Patents

Literature

349results about "Metal coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separator for nonaqueous electrolyte batteries, nonaqueous electrolyte battery using it, and method for manufacturing separator for nonaqueous electrolyte batteries

InactiveUS6511774B1High tear strengthEnhanced penetration strengthNon-aqueous electrolyte accumulatorsCell seperators/membranes/diaphragms/spacersHigh energyEngineering

The present invention provides a separator for non-aqueous electrolyte batteries which neither breaks nor slips off at the time of fabrication of battery, gives excellent battery fabricability, causes no internal short-circuit caused by contact between electrodes even if the electrodes are externally short-circuited, can inhibit ignition of battery and produces high energy density and excellent cycle life, and further provides a non-aqueous electrolyte battery using the separator and a method for manufacturing the separator. That is, the present invention relates to a separator for non-aqueous electrolyte batteries which comprises a porous base containing at least one member selected from a porous film, a woven fabric or nonwoven fabric containing an organic fiber and a paper and an organometallic compound applied to the porous base; a method for the manufacture of the separator for non-aqueous electrolyte batteries which comprises allowing said porous base to contact with a solution of organometallic compound by impregnation, coating or spraying, followed by drying or curing with heating to apply the organometallic compound to the porous base; and a non-aqueous electrolyte battery using the separator.

Owner:MITSUBISHI PAPER MILLS LTD

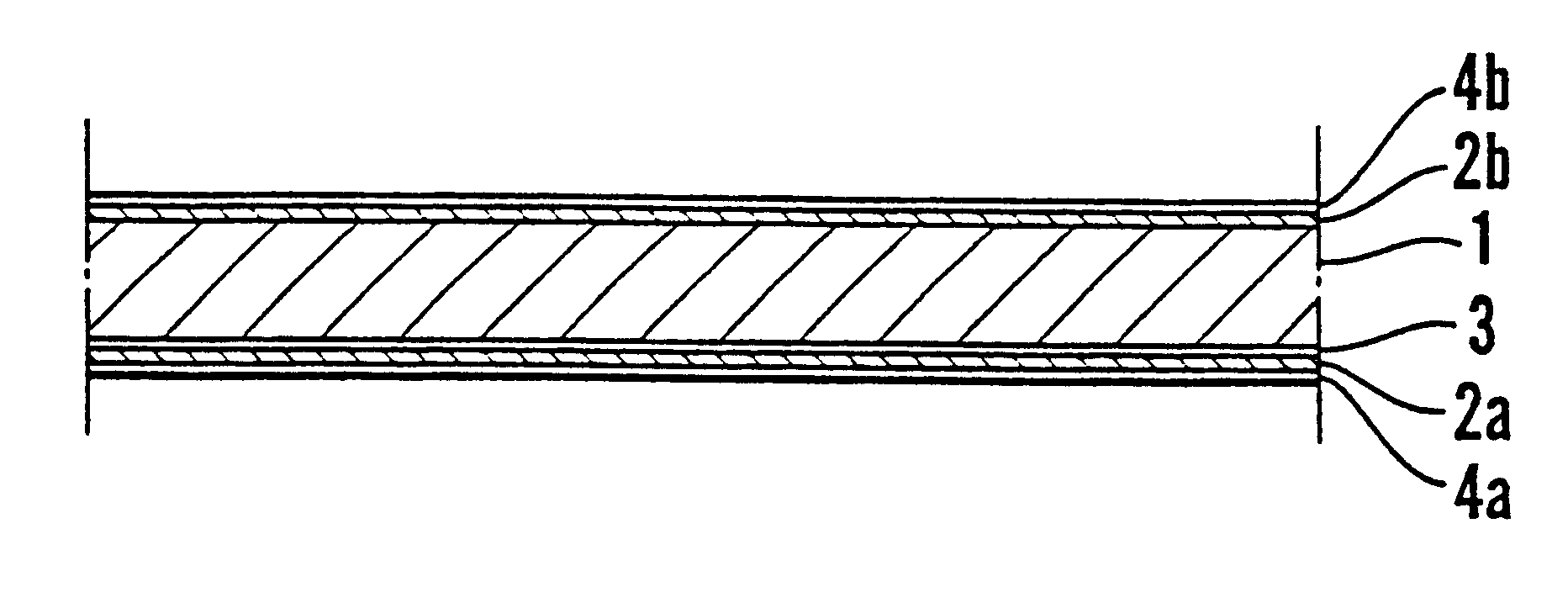

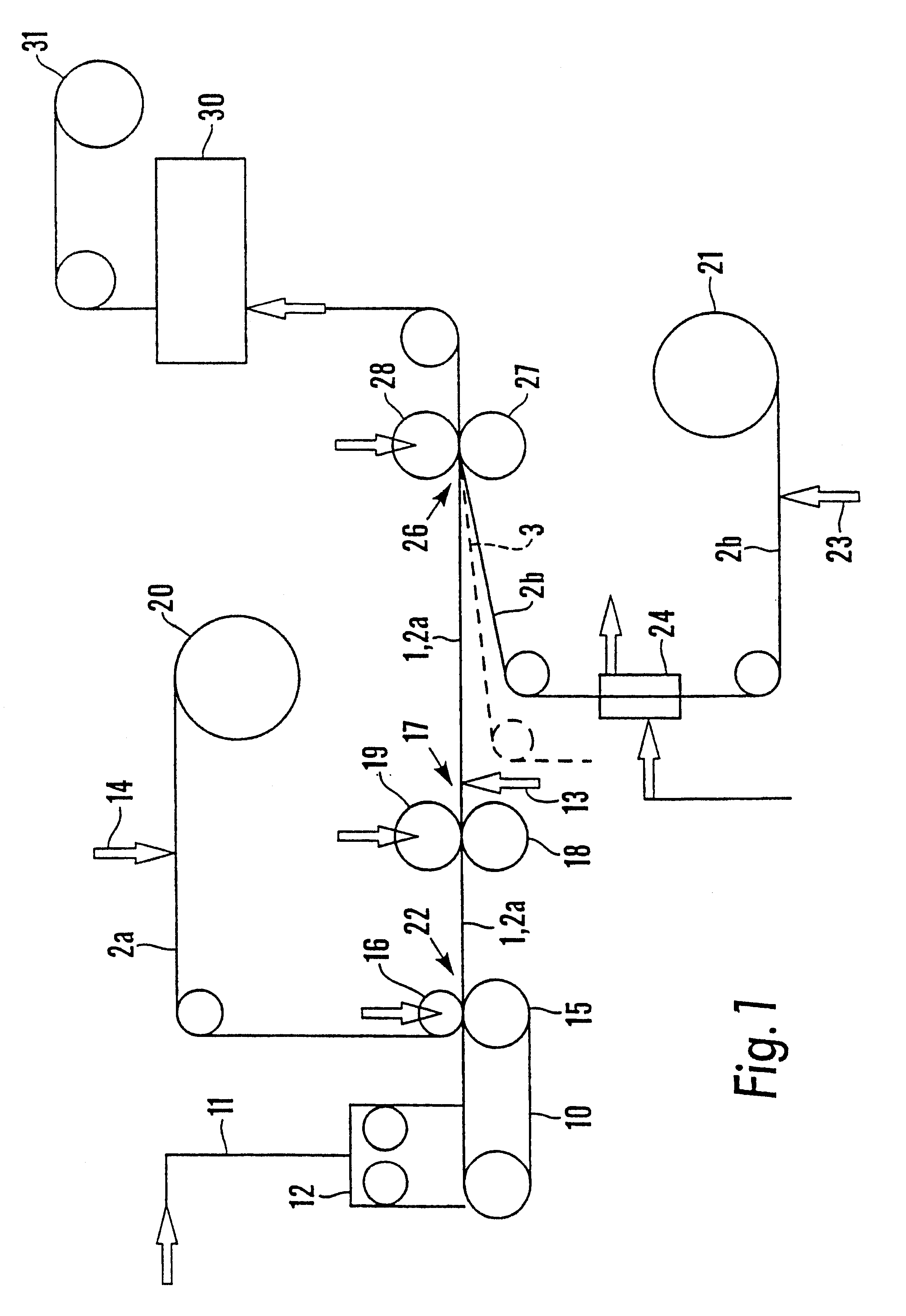

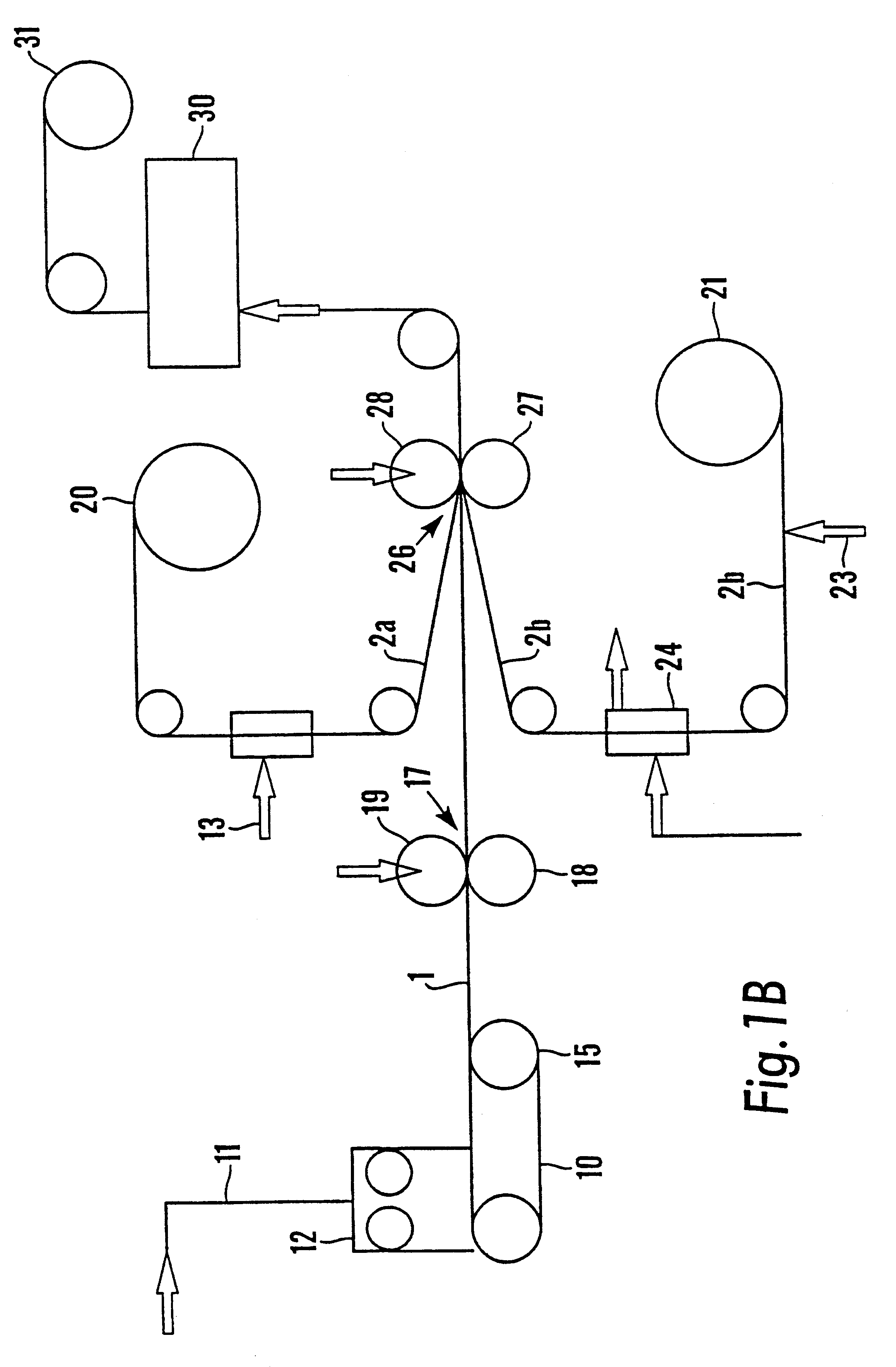

Paper or paperboard laminate and method to produce such a laminate

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

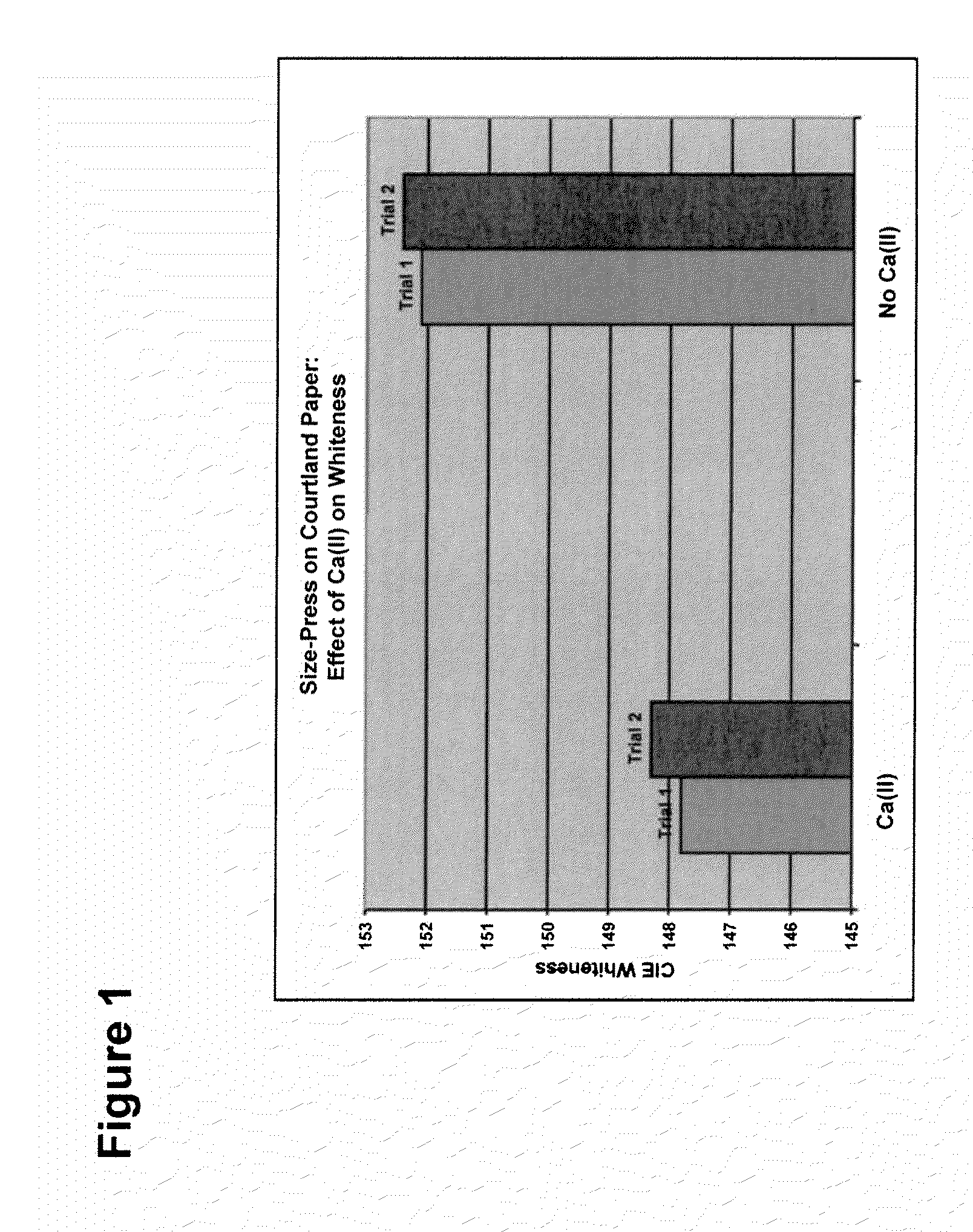

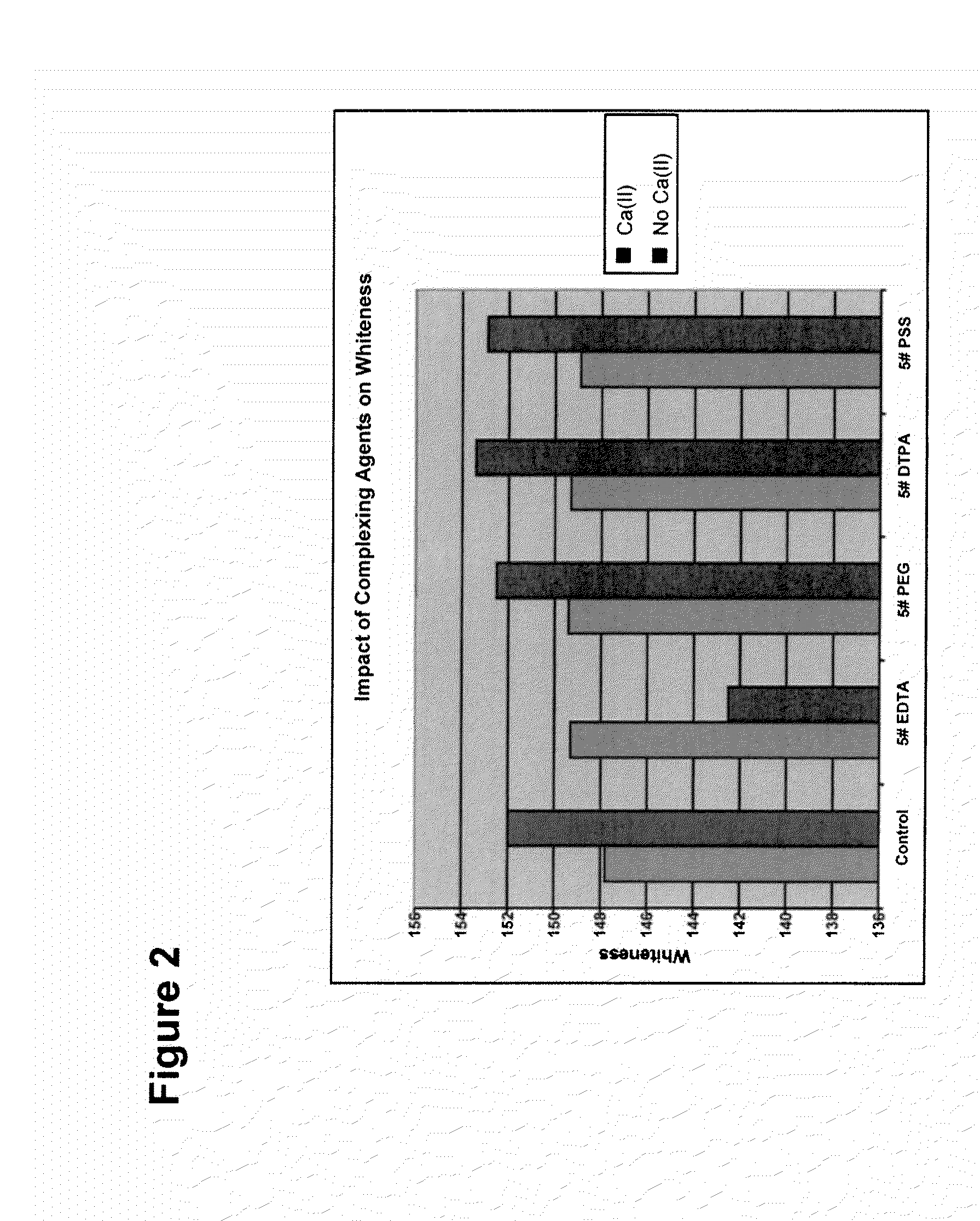

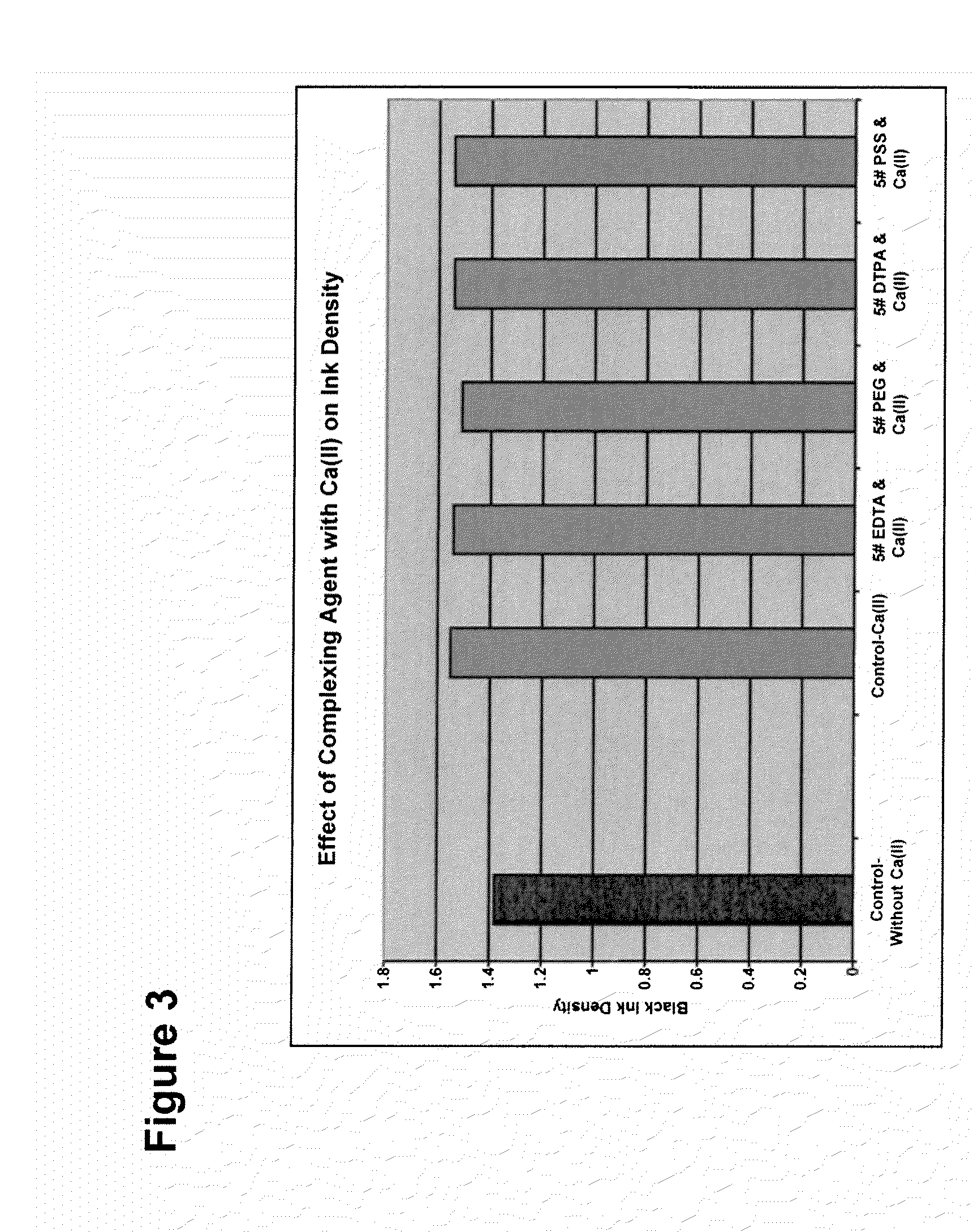

Composition and recording sheet with improved optical properties

ActiveUS20090317549A1Good optical performanceImprove printing effectNatural cellulose pulp/paperSpecial paperOptical propertyDivalent metal

Owner:GLOBAL HLDG II INC

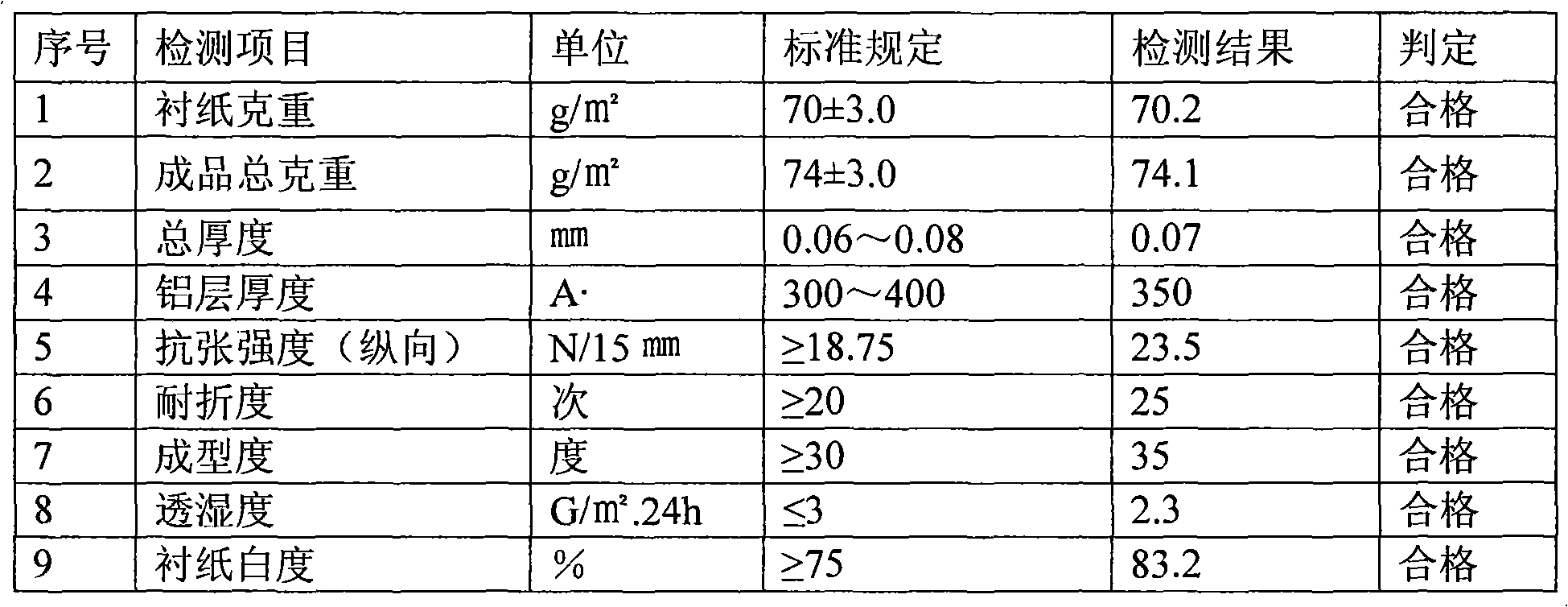

Cigarette perfuming agent and its preparation method and application

InactiveCN101215805AImprove qualityMellow tasteNon-fibrous pulp additionNon-macromolecular adhesive additivesAluminum foilInternal quality

The invention discloses a cigarette flavor enhancer and a process for preparation and the application, the flavor enhancer agent is mixed by flavor materials with stronger volatility and outstanding characteristic and plant extraction which has promoting effect to the smoking of cigarette, the improvement of the internal quality is firstly achieved by cigarette packing material through the invention, and the process comprises coating flavor enhancer agent on the surface of aluminum foil inner lining paper according to the proposition which is 0.01%-5%, or adding into the existing adhesive agent for aluminum foil liner paper according to the proposition which is 0.01%-5%, making full use of the characters that aluminum foil liner paper directly contacts with cigarettes, continuously decorating and improving the smoking of cigarette, and covering imperfect breath of the existing aluminum foil liner paper itself. The invention can have a good connection with the existing cigarette technique and equipment, and production can be achieved by the invention without adjusting the existing equipment. The invention has the advantages of reasonable process, convenient operation and low production cost, which has an excellent application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

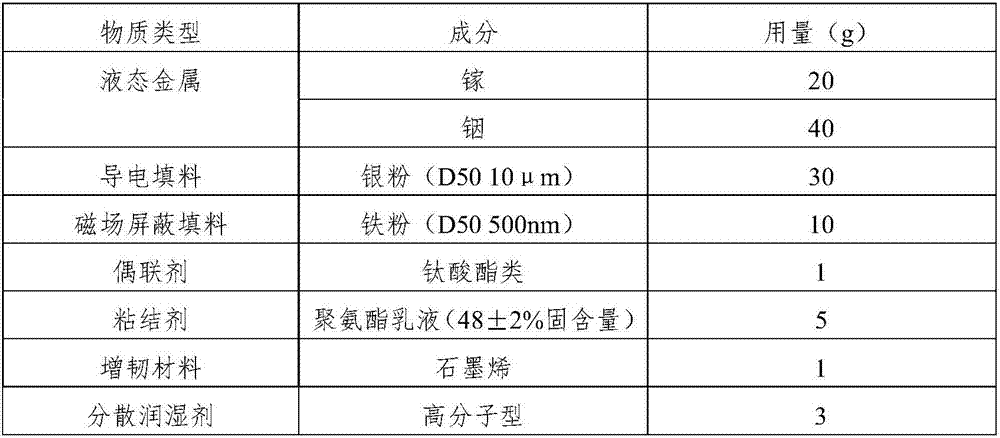

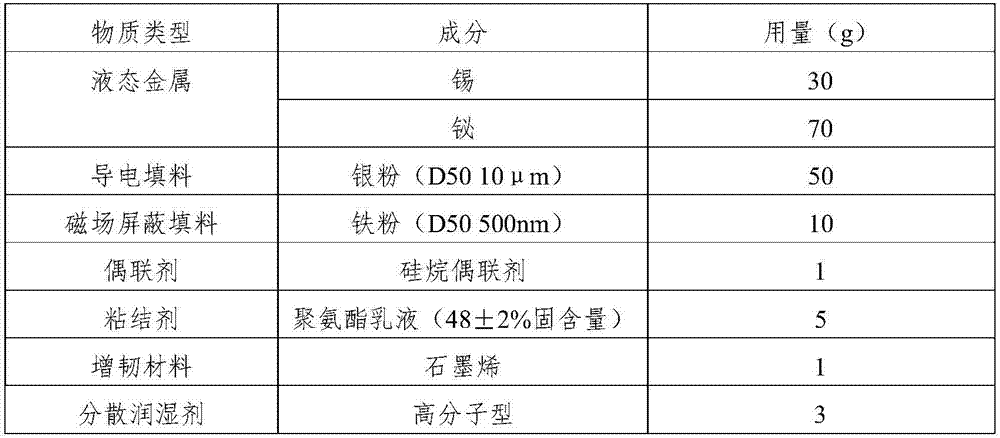

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

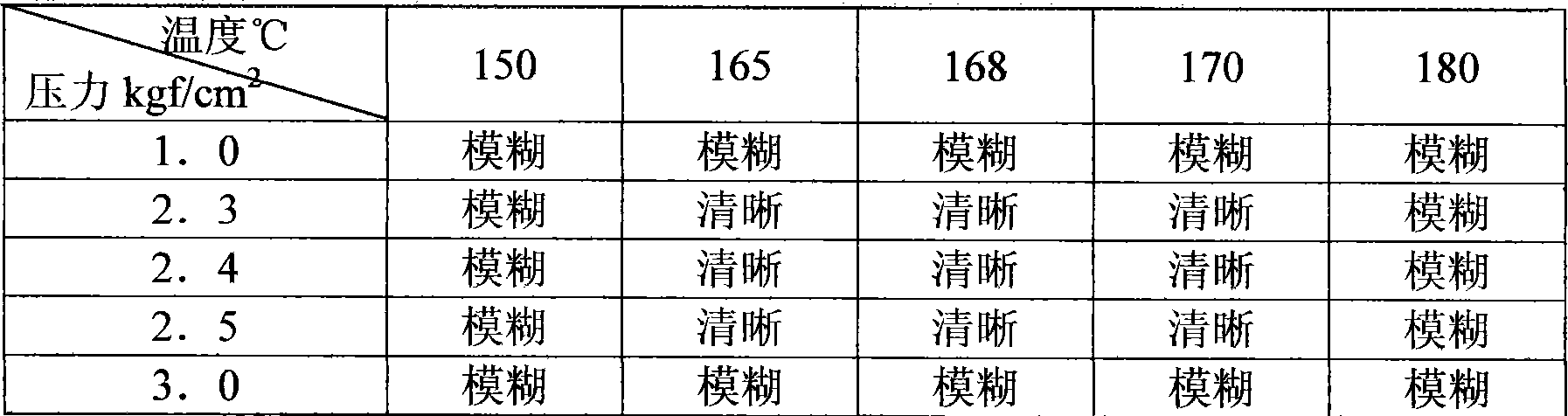

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

High-strength directly aluminizing water-based base coat and preparation method and application of high-strength directly aluminizing water-based base coat

ActiveCN103866607AGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

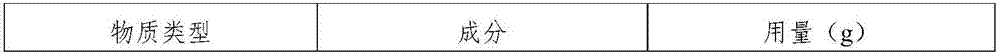

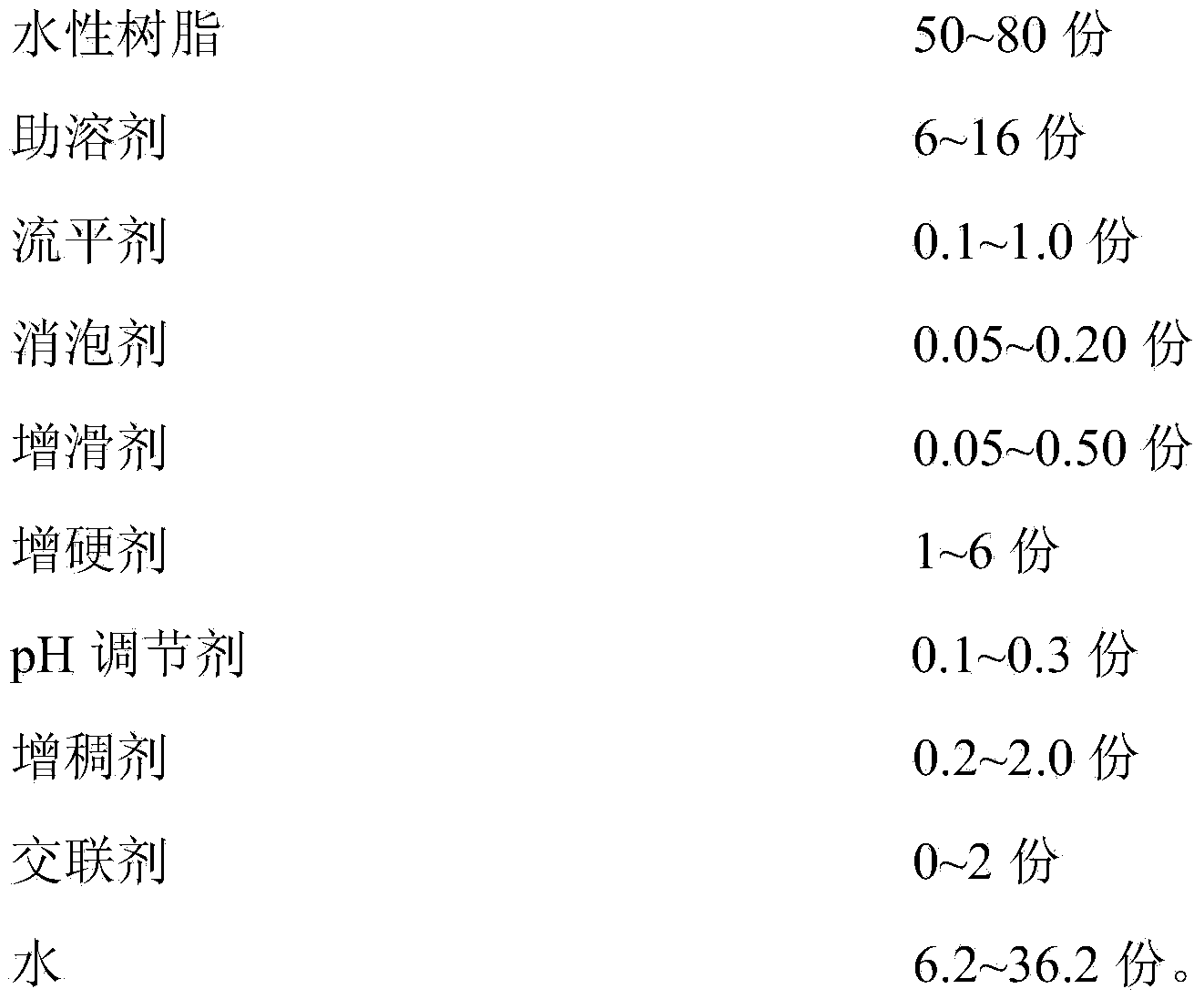

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

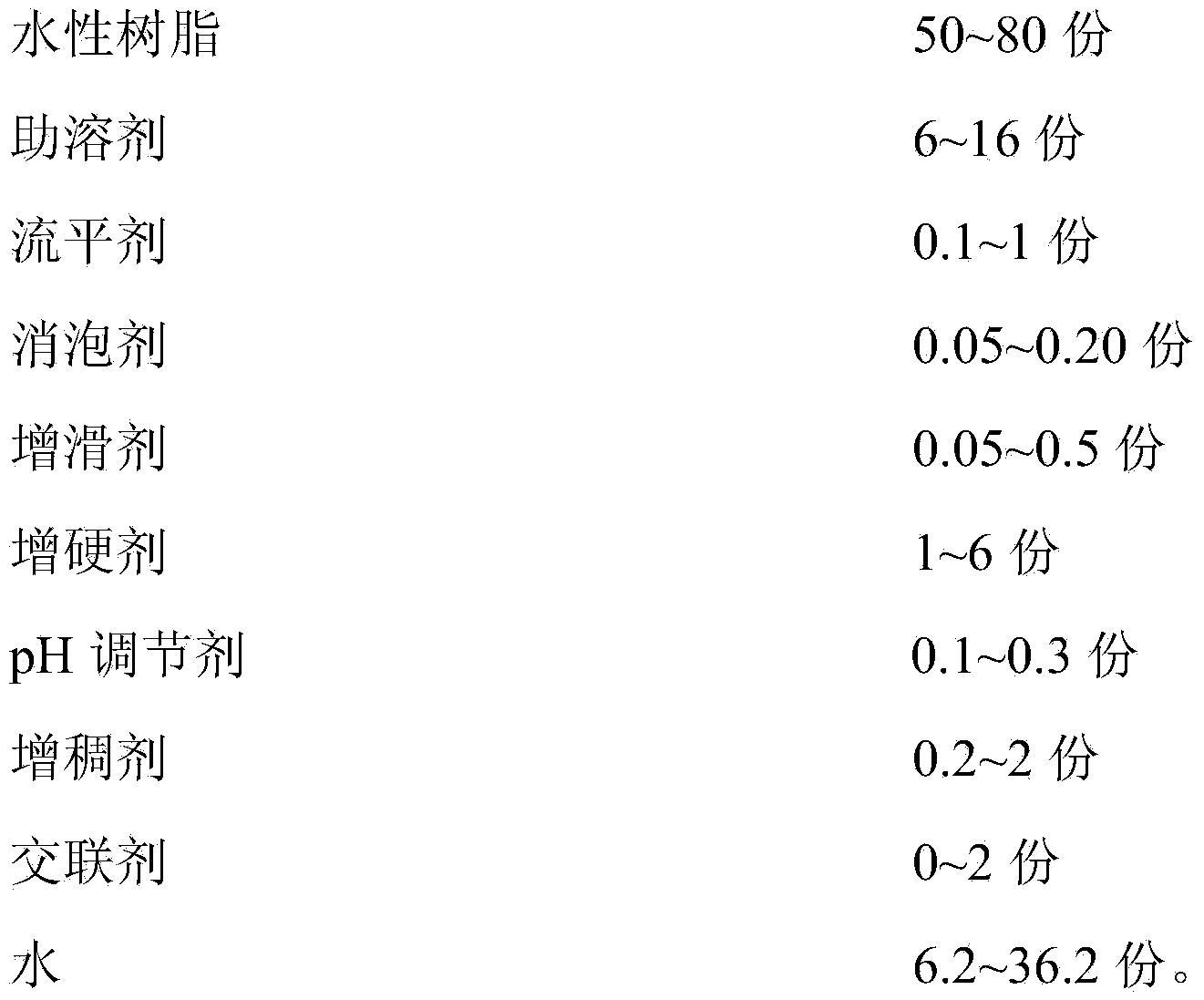

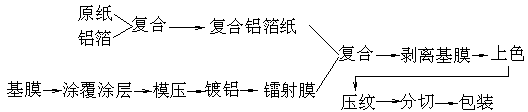

Method for preparing holography sputtering internal lining paper

InactiveCN101270557AImprove product qualityReduce defectsSpecial visual effect coatingsMechanical working/deformationPulp and paper industryWater requirement

The invention relates to a manufacture method for holographic direct plating lining paper which belongs to the technical field of an aluminum-plated paper manufacture method. The working procedures include: (1) providing a film; (2) carrying out laser holographic contour forging treatment on the film; (3) coating a layer of compound glue dope on the surface of the film with the holographic layer and then compounding with a lining paper base; (4) peeling off the film to obtain the paper base with holographic information and meeting the water requirements of aluminum plating; (5) plating aluminum on the coat of the paper base; (6) subsequent treatment of aluminum plating; core: compounding the coat printed with a holographic pattern on the paper base to replace the spreading pre-treatment on the paper base and directly carrying out vacuum aluminum plating on the surface of a dope layer. The invention has the effects that: 1, the quality of the holographic lining paper is high and completely removes various defects of the lining paper manufactured by a common direct plating method; 2 the technique step is simple; besides, as a BOPP film can be repeatedly used, the cost can be reduced, thus being suitable for batch manufacture; 3, compared with the common direct plating lining paper, the holographic pattern is added, thus being beneficial to anti-fake of the product and improving the grade of the product.

Owner:YANTAI BOYUAN TECH MATERIALS

Single coating transfer aluminum plating coating, and preparation and use thereof

InactiveCN101407689AAppropriate molecular weight rangeHigh viscosityCoatings with pigmentsCoatingsCelluloseHigh surface

The invention relates to a single-coated transfer aluminium-plated coating, a preparation method and an application thereof, wherein, the coating takes the following components with the contents (weight percent) as raw materials: 0 to 16 weight percent cellulose resin; 0 to 6 weight percent vinyl chloride-vinyl acetate resin; 4 to 20 weight percent polyacrylate resin; 0 to 1 weight percent auxiliary agent and 70 to 87 weight percent solvent. Compared with the prior art, the invention has the following advantages: (1) the single-channel coating is adopted, compared with two times of coating, the process is simple, the production efficiency is high, the energy consumption is less, the emission is less, the coating amount is less and the cost is low; (2) the product has good technological adaptability and is applicable to the different technological conditions of different manufacturers; (3) a coating layer has excellent comprehensive performance, great peeling performance, good adhesion with aluminium, wear resistance, temperature resistance, solvent resistance, good flexibility, high surface luminance brightness and good adaptability with ink printing; and (4) the coating and the coating layer have no triphenyl or other solvents which are prohibited by the industry, thereby being safe and environment-friendly.

Owner:SHANGHAI WEIKAI CHEM

Magnetic paint

Magnetic receptive Paints and coatings have been developed to allow one to paint a wall with this coating and apply magnets to this surface. The further development of magnetic receptive coatings incorporates the use of multiple size particles giving the finished surface a smoother appearance and increasing the particle load in the dry mill surface. This is useful in the coating of substrates where the need to coat the thinnest possible coating on the surface of a substrate such as papers and films as well as painting on walls, gives you the highest magnetic receptive surface possible at the thinnest mill thickness of applied coating.

Owner:DEETZ DAYTON JOSEPH

Preparing technological process of laser aluminum plating paper

ActiveCN101324040AHigh glossGood film formingSpecial visual effect coatingsDecorative surface effectsSurface tension gradientAdhesive

The invention relates to a process method for preparing laser aluminium-plated paper, comprising the steps as follows: OPP film or PET film is coated with a disjuncting layer which is coated with an imaging layer that is mould pressed with laser patterns; the mould pressing layer is coated with adhesive; the OPP film or the PET film is stripped and enwound by a stripping machine, thus obtaining a paper substrate containing the disjuncting layer, the imaging layer and the mould pressing layer; the paper substrate is directly plated with aluminium in vacuum and the aluminium is plated on the disjuncting coating layer; the aluminium-plated layer is coated with a waterborne environmental-protective profile coating protection layer; the laser aluminium-plated paper is obtained by moisture reobtaining and resolved shearing; the process of the invention reasonably chooses resin solvent and adhesive on the basis of a plurality of tests, simultaneously, the process of the invention utilizes suitable tenacity endowed by the molecular structure when the resin and the adhesive are in a coating state, and the performance of the adhesion to optimize the proportion according to the principle of combined surface tension gradient distribution between layers, thus forming the coating layer with high blare, good film-forming performance, environmental-protection and excellent printing performance and good alkali solution permeability simultaneously.

Owner:青州金青云新材料有限公司

Picture-grade high-light water-proof colour ink-jet printing paper

InactiveCN1814913AHigh transparencyHigh whitenessSpecial visual effect coatingsMetal coatingsPulp and paper industrySilicon

Photo-stage high brightness water-proof color ink-jet printing paper includes a basic material and a coat coated on it characterizing that said coat contains nm modified Al2O modified by a strong anode ion dispersing agent and a bonder, since the coat contains modified Al2O with the diameter of 30-80nm and inorganic silicon sol with the diameter smaller than 20nm, the invented paper can either absorb water ink or make the ink not to disperse.

Owner:SHANTOU XINXIE SPECIAL PAPER TECH

Method for producing laser transfer directly-plating paper

InactiveCN101725078AImprove barrier propertiesAvoid harmSpecial paperPaper/cardboardWater basedOrganic solvent

The invention provides a method for producing laser transfer directly-plating paper, comprising the following steps of: (1) carrying out laser mould pressing on a BOPP thin film; (2) coating a layer of coating on a mould pressing surface of the BOPP thin film and with a compound machine after mould pressing, immediately compounding the paper and the coating surface of the BOPP thin film, wherein the size of the paper is 30-100g / m<2>; (3) stripping the BOPP thin film from the paper; (4) placing the stripped paper into an aluminizing machine and aluminizing on the transfer coating surface; and (5) coating a layer of coating on an aluminizing surface of the paper and drying. The invention avoids the defects of two methods, combines a transfer method and a directly-plating method, omits a composite adhesive used by the transfer method, simplifies the process flow, uses an environment-friendly water-based coating, avoids the harm of organic solvents with high content in the coating used by the transfer method to the environment and human body and simultaneously has more excellent laser mould pressing effect, higher glossiness and definition in comparison with the directly-plating method.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Silver-loaded antibacterial paper and preparing method thereof

InactiveCN105780590AFast and good bactericidalFast and good bacteriostasisWater-repelling agents additionReinforcing agents additionPaper productionBleach

The invention discloses silver-loaded antibacterial paper.The silver-loaded antibacterial paper is prepared from a silver-loaded antibacterial agent, a softening agent, a dry strength agent, a wet strength agent, a drying agent, a retention agent, a sizing agent, an antibacterial agent, a dispersing agent and a decolorizer additive.The invention further discloses a preparing method of the silver-loaded antibacterial paper.The method comprises the following steps that pulping, pulp dispersing, pulp milling and pulp beating are carried out, the silver-loaded antibacterial agent is added into the pulp sizing agent, the sizing agent is conveyed, pulp is fed onto a net to be shaped and pressed into paper, pressing is carried out, and dry dehydration and paper forming are carried out.Compared with the prior art, the antibacterial paper and the antibacterial paper production method have the advantages that prebiotics and the antibacterial agent are used in the antibacterial paper in a combined mode, it is ensured that the antibacterial paper has the fast and good sterilization and bacteriostasis effects, can well restrain breeding and growth of microorganisms of the antibacterial paper, the damage to the quality of the antibacterial paper due to breeding of the microorganisms is avoided, and the quality of the antibacterial paper is ensured.

Owner:上海渊泉集币收藏品有限公司

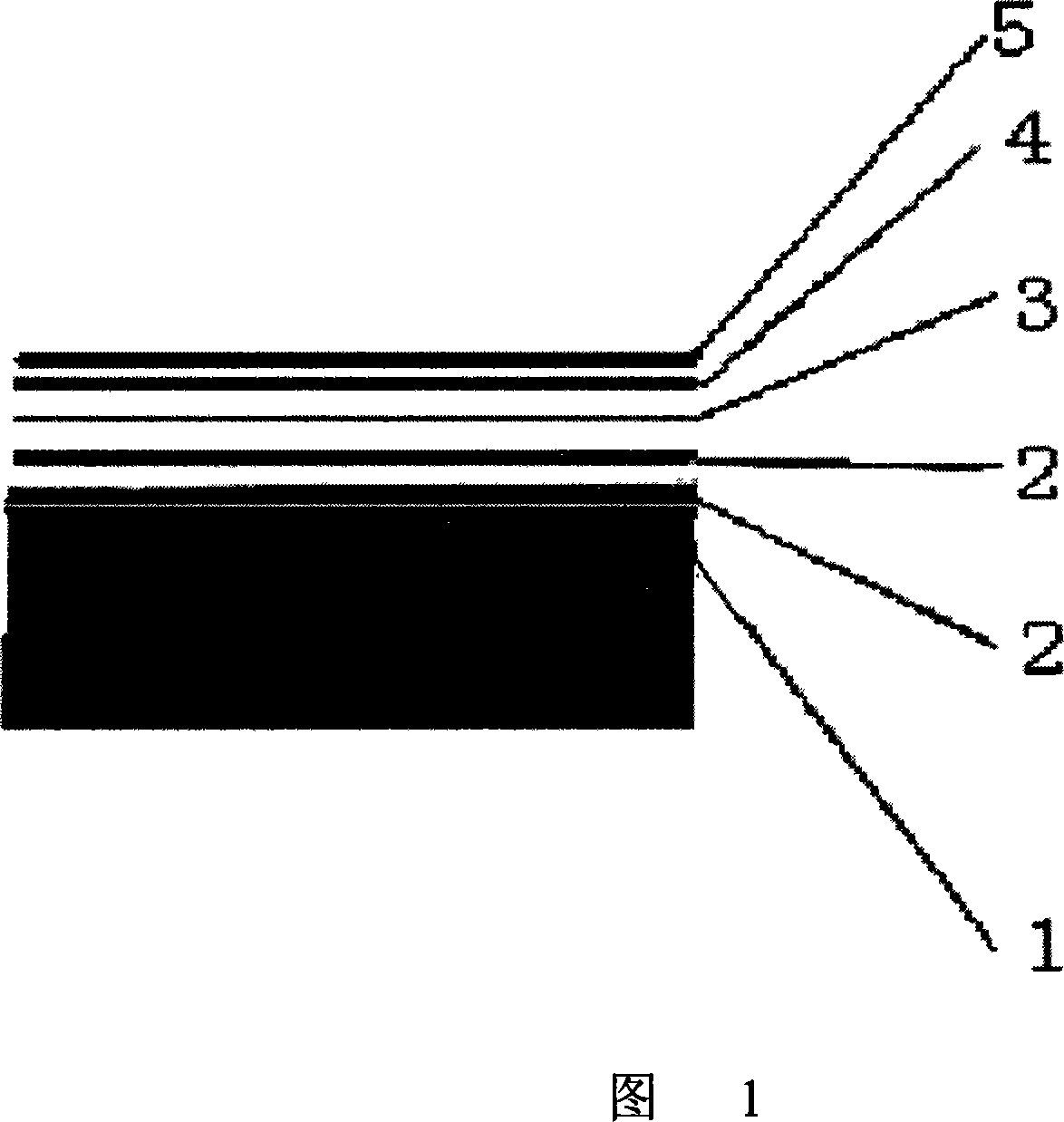

Prepreg containing aromatic synthetic fiber paper and printed circuit board manufactured from same

InactiveCN102174770AReduce weightSatisfy the use environmentPrinted circuit aspectsSynthetic cellulose/non-cellulose material pulp/paperEngineeringThermal stability

The invention relates to a prepreg manufactured from aromatic synthetic fiber paper used as a printed circuit board, and a copper clad board as well as printed circuit board manufactured from the prepreg. The synthetic fiber paper used as the base material of the base board of the circuit board is manufactured from the following materials in percentage by weight: 10-90% of structural fiber (para-position aramid fiber) and 90-10% of tacky fiber (para-position aramid fibrid or pulp). In the invention, the base board of the circuit board and the printed circuit board using the synthetic fiber paper as the base material have the advantages of light weight, good temperature tolerance, high thermal stability and fine processability.

Owner:深圳昊天龙邦复合材料有限公司

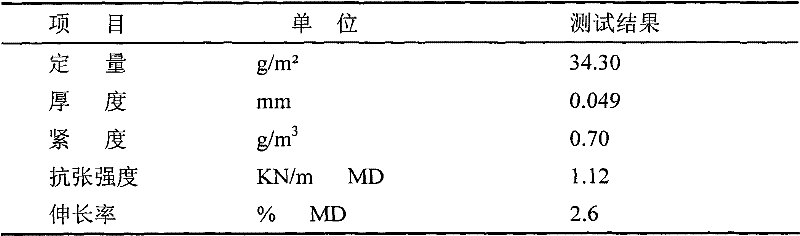

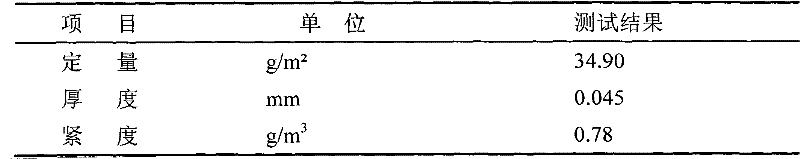

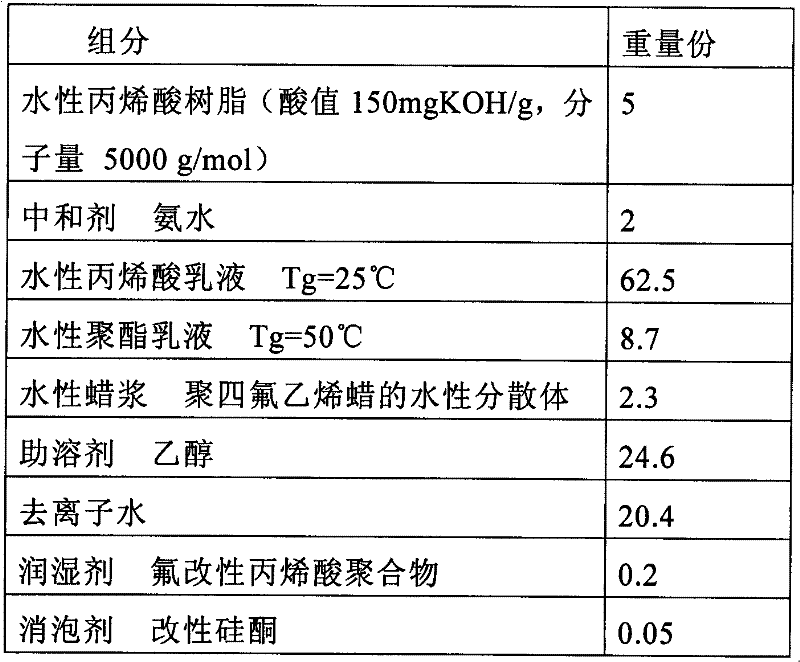

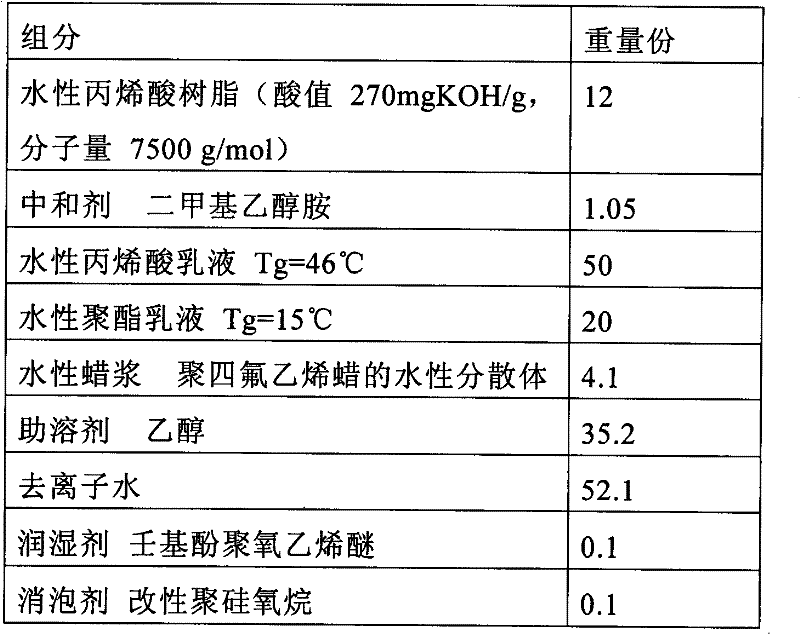

Environmentally-friendly aqueous matte aluminized paper undercoating paint and preparation method as well as application thereof

ActiveCN102363933AGood matte effectImprove wear resistanceDefoamers additionCoatingsEnvironmental resistancePolyester

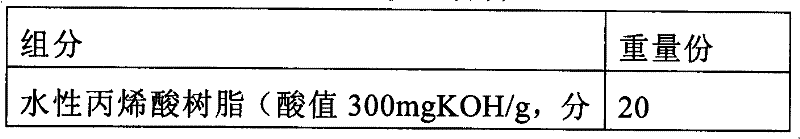

The invention relates to an environmentally-friendly aqueous matte aluminized paper undercoating paint and a preparation method as well as application thereof. The paint comprises the following component raw materials in parts by weight: 5-20 parts of aqueous acrylic resin, 0.5-8 parts of neutralizing agent, 50-70 parts of aqueous acrylic emulsion, 10-20 parts of aqueous polyester emulsion, 1-5 parts of aqueous wax slurry, 20-45 parts of cosolvent, 20-80 parts of de-ionized water, 0.1-0.3 part of moistening agent, 0-0.2 part of rheological control agent and 0.05-0.2 part of defoaming agent, and can be used for surface treatment of cigarette inner lining paper. Compared with the prior art, the paint has the advantages of aqueous environmental friendliness, high metal glossiness, superior coverage and wear resistance; and the problem that directly plated paper made by the conventional paint cannot achieve effects of metal feeling and flatness of a matte aluminum foil is solved.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

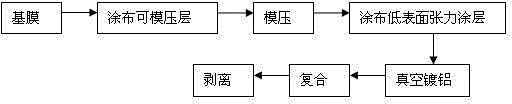

Process for preparing composite transfer straightly plated cardboard

A method for preparing composite transfer direct-plating cardboard, comprising the following steps in sequence: (1) providing a film with a corona value on the surface to be treated within the range of 30-46 dynes; (2) forming a film on the surface to be treated (3) make the one side of the coating layer of the film and the side of the cardboard composite; (4) peel off the film to obtain dry transfer cardboard; (5) coat the obtained transfer cardboard Aluminum plated on the layer. In a preferred embodiment, the preparation method of the composite transfer direct-coated cardboard further includes the step of performing laser holographic embossing treatment on the surface of the film to be treated before the step (2). In another preferred embodiment, the preparation method of the composite transfer direct-coating cardboard further includes step (6) coating a second paint on the obtained aluminum-coated layer to form a protective layer. Compared with the prior art, the present invention has the advantages of simple steps, convenient operation, suitability for large-scale production, high product quality and cost reduction.

Owner:广东东南薄膜科技股份有限公司

Long-acting slow release type aluminum foil paper and preparing method thereof

ActiveCN101215803AImprove qualityImprove inner qualityNon-fibrous pulp additionFlexible coversChemical reactionPulp and paper industry

The invention discloses a long-acting slow-release-type aluminum foil liner paper and a process for preparation, and the process comprises choosing inner lining paper whose permeating degree is 10-30000CU, coating cigarette modified addition agent or flavoring agent on the surface of the inner lining paper, or adding in the existing adhesive agent which is used by aluminum foil liner paper according to the proposition which is 0.01%-5%, bonding the aluminum foil liner paper and ventilating inner lining paper according to the conventional process, and getting acceptable products after cutting and removing peculiar smell. The invention makes full use of the characters that aluminum foil liner paper directly contacts with cigarette, material which is added can continuously give off flavor components when cigarettes are stored in a storeroom, and which can effectively have a physical and chemical reactions with cigarettes, inner quality is prompted to be improved, and absorbing taste is more pure and comfortable. The invention can have a good connection with the existing cigarette technique and equipment, and production can be achieved by the invention without adjusting the existing equipment.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Ultraviolet curing aluminized transferring coating and preparation method and application thereof

ActiveCN102533068AEliminate volatilizationReduce consumptionSurface covering paperPolyurea/polyurethane coatingsUltraviolet lightsPliability

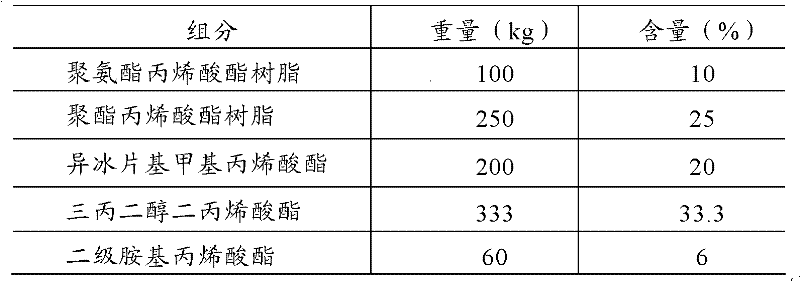

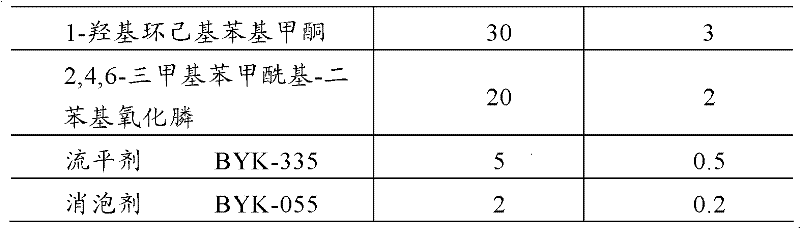

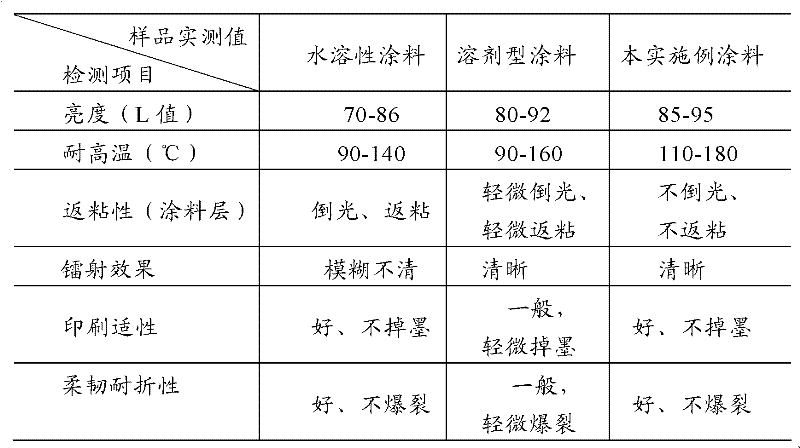

The invention relates to ultra-violet curing aluminized transferring coating and a preparation method and an application of the coating. The coating is prepared from the following components (by weight percent) as raw materials: 25-50 of acrylic ester resin, 32-60 of acrylic ester monomers, 3-15 of photoinitiator, and 0.5-3 of assistant, wherein the acrylic ester monomers at least comprise amino acrylic ester accounting for more than 5% of the total weight of the coating. The coating does not contain solvent, can be dried and solidified by adopting ultraviolet light source irradiation, completely removes volatilization of harmful solvent in coating process, does not need heat energy in the solidifying and greatly reduces energy consumption. After being carried out on coating drying, the coating has a coating film with good flexibly, can be carried out on laser mould pressing, is good in adhesiveness with an aluminum layer, can be easy to peel from a base film, is good in transitivity, resists high temperature, has excellent after-tack in a height temperature and high humidity environment, can be carried out on recoating, is good in printability and can completely meet all technical indexes of aluminized transferring coating.

Owner:SHANGHAI ZIJIANG METALLIZATION ENVIRONMENTAL PROTECTION MATERIAL

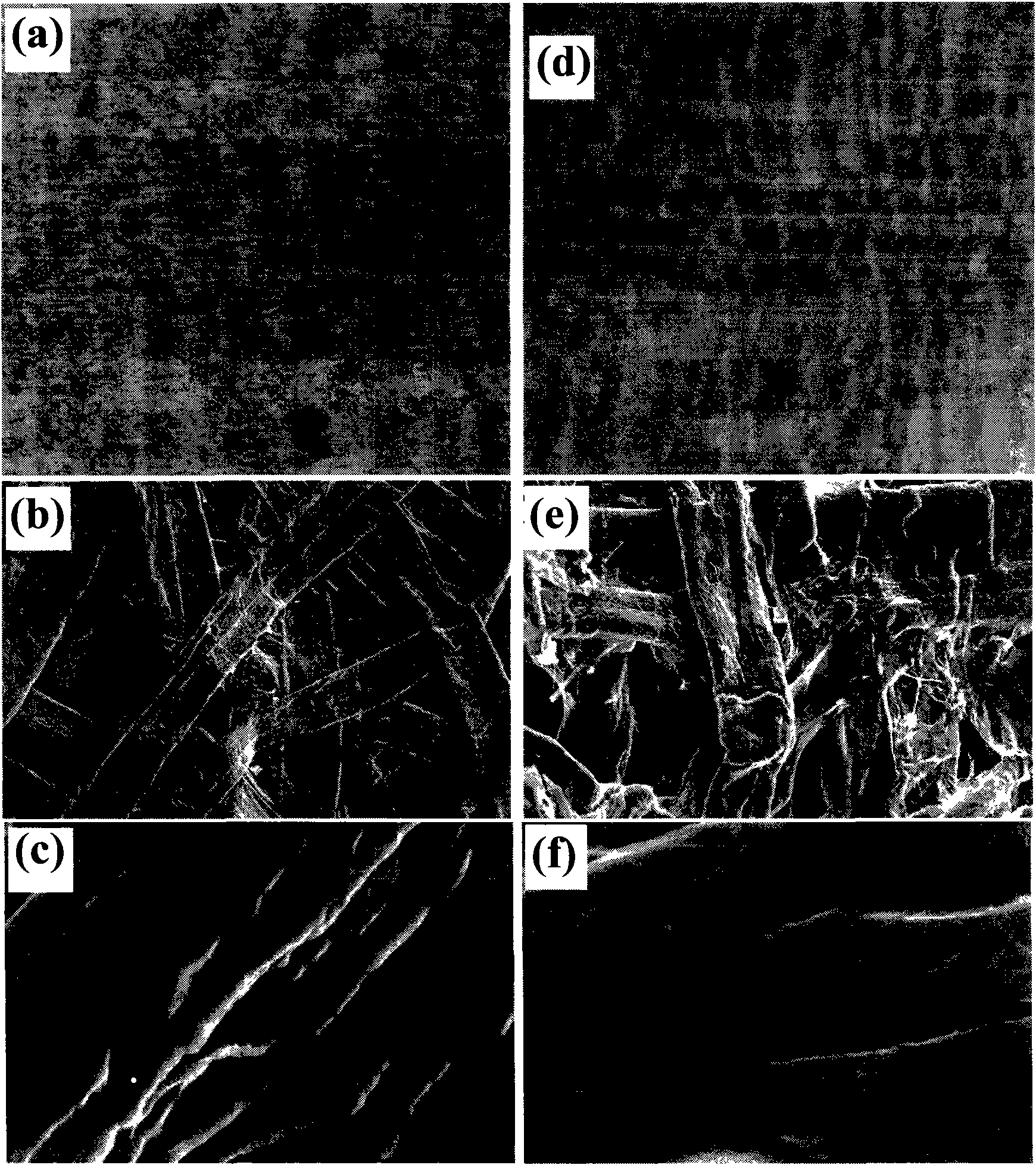

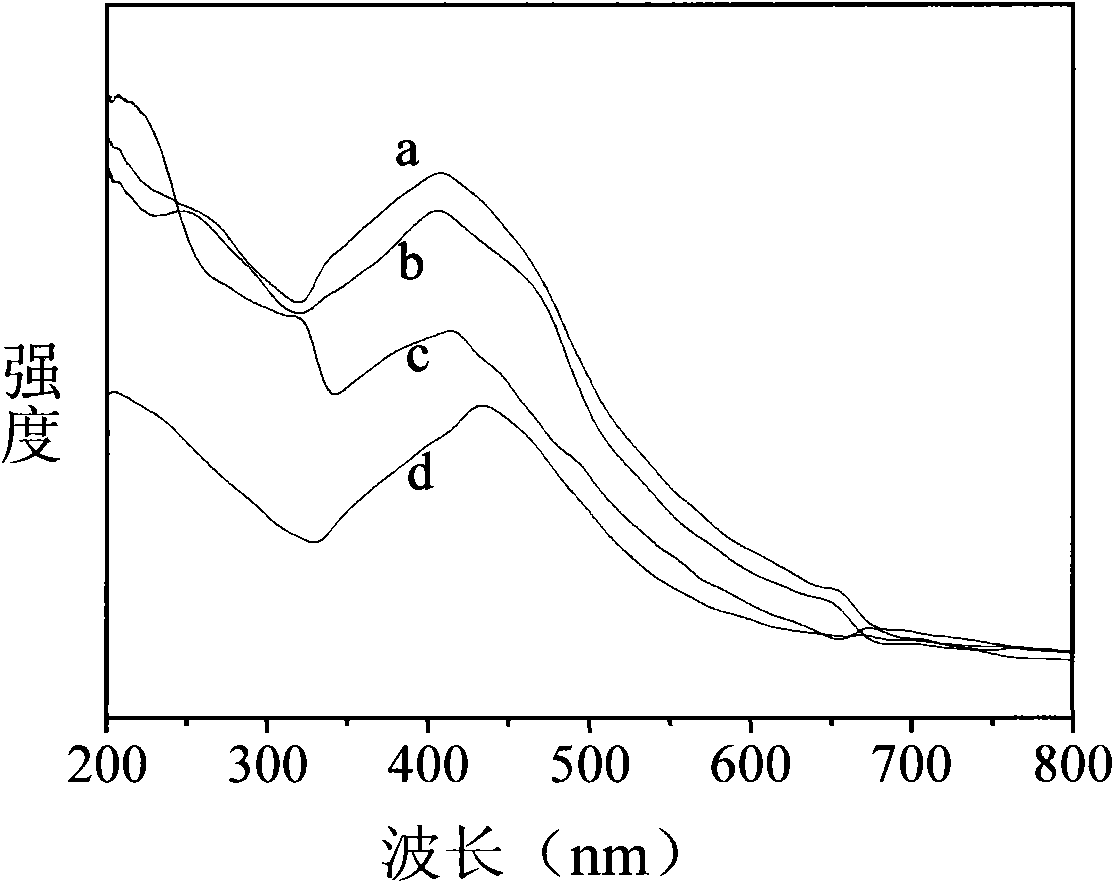

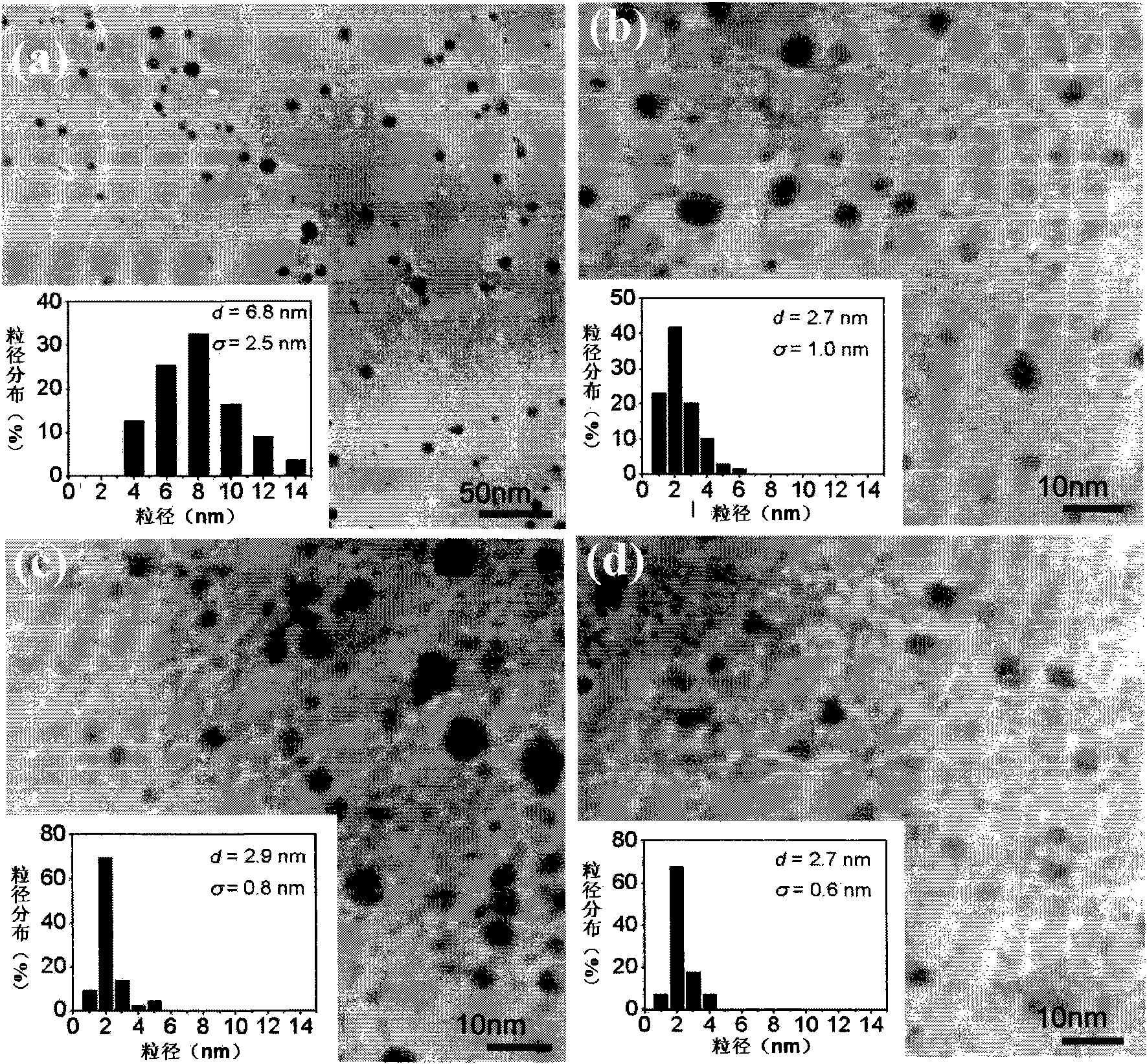

Method for in-situ preparation of silver nanoparticles loaded on natural cellulose sheet

ActiveCN101624798ASmall particle sizeNarrow particle size distributionMetal coatingsCelluloseNatural fiber

The invention belongs to the technical field of nanometer material preparation and particularly relates to a method for the in-situ preparation of silver nanoparticles loaded on a natural cellulose sheet. In the method, natural fibers which are rich in natural world and serve as a template are subjected to soak in aqueous solution of silver nitrate, rinse by solution of absolute ethanol, soak in aqueous solution of sodium borohydride for reduction, rinse by high-purity deionized water and other processes to form the silver nanoparticles loaded on natural cellulose sheet in situ. Compared with the conventional product of silver nanoparticles loaded in situ, the product prepared by the method has the advantages that: 1, the particle size of the prepared silver nanoparticles is small and the particle size distribution of the prepared silver nanoparticles is narrow; 2, the natural cellulose sheet adopted as a loading substrate is low in cost and environmentally friendly; and 3, the preparation process can be carried out at normal temperature without any protective agent and stirring facilities, so the preparation technology is simple. Due to the excellent performance of the silver nanoparticles, the product has great application values in aspects such as antibiosis, catalysis and signal enhancement.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation process of laser golden vacuum aluminized paper and transfer coating used for preparation process

ActiveCN102864683AImprove the level of green environmental protectionSave energyCoatings with pigmentsCoatingsEmulsionAcrylic resin

The invention discloses a preparation process of laser golden vacuum aluminized paper and a transfer coating used for the preparation process. The transfer coating consists of solvent type acrylic resin emulsion, paint type color paste and a solvent including n-propyl ester and butanone, wherein the color type color paste comprises color paste yellow and color paste red; the mass ratio of the solvent type acrylic resin emulsion to the color paste yellow to the color paste red is (9-11): (0.8-1.2): (0.08-1.2); the mass ratio of the solvent type acrylic resin emulsion to the solvents is 100: (1.5-2.5); the mass ratio of the n-propyl ester to the butanone in the solvent is (0.5-1.5): (0.5-1.5); the transfer coating is uniformly coated on a transfer transparent base film to form a uniform and compact transfer coating and then a continuous bright metal aluminum layer is plated to form a transfer film; the transfer film is adhered to bottom paper by using a transfer adhesive; the base film is separated from the paper sheet, so that only are the transfer adhesive, the aluminum layer and the coating remained on the surface of the paper sheet; and the stripped base film can be newly coated and reutilized. According to the preparation process, the process cost can be effectively reduced, and the displacement of VOC (Volatile Organic Compounds) is reduced.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

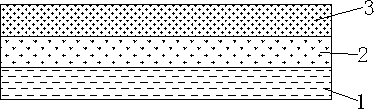

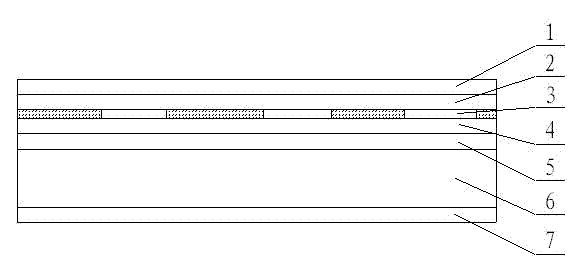

Vacuum-coated aluminum paper having false-proof hologram pattern and method for making same

InactiveCN101135124AHigh degree of moldingHigh glossSpecial paperPaper/cardboardAluminum coatingMaterials science

The present invention is vacuum aluminum plating paper with anti-fake holographic pattern and its making process, and belongs to the field of aluminum plating paper making technology. The vacuum aluminum plating paper comprises one paper base and one primary coating, one aluminum coating, one bright coating and one characterized anti-fake holographic pattern layer successively on the paper base. Its making process includes the following steps: sorting paper base, painting the primary coating, vacuum plating aluminum to form the aluminum coating, painting the bright coating, loading the anti-fake holographic pattern layer, rehumidifying, embossing, cutting, printing, etc. The vacuum aluminum plating paper with anti-fake holographic pattern has bright pattern and optional laser anti-fake effect and relatively simple production process.

Owner:YANTAI BOYUAN TECH MATERIALS

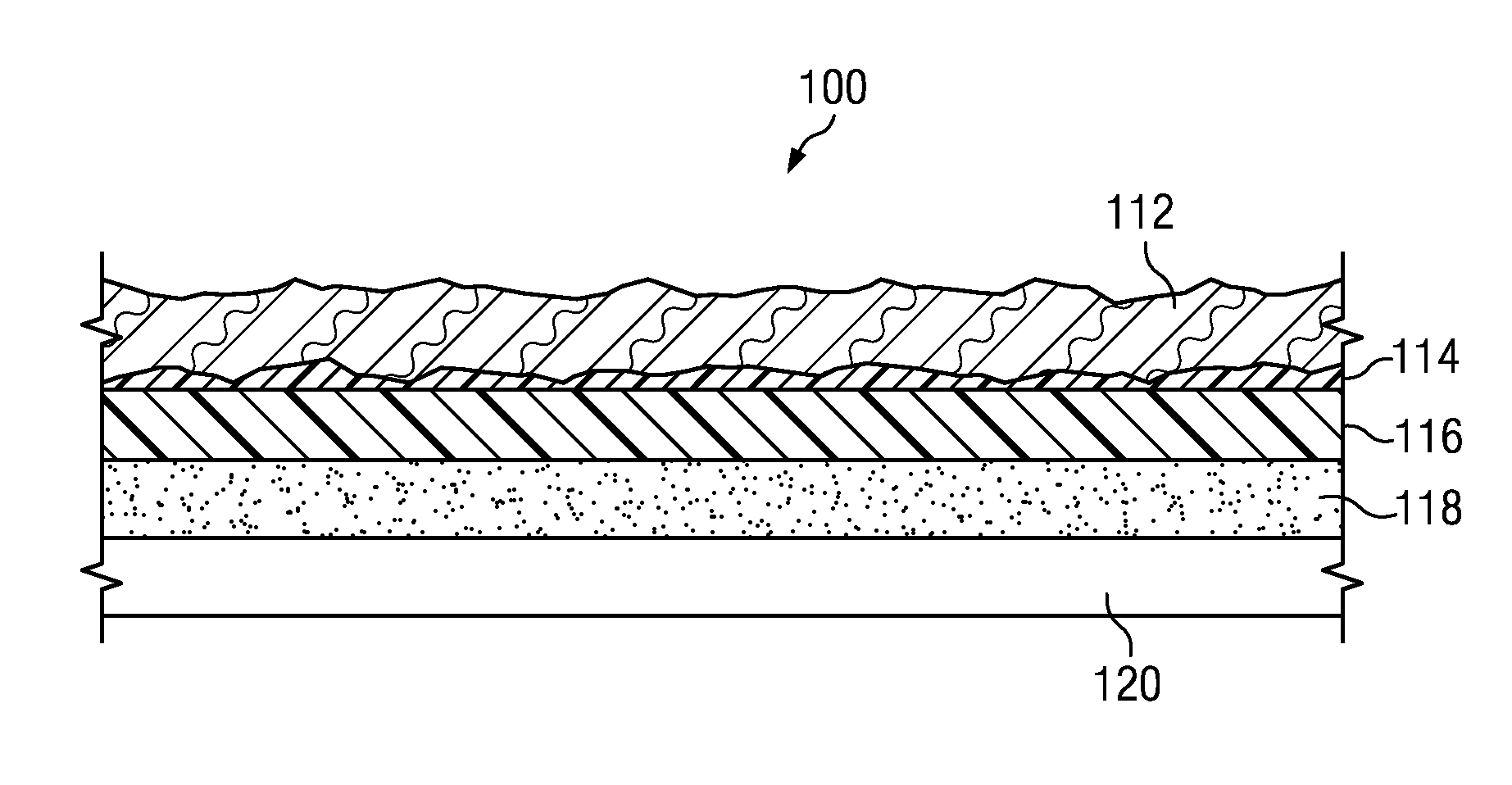

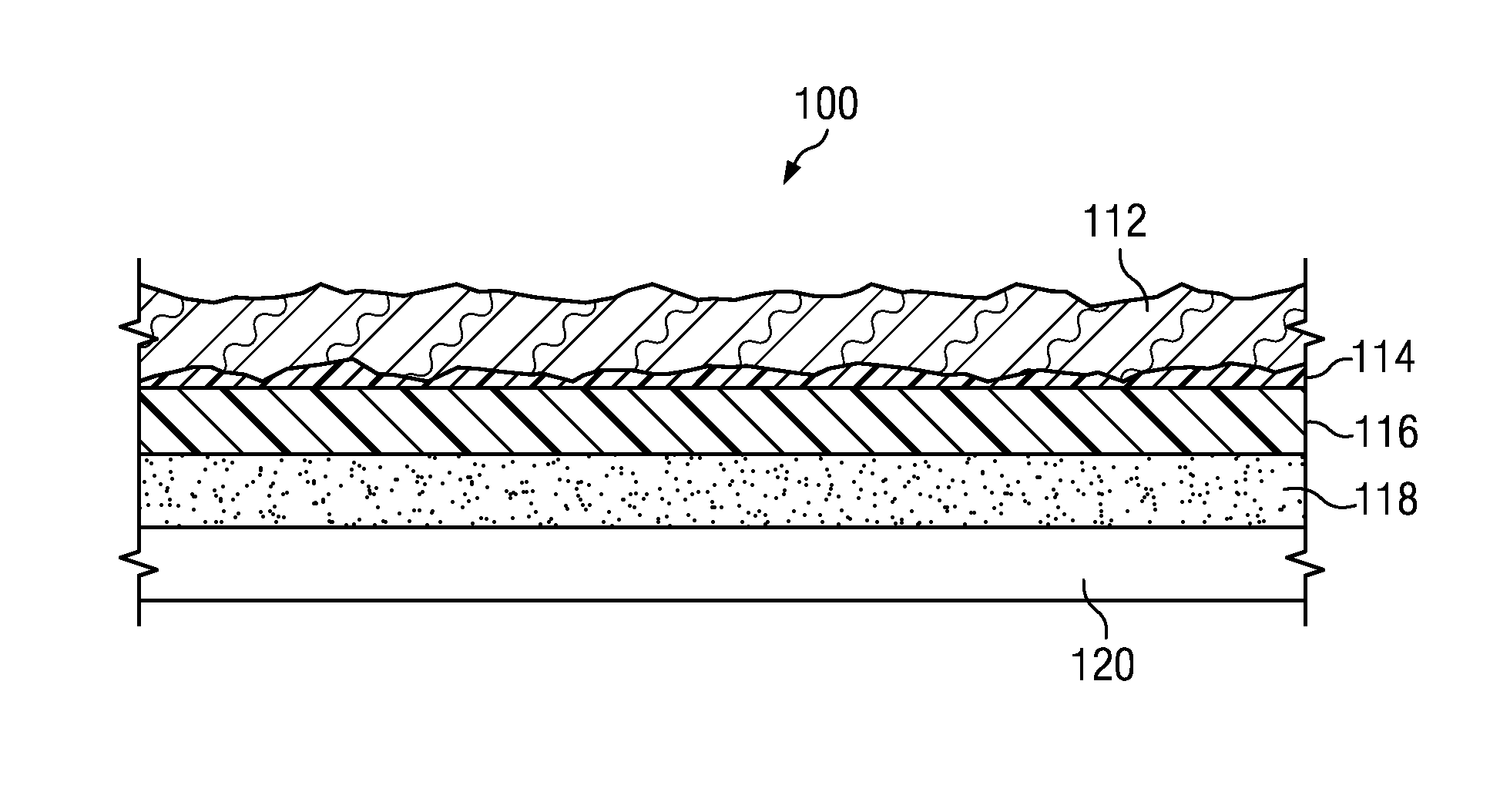

Metallized paper packaging film and process for its production

InactiveUS20130101831A1Coatings with pigmentsSynthetic resin layered productsPulp and paper industry

A multi-layer paper-based packaging material is provided that has adequate barrier properties. At least one surface of the paper is smoothed and then a barrier layer is applied. The paper can also include optional primer and heat-seal layers.

Owner:FRITO LAY NORTH AMERICA INC

Method for producing laser hologram lining paper for cigarette packaging

The invention aims at providing a method for producing direct transfer laser hologram lining paper, which can be used for obtaining fine and clear laser patterns and comprises the following steps of: performing laser hologram mold compression and vacuum aluminizing on a BOPP (Biaxially-Oriented Polypropylene) film, coating a coating layer on the aluminized layer, stripping out the BOPP film after the coating layer is compounded with original paper through rolling, and coating gloss oil. Through the method, the technical process is simplified, the pure aluminum foil layer in the common laser hologram lining paper is omitted, and the adhesive is compounded by using a dry method. Compared with the compounding of common laser aluminum foil, the use amount of metal aluminum and the adhesive is omitted, and the energy consumption and the production cost are reduced. By using water-based back paint and surface paint, the harm of auxiliaries remained in the raw paint to the environment and human bodies is eliminated, the stripped BOPP film can be reused, and another mold compression of laser hologram patterns is not required.

Owner:SHANTOU XINDA COLOR PRINTING PACKAGING MATERIALS

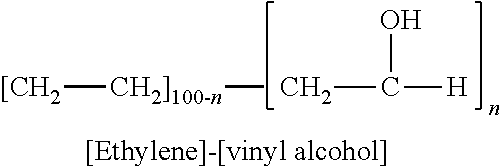

High-gloss paint for vacuum aluminized paper and preparation method and application thereof

ActiveCN102174775AHigh glossImprove wear resistanceCoatingsMetal coatingsAcrylic resinPolyvinyl alcohol

The invention provides high-gloss paint for vacuum aluminized paper and a preparation method and application thereof. The high-gloss paint comprises the following components in parts by weight: 0.5-2.0 parts of hydroxyl acrylate resin, 2-10 parts of polyvinyl alcohol, 5-35 parts of acrylic resin, 0.5-15 parts of neutralizer, 100 parts of acrylate resin, 0.1-1.0 part of defoaming agent, 0.2-0.8 part of flatting agent and 500-1000 parts of water. As for the prepared high-gloss paint for treatment of vacuum aluminized paper, the solid weight content is 15-40%, and the pH value is 5-8. Besides, the high-gloss paint can effectively overcome the disadvantages of the existing process, so that the gloss, abrasive resistance and storage stability of the paint are greatly improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Heat-resistance type transfer aluminum plated paper and its producing process

InactiveCN101050605AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveHeat resistance

The present invention relates to a temperature-resistant type transfer aluminized paper and its production process. Said process successively includes the following steps: coating release layer on the film; coating anchoring layer on release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer; then making them be combined with paper; stripping film from release layer so as to obtain the invented temperature-resistant type transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

Production technology for laser hollow-out aluminized paper

InactiveCN104532668AReduce usagePrevent volatilizationDecorative surface effectsCoatingsInformation layerMetallic aluminum

The invention relates to a production technology for laser hollow-out aluminized paper. The technology comprises: coating a base membrane containing a laser information layer with a low-surface-tension coating containing picture and text, performing vacuum aluminizing, depositing a metal aluminium layer on the place without being coated with the low-surface-tension coating, then combining with paper, and peeling, so as to obtain the aluminized paper containing the laser information and hollow-out picture and text. The production technology is simple, high in production efficiency and low in cost, and the production process is relatively beneficial for environment protection. The picture and text on the laser hollow-out aluminized paper produced by the technology is capable of replacing a part of picture and text needing printing at a later period, and the laser hollow-out aluminized paper can be used as an exquisite packaging material after being subjected to simple bar code printing, gold stamping and die cutting. The technology helps to substantially reduce usage of printing ink, avoid evaporation of a large amount of organic solvents, reduce volatile organic compound residual quantity of printed matters, and enable the packaging material to be relatively environment-friendly and safe and enhanced in anti-fake property.

Owner:YANTAI BOYUAN TECH MATERIALS

Die pressing coating capable of being transferred onto composite metal surface and laser film comprising die pressing coating

InactiveCN102912673AAvoid deformationImprove compactnessCoatingsCoatings without pigmentsCelluloseAcrylic resin

The invention discloses a die pressing costing capable of being transferred onto a composite metal surface. The die pressing costing comprises 6-10% of cellulose acetate butyrate, 4-8% of acrylic resin, 2-6% of nitrocotton liquid, 25-35% of butanone, 10-20% of propylene glycol monomethyl ether and 28-32% of ethyl acetate, and is 1.3-1.5 micrometers in thickness. The die pressing coating is compact in surface, not easy to erode by solvent utilized in follow-up processing, suitable in strength for die pressing, good in stripping, and particularly suitable for being transferred onto an aluminum foil surface of composite aluminum foil paper to be colored and embossed after the die pressing, so that the composite aluminum foil paper with laser effect can be obtained. The invention further provides a laser film comprising the die pressing coating. The laser film comprises a basic film, and the die pressing coating which is provided with laser patterns after die pressing treatment is coated on the basic film, and a vacuum aluminum coated layer is arranged on the die pressing coating. The composite aluminum foil paper with bright, smooth and massive laser effect can be obtained by compositing the laser film with the composite aluminum foil paper and peeling the same off, and the process is easy to control.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH +1

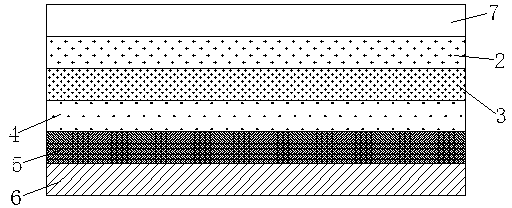

Transfer hollow-out-out sprayed metallic paper or card paper and production process thereof

InactiveCN102535258AHighlight the packaging effectHighlight the noble packaging effectSpecial paperPaper/cardboardAdhesive gluePlastic film

The invention discloses a piece of transfer hollow-out sprayed metallic paper or card paper which is characterized by sequentially comprising a strippable coating (2), a hollow-out sprayed metallic layer (3), a glue layer (4) and a piece of paper (6) from top to bottom; and besides the four layers, the transfer hollow-out metalized paper also can comprise any one or more of a surface coating (bright oil layer) (1), a coloring layer (5) and a back coating (7). In the invention, through adopting a relief printing process principle, a low-surface tension coating which contains pre-designed patterns and / or characters is printed on a plastic film which is coated with the strippable coating; then vacuum spraying is carried out to obtain a metallic layer which cannot be deposited on the low-surface tension coating and can be deposited on other places without the low-surface tension coating coated; the hollow-out metallic layer is composited with the paper by use of glue; and the plastic film is processed by resurgence or back coating after being stripped to obtain the sprayed metallic paper or card paper with hollow-out patterns and / or characters.

Owner:YANTAI BOYUAN TECH MATERIALS

Packing paper with micro-sign for cigarette and producing method thereof

ActiveCN101168943AImprove identification rateBright metal textureSpecial visual effect coatingsFlexible coversCigarette usePulp and paper industry

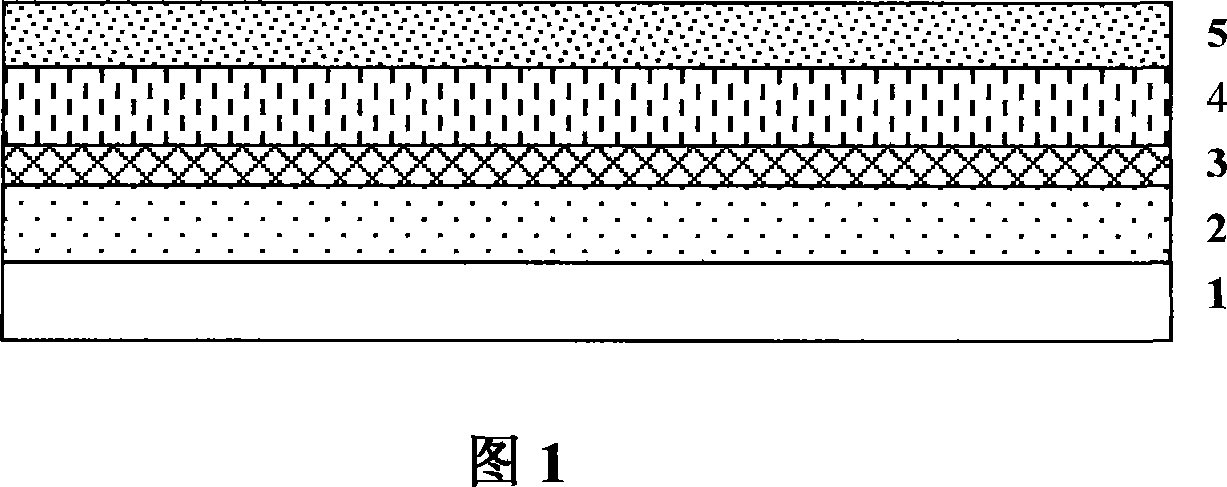

The invention relates to cigarette packing tipping paper, in particular to a production method of a cigarette-purpose tippling paper with a laser microfilm anti-counterfeit sign. The tipping paper comprises a bottom layer, a binding layer, an aluminum coating, a surface coating and a printing layer which are mutually compounded in sequence, wherein, a microfilm anti-counterfeit sign composed of a microfilm character or a RMB paper money line is arranged on a surface coating, and the size of the microfilm anti-counterfeit sign can reach 0.2 mm. The invention has the production method of the cigarette-purpose tipping paper with the microfilm anti-counterfeit sign that a strippable surface coating is coated on a high molecule light film in advance, and then the laser microfilm anti-counterfeit sign which forms an aluminum transferring film after vacuum aluminum coat is molded and is compounded with the original paper, then various patterns are printed after uncovering the light film, and therefore the cigarette-used tippling paper with the laser microfilm anti-counterfeit sign can be obtained. The product of the invention has nicer anti counterfeit performance.

Owner:JIANGSU DAYA NEW PACKAGING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com