Efficient straight edge grinding method for glass and round and straight edge double-edge machine system

A glass and edging technology, which is applied in the direction of machine tools, grinding machines, and surface polishing machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of large machining allowance, difficult cooling capacity to meet high-efficiency processing, and easy softening of glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

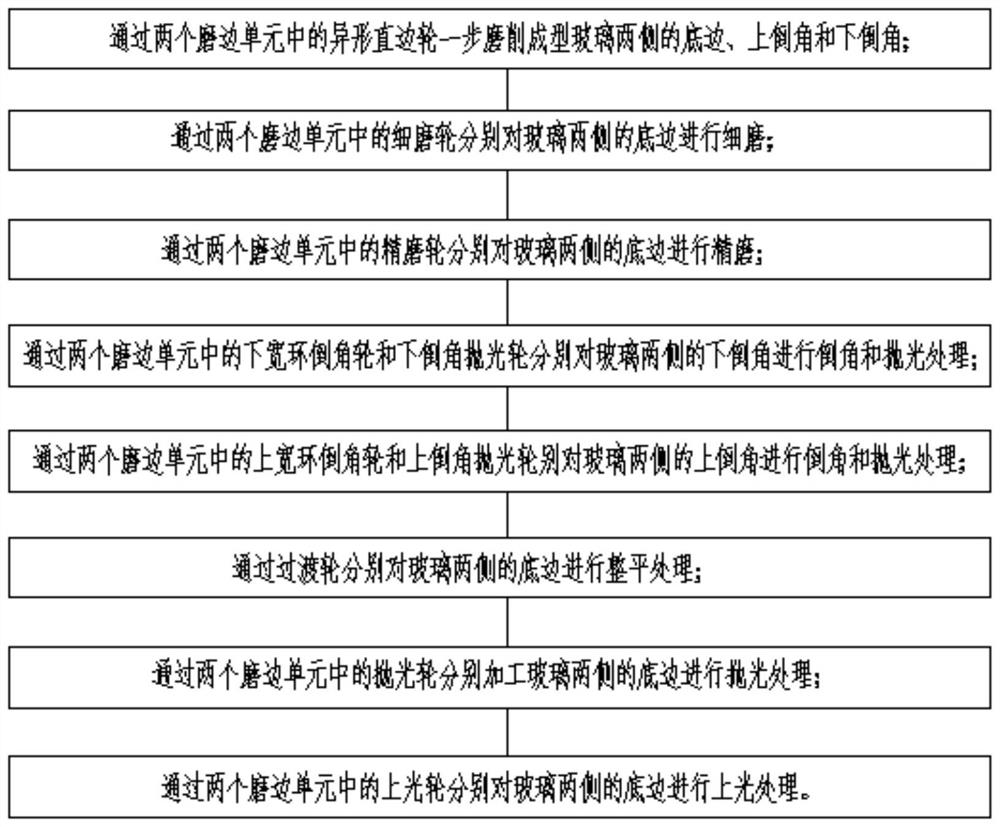

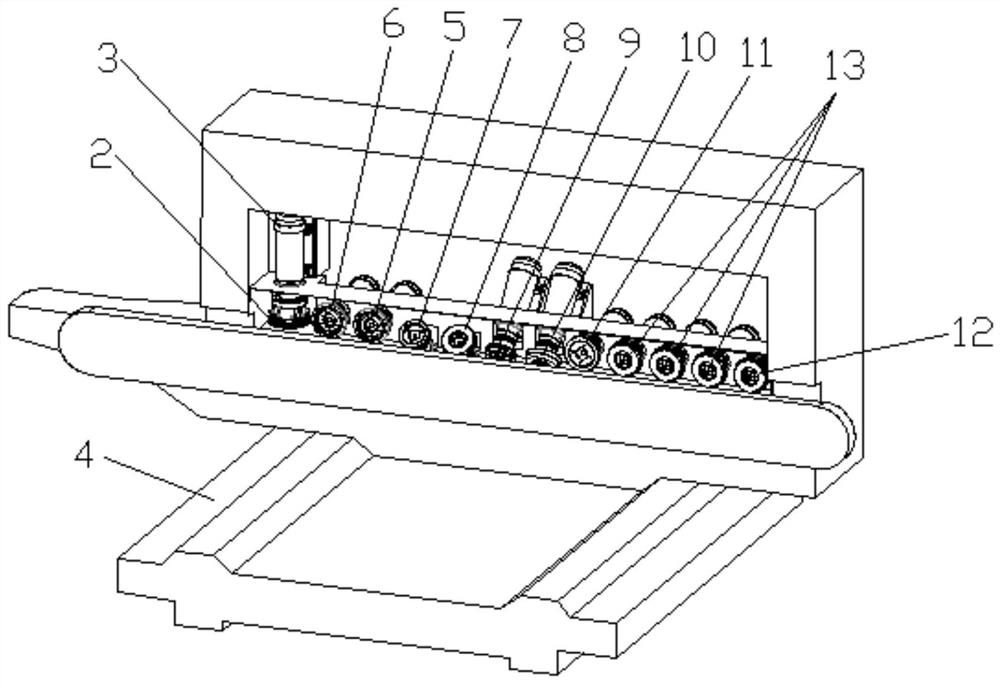

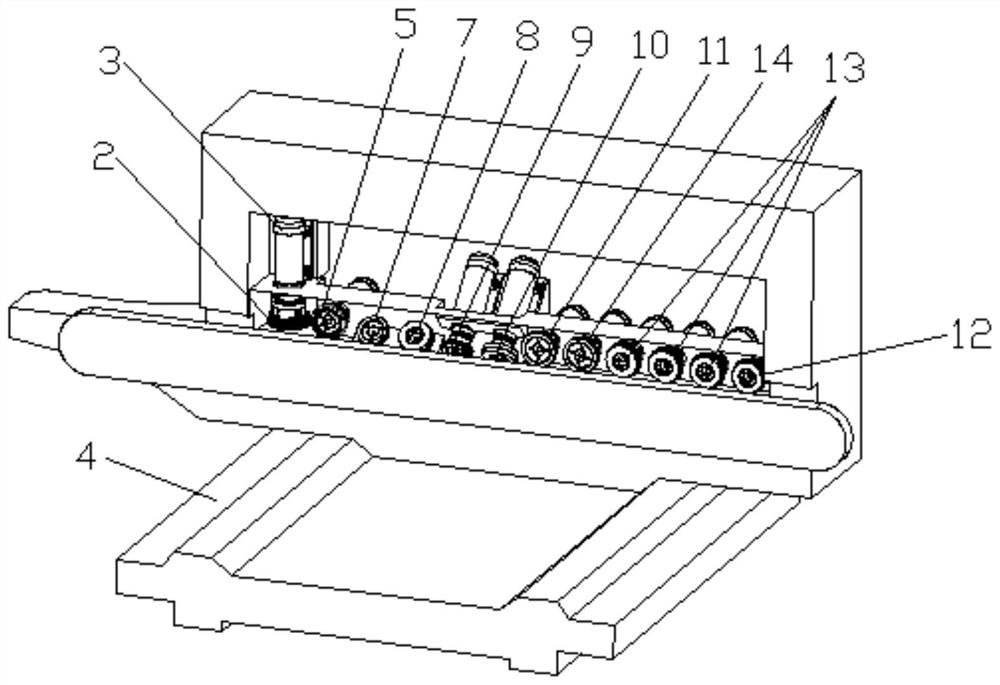

[0048] like Figure 1 to Figure 6 As shown, the present invention also provides a kind of efficient glass edge grinding method, comprising the following specific steps:

[0049] S1: Process the bottom edge, upper chamfer and lower chamfer on both sides of the shaped glass 1 in one step through two grinding and forming devices;

[0050] S2: using two chamfering and polishing devices to process the upper chamfer and the lower chamfer on both sides of the glass 1 for chamfering and polishing;

[0051] S4: Polishing the bottom edges on both sides of the glass 1 with two bottom edge polishing devices.

[0052] Using the above steps, in the process of edging the glass 1, its beneficial effect:

[0053] First, the bottom edge, upper chamfer and lower chamfer on both sides of the glass 1 are formed in one step by two grinding and forming devices, so as to realize one-round three-position processing; choose straight-sided special-shaped wheels, without increasing the number of grindi...

Embodiment 2

[0058] On the basis of Embodiment 1, in this embodiment, step S1 specifically includes the following steps:

[0059] S11: Grinding the bottom edge, upper chamfer and lower chamfer on both sides of the formed glass 1 in one step by two grinding and forming devices;

[0060] S12: Using two grinding and forming devices to finely grind the bottom edges of the glass 1 on both sides.

[0061] Using the above steps, in the process of edging the glass 1, its beneficial effect:

[0062] Firstly, the bottom edge, upper chamfer and lower chamfer on both sides of the glass 1 are formed in one step by two grinding and forming devices, realizing one round of three-position processing; choosing a straight edge special-shaped wheel, without increasing the number of grinding wheels, The rough machining of the upper and lower chamfers and the bottom edge is realized, which reduces the cost of the whole machine; due to the natural running-in angle of the special-shaped wheel, it can adapt to di...

Embodiment 3

[0073] On the basis of any one of Embodiment 1 to Embodiment 2, in this embodiment, step S2 specifically includes the following steps:

[0074] S21: respectively chamfering and polishing the lower chamfers on both sides of the glass 1 through two chamfering and polishing devices;

[0075] S22: chamfering and polishing the upper chamfers on both sides of the glass 1 by using two chamfering and polishing devices.

[0076] Using the above steps, in the process of edging the glass 1, its beneficial effect:

[0077] The two chamfering and polishing devices sequentially chamfer and polish the bottom chamfer and the top chamfer on both sides of the glass 1 to ensure the processing quality of the top chamfer and bottom chamfer on both sides of the glass 1 . The processing amount at the pre-order chamfering position is greatly eliminated, and the remaining processing amount is small, which is fully suitable for the characteristics of the smaller the cutting amount of the cup wheel, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com