Machine tool for processing spiral taper gear with six axes, five linkage axes

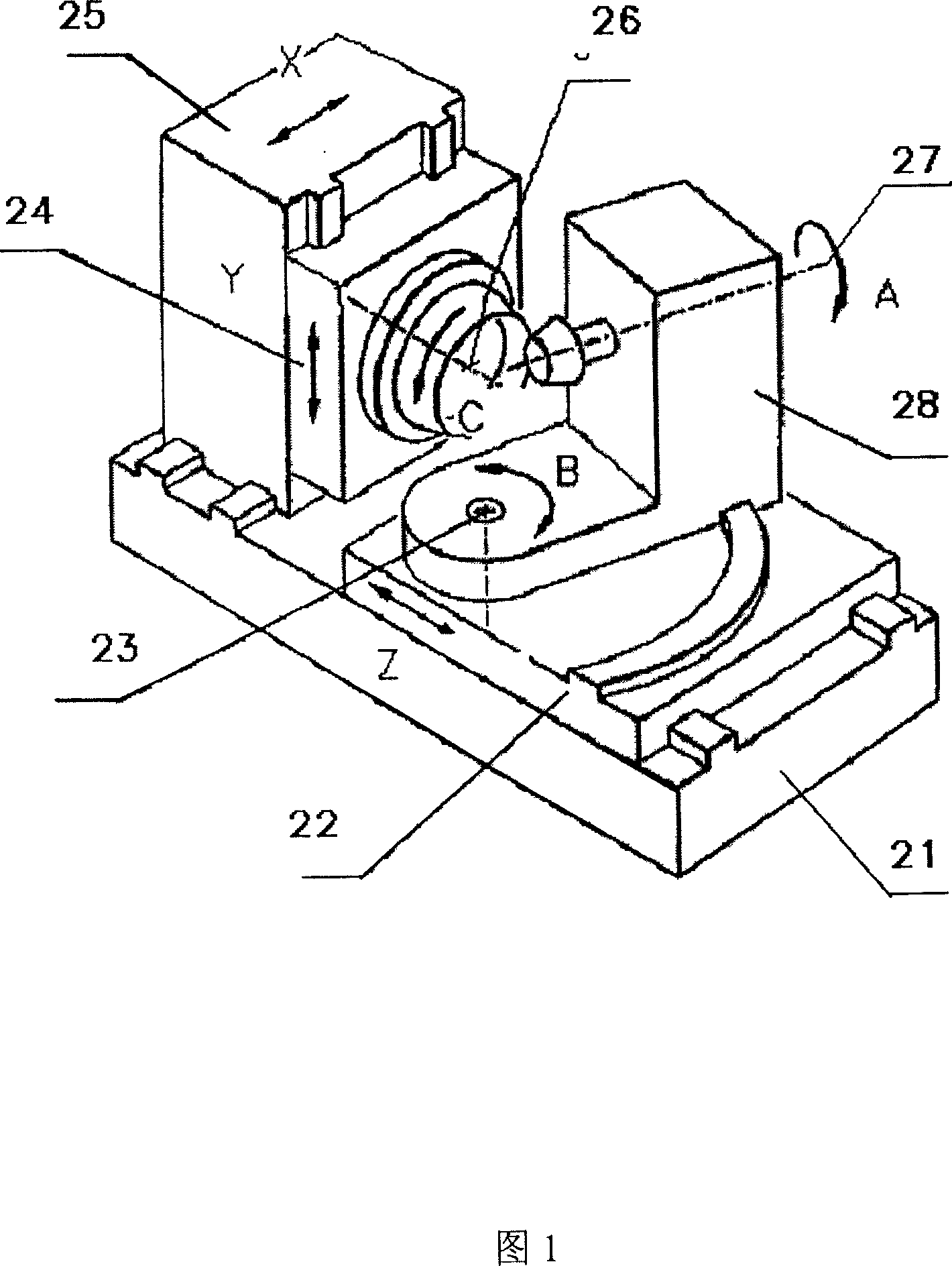

A technology for spiral bevel gears and processing machine tools, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc., and can solve the problems of insufficient use of numerical control technology, complex shape of workpiece box 28, and poor processing manufacturability, etc. Problems, to achieve the effect of compact structure, small footprint and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

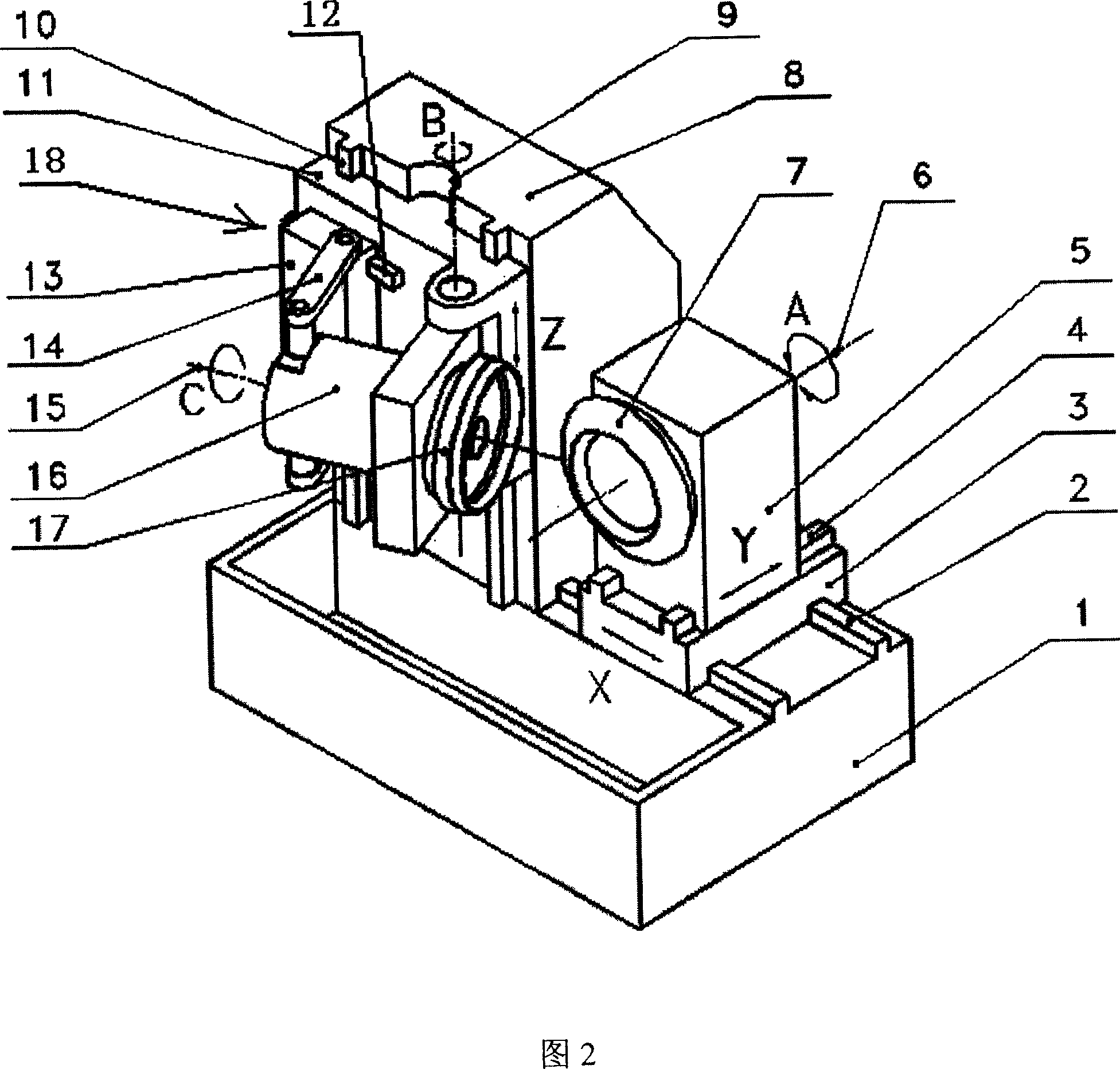

[0041] According to Figure 2 and the machine tool with the above structure, the three linear guides and the sliding drive mechanism adopt rolling guides and ball screws, and the servo motor transmits the rotation of the motor to the ball screws through a direct connection or a reduction device, driving the X-axis to slide Table 3, workpiece box 5 and Z-axis sliding table 11 move (directly driven by linear motors can also be used); the displacement of X-axis, Y-axis and Z-axis is measured by grating ruler and closed-loop control; C-axis 15 uses spindle motor or frequency modulation motor Driven by gears or pulleys (directly driven by an electric spindle or a torque motor); the rotation of the tool box 16 around the B-axis 9 is indirectly driven by a crank-link mechanism, and its rotation angle is measured and controlled by a high-precision grating disc. A-axis 6 rotations are driven by servo motors and worm gear pairs or directly driven by high-torque motors, and the rotation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com