, comprising a handle 1, a blade area and a connecting area 3 between the two, the blade area includes three cutting edges 4 and three cutting grooves 5, and the cutting edge 4 The outer contour 41 rotates along the rotation axis 2 and the contour 7 is a drum shape with both ends contracted and the middle bulging. The upper end 71 and the lower end 73 of the drum shape have the same diameter, and the diameter of the middle bulging end 72 is larger than the upper and lower ends. The helix angle A of the blade is 40 degrees, and the handle 1 , the blade area and the connection area 3 are provided with a through axial hole 6 . The three cutting edges form a regular cutting edge, and at the same time, the three cutting edges are beneficial to the processing of the milling cutter itself.

Embodiment 2

[0014] Embodiment 2, the basic structure is the same as that of embodiment 1, the difference is that the helix angle A selected in embodiment 1 is 40 degrees, and the helix angle A selected in this embodiment is 0 degrees, that is, straight edge processing, straight edge tool It is easy to process itself, the cost of manufacturing milling cutters is low, and the surface finish is high.

[0015] According to needs, the helix angle A can also be made to be 80 degrees or slightly larger, which is feasible in theory and practice, but this will increase the manufacturing cost, and the excessively large helix angle A will cause serious distortion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com