High-fidelity loudspeaker cone and production process thereof

A speaker paper and paper cone technology, which is applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of poor structural stability of the paper cone, poor speaker fidelity, and good fidelity of the paper cone, achieving guaranteed strength, good sound quality, high fidelity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

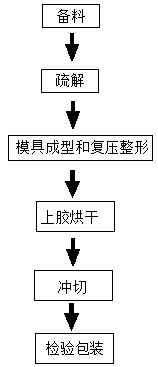

Image

Examples

Embodiment 1

[0022] Take out 40 parts of sisal pulp, 20 parts of flax pulp and 10 parts of fluff pulp according to the weight ratio of 4-2-1, remove the hard lumps and impurities, and carry out dust cleaning treatment, and soak them separately for 30 minutes. Permeability shall prevail. When dipping, the liquid level should exceed the pulp surface, and water shall be added in due course. Put hot water at 75°C in a clean tank, add 1 part of rosin while stirring the hot water, and add cold water to lower the solution temperature after emulsification. Lower the temperature to 30°C and set the volume to the specified concentration. Put an appropriate amount of water into the beater, turn on the power, shred the impregnated wood pulp, and put them into the beater one by one to decompose. After decomposing for about 5 minutes, stop the machine and dig out. Re-start the machine to defuse the pulp that has stopped at a dead corner, and then deflate again for 3 minutes, then take a small amount of t...

Embodiment 2

[0025] Take out 45 parts of sisal pulp, 22.5 parts of flax pulp and 11.3 parts of fluff pulp according to the weight ratio of 4-2-1, remove the hard lumps and impurities, and carry out dust cleaning treatment, respectively impregnated for 40 minutes, all impregnated with pulp When soaking, the liquid level should exceed the surface of the pulp, and water should be added in time. Put 80°C hot water in a clean tank, add 1 part of paraffin while stirring the hot water, and add cold water to lower the solution temperature after emulsification. Lower the temperature to 35°C and set the volume to the specified concentration. Put an appropriate amount of water into the beater, turn on the power, shred the impregnated wood pulp, and put them into the beater one by one to decompose. Stop the machine after decomposing for about 8 minutes. Re-start the machine to defuse the pulp that has stopped at a dead corner, and then deflate again for 4 minutes, then take a small amount of the deflat...

Embodiment 3

[0028]Take out 40 parts of sisal pulp, 20 parts of flax pulp and 10 parts of fluff pulp according to the weight ratio of 4-2-1, remove the hard lumps and impurities, and carry out dust cleaning treatment, and soak them separately for 50 minutes. Permeability shall prevail, the liquid level shall exceed the pulp surface during immersion, and water shall be added in time, and hot water at 85°C shall be put in a clean tank, and 2 parts of acrylic polyester waterproofing agent shall be added while stirring the hot water, and all emulsified before adding Lower the temperature of the solution to 40°C with cold water and set the volume to the specified concentration. Put an appropriate amount of water into the beater, turn on the power, shred the soaked wood pulp, and put them into the beater one by one for about 10 minutes. After that, stop the machine, dig out the pulp lumps that have stopped in the dead corner, and restart the machine to defuse it. After thawing again for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com