Packing paper with micro-sign for cigarette and producing method thereof

A technology for cigarette tipping paper and a production method, which is applied in the directions of wrapping paper, wrapping paper, special paper, etc., can solve the problems of reducing the production efficiency of tobacco products, the inability to achieve high-precision tipping paper, and the inability of the tipping paper to meet the requirements. , to achieve the effect of brilliant colors, fully guaranteed anti-counterfeiting functions, and clear and fine anti-counterfeiting patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

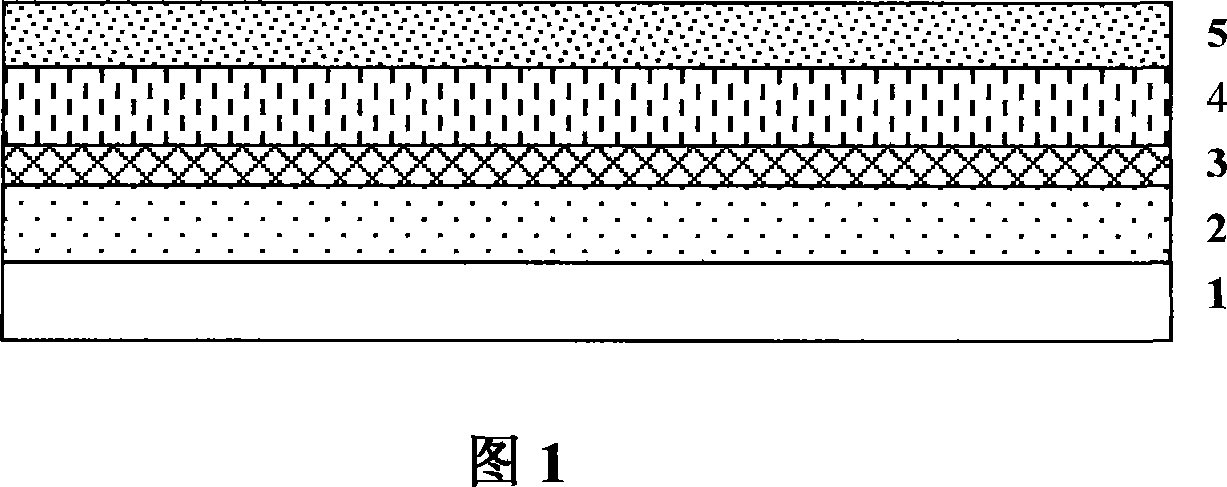

[0017] The present embodiment produces cigarette tipping paper with laser miniature marks as shown in the accompanying drawings, and the specific steps are as follows:

[0018] a. Coating: Use PET film as the base material, and evenly coat cellulose acetate butyrate and nitrocellulose materials on the base material, and the usage amount is 0.8~1.5g / m 2 , to be dried and solidified to form a strippable transparent surface coating 4 with a thickness of 0.5-1.0 μm;

[0019] b. Plate making: holographic photography is adopted, laser engraving is used to make templates, and there are miniature characters and RMB banknote patterns on the templates, and the size of the miniature characters is 0.2mm;

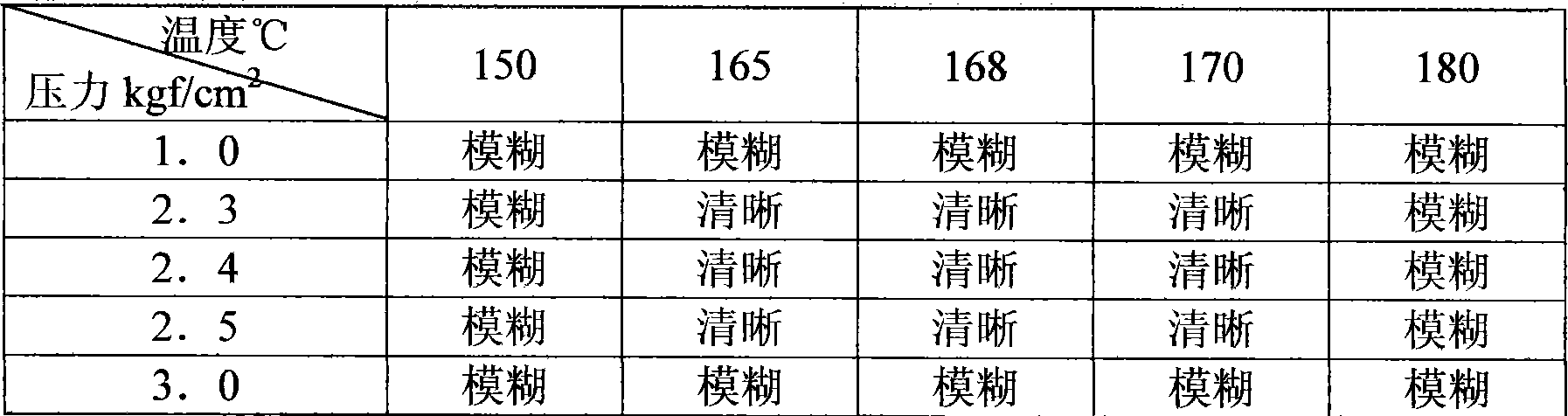

[0020] c. Molding: heating the plate roller to the molding temperature, and embossing the miniature version on the template to the surface coating 4 under the molding pressure so that the surface coating 4 has a miniature anti-counterfeiting mark with the same pattern as the template; m...

Embodiment 2

[0026] This embodiment produces the tipping paper for cigarettes with laser miniature marks as shown in the accompanying drawings. The specific steps are the same as those described in Embodiment 1, and only the two process parameters of molding temperature and molding pressure are changed. Molding temperature: 168°C; Molding pressure: 2.4kgf / cm 2 .

[0027] The image definition, an important index of molding quality, is used to judge the produced cigarette tipping paper. The detection method is the same as in Example 1. The imaging definition of the miniature anti-counterfeiting mark is good, and the miniature anti-counterfeiting mark is complete and clear.

Embodiment 3

[0029] This embodiment produces the tipping paper for cigarettes with laser miniature marks as shown in the accompanying drawings. The specific steps are the same as those described in Embodiment 1, and only the two process parameters of molding temperature and molding pressure are changed. Molding temperature: 170°C; Molding pressure: 2.5kgf / cm 2 .

[0030] The image definition, an important index of molding quality, is used to judge the produced cigarette tipping paper. The detection method is the same as in Example 1. The imaging definition of the miniature anti-counterfeiting mark is good, and the miniature anti-counterfeiting mark is complete and clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com