Production technology for laser hollow-out aluminized paper

A production process and technology of aluminized paper, which is applied in the process of producing decorative surface effects, papermaking, paper coatings, etc., can solve the problems of complex preparation method of laser hollow aluminized paper, low overall production efficiency, environmental pollution, etc. To achieve the effect of novel and beautiful appearance, strong anti-counterfeiting effect and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

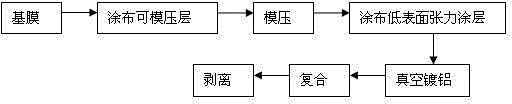

Image

Examples

Embodiment 1

[0026] Example 1 A production process of laser hollowed aluminized paper

[0027] Implementation steps:

[0028] (1) Coat the moldable coating on the surface of the PET film with a 200-mesh wire roller at a speed of 100m / min on the coating machine, and dry the coated PET film in a hot oven at a temperature of 80-150°C to form a film , the film is a moldable coating.

[0029] (2) Use a molding machine at a speed of 40m / min and a molding temperature of 130°C to imprint and transfer the laser information on the holographic nickel plate with a three-dimensional pattern to the moldable coating, step 1] of the moldable coating Become a laser information layer.

[0030] (3) Use a positive image resin roller with a diamond pattern and a 250 mesh ceramic roller to coat a layer of fluorine oil on the position of the diamond pattern on the laser information layer as a low surface tension coating.

[0031] (4) Send the PET film containing the laser information layer and the fluorine ...

Embodiment 2

[0036] Example 2 A Production Process of Sprayed Aluminum Cardboard Containing Red Hollow Text

[0037] Implementation steps:

[0038] (1) Coat the moldable coating on the surface of the PET film with a 220-mesh wire roller at a speed of 110m / min on the coating machine, and dry the coated PET film in a hot oven at a temperature of 80-150°C to form a film , the film is a moldable coating.

[0039] (2) Using a molding machine at a speed of 50m / min and a molding temperature of 120°C, imprint and transfer the laser information on the nickel plate to the moldable coating; the moldable coating in step 1] becomes the laser information layer.

[0040] (3) Design the size and position of the text according to the needs, and laser engrave the designed running script "Boyuan" on the resin roller to make a positive image resin roller; on the laser information layer, use the positive image resin roller and 250 Mesh wire ceramic roller is coated with a layer of silicone oil as a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com