Miniature total pressure probe and its manufacturing method

A manufacturing method and a probe technology, which are applied in the direction of measuring fluid pressure, measuring fluid velocity by using differential pressure, measuring devices, etc., can solve the problem of not being able to know the distribution of inlet and outlet flow losses along the process, and the measurement results are not detailed and accurate enough. Technical complexity and other issues, to achieve the effect of low processing roughness, reduce the processing surface roughness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

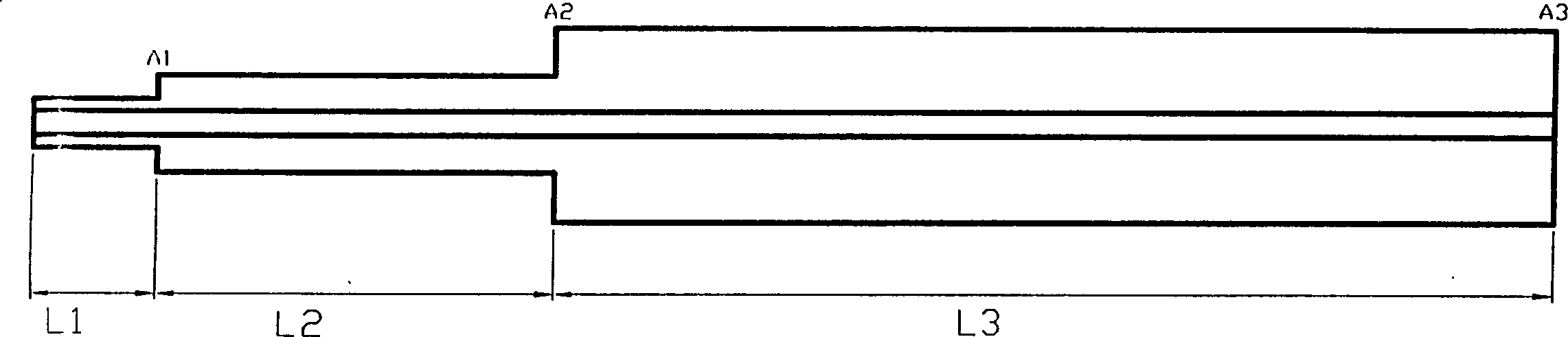

[0015] The lengths L1, L2, and L3 of the three tubes in Example 2 are 2mm, 8mm, and 20mm, respectively.

Embodiment 3

[0016] The lengths L1, L2, and L3 of the three tubes in Example 3 are 2 mm, 10 mm, and 24 mm, respectively.

[0017] Manufacturing method of miniature total pressure probe

[0018] Step (1) of the micro-EDM process is to conduct pulse discharge on a round tube with an outer diameter of 0.4mm during the EDM process, and the EDM will cause the removal of material microgroups and the generation of discharge pits, thereby forming the first-level outer diameter 0.2mm, two-stage stepped circular tube with a second-stage outer diameter of 0.4mm.

[0019] Pure water micro-electrolytic machining process step (2) is to use the above-mentioned two-stage stepped circular tube as the tool anode, a metal plate as the tool cathode, use pure water as the working fluid, and apply an electric field to quickly polish the end face of the circular tube to avoid The edge erosion of the end face caused by stray corrosion ensures clear edges and corners, and the enhanced conductive connection proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com