Prepreg containing aromatic synthetic fiber paper and printed circuit board manufactured from same

A technology of synthetic fibers and prepregs, applied in printed circuits, printed circuits, printed circuit components, etc., can solve problems such as unstable bonding of fiber paper and substrate size changes, and achieve good processing performance, high temperature resistance, and thermal stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare the present embodiment 1 synthetic fiber paper in the following proportions:

[0037] Aramid 1414 fiber (5-6mm) 80 parts by weight (hereinafter referred to as "parts")

[0038] Aramid 1414 precipitated fiber 20 parts

[0039]The aramid 1414 fiber with the above content is decomposed into pulp A at a concentration of 1% by weight in a hydropulper, and the 1414 precipitated fiber is decomposed in a hydropulper at a concentration of 2%, and the beating degree is controlled by grinding and beating About 75° SR, make slurry B. After the slurry A and the slurry B are uniformly mixed in the batching tank to form papermaking pulp that can be added to the headbox of the papermaking wire, 5 parts of polyethylene oxide are added to the pulp stabilization box. The head of the slurry on the net is adjusted by the stock stabilizing box, and the slurry is evenly distributed on the paper forming wire in the headbox, and the excess slurry is overflowed to the white water pool....

Embodiment 2

[0043] Prepare the present embodiment 2 fiber papers in the following proportions:

[0044] Aramid 1414 fiber (5 ~ 6mm) 20 parts

[0045] Aramid 1414 precipitated fiber 80 parts

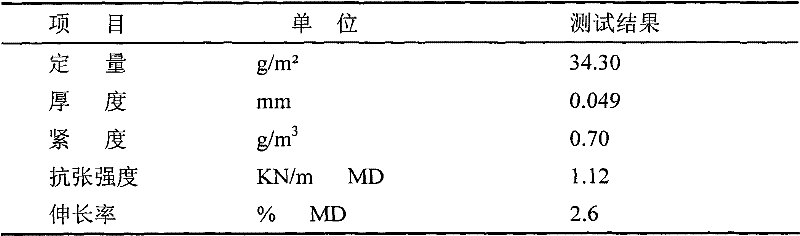

[0046] This embodiment adjusts the consumption of aramid 1414 fiber and fibrid, the preparation method of fiber paper is the same as that of Example 1, and the results obtained are shown in Table 2:

[0047] Table 2 Physical and mechanical properties of fiber paper

[0048]

[0049]

Embodiment 3

[0051] Prepare the present embodiment 3 fiber papers in the following proportions:

[0052] Aramid 1414 fiber (5 ~ 6mm) 70 parts

[0053] Aramid 1414 precipitated fiber 30 parts

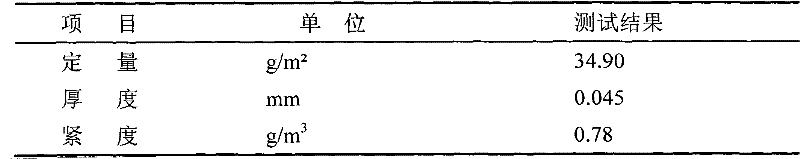

[0054] This embodiment adjusts the consumption of aramid 1414 fiber and fibrid, the preparation method of fiber paper is the same as that of Example 1, and the results obtained are shown in Table 3:

[0055] Table 3 Physical and mechanical properties of fiber paper

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com