Transfer hollow-out-out sprayed metallic paper or card paper and production process thereof

A metal spraying and production process technology, applied in the field of packaging materials and decorative materials, to achieve the effect of reducing residues, reducing usage, and avoiding the volatilization of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

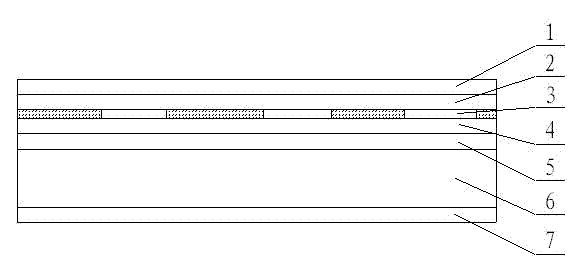

[0040] Example 1 A production process of transfer hollowed-out aluminum-coated paper

[0041] The hollow pattern of this embodiment is attached figure 2 In the five-pointed star pattern shown, the color of the hollowed-out five-pointed star is the original white of the paper.

[0042] Implementation steps:

[0043] (1) Design the size and position of the five-pointed star pattern according to the needs, and laser engrave the designed five-pointed star on the resin roller to make a five-pointed star pattern positive image resin roller.

[0044] (2) Coating a peelable coating on the PET plastic film, heating and drying the coating.

[0045] (3) Using the principle of letterpress printing, on the peelable coating, use a five-pointed star positive pattern resin roller and a 200-mesh mesh ceramic roller to print a layer of fluorine oil on the five-pointed star position.

[0046] (4) Send the PET plastic film containing the strippable coating and the fluorine oil layer into th...

Embodiment 2

[0051] Example 2 A Production Process of Sprayed Aluminum Cardboard Containing Green Hollow Text

[0052] The hollow pattern of this embodiment is attached image 3 As shown in the text, the color of the hollow text is green.

[0053] Implementation steps:

[0054] (1) Design the size and position of the text according to the needs, laser engrave the designed text on the resin roller, and make an attached image 3 The text pattern shown is a positive image resin roll.

[0055] (2) Coating a peelable coating on the BOPP plastic film, heating and drying the coating.

[0056] (3) Using the principle of letterpress printing, on the peelable coating, use a positive image resin roller and a 220-mesh mesh ceramic roller to print a layer of silicone oil on the text position.

[0057] (4) Send the BOPP plastic film containing the peeling layer and silicone oil coating to the vacuum spraying aluminum system for aluminum spraying, and deposit a very thin layer of aluminum on the pe...

Embodiment 3

[0063] Example 3 A production process of wear-resistant spray-coated aluminum cardboard containing green hollow text

[0064] The hollow pattern of this embodiment is attached image 3 As shown in the text, the color of the hollow text is green.

[0065] Implementation steps:

[0066] (1)~(7) are identical with embodiment 2 steps (1)~(7),

[0067] (8) The cardboard obtained in step (7) is coated with a layer of water-based varnish topcoat on the aluminum layer with a 250-mesh screen roller, and heated and dried to obtain a coating with strong scratch resistance and wear resistance. The varnish component is water-based polyurethane modified acrylic resin, or other commercially available resin coatings that can achieve the same effect.

[0068] (9) The cardboard obtained in step (8) is coated with a water-soluble modified starch coating on the back of a 150-mesh screen roller, heated to regulate the moisture content of the cardboard, and the water absorption / release balance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com