Thermosetting resin composition and prepreg laminate for circuit board and printed circuit board each made therewith

A technology of resin composition and printed circuit board, which is applied in the direction of printed circuit, printed circuit parts, circuit substrate materials, etc., and can solve the problems of low water absorption, loss of glass transition temperature, failure to meet flame retardant standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The present invention will be described in detail as follows according to the embodiments. However, the present invention is not limited to the scope of the examples. Hereinafter, unless otherwise specified, the parts represent "parts by weight", and the % represents "% by weight".

Synthetic example 1

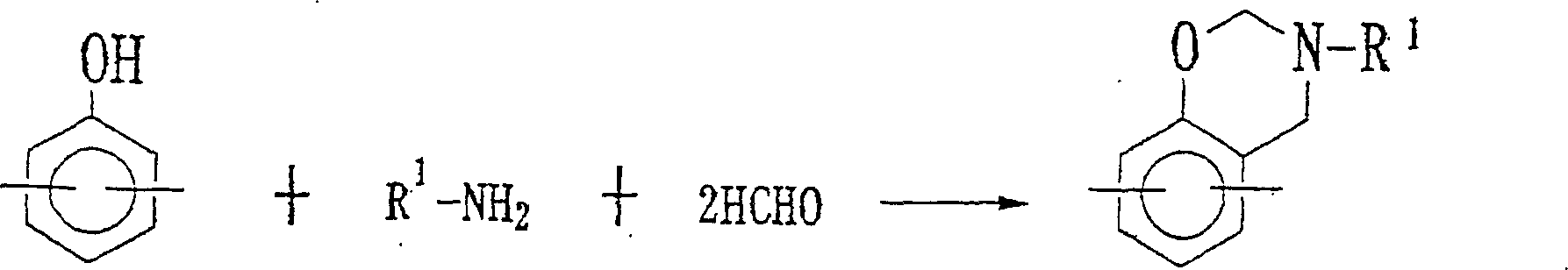

[0053] (A-1) Synthesis of thermosetting resin mainly composed of dihydrobenzoxazine ring

[0054] Equipped with a thermometer, a stirrer, and a condenser, add 1,000 g of bisphenol F and 920 g of methanol to a 5-L flask in a dropping device, and dissolve at 50° C. while stirring. Among them, 652 g of paraformaldehyde was added. Then, under stirring, 930 g of aniline was added dropwise in 1 hour. After 1 hour, it was brought to 78 to 80° C., reacted under reflux for 7 hours, and then decompressed and concentrated at 360 mm Hg. Concentration was continued under the reduced pressure, and when the resin temperature reached 110° C., the degree of reduced pressure was increased to 90 mm Hg. After confirming that no more liquid flowed out, the resin was taken out and placed in a tray to obtain a thermosetting resin (A1) mainly composed of a dihydrobenzoxazine ring whose softening point was 78°C.

Synthetic example 2

[0056] (A-2) Synthesis of thermosetting resin mainly composed of dihydrobenzoxazine ring

[0057] The above-mentioned thermosetting resin (A1) mainly composed of dihydrobenzoxazine rings was heated at 110°C for 6 hours under normal pressure to prepare a resin containing dihydrobenzoxazine rings with a softening point of 110°C. Thermosetting resin (A2) as the main component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com