Vacuum-coated aluminum paper having false-proof hologram pattern and method for making same

A technology of vacuum aluminized paper and holographic pattern, which is applied in the direction of paper, papermaking, special paper, etc., can solve the problems that cannot meet the requirements of high-end anti-counterfeiting packaging, the rough and porous paper surface cannot be effectively covered, and the mirror reflection is not high. The effect of eliminating rough and porous phenomena, overcoming long production processes, and saving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

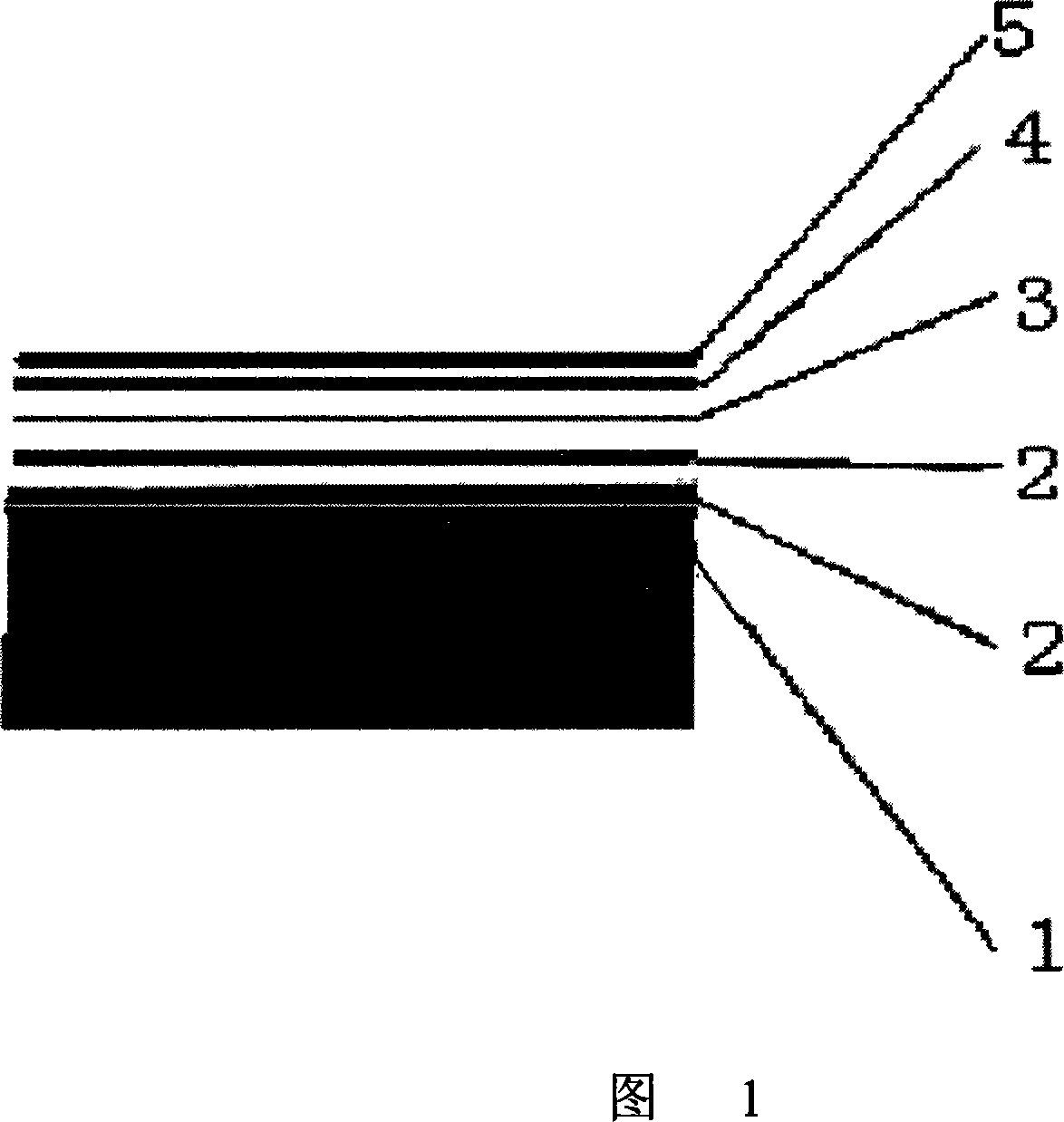

[0027] With reference to Fig. 1, this embodiment is an improvement on the existing vacuum direct aluminum plating technology. The vacuum aluminum-coated paper with anti-counterfeit holographic pattern includes a base coat 2 on the paper base 1, and an undercoat layer 2 on the base coat 2. It is an aluminum-plated layer 3, on which is a glossy coating 4, and its special feature is that a layer of laser anti-counterfeiting holographic pattern coating 5 is provided on the glossy coating 4 by hot pressing, and the anti-counterfeiting holographic laser pattern coating 5 is Laser anti-counterfeiting holographic information pattern coating obtained by hot pressing or cold pressing process, the base coat 2 is 1.0-3.0 g / m2, the thickness of the aluminized layer 3 is 0.02-0.04 microns, and the glossy coating 4 is 1.5-3.0 grams per square meter, the thickness of the anti-counterfeiting holographic pattern coating 5 is 0.01-0.03 microns;

[0028] The preparation method of the vacuum alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com