Patents

Literature

32results about How to "High elastic rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

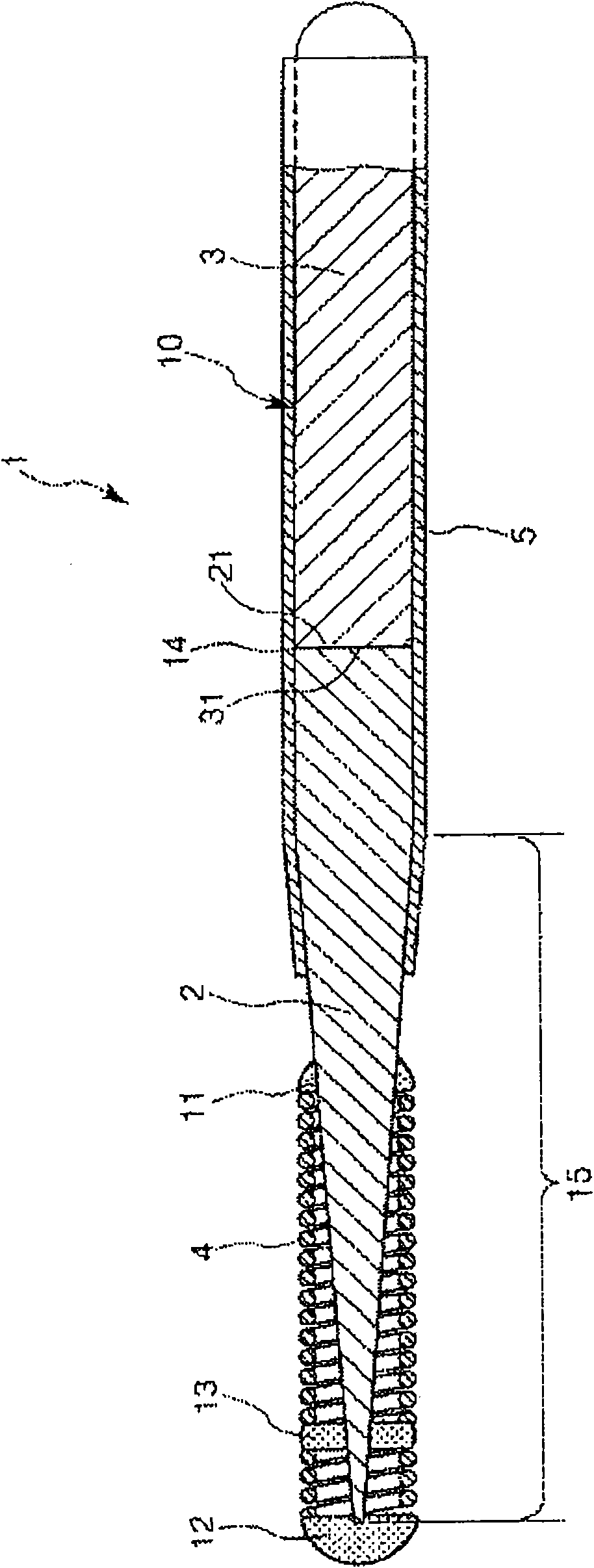

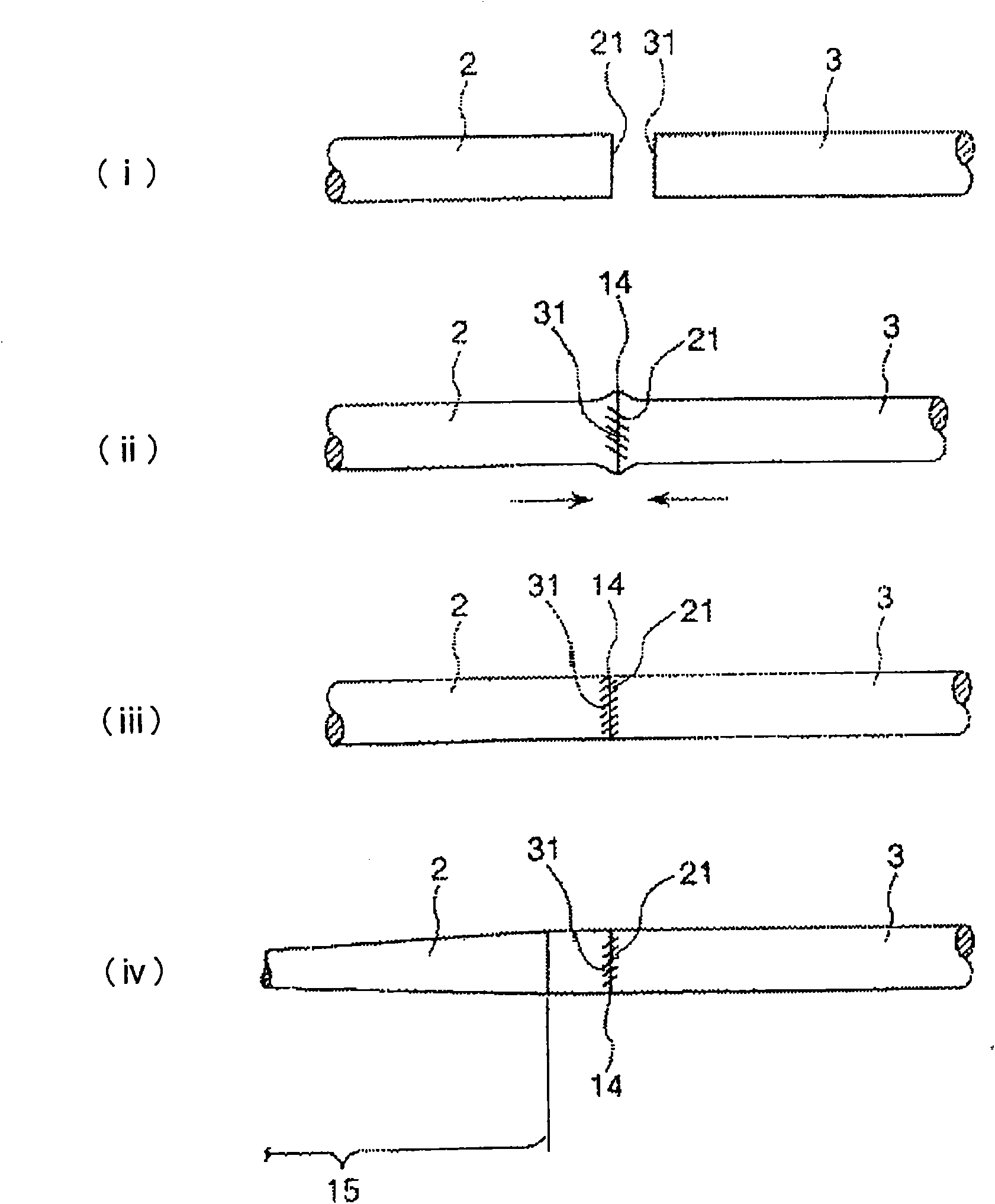

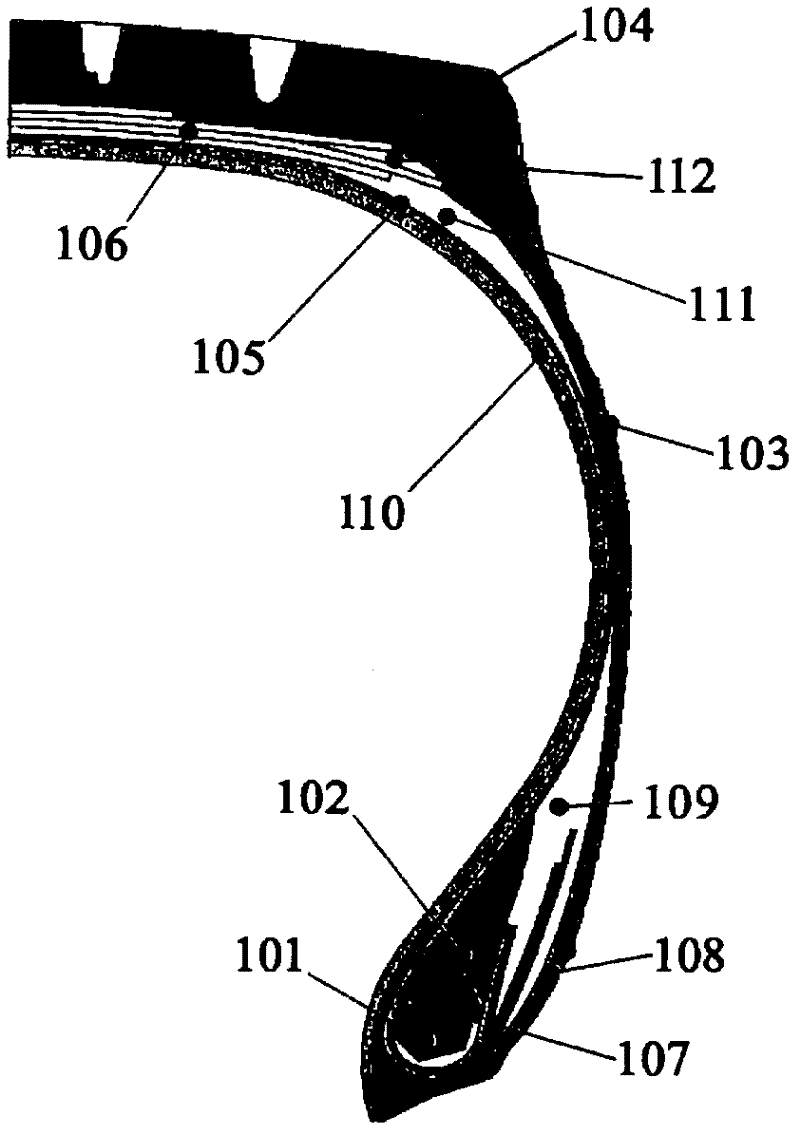

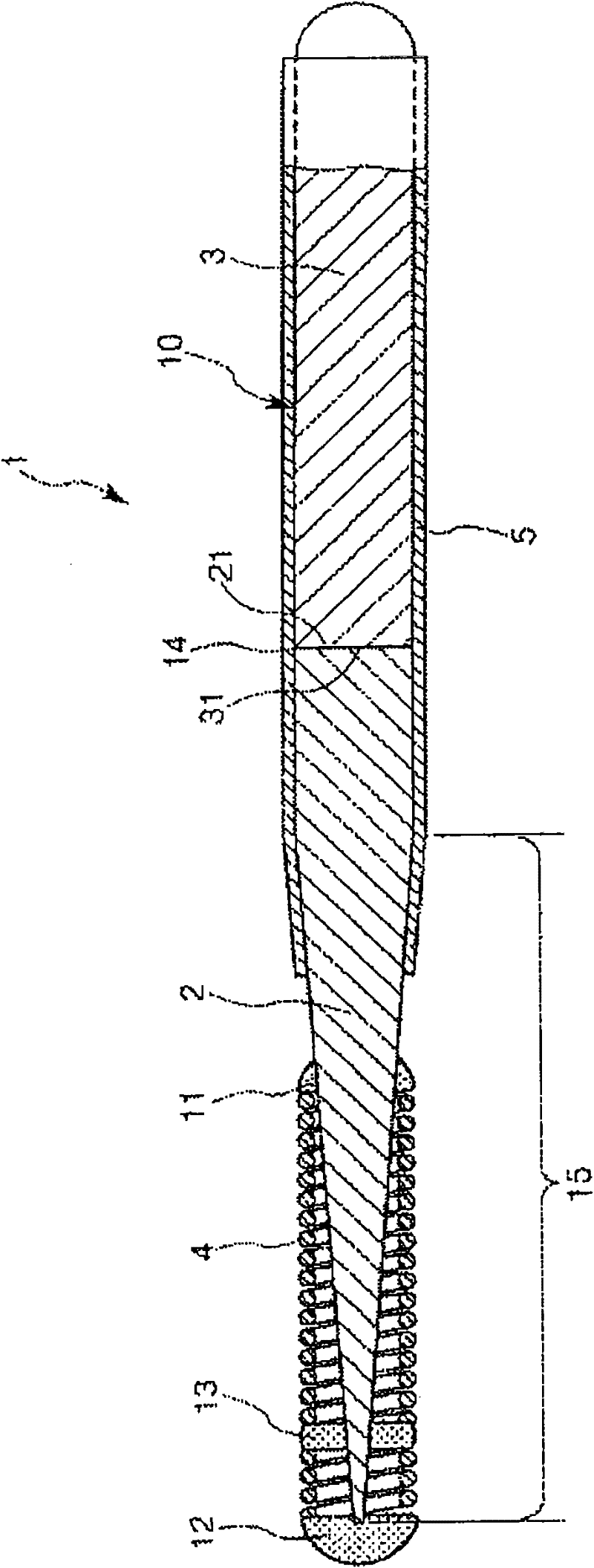

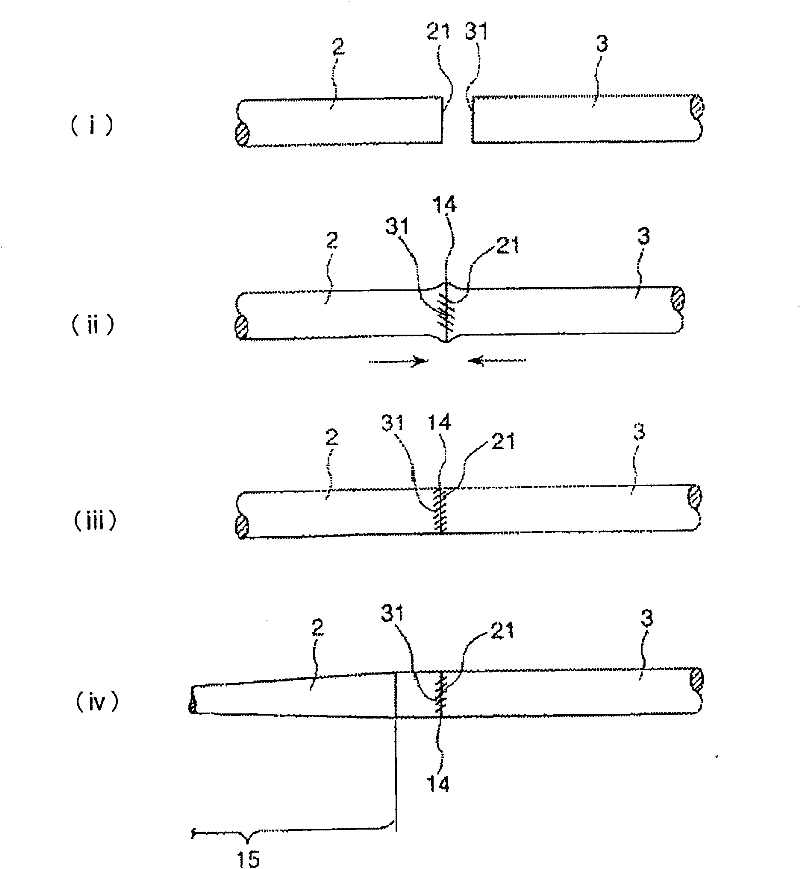

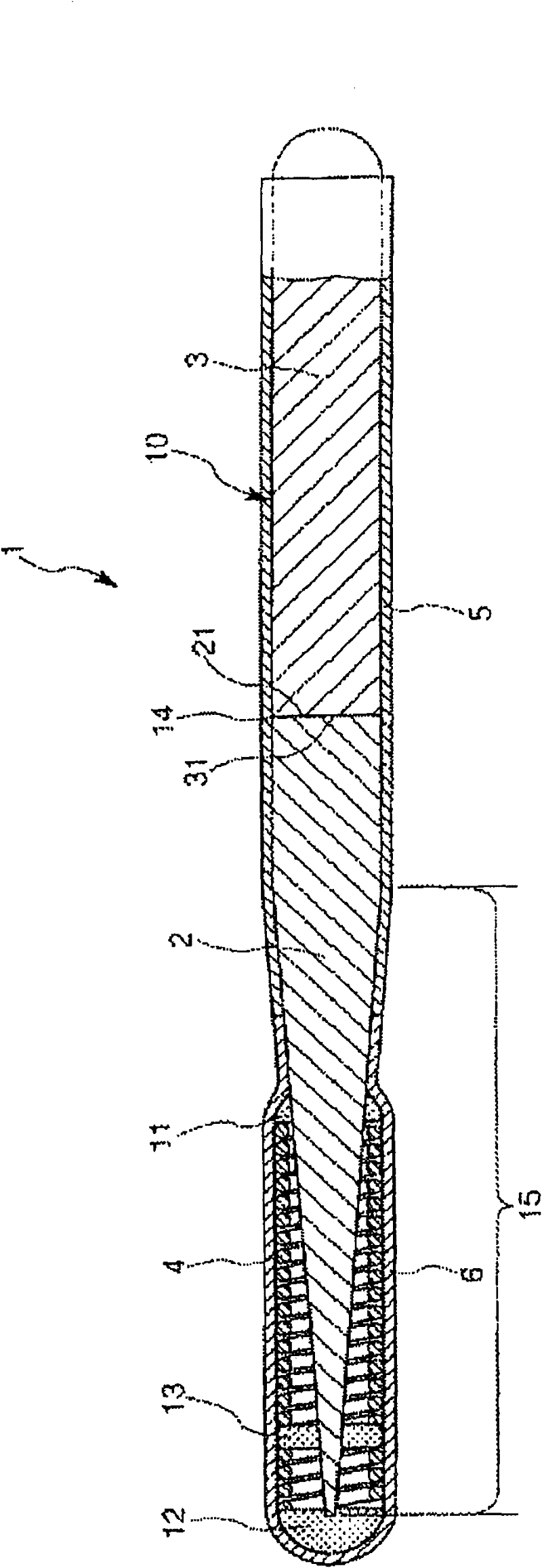

Guide wire and stent

ActiveCN101674861AEasy to slideExcellent X-ray contrastStentsGuide wiresPlastic materialsYoung's modulus

A guide wire that due to its wide elastic region and high Young's modulus, simultaneously has pliability and pushability, and that even when its surface is coated with a plastic material of high melting point, is highly impervious to influences of heat treatment, and that has excellent slidability and excels in weldability between a distal-end-side base material and a proximal-end-side core material. The guide wire has a core material comprising a distal-end-side core material and a proximal-end-side core material. The distal-end-side core material is made of an iron alloy having shape memorycapability and superelasticity, consisting essentially of two phases of gamma-phase and gamma'-phase and exhibiting, in a thermal hysteresis of martensite transformation and reverse transformation, adifference between reverse transformation completion temperature (Af-point) and martensite transformation starting temperature (Ms-point) of 100 DEG C or below. The proximal-end-side core material ismade of an alloy containing iron and has an elastic modulus higher than that of the distal-end-side core material. The distal-end-side core material and the proximal-end-side core material are weldedtogether.

Owner:TERUMO KK

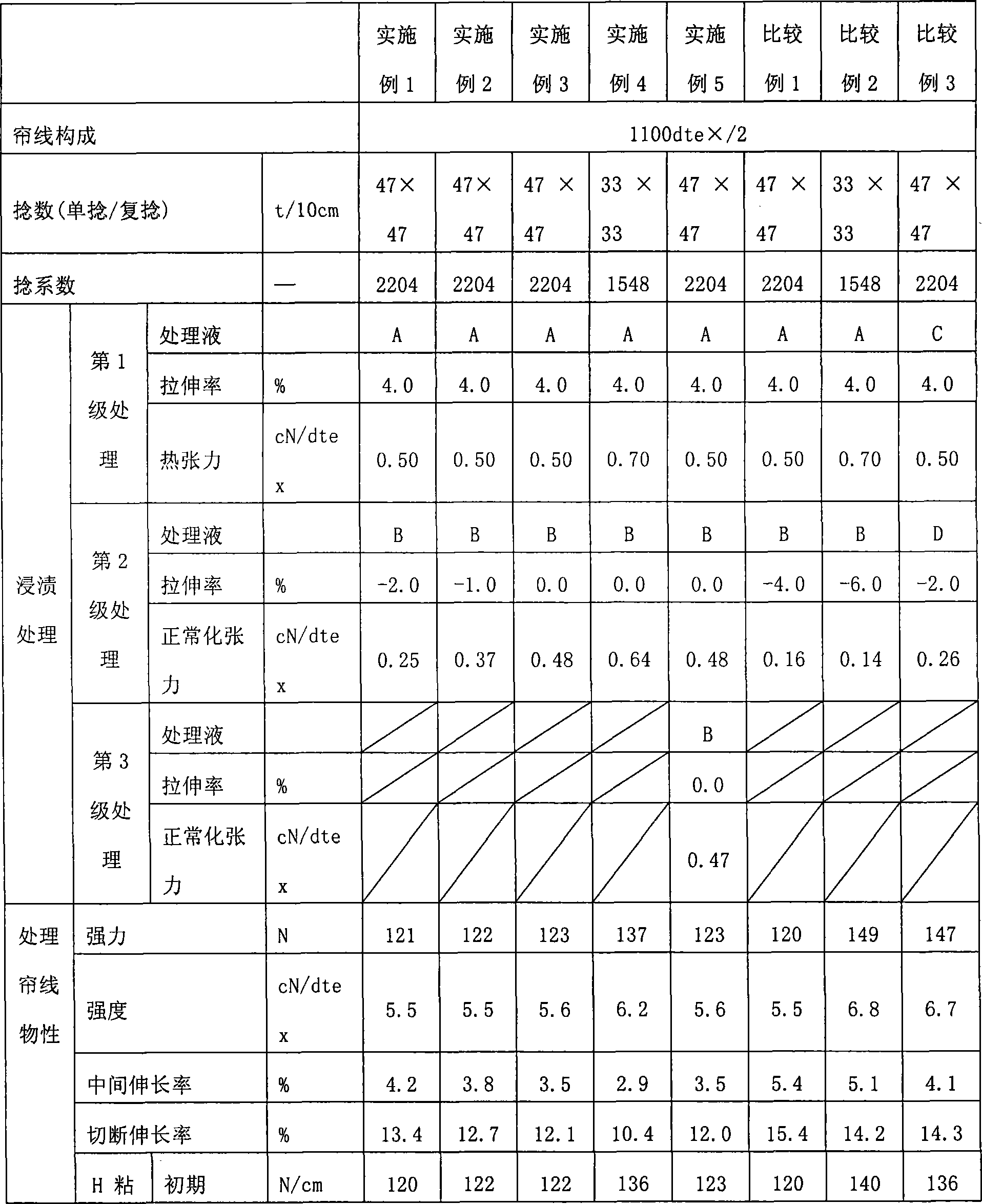

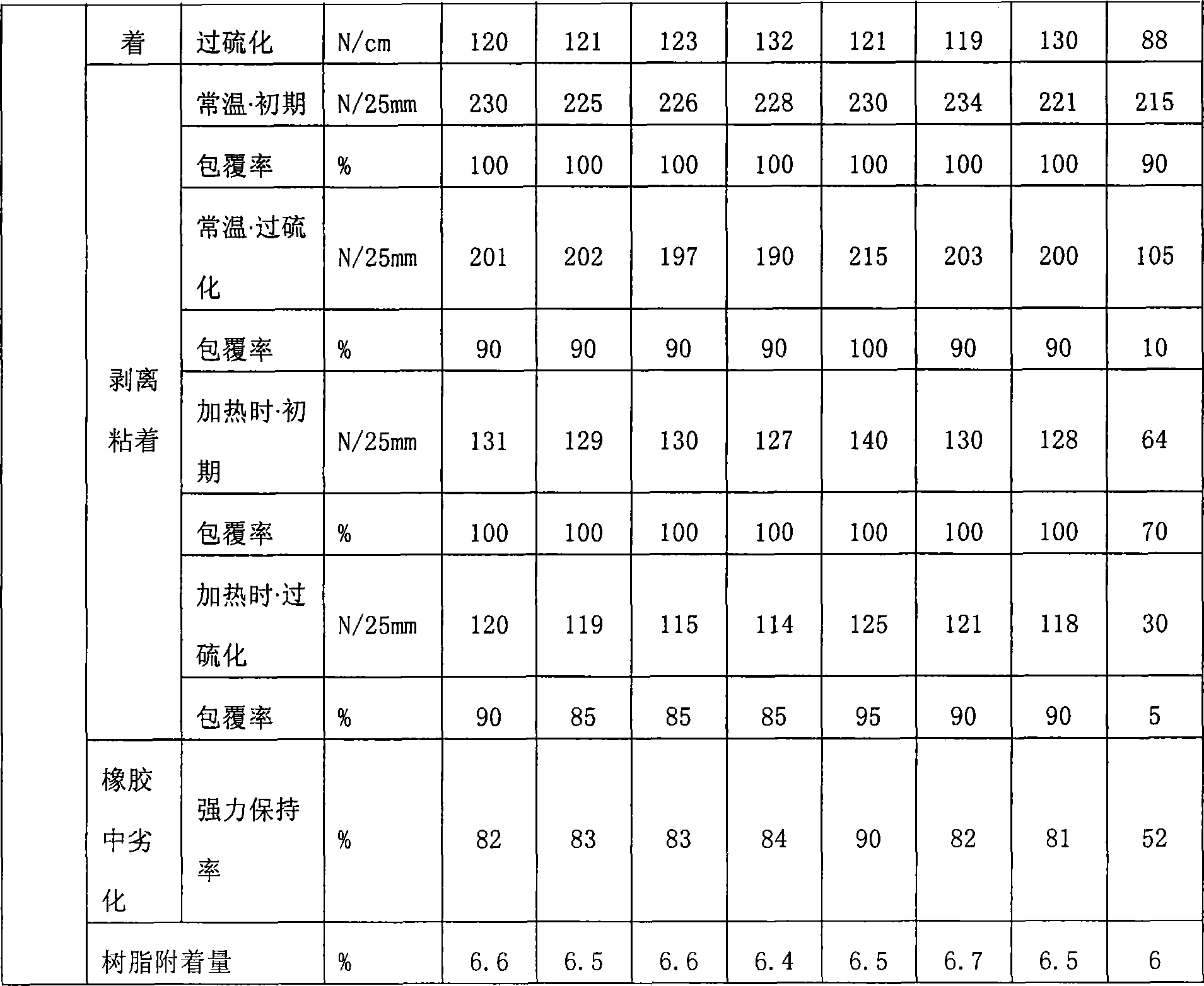

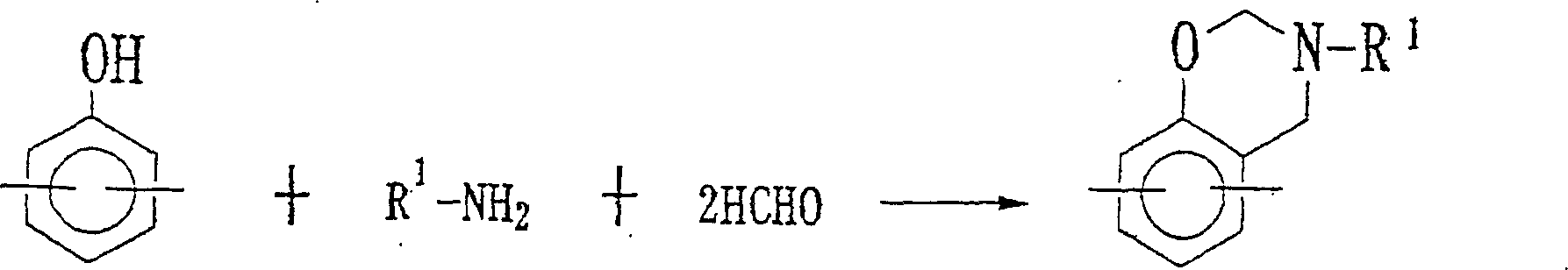

Rubber-reinforcing polyester cord and method for producing the same

InactiveCN1981083AHigh elastic rateImprove adhesionFibre treatmentSynthetic resin layered productsPolyesterFiber

It is provided a polyester cord for reinforcement of rubber suitable to the use for tire cap ply where a high elastic modulus is available and heat-resisting adhesive property and strength retaining rate upon exposure to high temperature for long time in rubber are significantly improved and also to provide a method for producing the same. A method for production of polyester cord for reinforcement of rubber, characterized in that , in bestowing adhesive property to rubber on a polyester fiber material, four members of (A) a treating solution containing a carrier, (B) an aqueous solution of a blocked isocyanate, (C) a dispersion of an epoxy compound and (D) a mixed solution of resorcinol-formaldehyde-latex (RFL) are combined as a treating solution and said polyester fiber material is subjected to a treatment by means of a one-stage or two or more multi-stage treatment, wherein said polyester fiber material is treated with a first treating solution compounded at least with (A) a treating solution containing a carrier, then treated with a second treating solution where at least (D) a mixed solution of resorcinol-formaldehyde-latex (RFL) is compounded and, after treating with the second treating solution in the final stage, a thermal treatment under a normalizing tension adjusted to not less than 0.2 cN / dtex is carried out.

Owner:TOYOBO CO LTD

Method for producing cellulose fiber

InactiveCN1772983AHigh strengthIncrease elasticityMaterial nanotechnologyArtificial filaments from cellulose solutionsPolyvinyl alcoholCellulose fiber

The present invention provides a cellulose fiber having high strength, high modulus of elasticity, and low shrinkage properties, and excellent performance in preventing fibrillation and adhesion to rubber. It is produced by dissolving 0.1% to 10% by weight of salt and polyvinyl alcohol in a liquid concentrated NMMO solution to produce an NMMO solution; mixing, swelling, and dissolving the NMMO solution and cellulose powder to produce a cellulose solution Extrude and spin the cellulose solution through a spinning nozzle with 500 to 2000 spinneret holes, and then solidify it through an air layer and a coagulation bath to obtain multifilaments; wash the obtained multifilaments with water, Drying, oiling and coiling.

Owner:HYOSUNG ADVANCED MATERIALS CORP

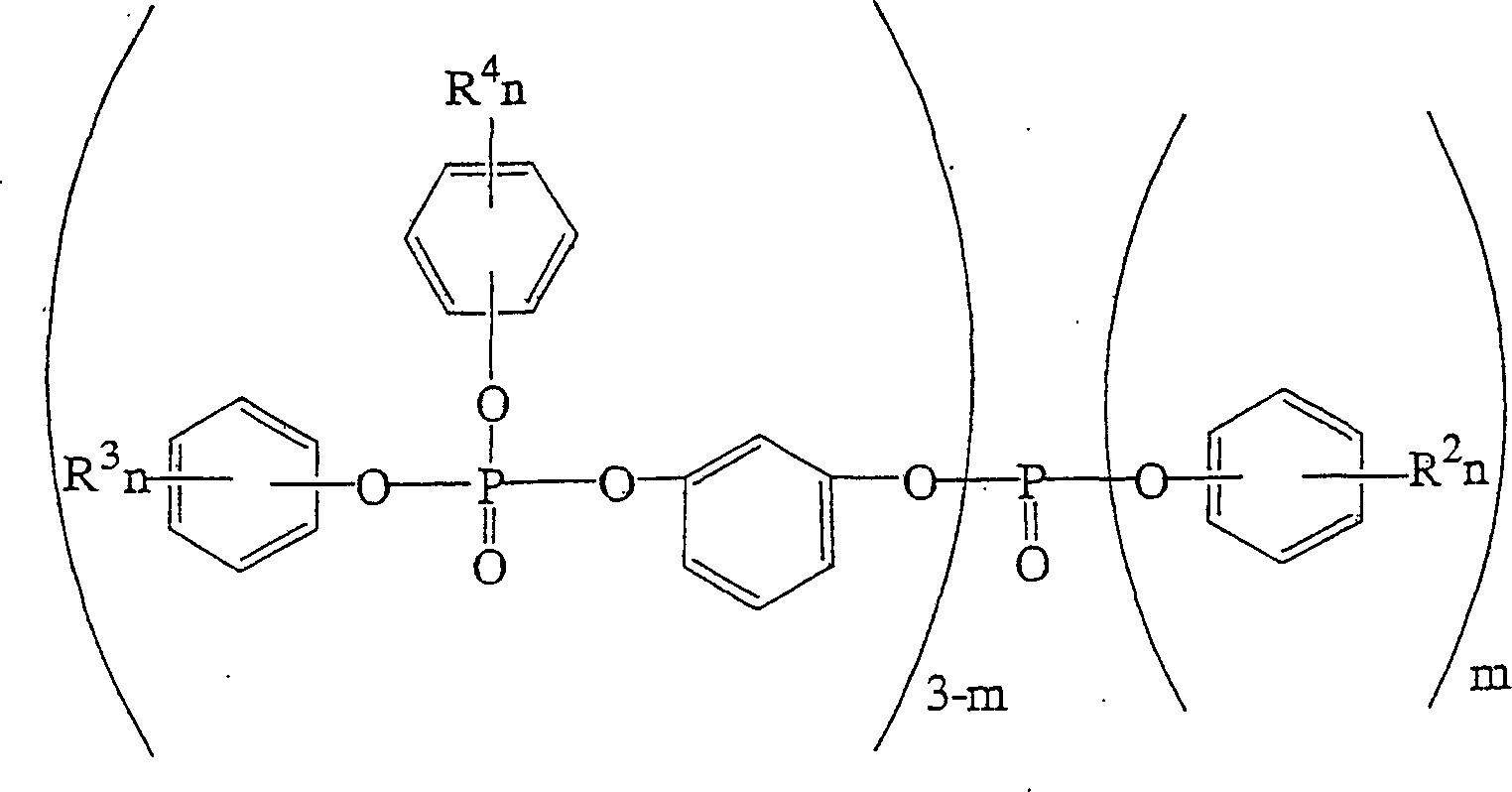

Thermosetting resin composition and prepreg laminate for circuit board and printed circuit board each made therewith

InactiveCN1484674AEasy to processLow dielectric dissipation factorSynthetic resin layered productsThin material handlingPolymer scienceTriazine

The present invention discloses a thermosetting resin composition which comprises (A) 35 to 75 parts by weight of a thermosetting resin comprising a compound having a dihydrobenzoxazine ring as a main component, (B) 10 to 25 parts by weight of a polycondensation product of a phenol, a compound having a triazine ring and an aldehyde, and (C) 10 to 45 parts by weight of an epoxy resin, based on 100 parts by weight of the total amount of organic solid components of Components (A), (B) and (C), and (i) a bisphenol F epoxy resin having a weight average molecular weight of 1,000 to 3,000, or (ii) a mixed epoxy resin of bisphenol F epoxy resin and bisphenol A epoxy resin having a weight average molecular weight of 1,000 to 3,000, is contained in Component (C) in an amount of 0 to 100% by weight of Component (C); and a prepreg, a laminated board for a wiring board and a wiring board using the same.

Owner:RESONAC CORP

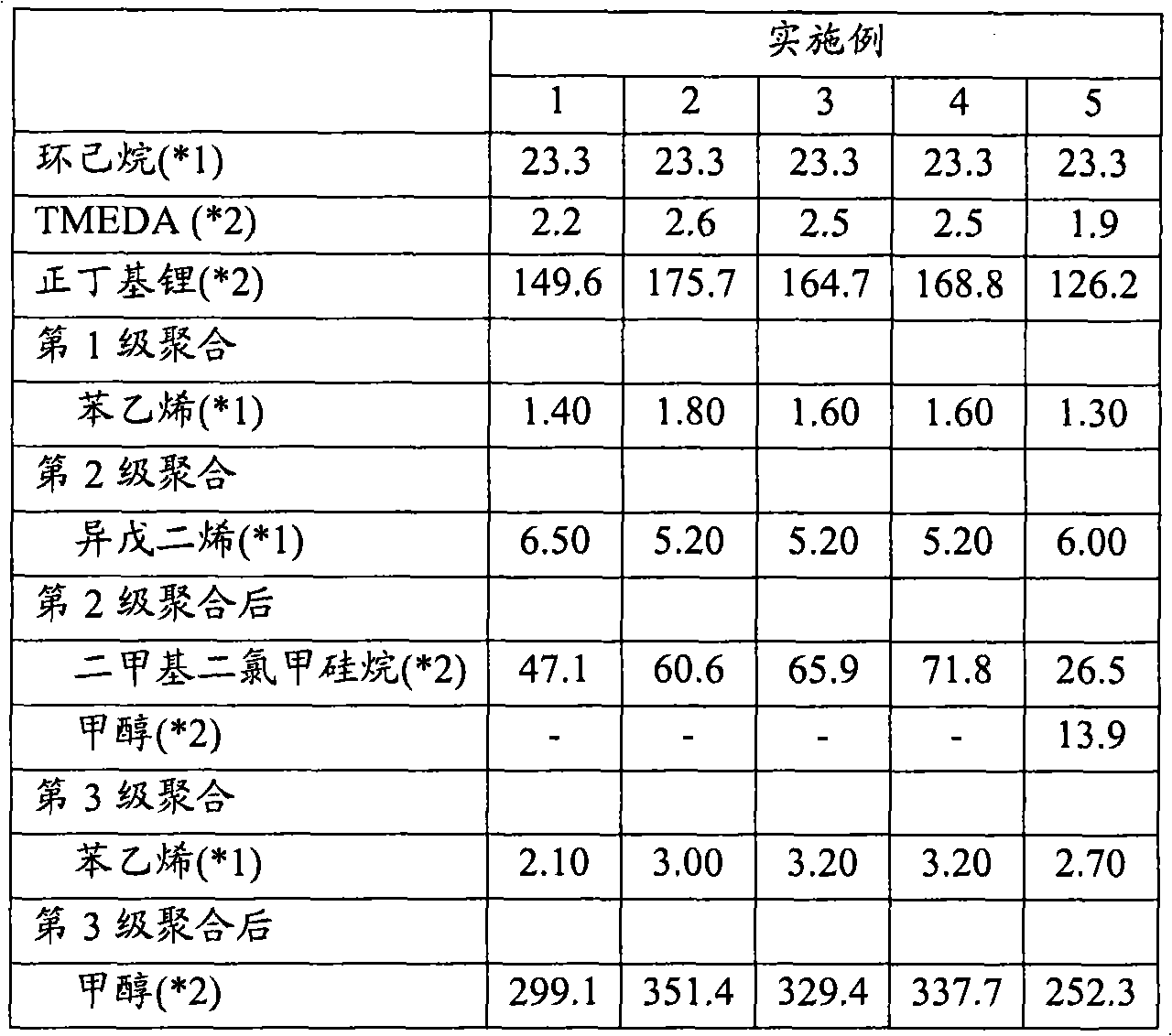

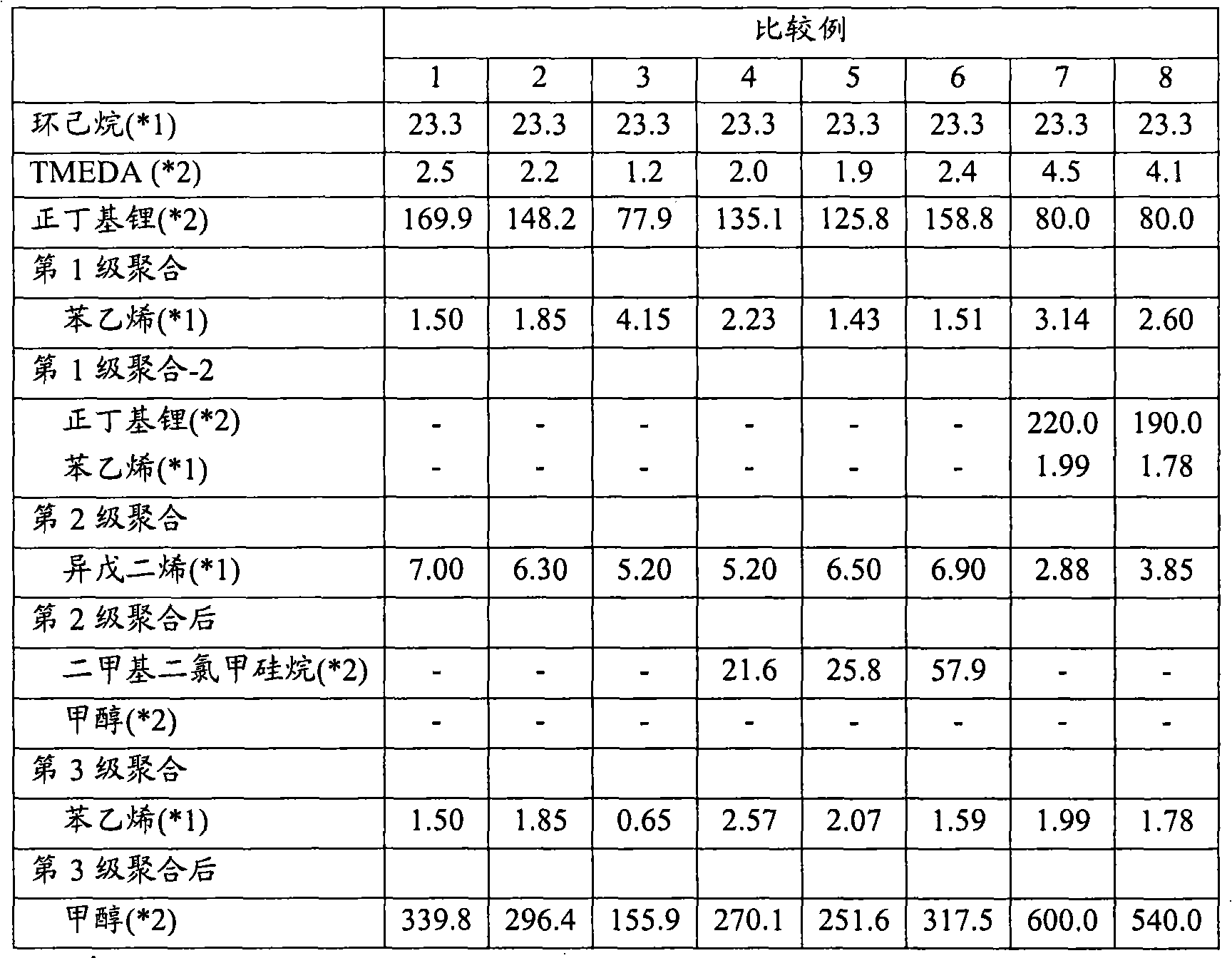

Block copolymer composition, method for producing the same, and film of the same

The invention provides a block copolymer composition containing an aromatic vinyl-conjugated diene-aromatic vinyl block copolymer having a high-level balance between high elastic modulus and small permanent elongation. The block copolymer composition contains a block copolymer A represented by formula (A) and a block copolymer B represented by formula (B). The weight ratio between the block copolymer A and the block copolymer B (A / B) is from 36 / 64 to 85 / 15, and the ratio of the aromatic vinyl monomer units relative to all polymer components in the block copolymer composition is 27-70% by weight. In the formulae, Ar1a, Ar1b and Ar2b each represents an aromatic vinyl polymer block having an Mw of 6,000-18,000; Ar2a represents an aromatic vinyl polymer block having an Mw of 40,000-400,000; Da and Db each represents a conjugated diene polymer block having a vinyl bond content of 1-20% by mole; and Db has an Mw of 60,000-400,000. Arla-Da-Ar2a (A), Ar1b-Db-Ar2b (B).

Owner:ZEON CORP

Acetal (dehyde) resin flat yarn, manufacture and use thereof

InactiveCN1424444AHigh strengthHigh elastic rateMonocomponent polyethers artificial filamentBagsPolyoxymethyleneYarn

A flat yarn of a high strength and a high modulus of elasticity, being excellent in solvent resistance, thermal stability and resistance to bending fatigue is provided. The flat yarn comprises polyoxymethylene copolymer containing o.5 to 10 moles of specified oxyalkylene units per 100 moles of oxymethylene units in the polymer chain principally comprising repeating oxymethylene units and having a melt index at 190 DEG C with load of 2160 g of 0.3 to 20 g / 10 min.

Owner:POLYPLASTICS CO LTD

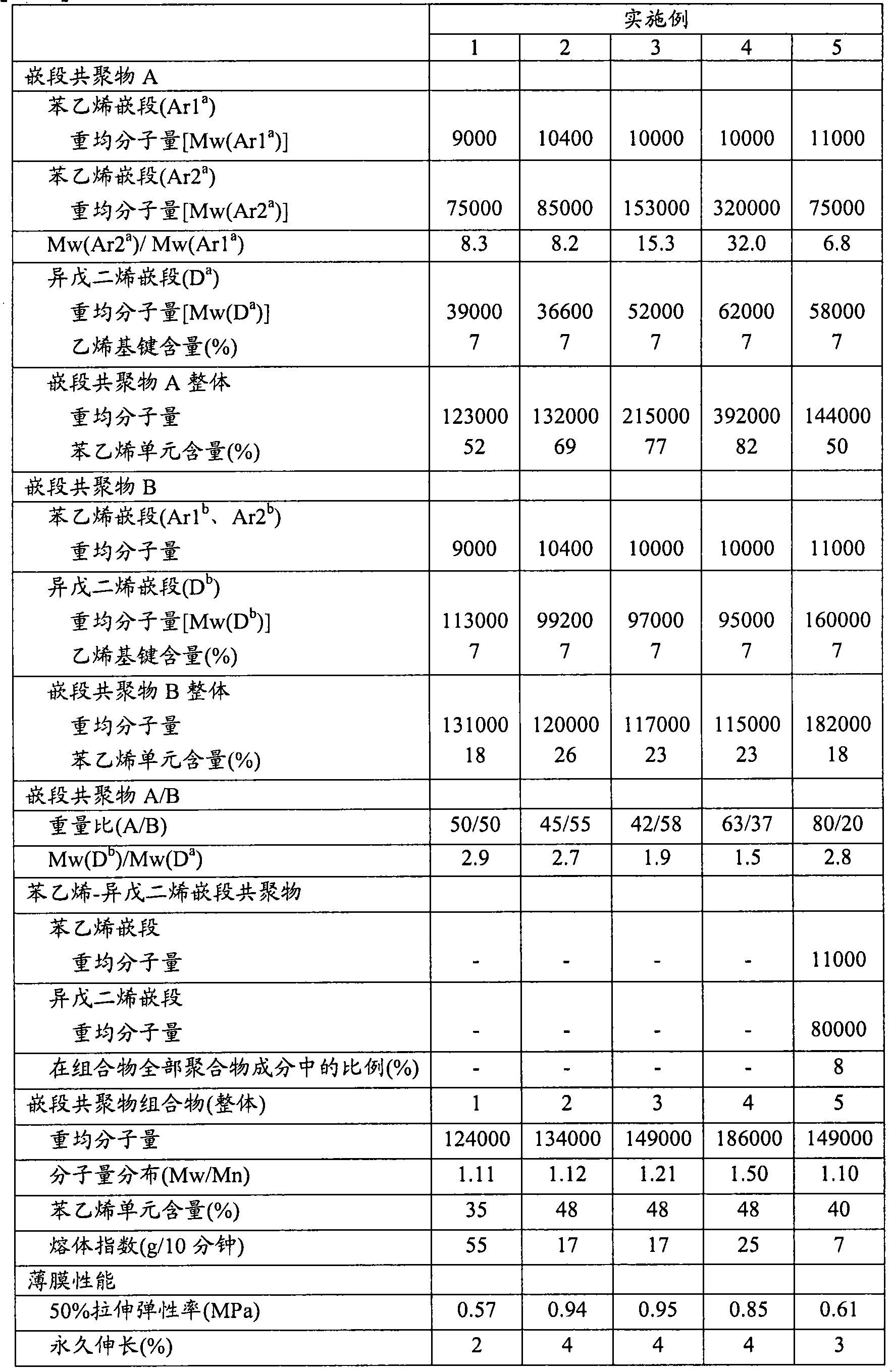

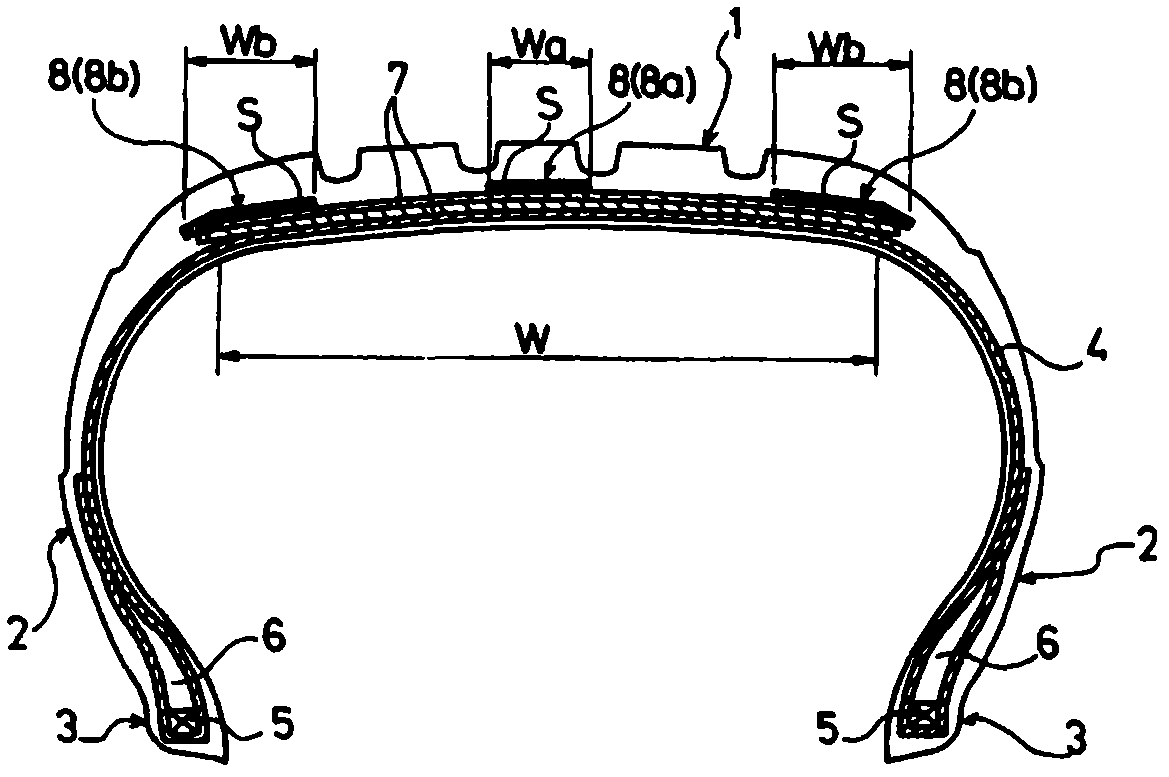

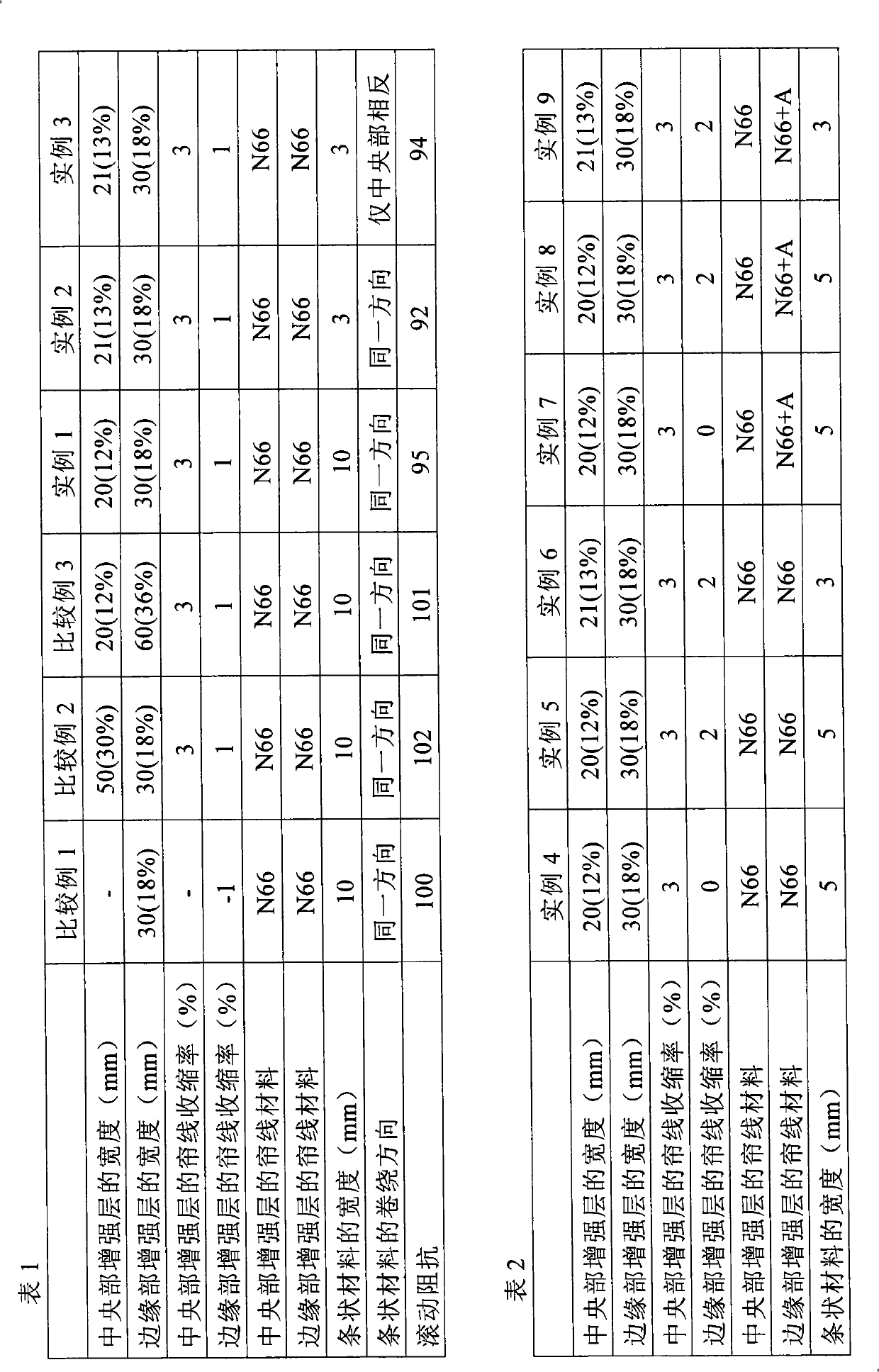

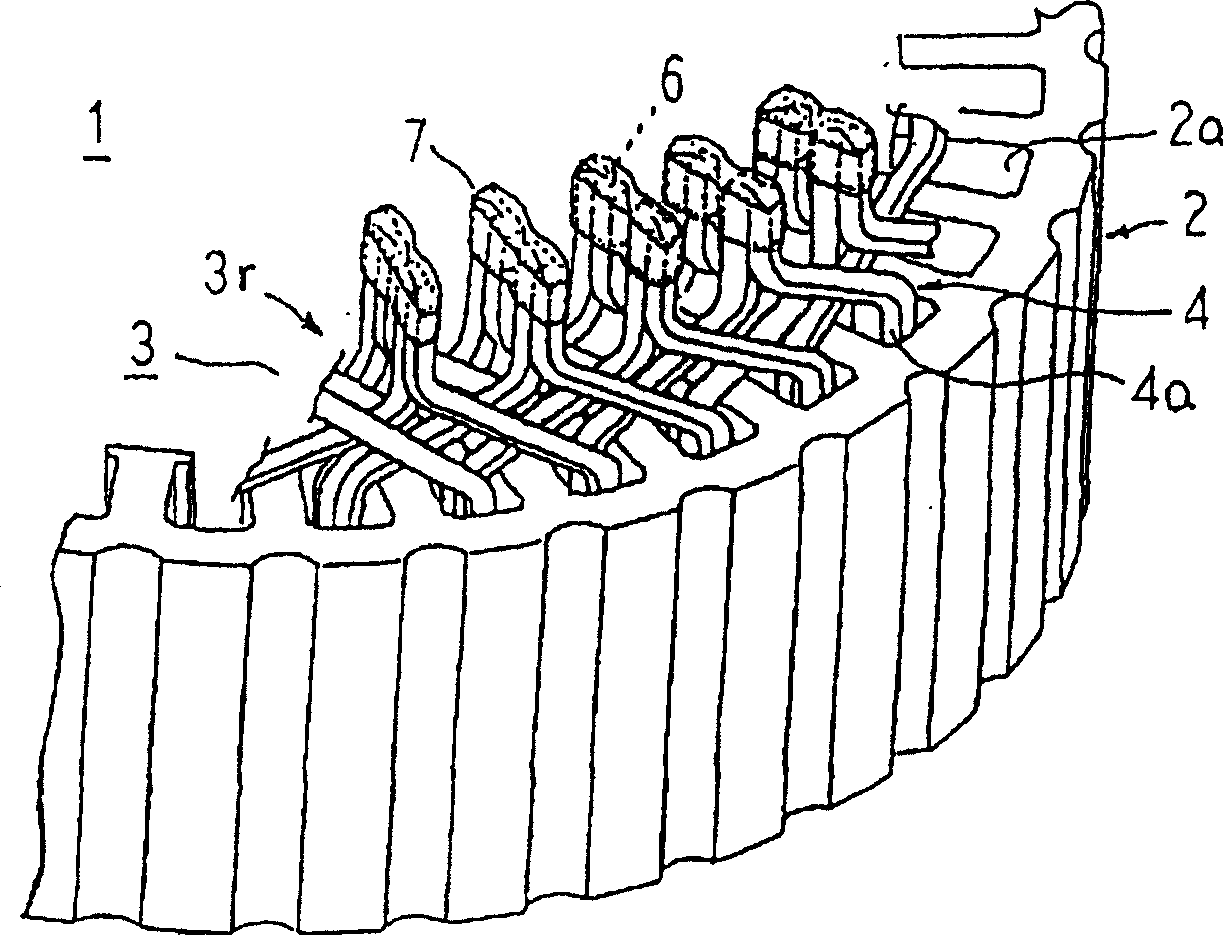

Pneumatic tire

InactiveCN102001263ASmall volumeReduce distortionPneumatic tyre reinforcementsWheelsFiberRolling resistance

The invention provides a pneumatic tire which effectively reduces rolling resistance. A pneumatic tire including a carcass layer (4) mounted between a pair of bead portions (3, 3), at least two layers of a belt layer (7) disposed on an outer circumferential side of the carcass layer (4) corresponding to a tread portion (1), and a belt reinforcing layer (8) having a strip material including at least one fiber cord wrapped spirally in a tire circumferential direction on an outer circumferential side of the belt layers, wherein the belt reinforcing layer (8) has a center portion reinforcing layer (8a) for reinforcing a center portion of the belt layers (7) and edge portion reinforcing layers (8b) for reinforcing edge portions of the belt layers (7), the center portion reinforcing layer (8a) and the edge portion reinforcing layers (8b) are mutually separated, a width Wa of the center portion reinforcing layer (8a) is from 5% to 25% of a width of a belt layer (7) having a smallest width, and a width of the edge portion reinforcing layers (8b) is from 10% to 35% of the width of the belt layer (7) having the smallest width.

Owner:THE YOKOHAMA RUBBER CO LTD

Resin composition for medical use, manufacturing method thereof, and medical kit

ActiveCN102811694AEasy to manufactureHigh strengthImpression capsSurgical adhesivesHydrogen atomMethyl group

Owner:田仲 持郎

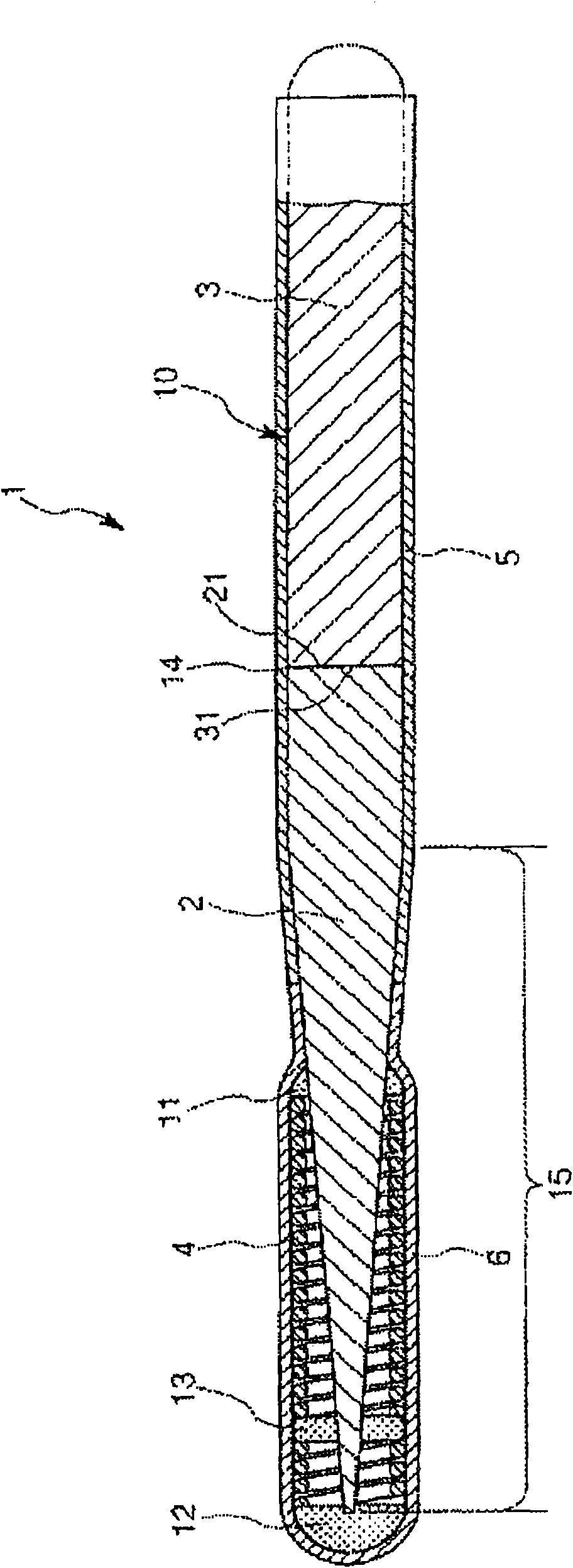

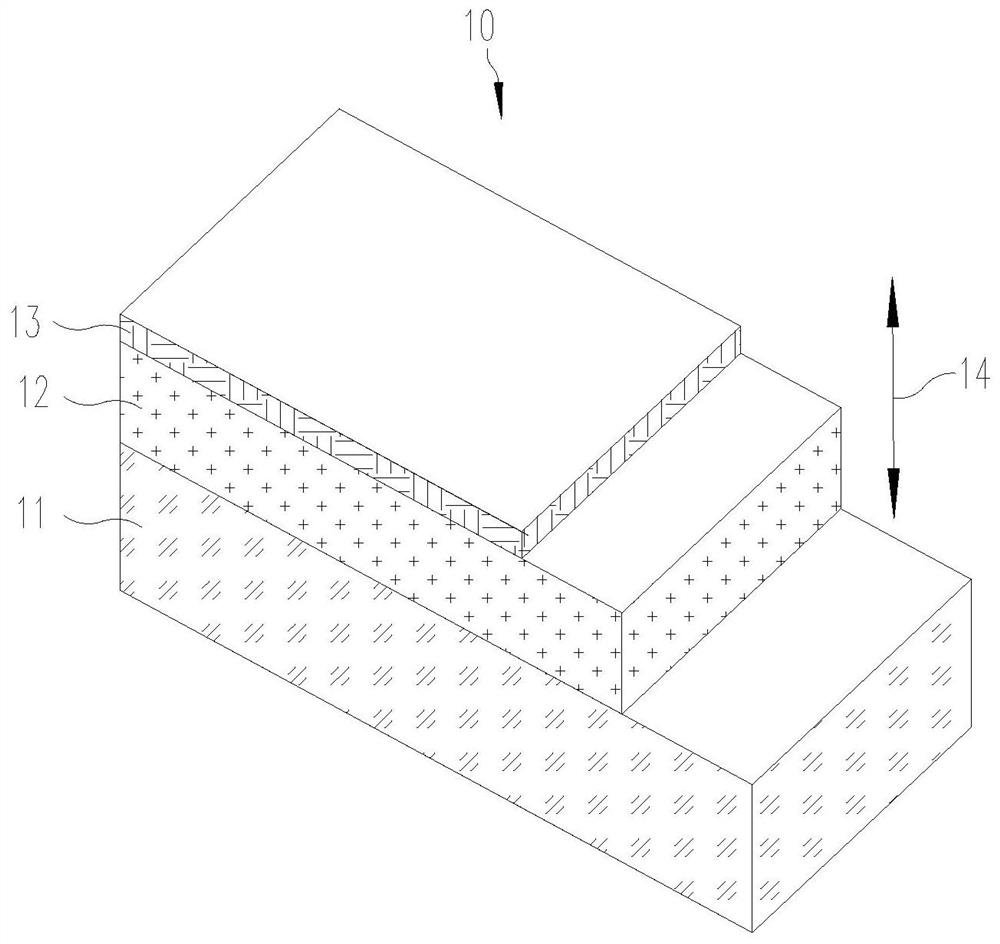

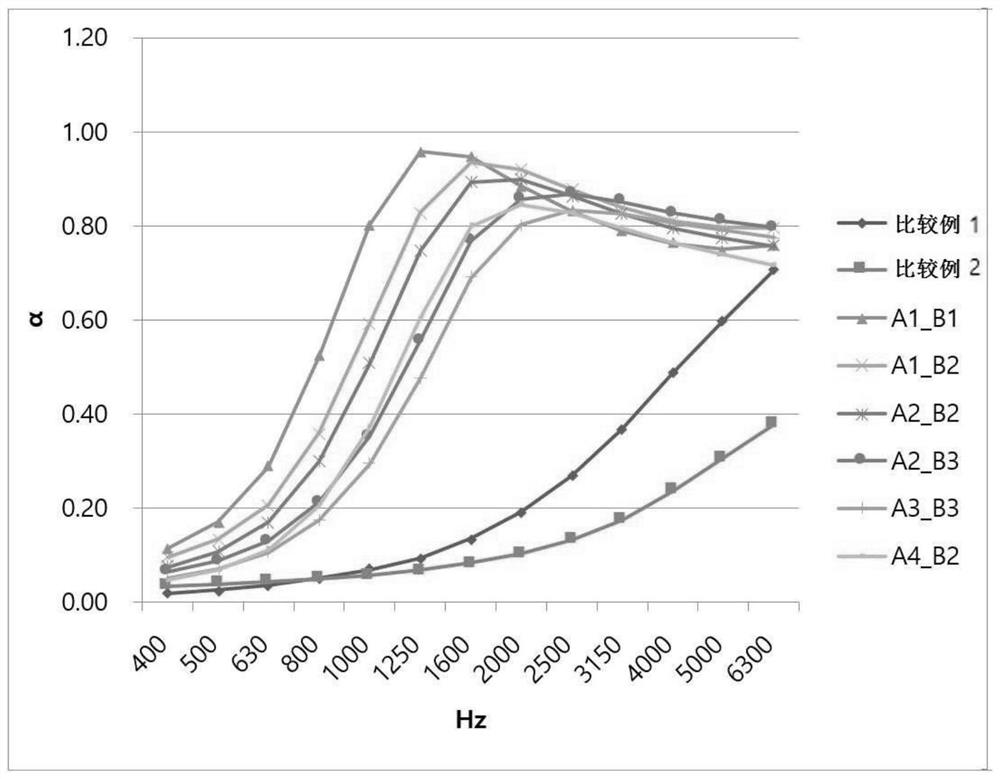

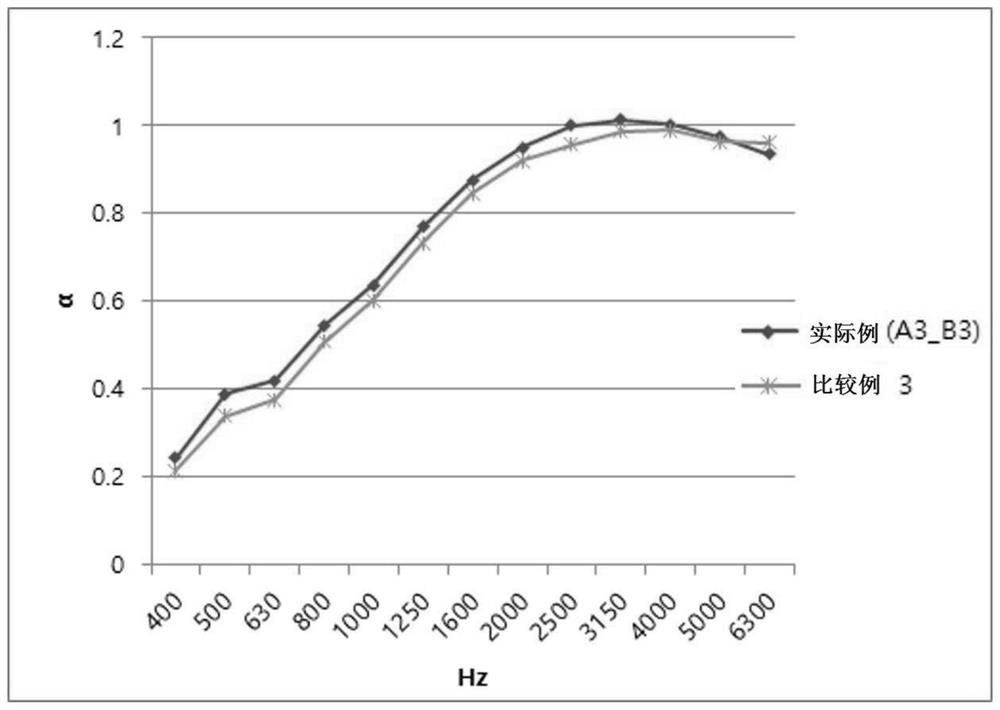

Composite sound-absorbing cotton for shock absorption of automobile component and automobile component

InactiveCN111605271AMaintain shape for long-term deformationHigh elastic rateSynthetic resin layered productsVehicle componentsEngineeringNonwoven fabric

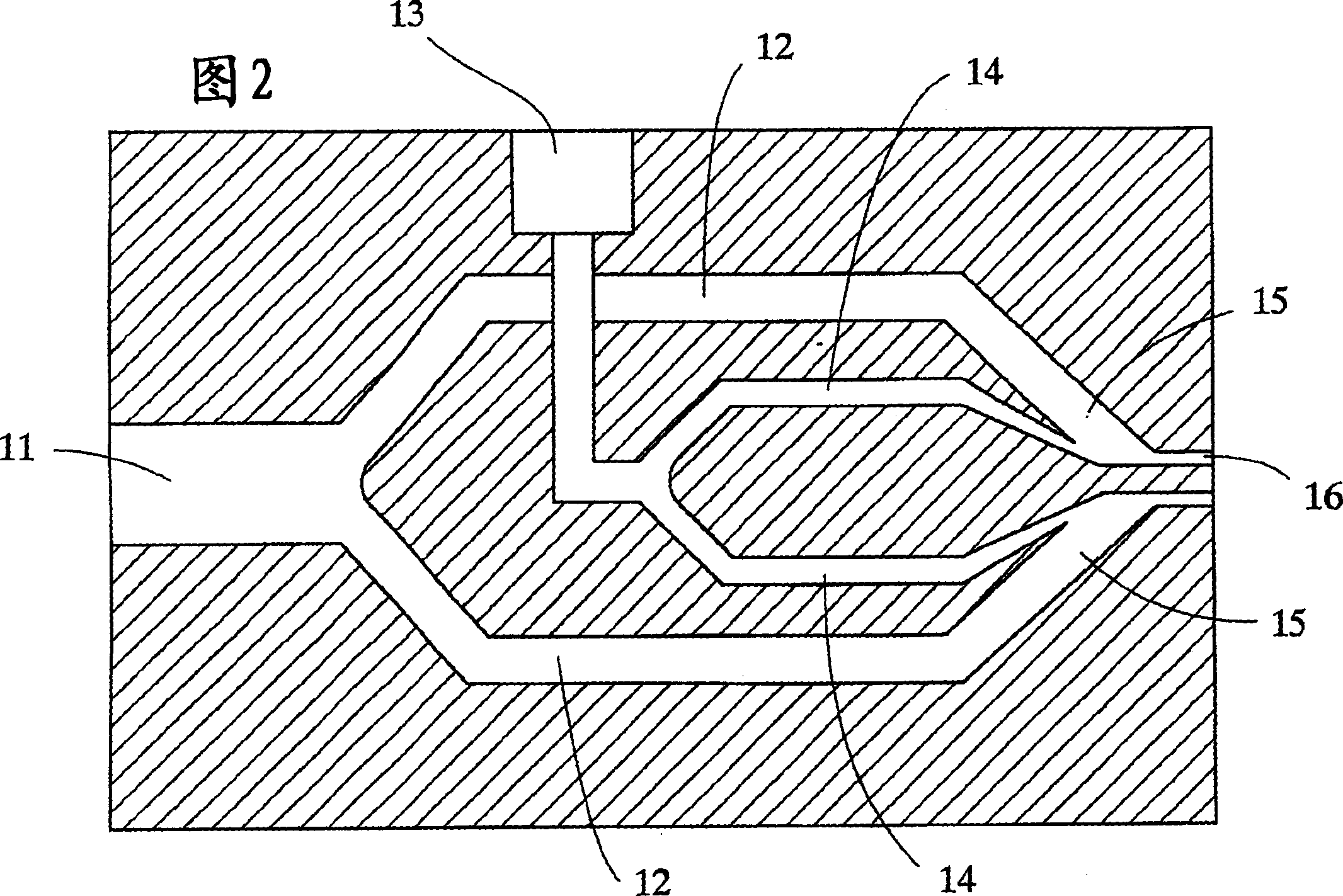

The invention provides composite sound-absorbing cotton for shock absorption of an automobile component. The composite sound-absorbing cotton (10) comprises a first sound-absorbing layer (11), a second sound-absorbing layer (12) and a third composite layer (13). The second sound-absorbing layer (12) has a thickness direction (14). The first sound-absorbing layer (11) covers one side of the secondsound-absorbing layer (12) in the thickness direction (14) thereof. The third composite layer (13) is bonded to the other side of the second sound-absorbing layer (12) in the thickness direction (14)thereof. The first sound-absorbing layer (11) is made of a high-elasticity supporting fiber material. The second sound-absorbing layer (12) is made of an ultrafine fiber material. The third compositelayer (13) is made of a non-woven fabric material. The superfine fibers and the high-elasticity supporting fibers are compounded, so that the use amount of the superfine fibers is reduced, meanwhile,sound absorption performance is maintained; the high-elasticity supporting fibers have high elasticity, the thickness of the sound absorption material can be improved, and the long-term deformation ofthe shape of the sound absorption cotton is maintained.

Owner:北京海纳川瑞延汽车饰件有限公司

Multi-layer tube

InactiveCN1650126AHigh melt adhesionWon't peel offSynthetic resin layered productsFlexible pipesPolymer scienceHexafluoropropylene

Owner:SAMSUNG GROUP

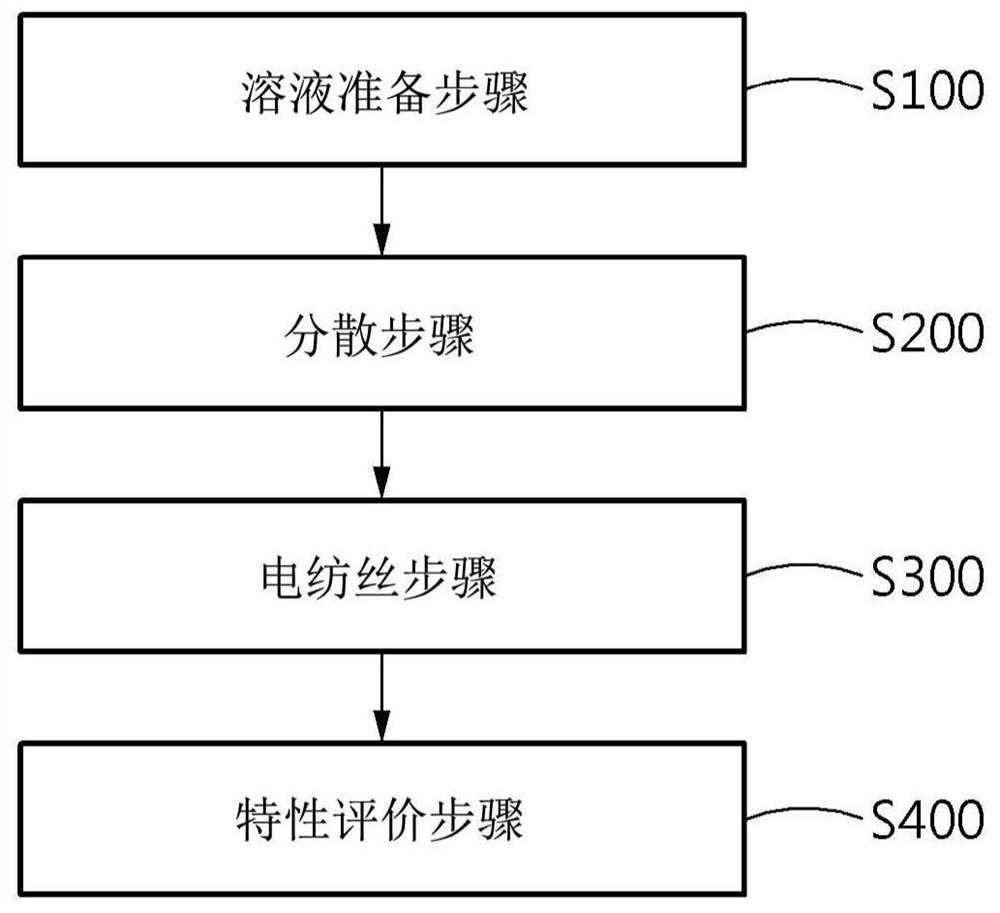

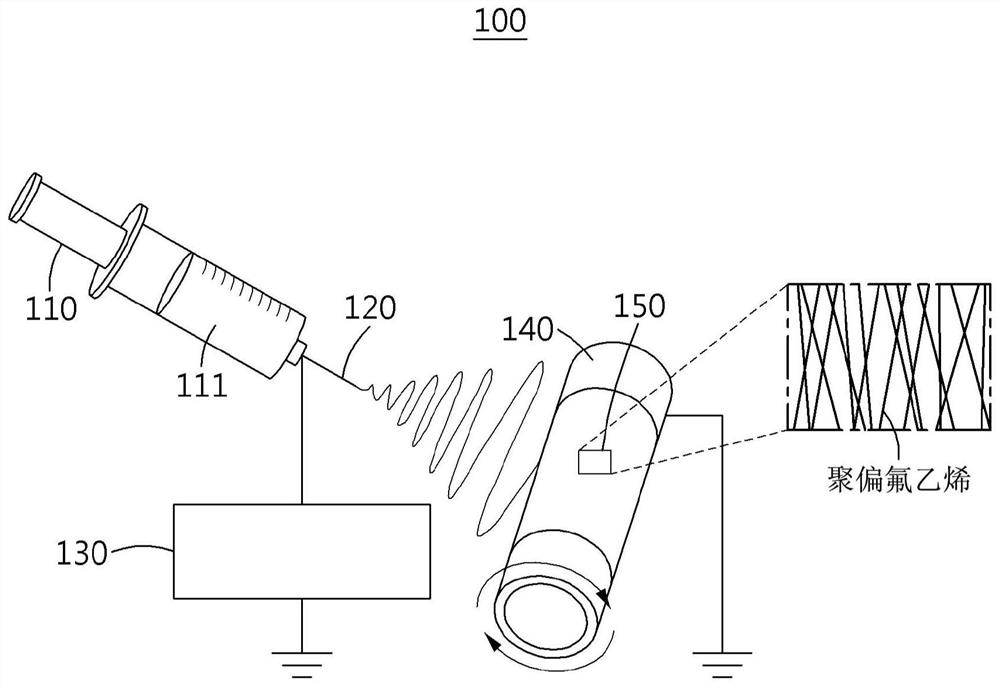

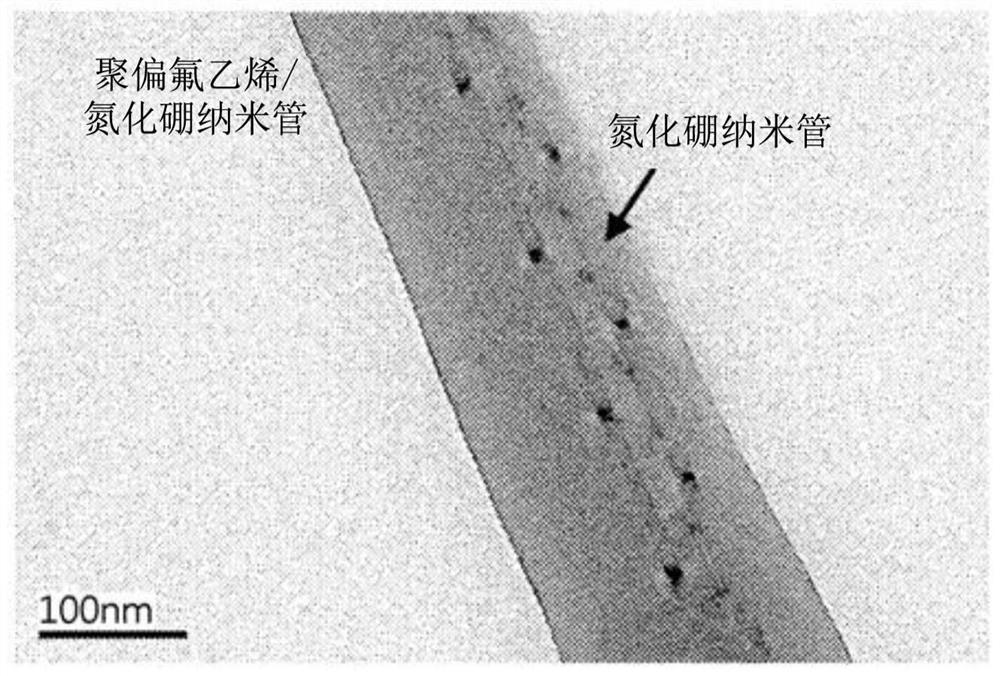

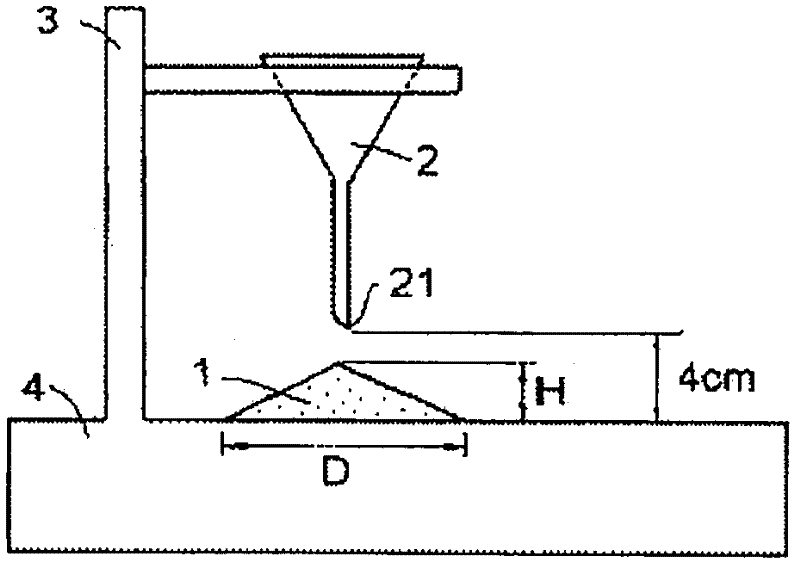

Method and apparatus for manufacturing polymer composite piezoelectric material having boron nitride nanotubes dispersed therein, and polymer composite piezoelectric material manufactured by the method

PendingCN112585774AExcellent piezoelectric propertiesMaximize the effect of polarizationMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyNanofiberBoron nitride

A method for manufacturing a polymer composite piezoelectric material having boron nitride nanotubes (BNNTs) dispersed therein, according to one embodiment of the present invention, may comprise: a solution preparation step for preparing a polymer solution; a dispersion step for dispersing BNNTs in the polymer solution; and an electrospinning step for, by using an electrospinning method, carryingout electrospinning on the polymer solution having the BNNTs dispersed therein, thereby producing a polymer composite piezoelectric material on a nanofiber.

Owner:ネイール テクノロジー

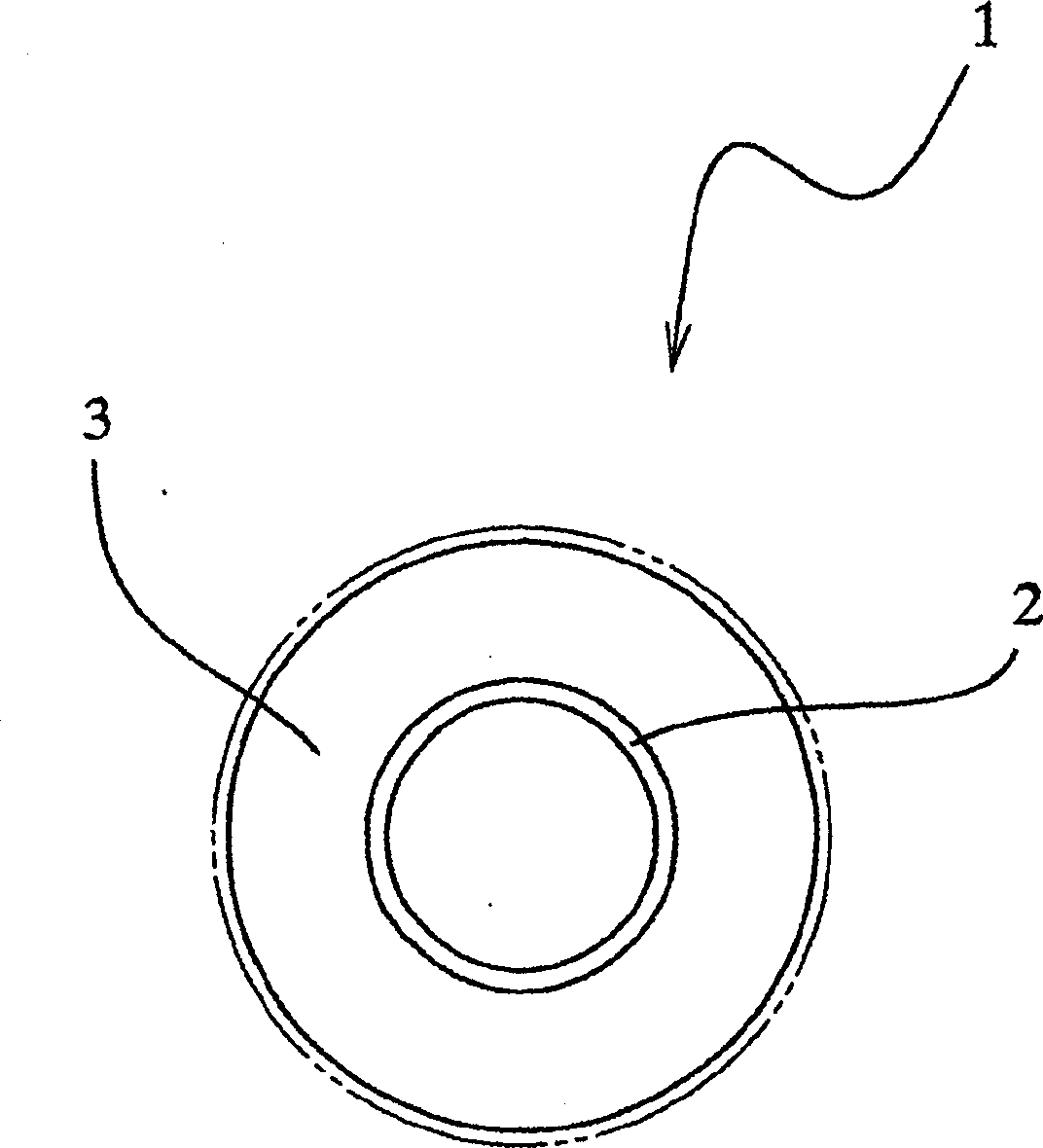

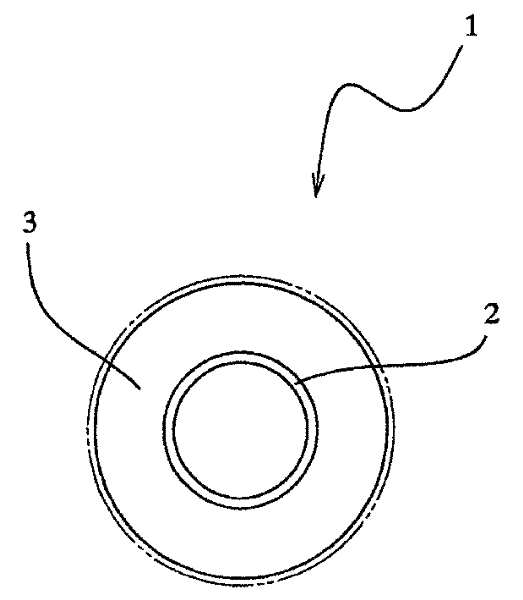

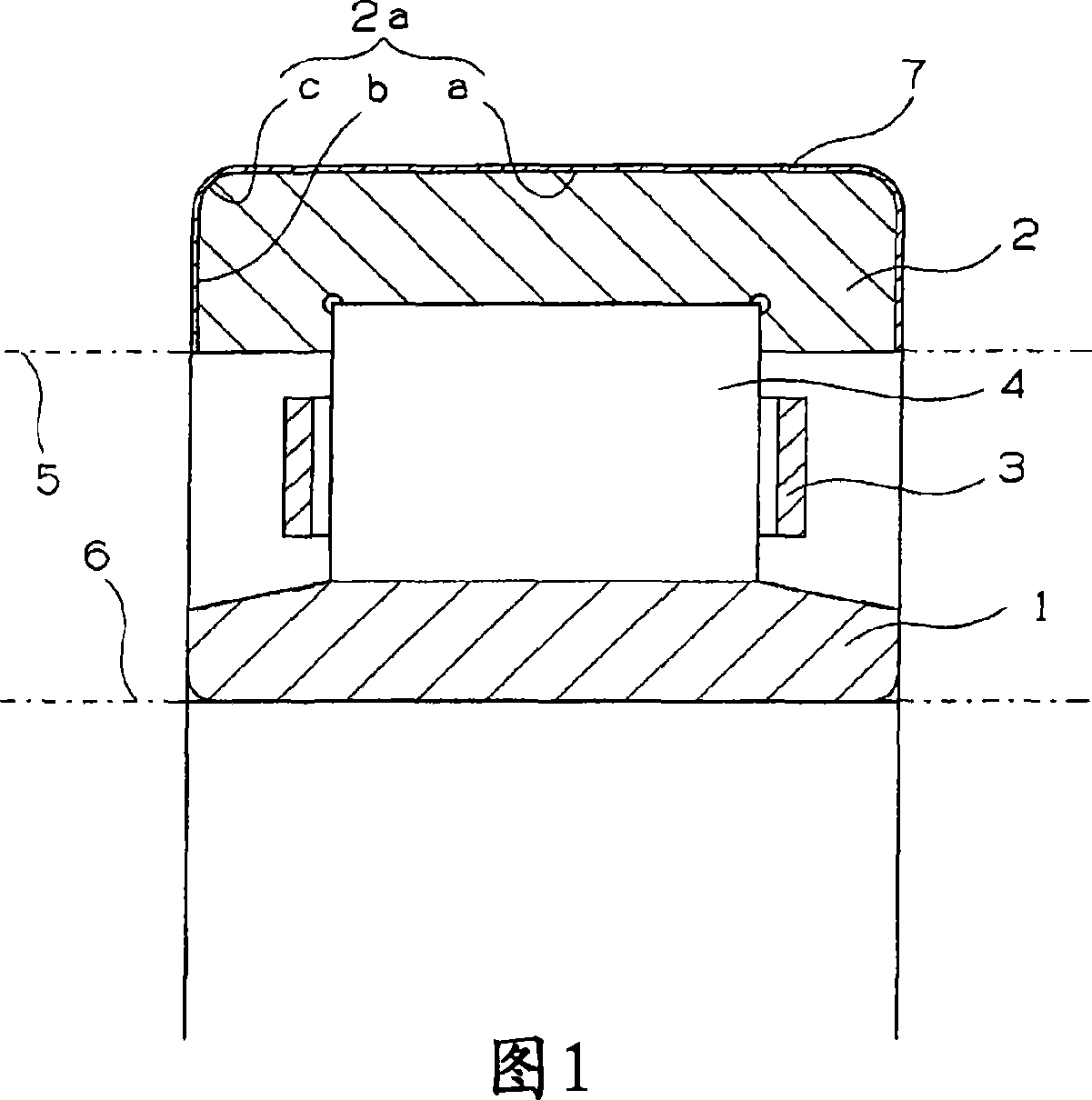

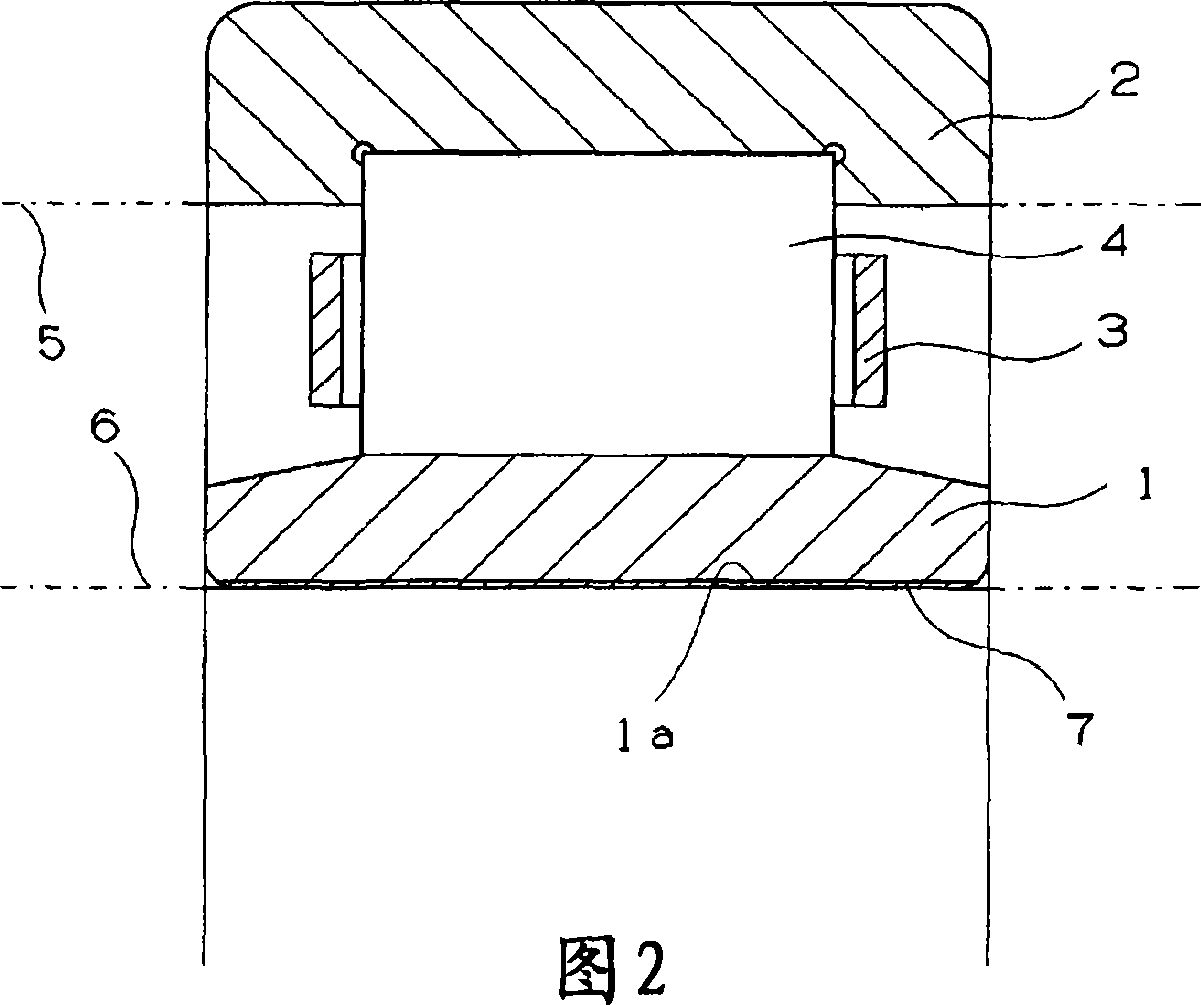

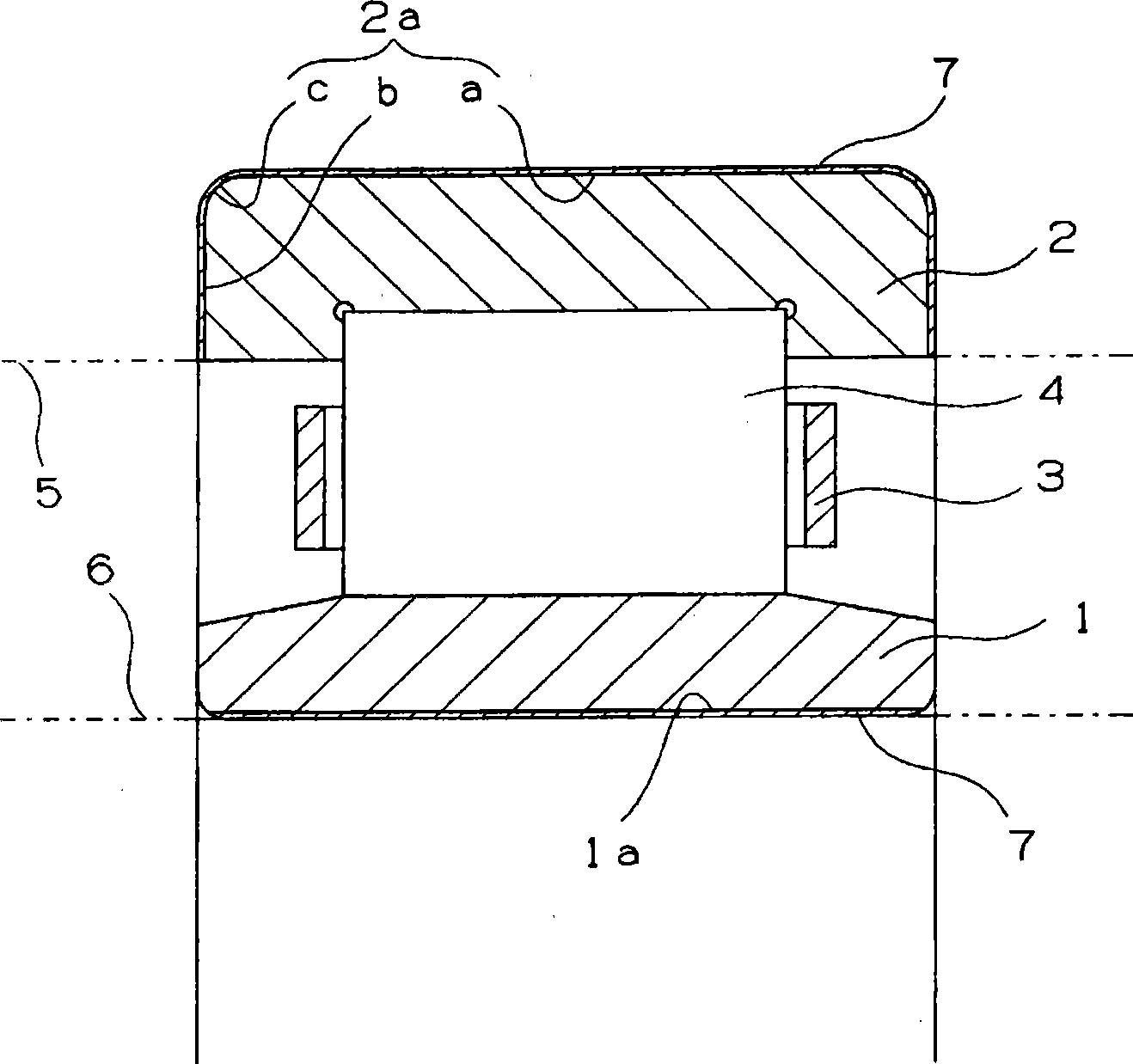

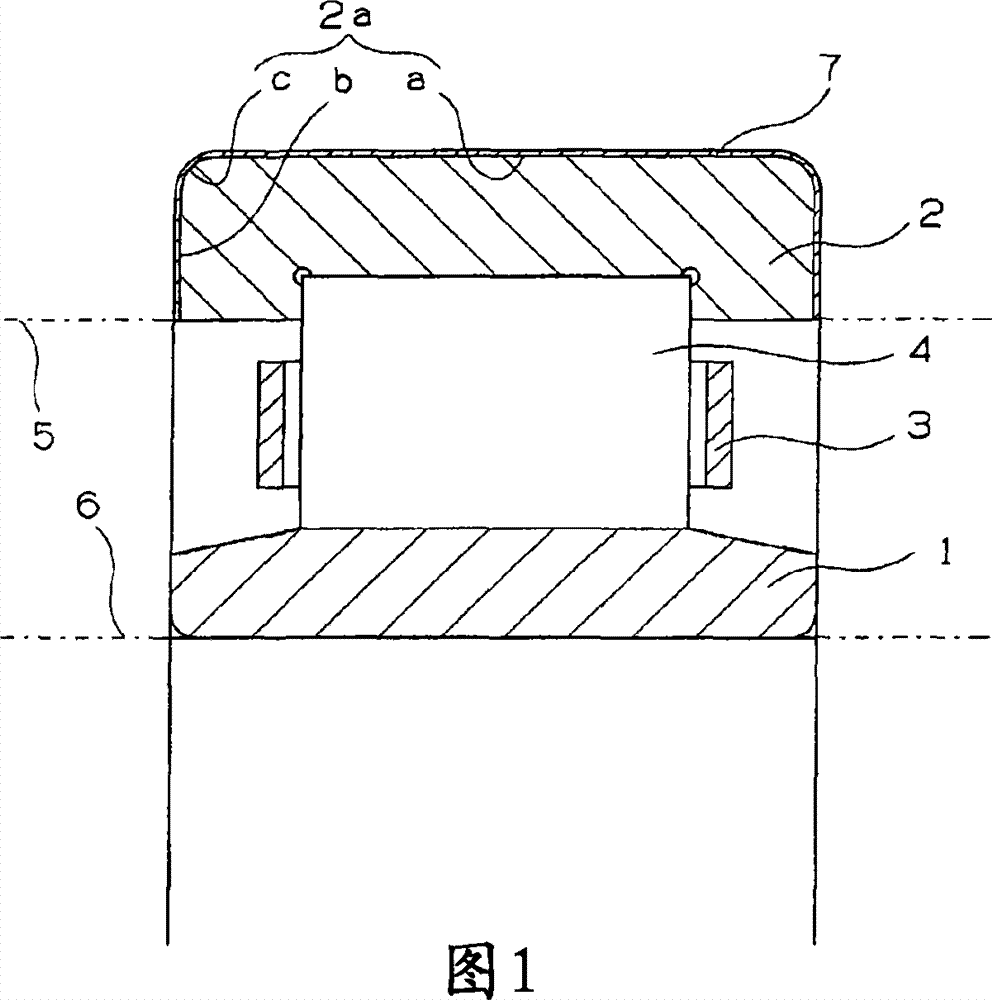

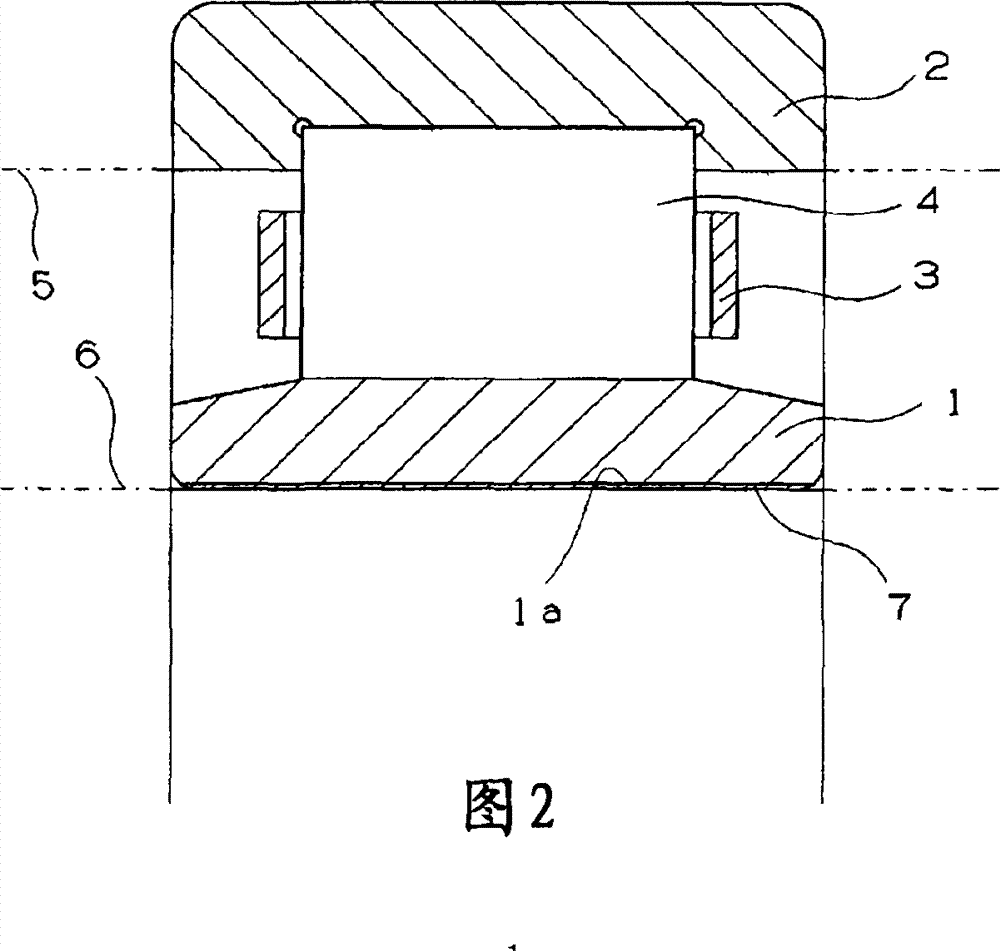

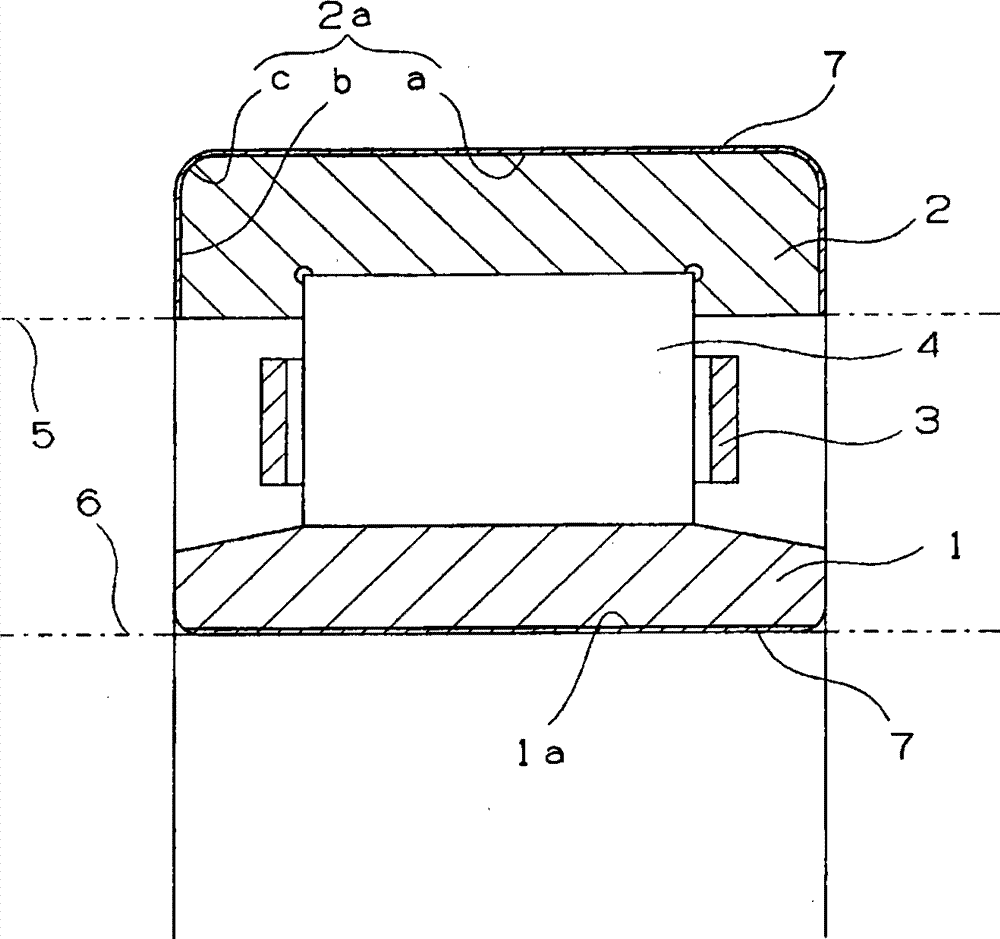

Rolling bearing and method for manufacturing the same

InactiveCN101395394AImprove insulation performanceAccelerated corrosionBearing componentsThermal sprayingRolling-element bearing

This invention provides a rolling bearing comprising a dense ceramic layer formed by a method alternative to a thermal spraying method, and having excellent insulating properties and corrosion resistance and chemical resistance, for example, resistance to chemicals such as acids and alkalis. The rolling bearing comprises an inner ring (1), an outer ring (2), and a plurality of rolling elements (4) interposed between raceway faces of the inner and outer rings. A ceramic film (7) is provided on at least one peripheral face selected from the inner peripheral face of the inner ring (1) and the outer peripheral face of the outer ring (2). The ceramic film is a film formed by an aerosol deposition method utilizing, for example, alumina fine particles as a raw material for aerosol. The film may be formed, for example, by fixing an aerosol ejection nozzle and axially moving the outer ring or inner ring using a positioning XY table while being rotated by an object rotation motor.

Owner:NTN CORP

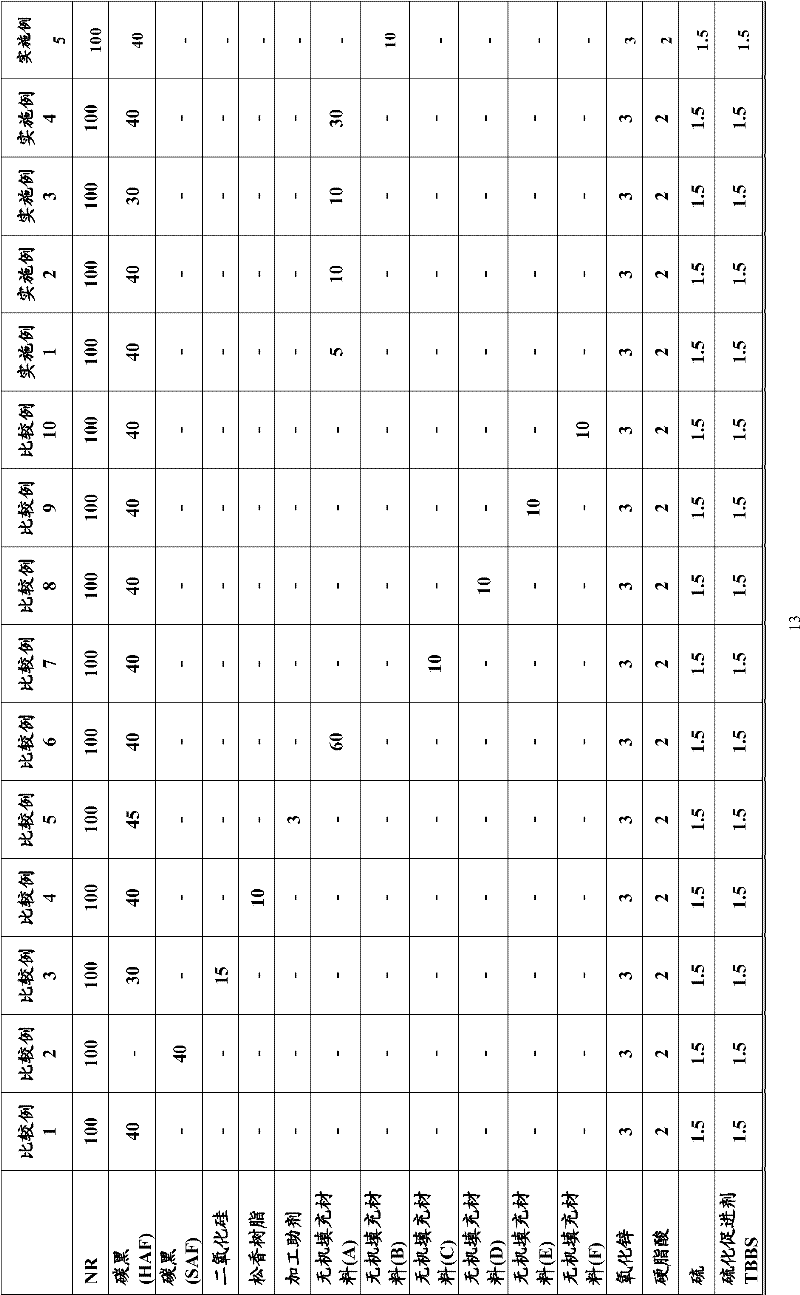

Rubber composition for tire and pneumatic tire

InactiveCN102653603AGood physical propertiesHigh elastic rateSpecial tyresMohs scale of mineral hardnessPolymer science

A rubber composition for tire, comprising at least a rubber component and an inorganic filler, wherein the inorganic filler has an angle of repose of 40 degrees or more, a Mohs' hardness of 2.0 or less, a BET specific surface area (BETS) (m2 / g) of 10 m2 / g or more, and a ratio (DBP) / (BET5) of the amount (ml / 100 g) of dibutyl phthalate (DBP) absorbed to the BET specific surface area (BET5) (m2 / g) of 2.0 or more, and wherein the content of the inorganic filler is from 0.5 to 50 parts by mass based on 100 parts by mass of the rubber component.

Owner:TOYO TIRE & RUBBER CO LTD

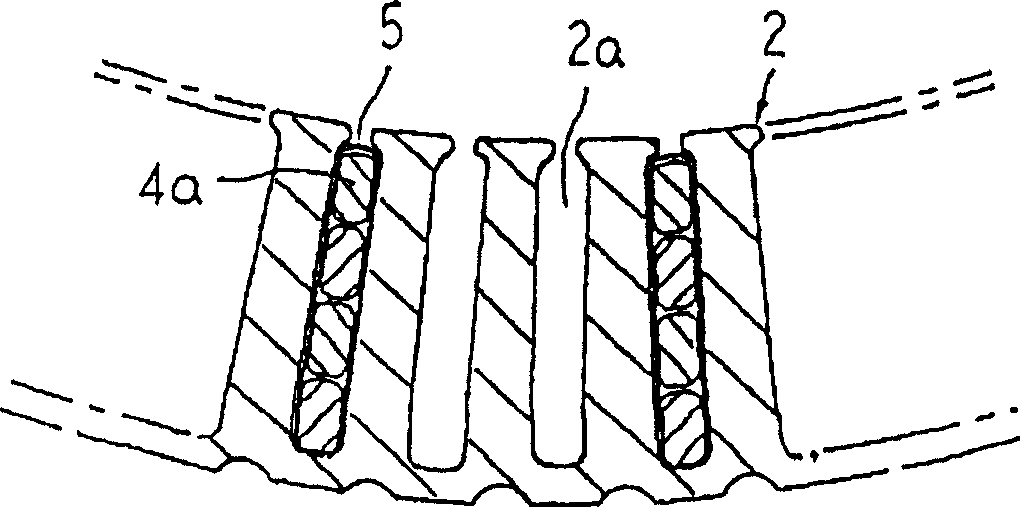

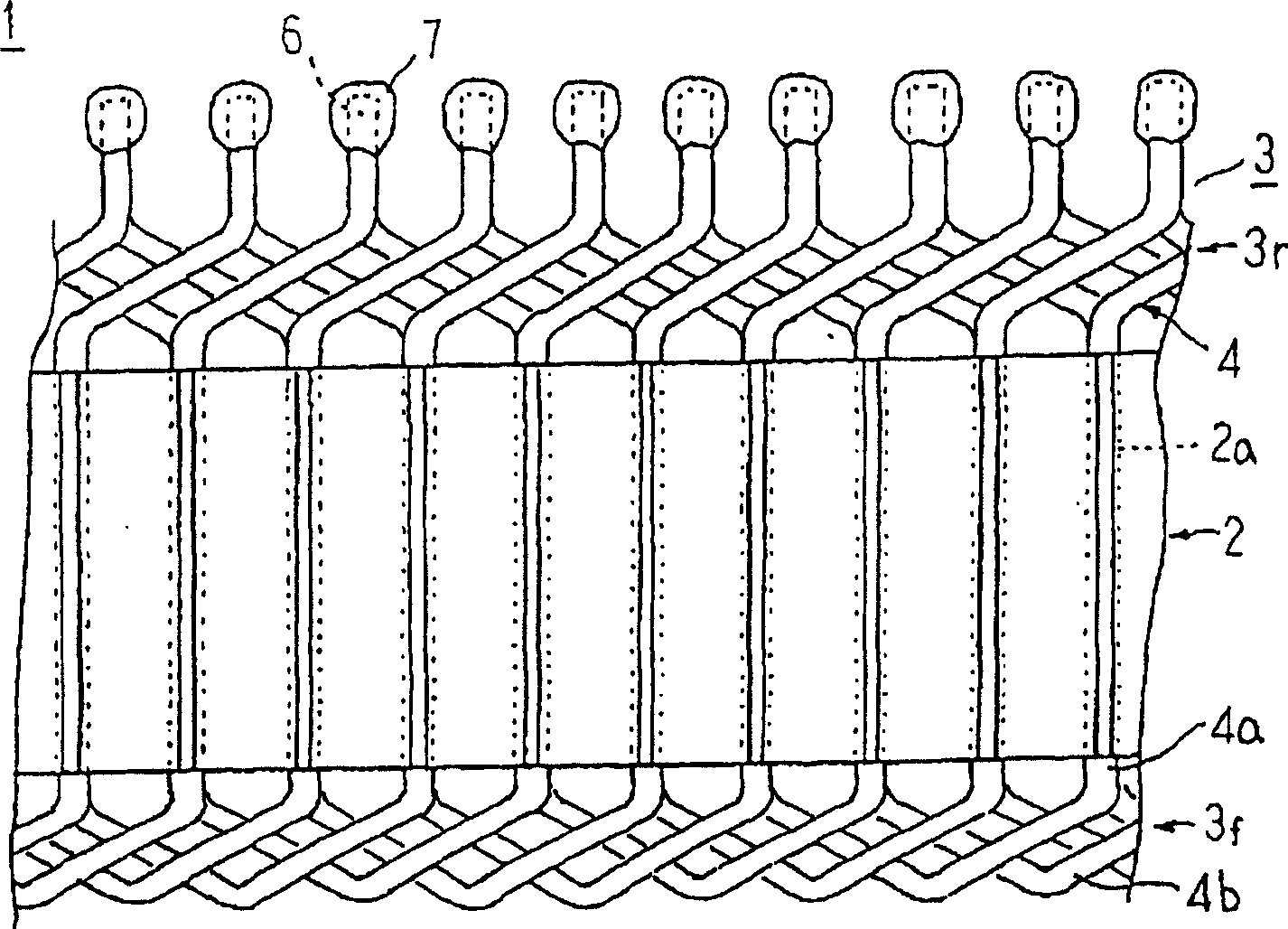

Stator of slewing electric machine

InactiveCN100490276CAvoid exposureImprove rigidityWindings insulation shape/form/constructionWindings conductor shape/form/constructionEpoxyElectrical conductor

To obtain a stator of a rotary electric machine wherein electromagnetic noise can be reduced and further electrical insulating properties can be secured.A stator winding is manufactured by inserting a U-shaped conductor segment into a slot from the first end face side of a stator core, and welding ends of the conductor segments to each other exposed to the second end face side of the stator core. Joints 6 between the ends of the conductor segments are disposed circumferentially and annularly in two rows on the second end face side of the stator core. Epoxy resin is applied so that the resin covers each joint 6 and the resin bridges two adjacent joints in the radial direction and forms a first insulating layer 8. Silicone resin is applied so that the resin covers the first insulating layer 8 and extends to the insulating coating 401 of the conductor segments 4, forming a second insulating layer 9.

Owner:MITSUBISHI ELECTRIC CORP

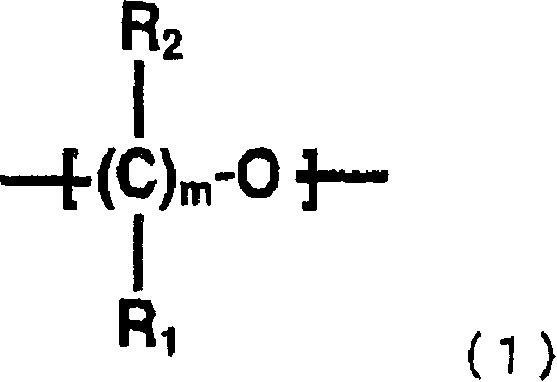

Polyketone fiber paper, polyketone fiber paper core material for printed wiring board and printed wiring board

InactiveCN101107397AHigh strengthHigh elastic rateSynthetic cellulose/non-cellulose material pulp/paperMonocomponent synthetic polymer artificial filamentEpoxyVoid ratio

An aliphatic polyketone fiber paper comprising aliphatic polyketone fibers and a polyketone fiber paper core material for a printed wiring board are provided. The polyketone fiber paper and the core material have high strength and modulus of elasticity; excellent dimensional stability, chemical resistance, heat resistance, adhesiveness and electrical insulation; and low dielectricity and water absorbance, and are thin, porous, and uniform. A printed wiring board prepared from the core material having a low dielectric constant, dimensional stability, electrical insulation, and properties of being uniformly bored by laser punching is also provided. The aliphatic polyketone fiber paper and the core material for a printed wiring board comprises 1 to 100% by mass of aliphatic polyketone fibers which comprise the repeating unit of the below-mentioned formula (1), the fibers having an average fiber length of 0.5 to 10 mm, an average fiber diameter of 0.1 to 20 [mu]m, a thickness of 5 to 200 [mu]m, a void ratio of 30 to 90%, and a strength per unit mass of 100 MN / kg or more. Also provided is a single layer or multilayer printed wiring board which comprises a core material impregnated or coated with a polymer resin, a low dielectric polymer resin, or a polyphenylene ether-based epoxy resin. -CH 2 -CH 2 -CO- (1).

Owner:ASAHI KASEI E-MATERIALS CORPORATION

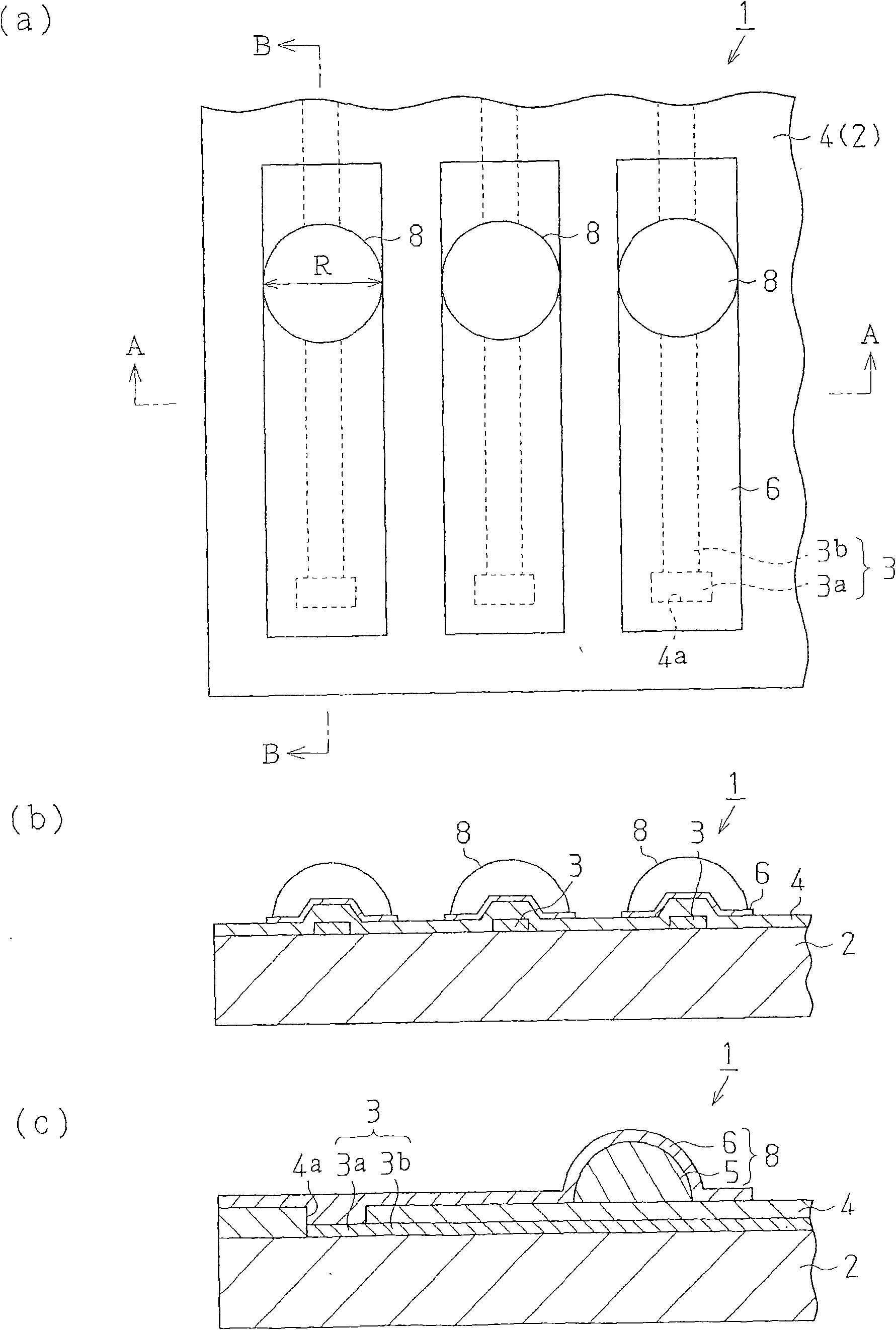

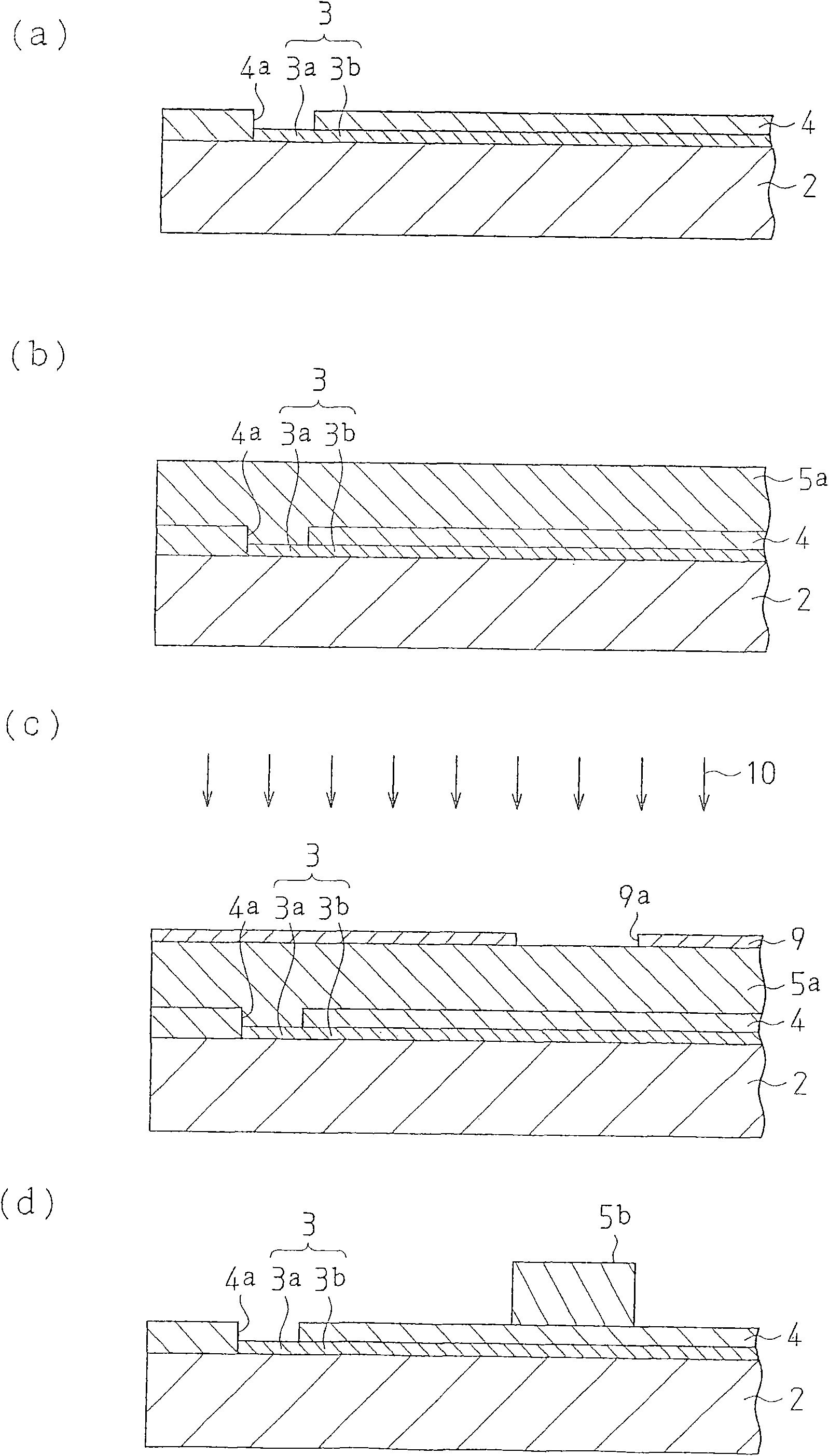

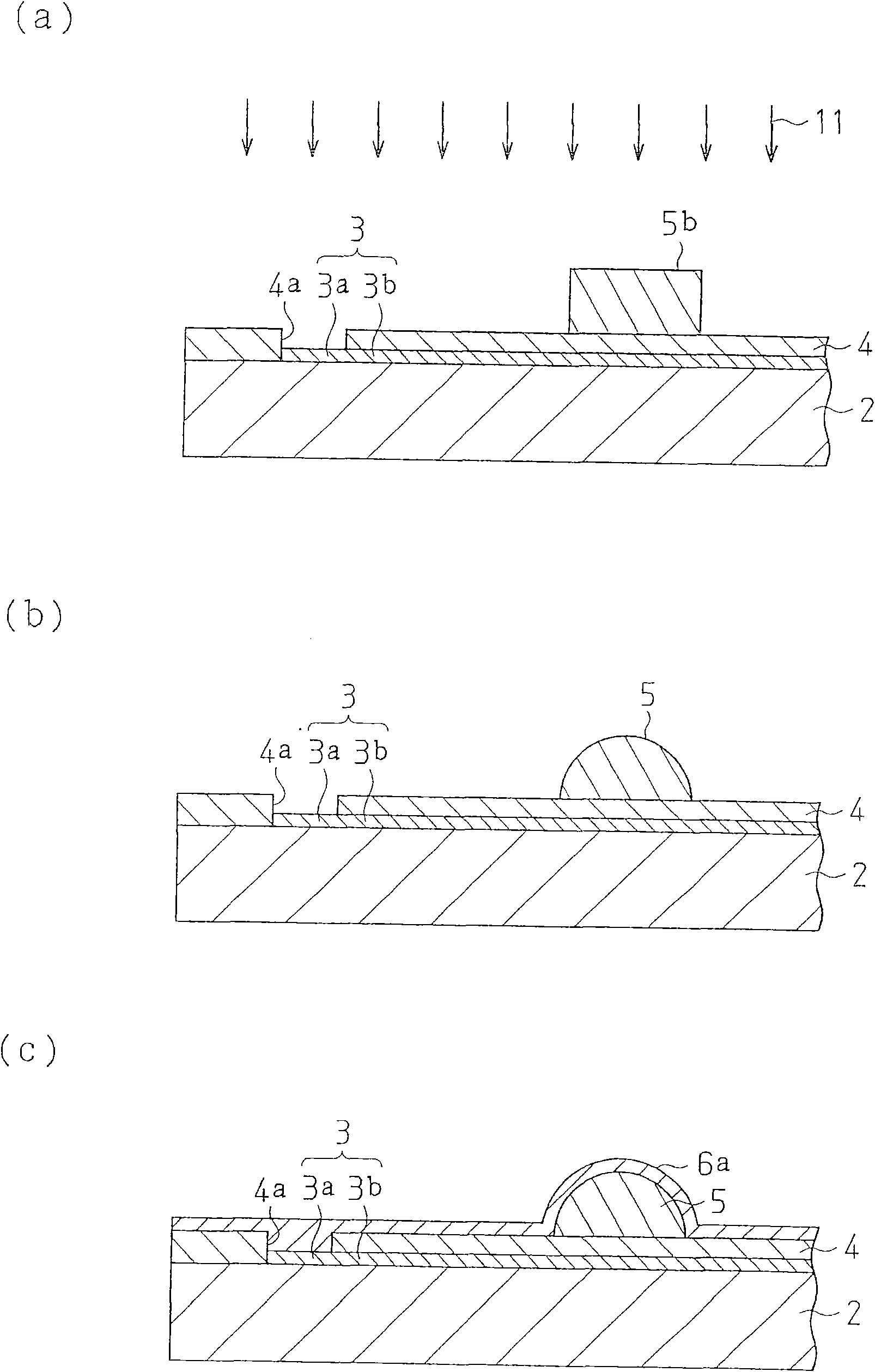

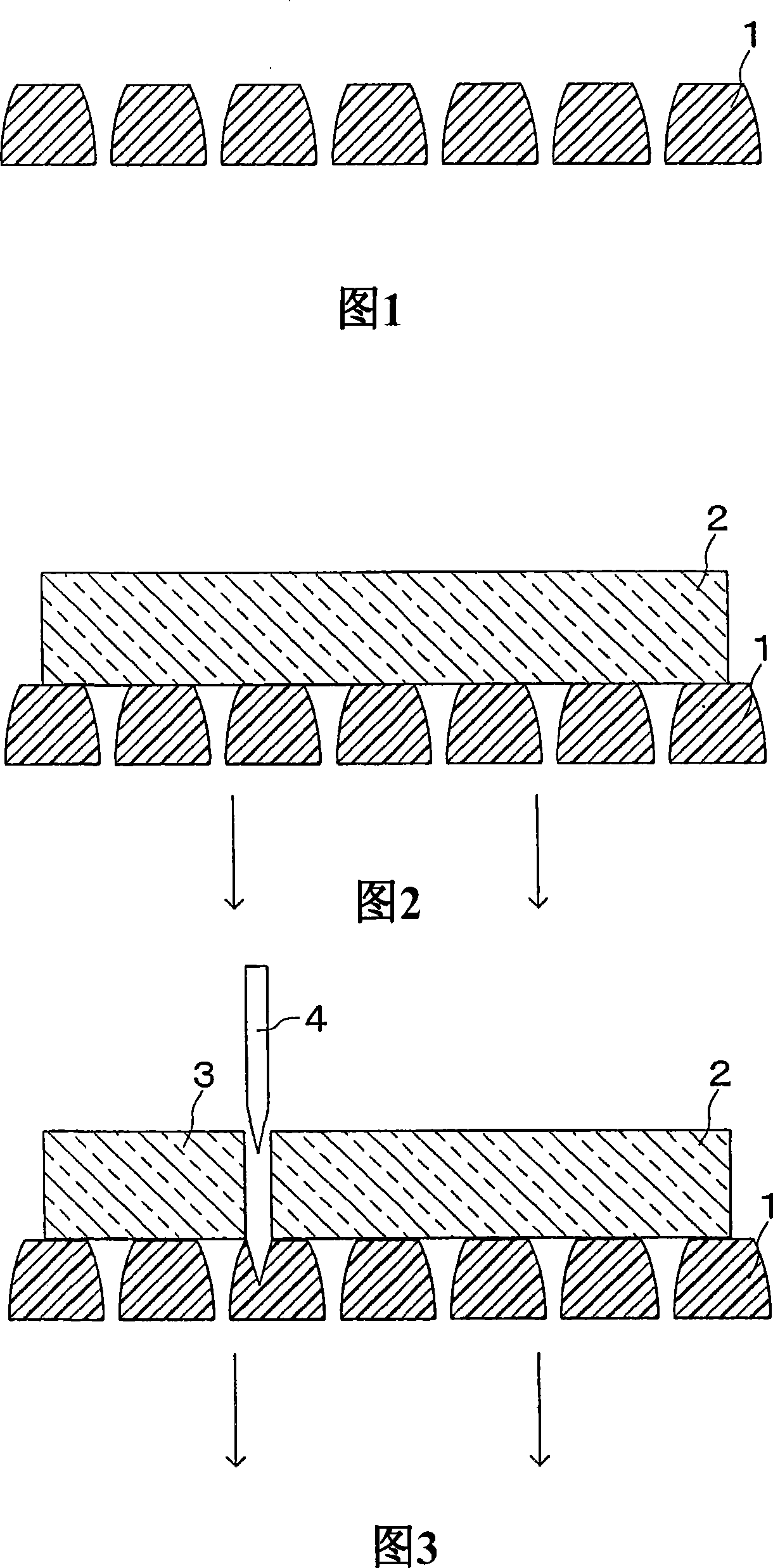

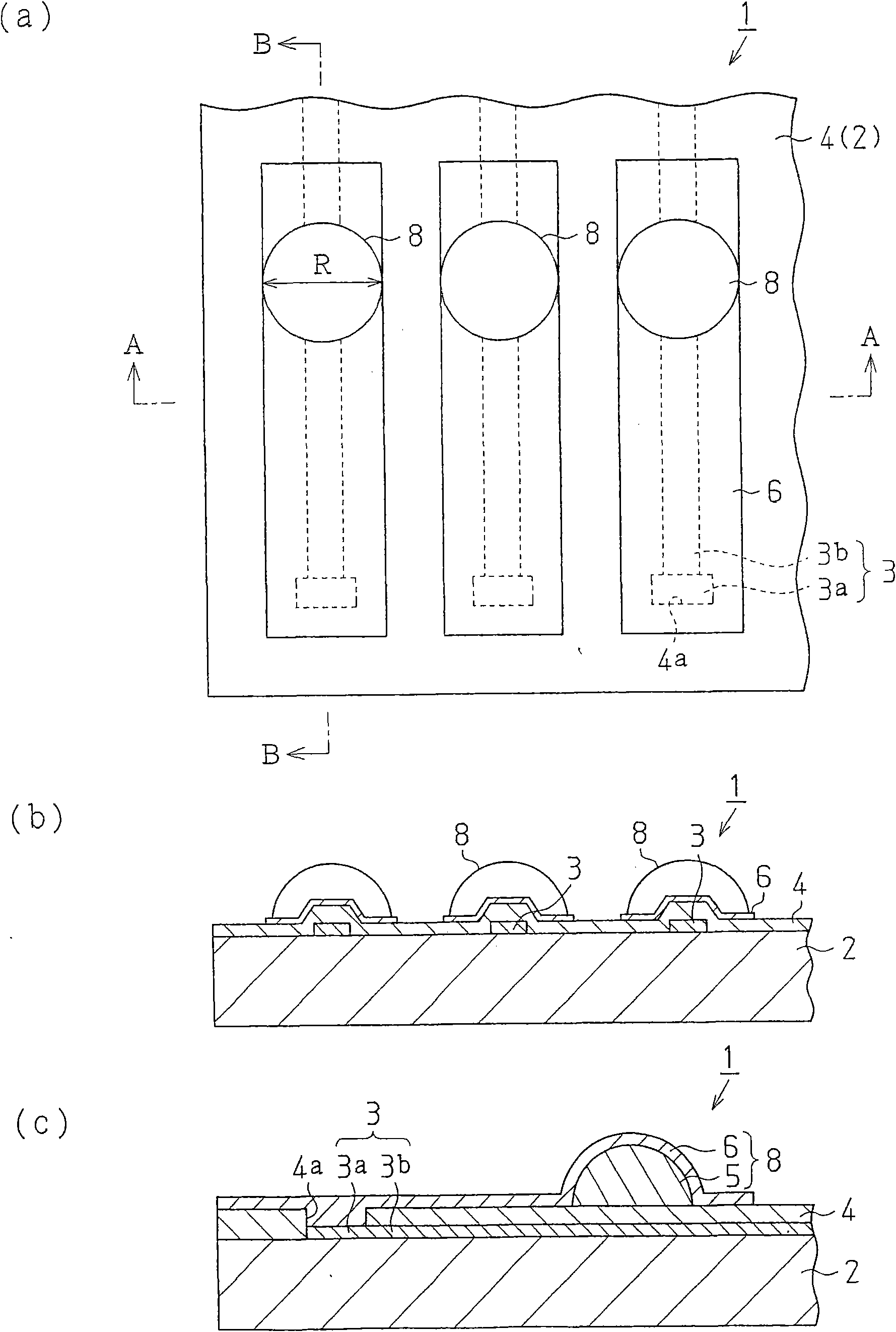

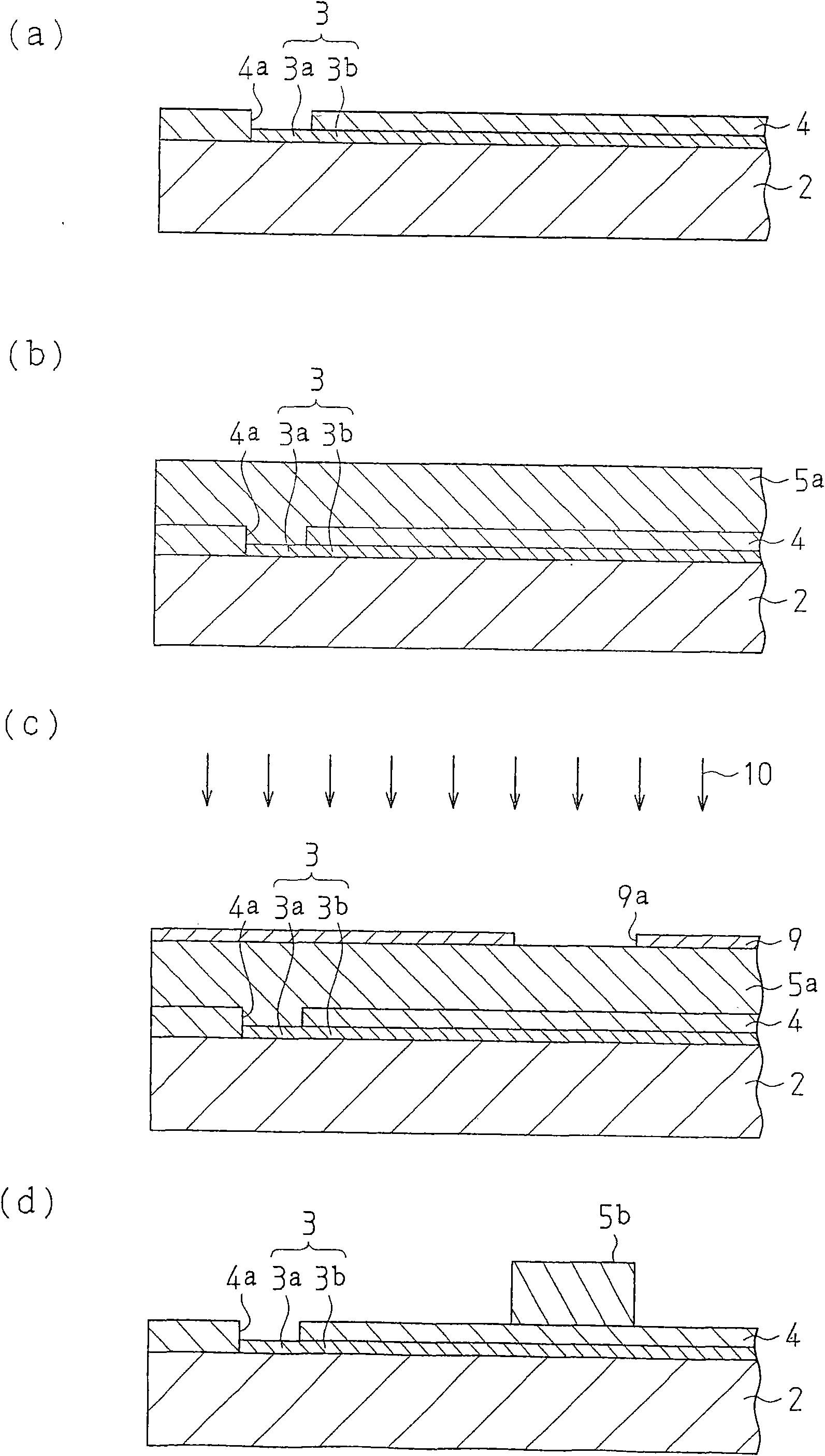

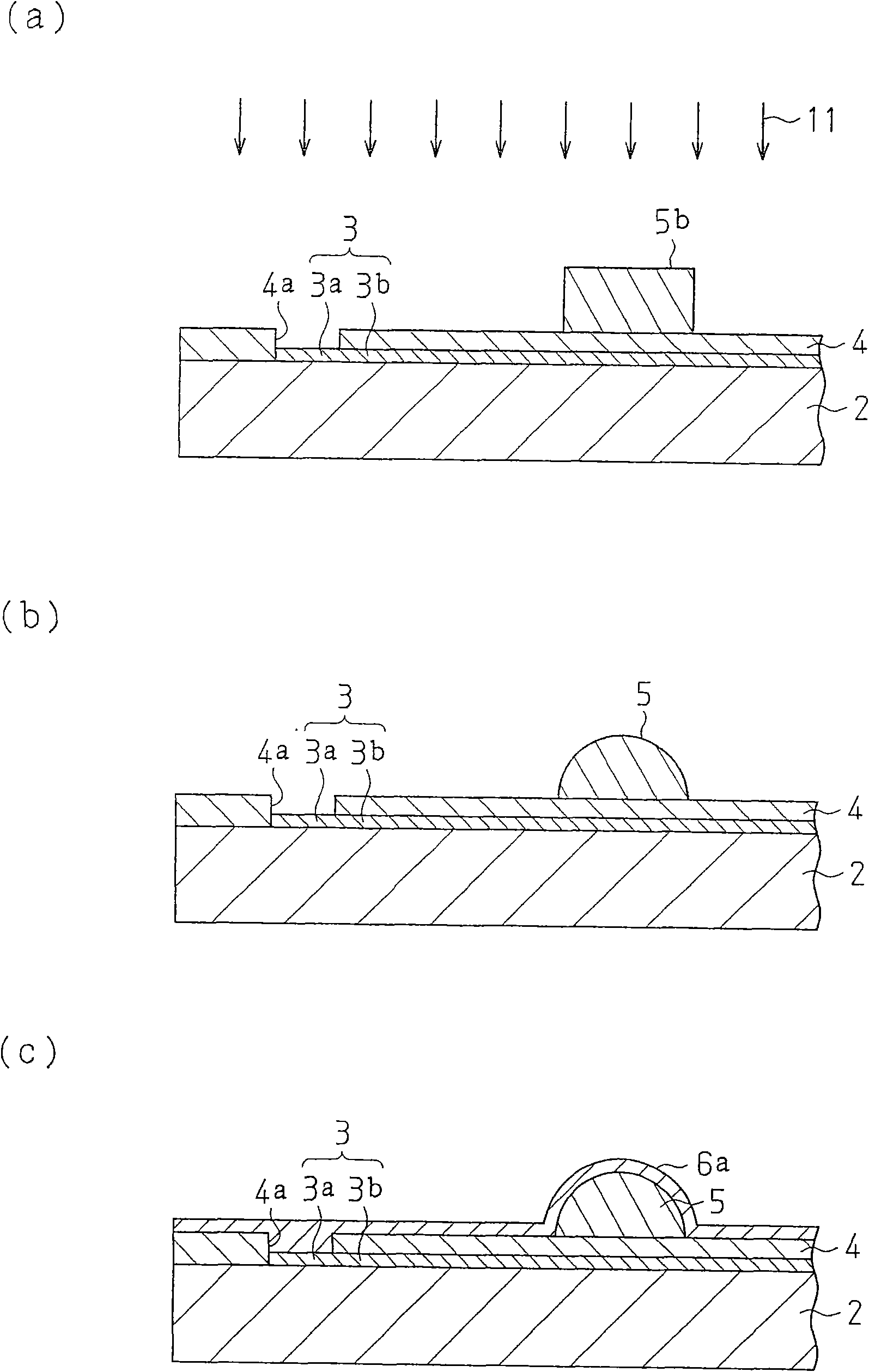

Method for manufacturing a semiconductor device, method and structure for mounting the semiconductor device

InactiveCN101562144AAvoid deformationSuppress disconnectionSemiconductor/solid-state device detailsSolid-state devicesProduction rateUV curing

The present invention provides a method for manufacturing a semiconductor device for improving a productivity of the semiconductor device, a method and a structure for mounting the semiconductor device. A protective layer (4) is coated with an acroid resin which is used as a light-sensitive resin for forming a bulging body (5), to form a resin layer. On the resin layer, a mask having an opening portion is located at a prescribed position, further part of the resin layer exposing from the opening portion is exposed by irradiating ultraviolet on the mask. By means of solidifying the resin through the ultraviolet, a cylinder-shaped bulging body (5b) having a plane top is formed. Then, the ultraviolet (11) is irradiated on the bulging body (5b) to heat the bulging body (5b), such that the acroid resin for forming the bulging body (5b) is melted. Due to a surface tension generated on the melted resin, the top of the planar bulging body (5b) is deformed into a smooth curved face. thereby a near-hemisphere-shaped bulging body (5) is formed from the bulging body (5b).

Owner:SEIKO EPSON CORP

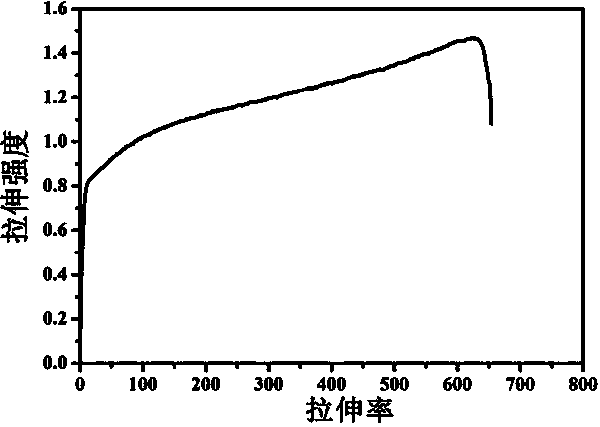

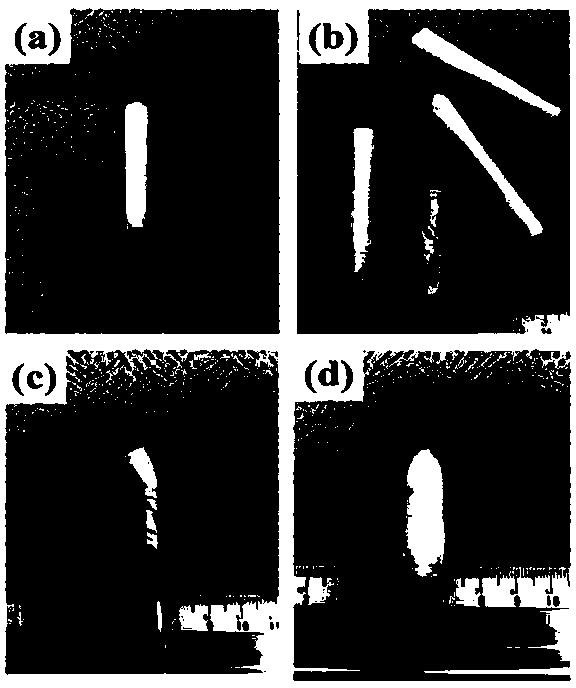

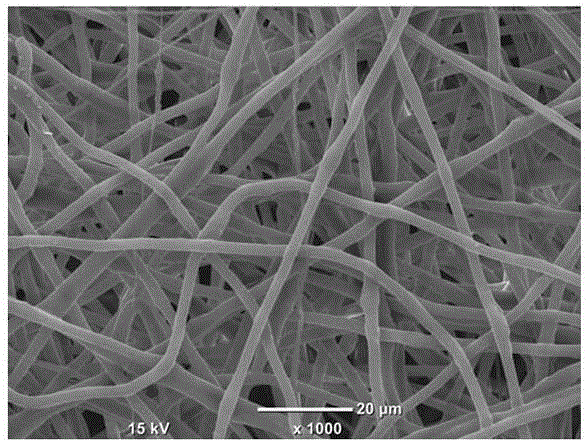

Three-dimensional porous fibrous skeleton as well as preparation method and application of three-dimensional porous fibrous skeleton

The invention discloses a three-dimensional porous fibrous skeleton as well as a preparation method and application of the three-dimensional porous fibrous skeleton. The three-dimensional porous fibrous skeleton is prepared by virtue of the following steps: dissolving poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in the mixed solution of chloroform and acetone to obtain a spinning solution in which the concentration of the polymer is 6wt%-12wt%; collecting on a tin foil by virtue of an electrostatic spinning process to obtain a fibrous membrane, winding the fibrous membrane by use of a glass rod, and unwinding the fibrous membrane from the glass rod after drying and flushing with ethanol, thereby obtaining the three-dimensional expansible porous fibrous skeleton. The three-dimensional porous fibrous skeleton has excellent biodegradability, biocompatibility and elastic property; when the three-dimensional porous fibrous skeleton is applied to the operative treatment of vertebral compression fracture caused by osteoporosis as a sacculus, the problems of bone cement leakage and easy collapse of calcium phosphate bone cement under 100% humidity can be effectively solved; as a result, the three-dimensional porous fibrous skeleton plays an important role in reducing the risk of the percutaneous kyphoplasty and popularizing and utilizing the calcium phosphate bone cement.

Owner:SUZHOU UNIV

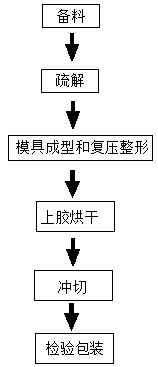

High-fidelity loudspeaker cone and production process thereof

PendingCN110080034AHigh elastic rateGuaranteed StrengthElectrical transducersWater-repelling agents additionMaterials preparationGlass fiber

The invention discloses a high-fidelity loudspeaker cone and a production process thereof. The cone comprises components in parts by weight as follows: 30-45 parts of sisal pulp, 10-25 parts of flax pulp, 5-15 parts of fluff pulp and 0.5-2 parts of carbon fiber powder. The cone production process comprises following steps: S1), material preparation: the sisal pulp, flax pulp and fluff pulp are taken out in the weight ratio, lumps and impurities are removed, dust cleaning treatment is performed, and soaking is respectively performed for 30-50 min. According to the high-fidelity loudspeaker coneand the production process cone thereof, mixed pulp of the sisal pulp, flax pulp and fluff pulp is used as a main material of the cone to provide rigidity and toughness of the cone, so that the elasticity of the cone is improved; the carbon fiber, bulletproof fiber and glass fiber are used as compound ingredients to ensure the strength of the cone, so that the stability of the paper cone is improved; the edge of the cone is soaked with glue, solder alloy is used for attaching to avoid flaking, the elasticity and fatigue resistance of cone are improved, and the tone of a loudspeaker is better.

Owner:广州市建桥音响配件有限公司

Method of manufacturing a polarizing plate, and a cutting mat used in the method

InactiveCN101101348AImprove wear resistanceNot easy to producePolarising elementsMetal working apparatusThin slabUltraviolet

A method of manufacturing a polarizing plate in which an original polarizing plate is cut accurately, cracks are not extended easily in a section and foreign substances are not attached easily on a polarizing plate to be obtained, and a cutting mat to be used in the method are provided. An original polarizing plate having a plurality of layers is fixed on a first principal surface of an ultrahigh molecular weight polyethylene porous sheet by drawing from the opposite side. The original polarizing plate is cut by a blade moving across the thickness of the original polarizing plate by using the porous sheet as a cutting mat to obtain a polarizing plate having a plurality of layers. A curable liquid, such as ultraviolet curable ink, is impregnated in vacant pores of the porous sheet, and is cured to obtain a sheet. The sheet thus obtained is particularly suitable for a cutting mat.

Owner:NITTO DENKO CORP

Method for manufacturing a semiconductor device, method and structure for mounting the semiconductor device

InactiveCN101562143AAvoid deformationSuppress disconnectionSemiconductor/solid-state device detailsSolid-state devicesProduction rateUV curing

The present invention provides a method for manufacturing a semiconductor device for improving a productivity of the semiconductor device, a method and a structure for mounting the semiconductor device. A protective layer (4) is coated with an acroid resin which is used as a light-sensitive resin for forming a bulging body (5), to form a resin layer. On the resin layer, a mask having an opening portion is located at a prescribed position, further part of the resin layer exposing from the opening portion is exposed by irradiating ultraviolet on the mask. By means of solidifying the resin through the ultraviolet, a cylinder-shaped bulging body (5b) having a plane top is formed. Then, the ultraviolet (11) is irradiated on the bulging body (5b) to heat the bulging body (5b), such that the acroid resin for forming the bulging body (5b) is melted. Due to a surface tension generated on the melted resin, the top of the planar bulging body (5b) is deformed into a smooth curved face. thereby a near-hemisphere-shaped bulging body (5) is formed from the bulging body (5b).

Owner:SEIKO EPSON CORP

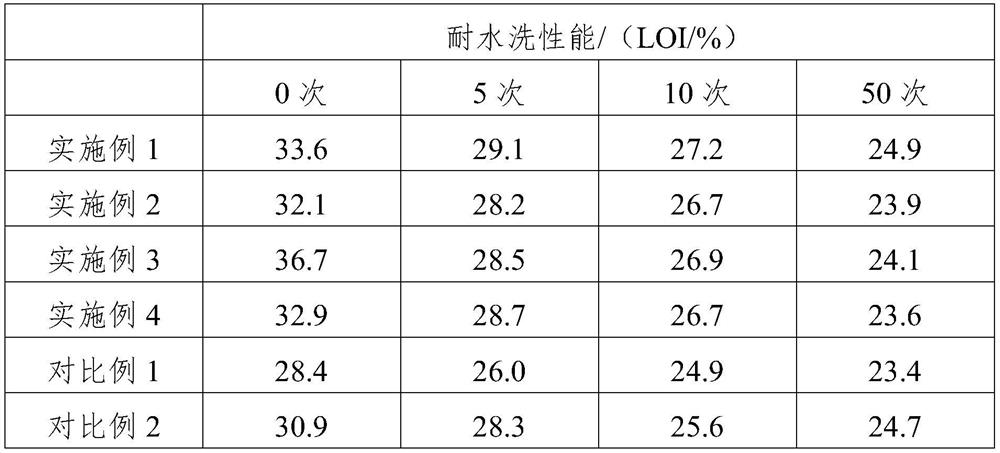

Flame-retardant modified polyacrylonitrile fiber

InactiveCN113430826AAvoid excessive oxidationImprove thermal conductivityHeat resistant fibresMonocomponent synthetic polymer artificial filamentPolymer scienceAcrylonitrile

The invention discloses a preparation method of flame-retardant modified polyacrylonitrile fiber. The method comprises the following steps of firstly, carrying out surface treatment on borate whiskers by using a silane coupling agent to obtain silanized borate whiskers; then blending the silanized borate whiskers and polyacrylonitrile to prepare polyacrylonitrile fiber; then grafting the polyacrylonitrile fiber with methyl methacrylate by using an ultraviolet grafting technology to obtain modified polyacrylonitrile fiber; and finally reacting the modified polyacrylonitrile fiber with phosphoric acid and urea to obtain the flame-retardant modified polyacrylonitrile fiber. According to the invention, the borate whiskers are introduced into the polyacrylonitrile, so that the mechanical strength and thermal conductivity of the fiber are effectively improved; and the methyl methacrylate is grafted on the surface of the polyacrylonitrile fiber through chemical grafting and interacts with the phosphoric acid and the urea, and flame-retardant phosphorus and nitrogen elements are introduced into the surface of fiber molecule, so that the flame retardance of the modified polyacrylonitrile fiber is effectively improved.

Owner:武汉度美迪新能源科技有限公司

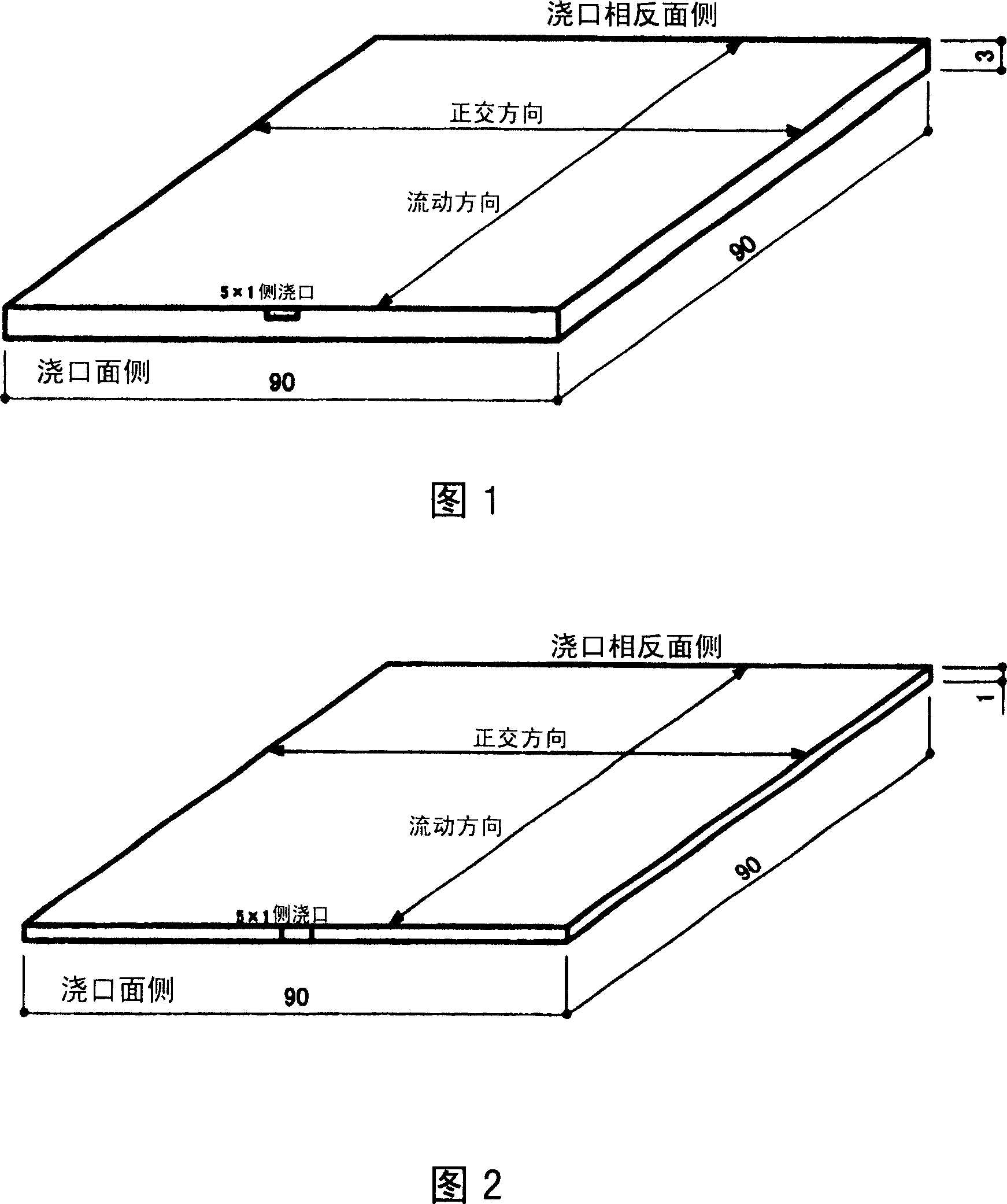

Resin material for molding and molded product

InactiveCN101085872ALow molding shrinkageHigh dimensional accuracyCoatingsMass ratioThermal deformation

To provide a resin material for molding excellently reducing molding shrinkage and affording a molded product having excellent thin-wall moldability, high dimensional accuracy according to design and excellent stability for thermal deformation and to provide the molded product using the material. The resin material for molding comprises a thermoplastic resin, one kind of fly ash and silica fume. The average particle diameter of the silica fume is <=1 / 10 of the average particle diameter of the one kind of fly ash and the compounding ratio of the one kind of fly ash / silica fume is (20 / 80) to (80 / 20) expressed in terms of mass ratio. The thermoplastic resin is contained in an amount of 10-40 vol.% in the resin material for molding.

Owner:SUMITOMO OSAKA CEMENT CO LTD

Magnesium alloy for bicycle

The invention provides a magnesium alloy for bicycles, the components and mass fractions of which are as follows: the Mg content is 90-92%, the Al content is 3-5%, the Mn content is 3-3.5%, and the rest is Ca. The beneficial effect of the invention is that adding aluminum element to the material components of the magnesium alloy improves the elastic modulus of the alloy material without affecting the stiffness of the magnesium alloy.

Owner:天津市四海亨通自行车股份有限公司

A three-dimensional porous fiber scaffold, preparation method and application

The invention discloses a three-dimensional porous fibrous skeleton as well as a preparation method and application of the three-dimensional porous fibrous skeleton. The three-dimensional porous fibrous skeleton is prepared by virtue of the following steps: dissolving poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in the mixed solution of chloroform and acetone to obtain a spinning solution in which the concentration of the polymer is 6wt%-12wt%; collecting on a tin foil by virtue of an electrostatic spinning process to obtain a fibrous membrane, winding the fibrous membrane by use of a glass rod, and unwinding the fibrous membrane from the glass rod after drying and flushing with ethanol, thereby obtaining the three-dimensional expansible porous fibrous skeleton. The three-dimensional porous fibrous skeleton has excellent biodegradability, biocompatibility and elastic property; when the three-dimensional porous fibrous skeleton is applied to the operative treatment of vertebral compression fracture caused by osteoporosis as a sacculus, the problems of bone cement leakage and easy collapse of calcium phosphate bone cement under 100% humidity can be effectively solved; as a result, the three-dimensional porous fibrous skeleton plays an important role in reducing the risk of the percutaneous kyphoplasty and popularizing and utilizing the calcium phosphate bone cement.

Owner:SUZHOU UNIV

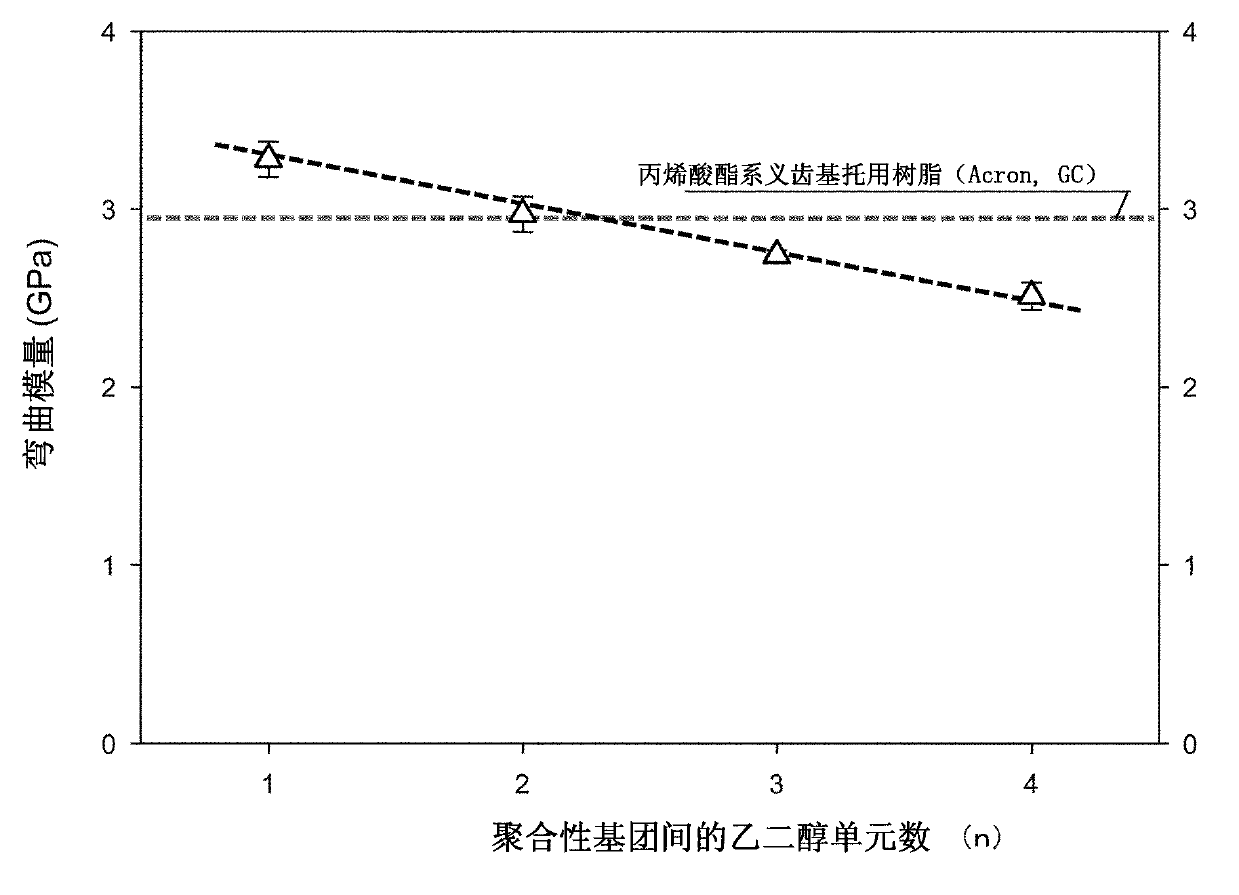

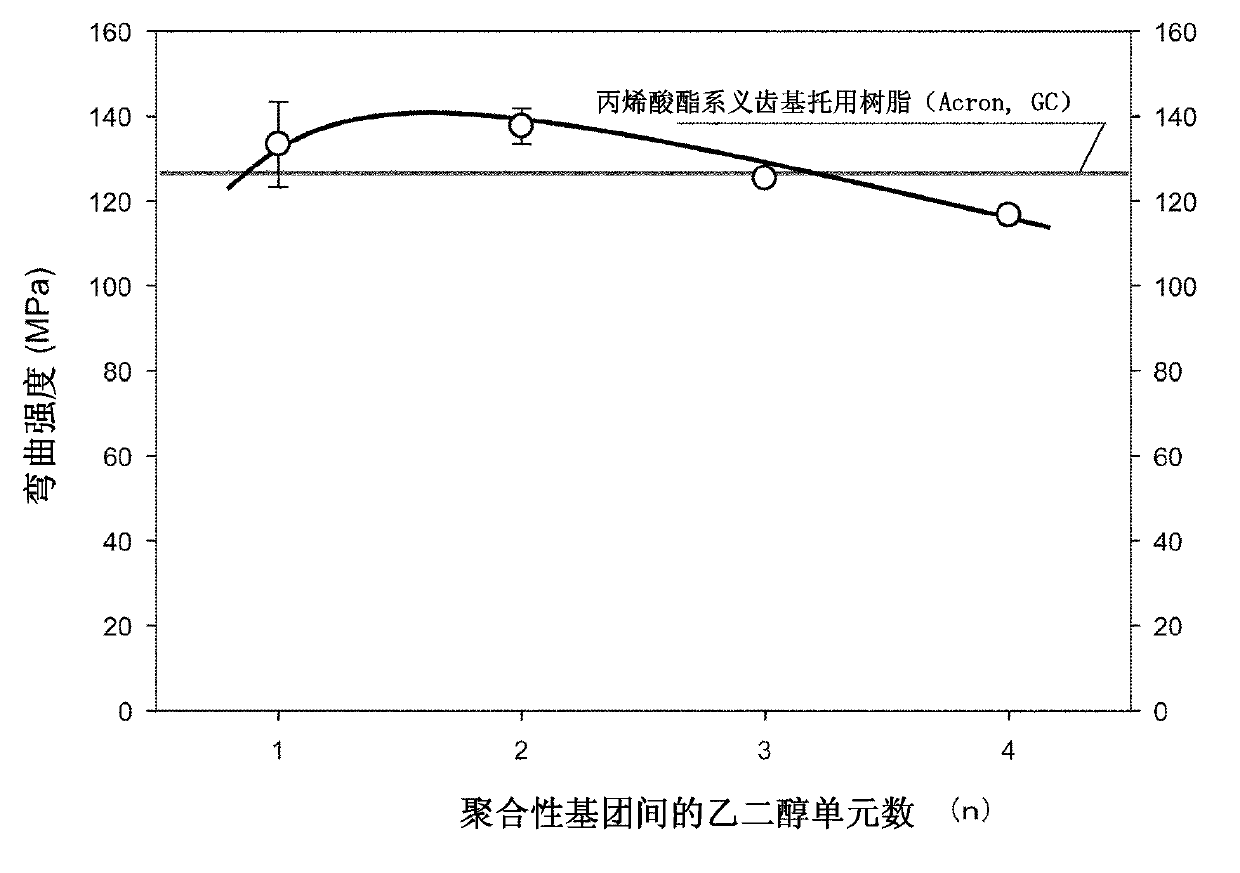

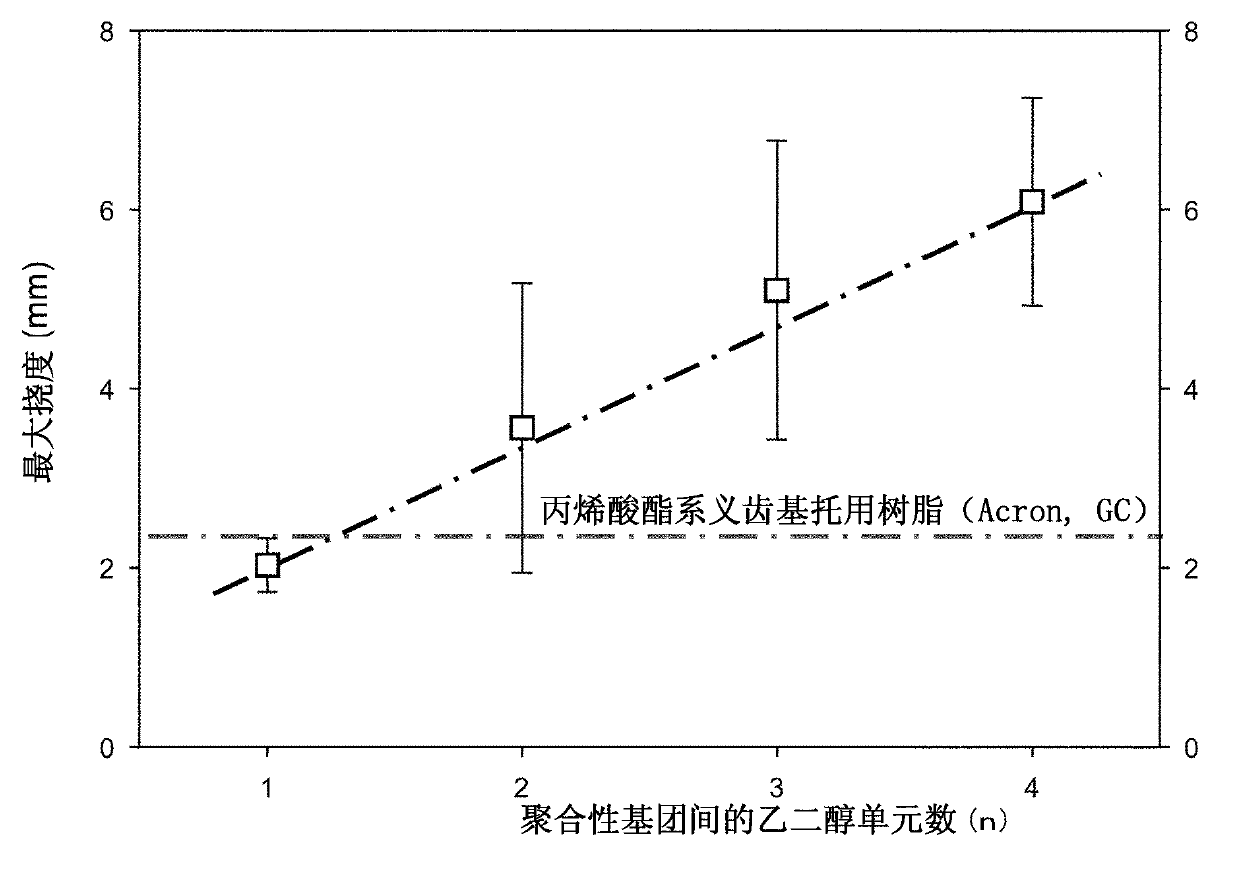

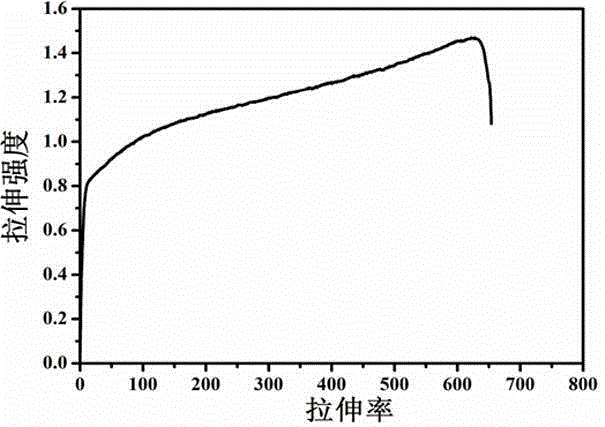

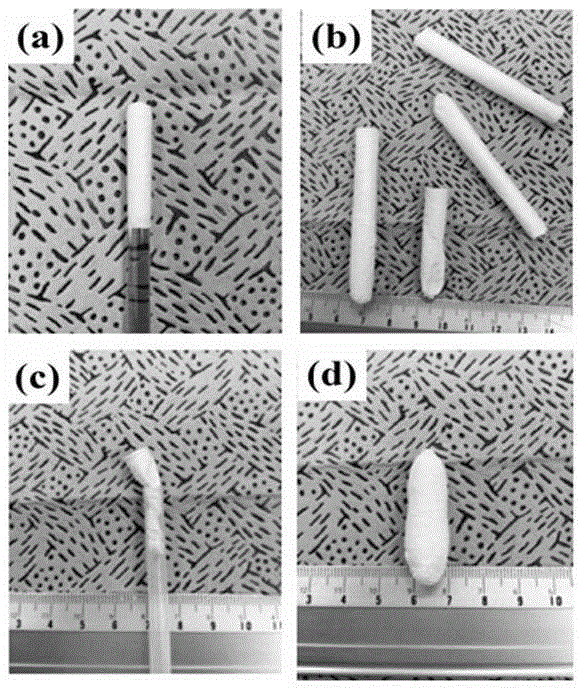

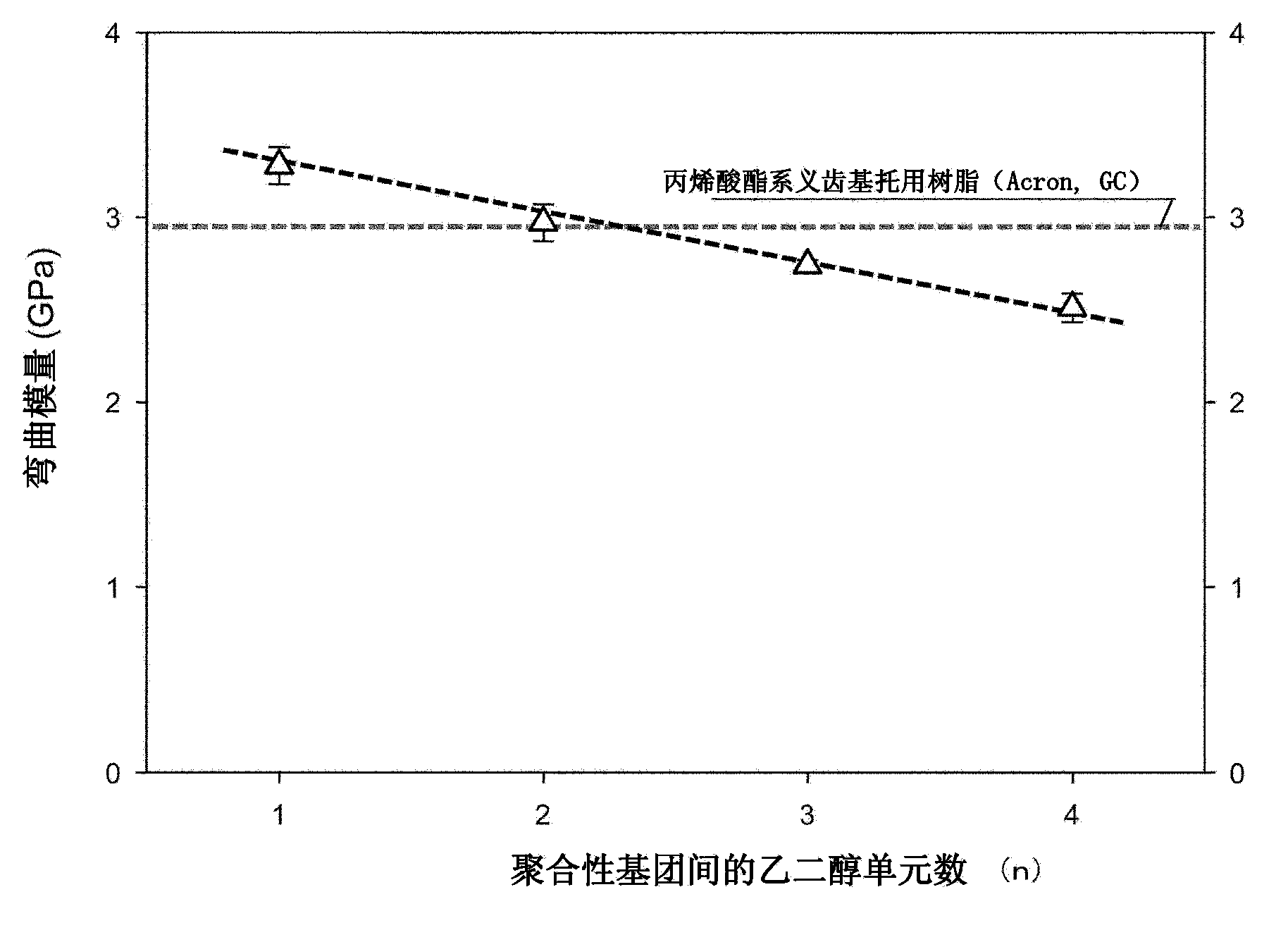

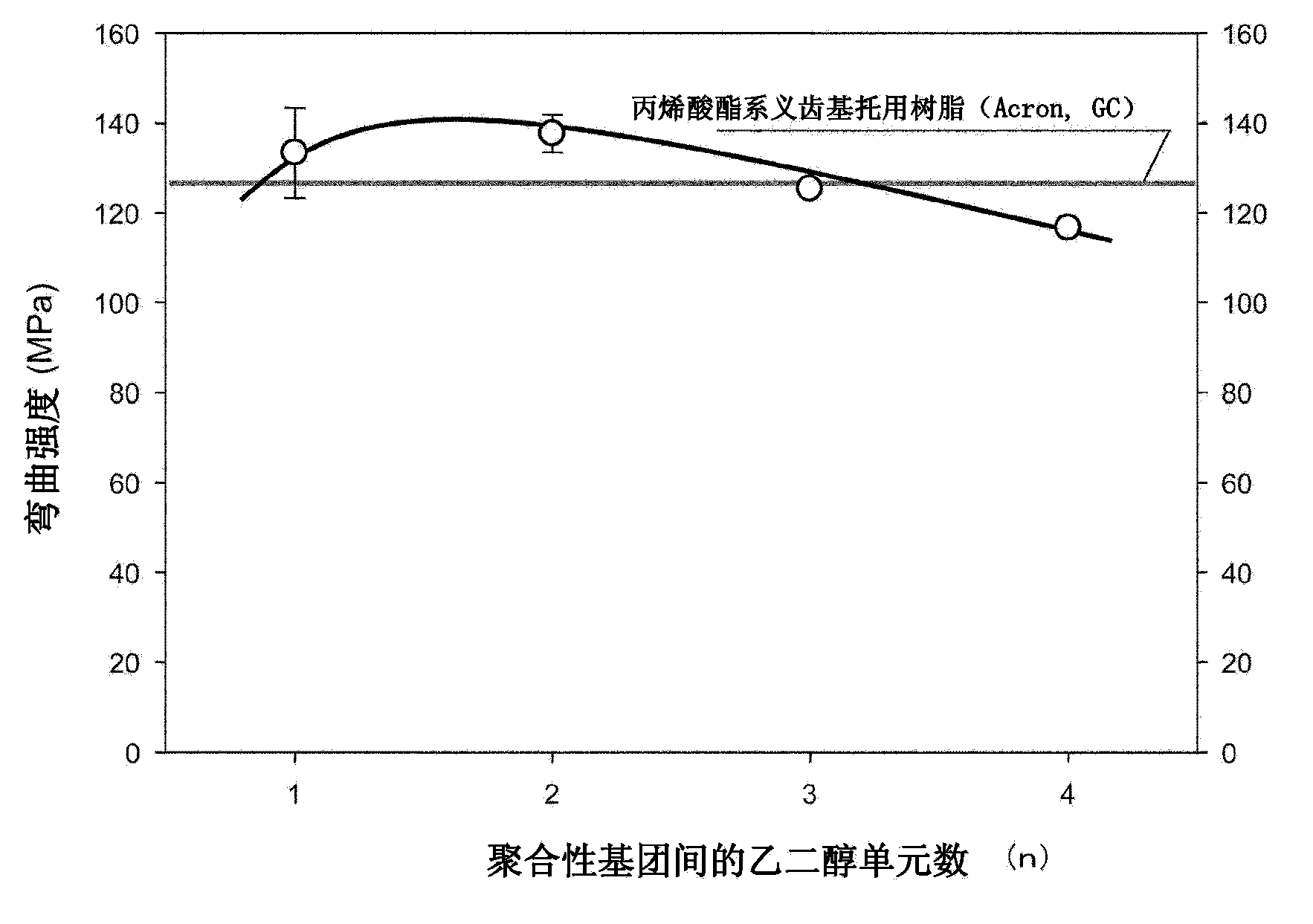

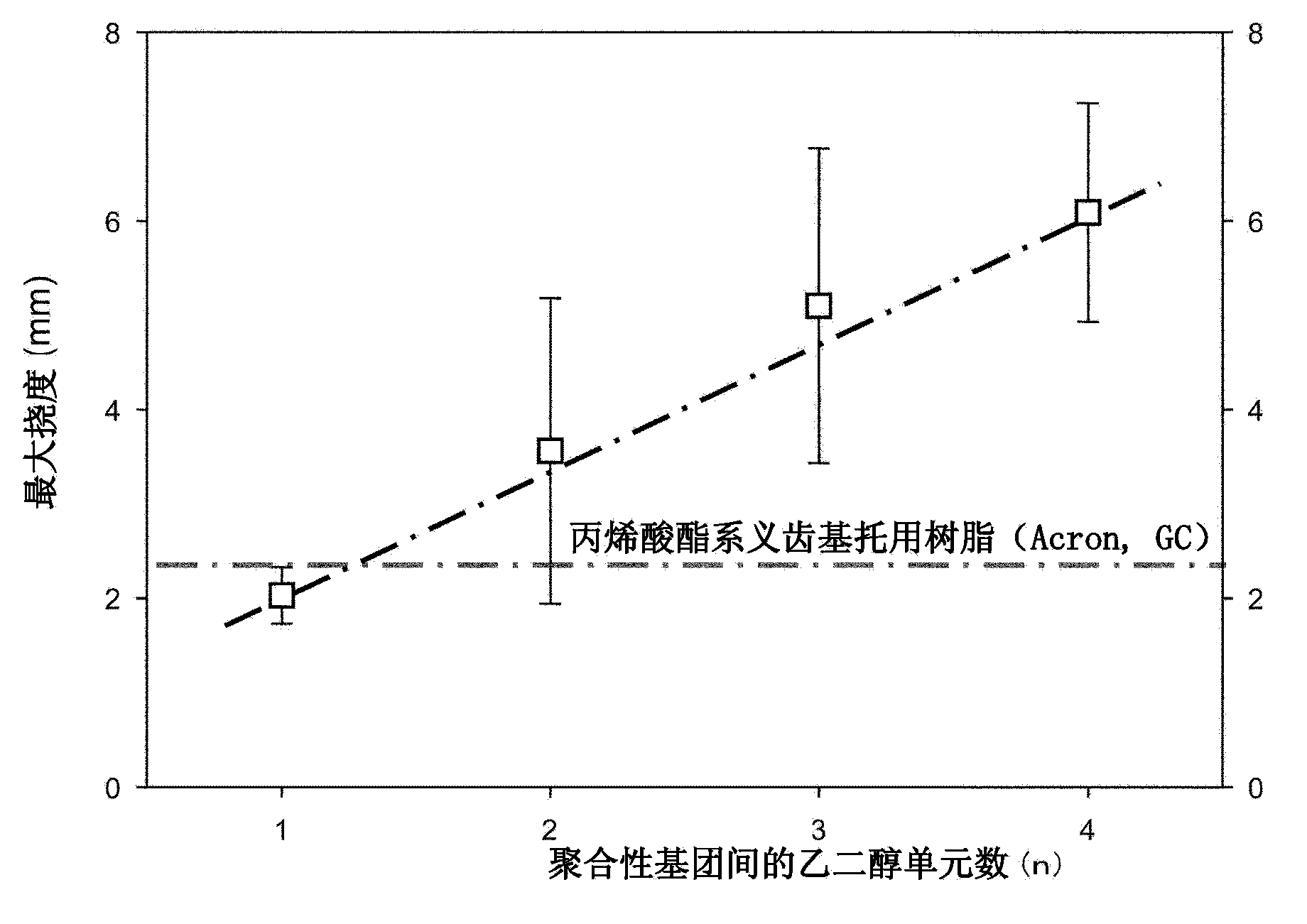

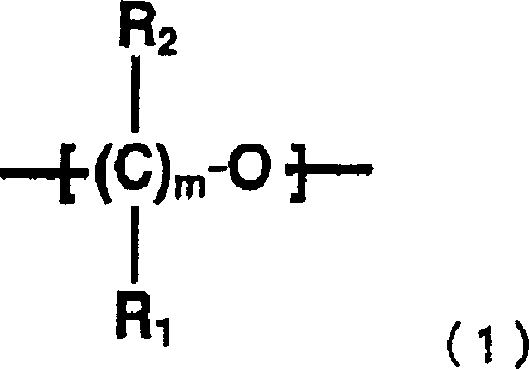

Resin composition for medical use, manufacturing method thereof, and medical kit

InactiveCN102811694BEasy to manufactureHigh strengthImpression capsSurgical adhesivesHydrogen atomDenture base

A medical resin composition, particularly a dental resin composition is produced by mixing a polymer (A) containing 70% by weight or more of methyl methacrylate units and a liquid of a monomer (B) containing 70% by weight or more of a compound (b1) represented by formula (1): wherein R denotes a methyl group or a hydrogen atom and n is an integer of 2 to 4, in the presence of a polymerization initiator (C) to increase a viscosity. The resin composition can be suitably used in producing a denture base, a mouthpiece or a bone cement. A shaped article formed using such a resin composition exhibits excellent mechanical properties, particularly toughness. Furthermore, such a resin composition can be prepared with ease.

Owner:田仲 持郎

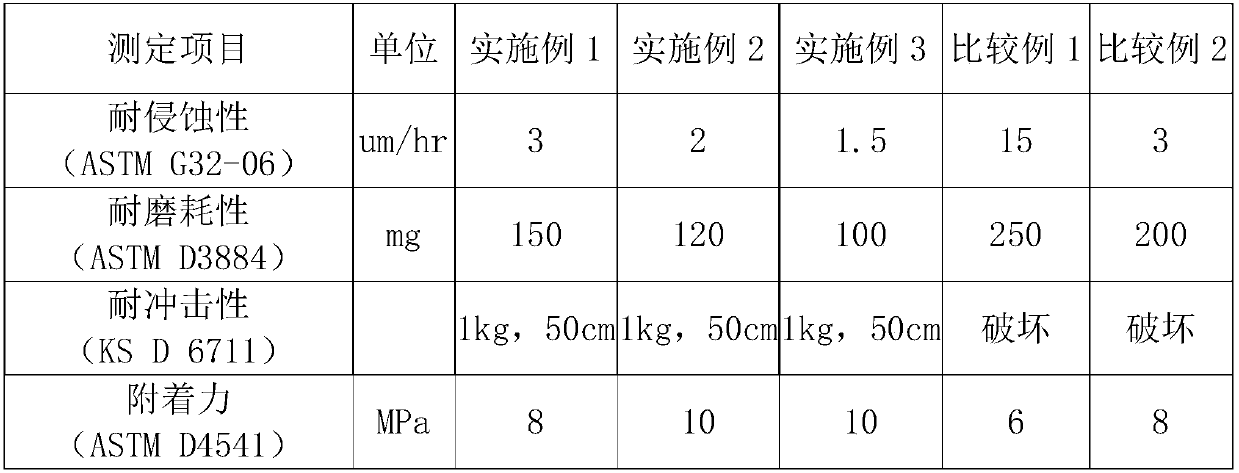

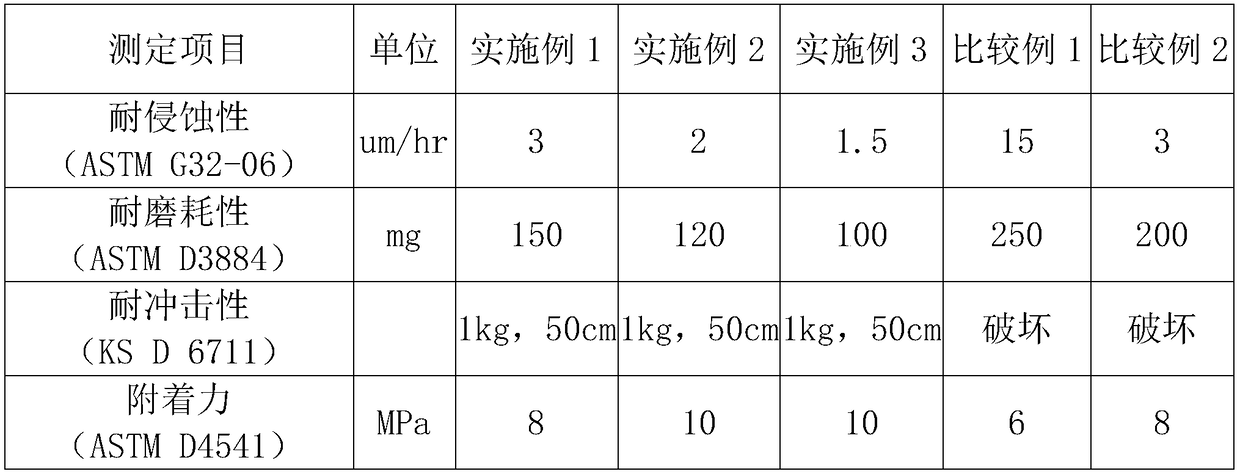

Corrosion-resistant cavitation-suppressing coating

InactiveCN110396359AExtend your lifeImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesCavitationPolypropylene

Corrosion-resistant cavitation-suppressing coating is disclosed. The coating includes an ultra-fast curing agent solution and a modified silicon nano-powder solution which are mixed in a volume ratioof 1:1-2. The ultra-fast curing agent solution is polyisocyanate. The modified silicon nano-powder solution includes, by weight, 30-33% of polypropylene oxide diamine, 8-10% of polyether triamine having a molecular weight of 5000, 10-15% of polyphenyl triamine, 8-17% of modified amino silicone, 2-11% of modified fluororesin, 1-2% of an adhesion promoter, 1-2% of pigment and 10-35% of nanometer powder. The coating has excellent mechanical properties, abrasion resistance, impact resistance, scratch resistance and stain resistance, and can suppress cavitation to reduce erosion, thereby prolongingthe service lifetime of a portion damaged by erosion.

Owner:上海沐皿新材料科技有限公司

Coating for erosion resistance and cavitation suppression

InactiveCN108997907AExtend your lifeImprove mechanical propertiesAntifouling/underwater paintsPaints with biocidesCavitationPollution

The invention discloses a coating for erosion resistance and cavitation suppression. The coating comprises an ultra-fast curing agent solution and a modified silicon nanopowder solution, wherein the ultra-fast curing agent solution and the modified silicon nanopowder solution are mixed according to a volume ratio of 1:(1-2); the ultra-fast curing agent solution is polyisocyanate; the modified silicon nanopowder solution comprises the following components in percentage by weight: 30-33% of polyoxypropylene diamine, 8-10% of polyether triamine with the molecular weight of 5000, 10-15% of polybenzenetriamine, 8-17% of modified amino silicone resin, 2-11% of modified fluorocarbon resins, 1-2% of an adhesion promoter, 1-2% of pigments and 10-35% of nanopowder. The coating disclosed by the invention has excellent machine physical property, wear resistance, impact resistance, scratch resistance and pollution resistance and is capable of inhibiting cavitation to alleviate erosion, so that theservice life of the erosion damage part is prolonged.

Owner:上海沐皿新材料科技有限公司

Rolling bearing and method for manufacturing the same

InactiveCN101395394BImprove insulation performanceAccelerated corrosionBearing componentsThermal sprayingAerosol deposition

This invention provides a rolling bearing comprising a dense ceramic layer formed by a method alternative to a thermal spraying method, and having excellent insulating properties and corrosion resistance and chemical resistance, for example, resistance to chemicals such as acids and alkalis. The rolling bearing comprises an inner ring (1), an outer ring (2), and a plurality of rolling elements (4) interposed between raceway faces of the inner and outer rings. A ceramic film (7) is provided on at least one peripheral face selected from the inner peripheral face of the inner ring (1) and the outer peripheral face of the outer ring (2). The ceramic film is a film formed by an aerosol deposition method utilizing, for example, alumina fine particles as a raw material for aerosol. The film may be formed, for example, by fixing an aerosol ejection nozzle and axially moving the outer ring or inner ring using a positioning XY table while being rotated by an object rotation motor.

Owner:NTN CORP

Polyformaldehyde resin made twisting yarn

InactiveCN1667165AHigh strengthHigh elastic rateMonocomponent polyethers artificial filamentYarnYarnPolyoxymethylene

This invention provides a twist yarn made of a polyoxymethylene resin having excellent durability and high strength / high modulus. The twist yarn made of the polyoxymethylene resin is obtained by twisting a plurality of single yarns or multifilaments composed of a polyoxymethylene copolymer containing a specific oxyalkylene unit in an amount of 0.5-10 mol per 100 mol oxymethylene unit in a polymer chain mainly composed of a recurring oxymethylene unit and having 0.3-70g / 10 min melt index (160 load at 190[deg.]C).

Owner:POLYPLASTICS CO LTD

Guide wire and stent

ActiveCN101674861BExcellent X-ray contrastLow tensile strengthStentsGuide wiresPlastic materialsPliability

A guide wire that due to its wide elastic region and high Young's modulus, simultaneously has pliability and pushability, and that even when its surface is coated with a plastic material of high melting point, is highly impervious to influences of heat treatment, and that has excellent slidability and excels in weldability between a distal-end-side base material and a proximal-end-side core material. The guide wire has a core material comprising a distal-end-side core material and a proximal-end-side core material. The distal-end-side core material is made of an iron alloy having shape memorycapability and superelasticity, consisting essentially of two phases of gamma-phase and gamma'-phase and exhibiting, in a thermal hysteresis of martensite transformation and reverse transformation, adifference between reverse transformation completion temperature (Af-point) and martensite transformation starting temperature (Ms-point) of 100 DEG C or below. The proximal-end-side core material ismade of an alloy containing iron and has an elastic modulus higher than that of the distal-end-side core material. The distal-end-side core material and the proximal-end-side core material are weldedtogether.

Owner:TERUMO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com