Grinding tool for hard alloy cutter grinding and preparation method thereof

A tool grinding and cemented carbide technology, which is used in grinding machine parts, grinding/polishing equipment, grinding devices, etc., and can solve the problem of weak bending resistance, low cooling efficiency, slow heat dissipation, etc. problems, to achieve the effect of reducing grinding head cracks or end face crushing, easy chip removal, and reducing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

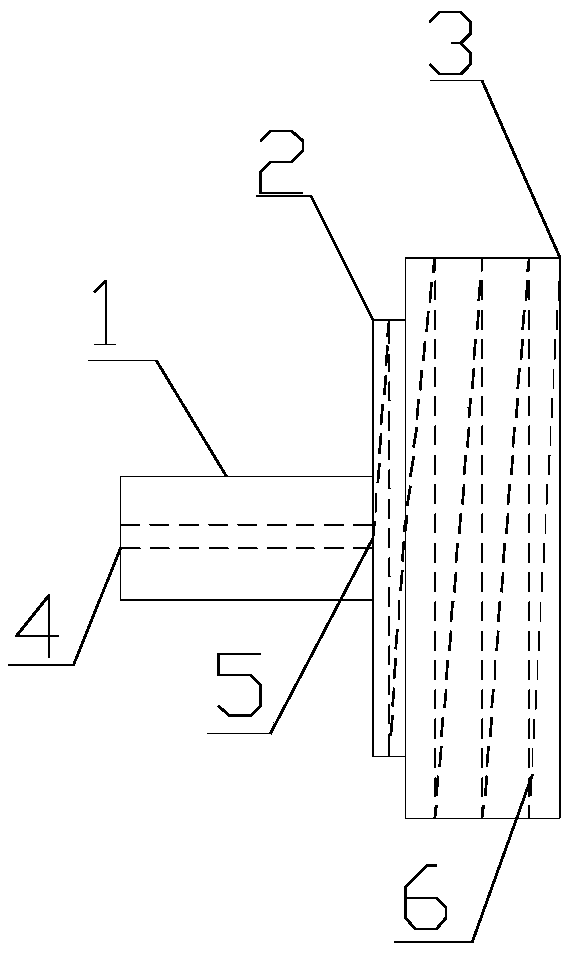

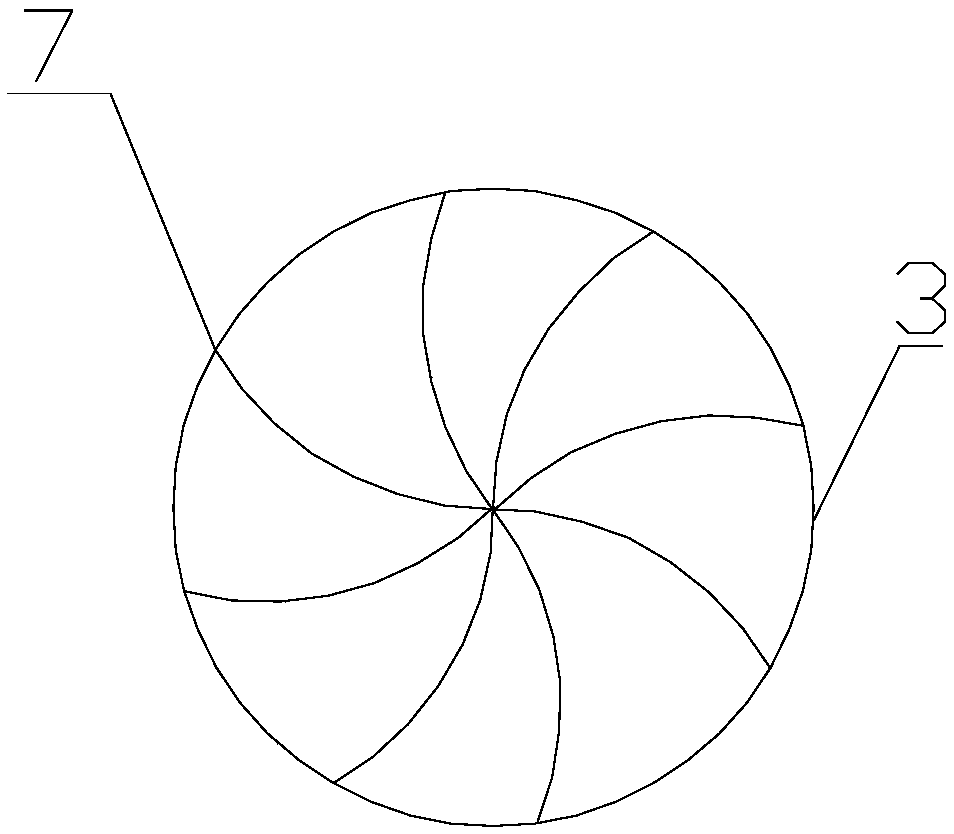

[0033] Embodiment 1: as Figure 1-2 A kind of preparation method of the abrasive tool that cemented carbide tool grinding is used, comprises following concrete steps:

[0034] a. The fixed end 1 and the base body 2 are integrally casted. After casting, the sand adhered to the base body cooling channel 5 and the hollow structure 4 is removed, so that the base body cooling channel 5 and the hollow structure 4 are connected for cooling gas or liquid flow;

[0035] b. After the fixed end 1 and the base body 2 are removed in step a, after heat treatment, carry out rough grinding and fine grinding on each surface of the fixed end 1 and the base body 2 with a grinder, and finally connect the front end of the base body 2 with the grinding head 3 Multiple fixing holes are drilled at the contact position for fixing the grinding head 3;

[0036]The preparation of c grinding head 3 includes: the main material includes zirconia 46wt%; yttrium oxide 12wt%; samarium trioxide 9wt%; Boron 3...

Embodiment 2

[0041] Embodiment 2: adopt the abrasive tool of above-mentioned embodiment 1 to carry out grinding to cemented carbide cutter, comprise the following steps:

[0042] In the first step, first inject cooling water into the cooling water tank of the grinding machine, fix the workpiece carbide tool on the fixture, then connect the cooling water pipe with the hollow structure 4 of the fixed end 1, and open the cooling water tank during grinding Valve, the cooling water passes through the hollow structure 4 of the fixed end 1, the cooling water enters the matrix cooling channel 5 of the matrix 2, and cools the matrix 2, and the cooling water enters the grinding head cooling channel 6 from the matrix cooling channel 5, and the grinding head 3 for cooling, and finally the cooling water enters the surface chip removal channel 7 from the grinding head cooling channel 6 to cool the grinding surface of the grinding head 3 and the surface of the workpiece carbide tool, and at the same time ...

Embodiment 3

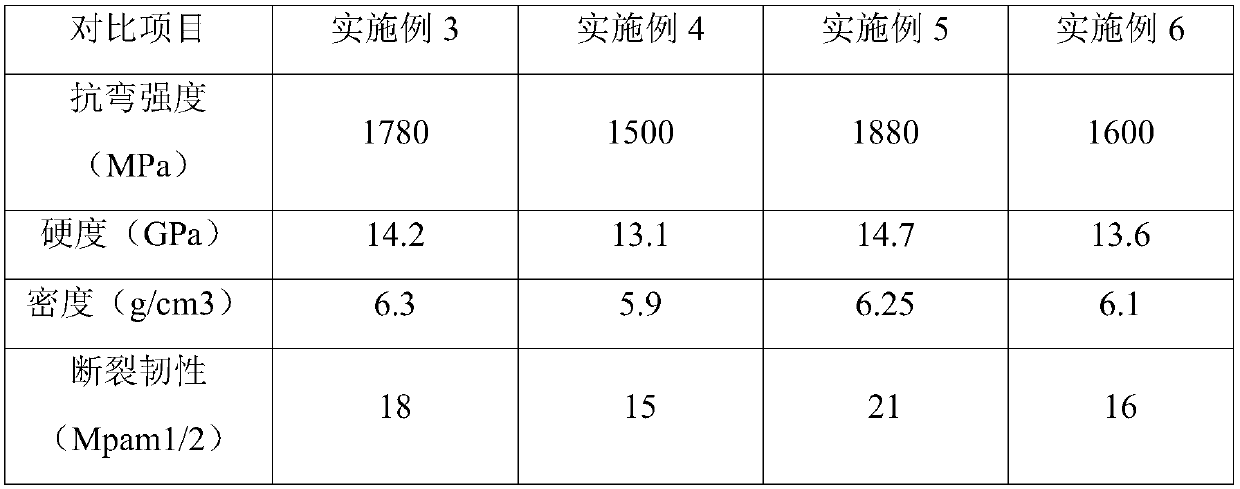

[0052] Example 3 formula: the main material includes 58wt% zirconia; 20wt% yttrium oxide; 8wt% samarium trioxide, and the abrasive includes 14wt% diamond;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com