Low-carbon sulphur free-cutting steel

A free-cutting steel and carbon-sulfur technology, applied in the field of low-carbon sulfur free-cutting steel, can solve the problem that the machined surface roughness may not be sufficient, and achieve the effect of small machined surface roughness, excellent hot workability and excellent surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

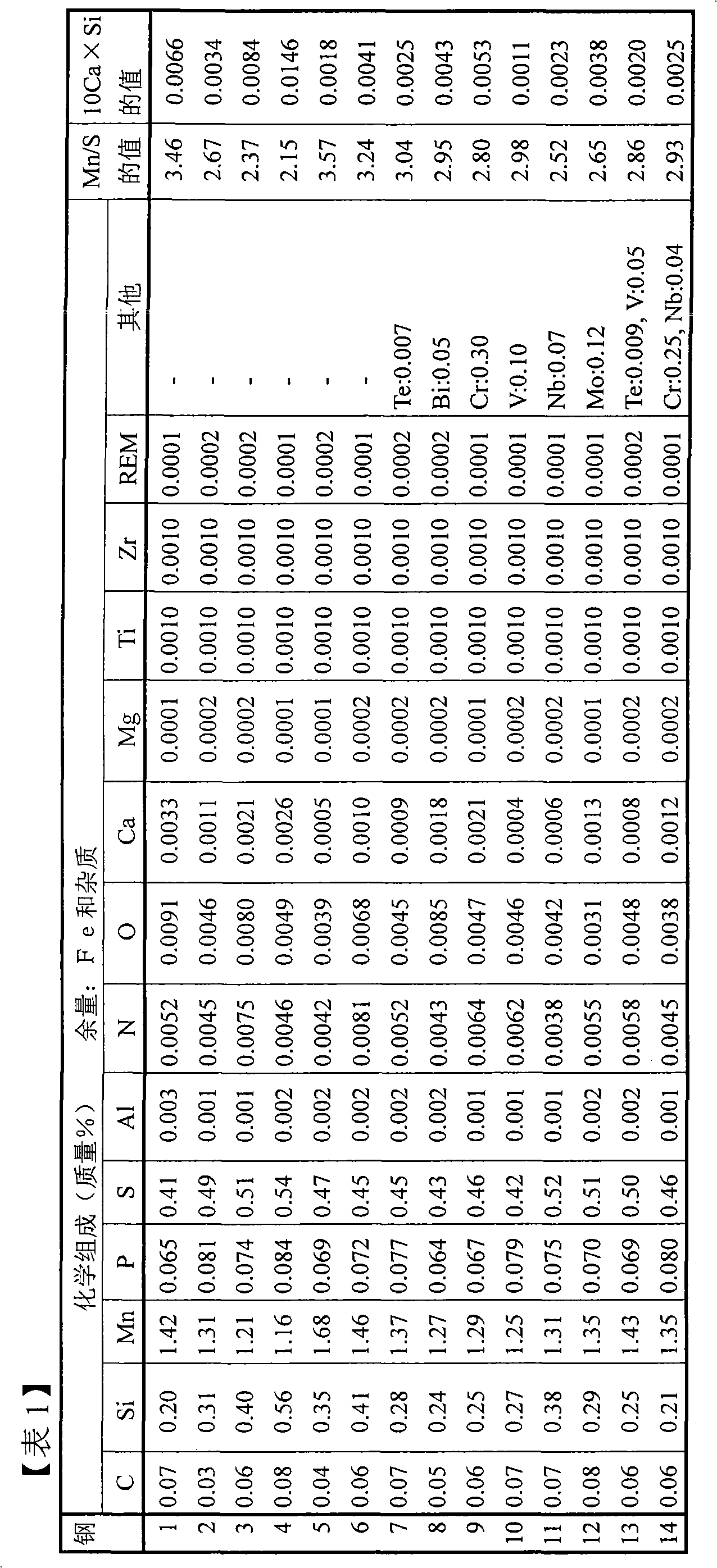

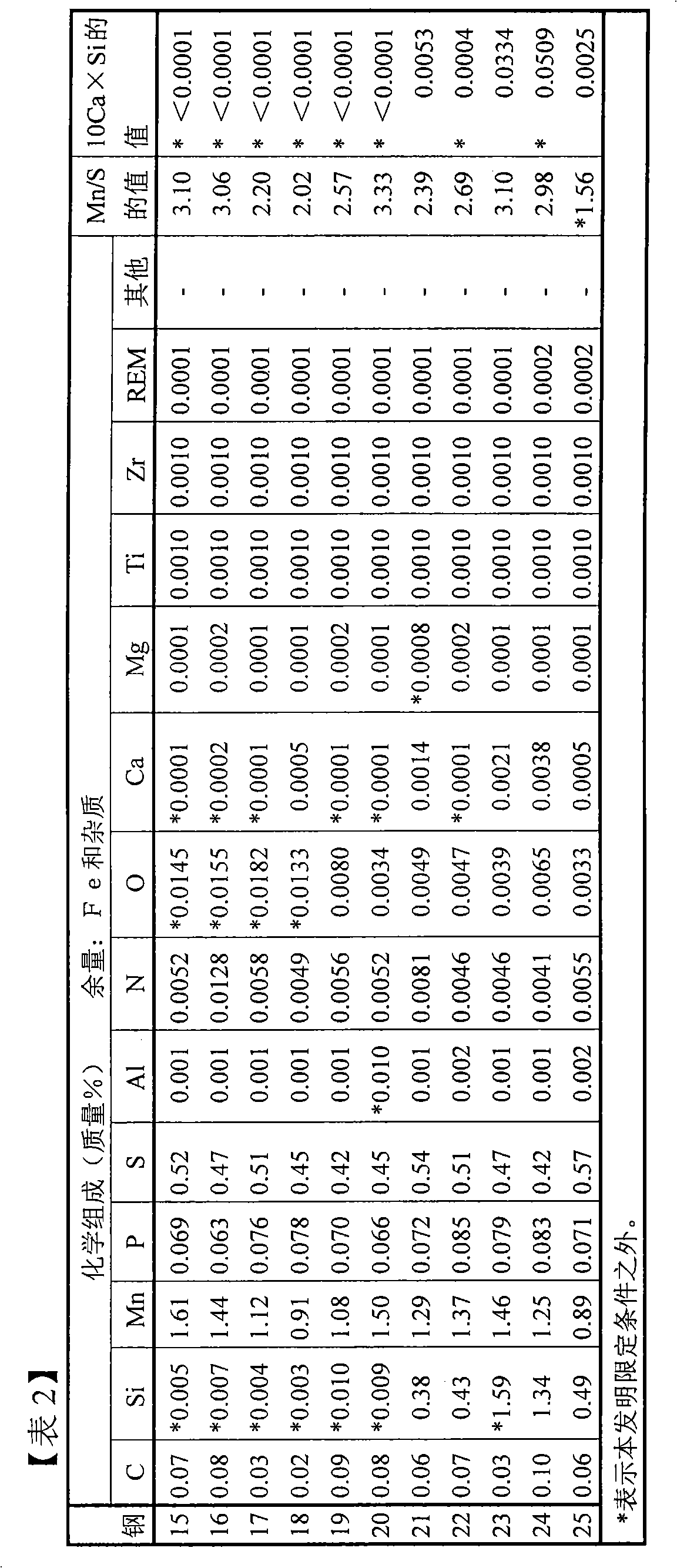

[0054] First, the chemical composition of the low-carbon sulfur free-cutting steel of the present invention and the reason for its limitation will be described. In addition, in the following description, "%" of content of each element shows "mass %".

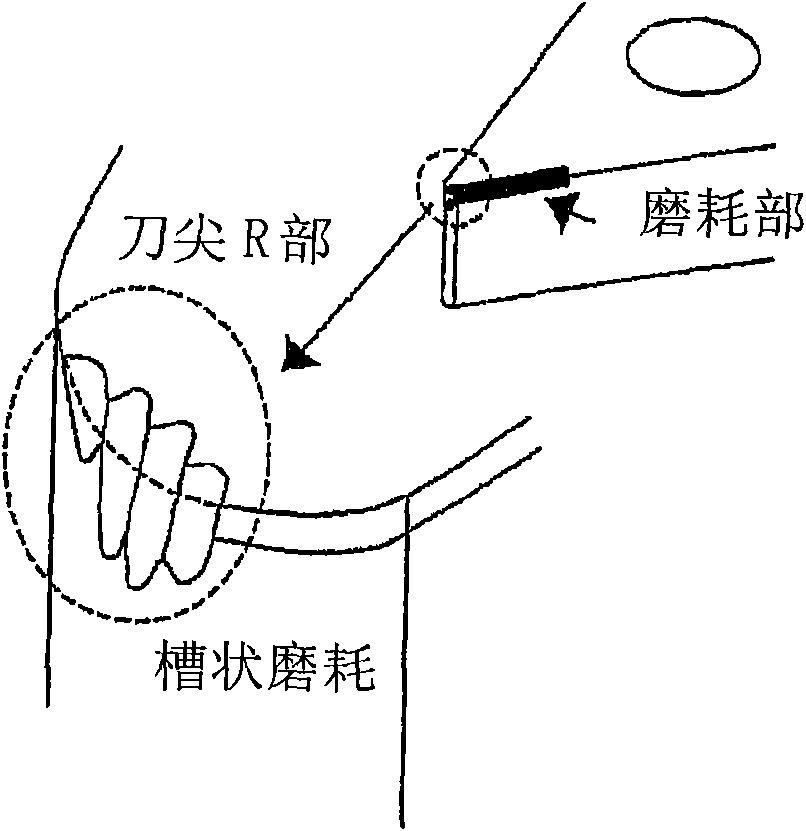

[0055] In the low-carbon sulfur free-cutting steel of the present invention, in the finish turning process, the most required point is to maintain a small machined surface roughness under the same tool during a long period of machining, and it is necessary to suppress the tool for this reason. Grooved wear on front end.

[0056] C: More than 0.02% and less than 0.20%

[0057] C is an element that has a great influence on machinability and strength. In finish turning using superhard tools, in order to reduce the roughness of the machined surface, the content of C must be kept below 0.20%. This is because when the C content is 0.20% or more, the hardness of the steel becomes high, and the groove-shaped wear at the tip of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com