Environmentally-friendly aqueous matte aluminized paper undercoating paint and preparation method as well as application thereof

A kind of aluminized paper, environment-friendly technology, applied in the direction of paper coating, coating, papermaking, etc., can solve the problems of poor surface flatness, no matte effect of direct-coated paper, constraints, etc., to achieve good wear resistance and pressure resistance , increase the effect of matte effect, wear resistance and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of an environment-friendly water-based matte aluminized paper primer, the method comprising the following steps:

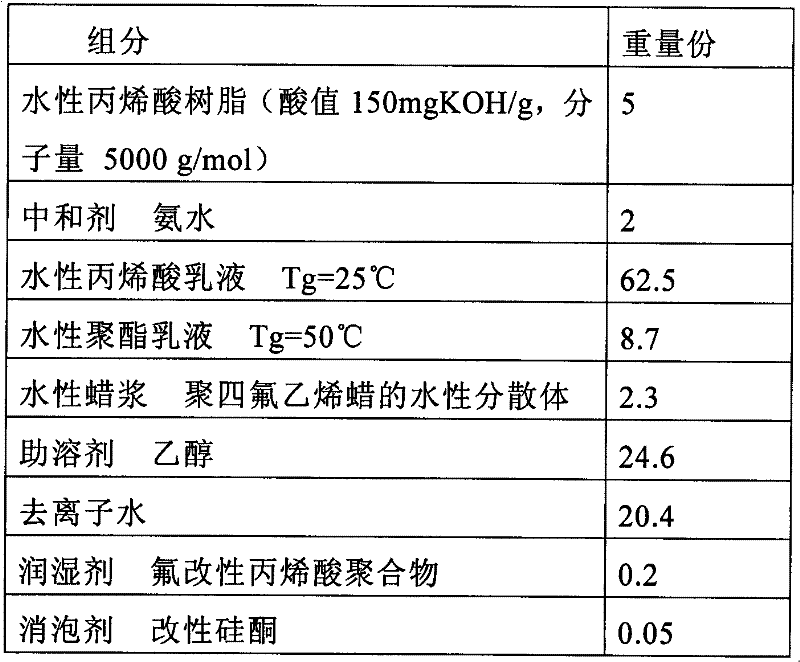

[0050] (1) Prepare materials according to the following components and content (parts by weight):

[0051]

[0052] (2) An acrylic resin, a neutralizing agent, and 12.1 parts of water were mixed, and the temperature was raised to 60° C. to obtain an aqueous acrylate resin solution.

[0053] (3) Put the acrylate aqueous solution, acrylic acid emulsion, water-based polyester emulsion, and water-based wax slurry prepared in (2) into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0054] (4) After mixing the co-solvent and the remaining deionized water evenly, add it to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0055] (5) Add a wetting agent into the reaction kettle, stir at a medium speed of 700-800 rpm for 10-20min;

[0056] (6) Add a defoamer to the reaction ...

Embodiment 2

[0058] A preparation method of an environment-friendly water-based matte aluminized paper primer, the method comprising the following steps:

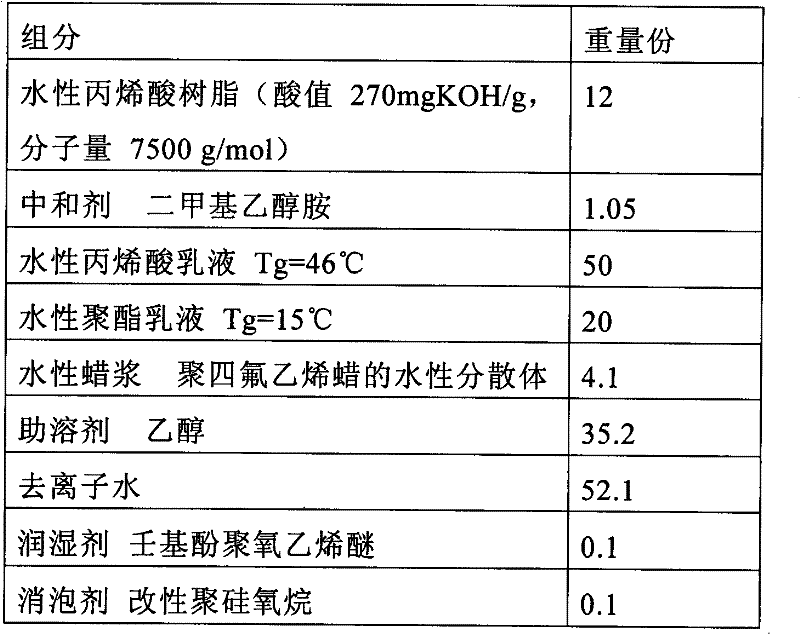

[0059] (1) Prepare materials according to the following components and content (parts by weight):

[0060]

[0061] (2) Mix an acrylic resin, a neutralizing agent, and 42.5 parts of water, and heat up to 60° C. to obtain an aqueous acrylate resin solution.

[0062] (3) Put the acrylate aqueous solution, acrylic acid emulsion, water-based polyester emulsion, and water-based wax slurry prepared in (2) into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0063] (4) After mixing the co-solvent and the remaining deionized water evenly, add it to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0064] (5) Add a wetting agent to the reaction kettle, stir at a medium speed of 700-800 rpm for 10-20min;

[0065] (6) Add a defoamer to the reaction kettle, stir at a high speed...

Embodiment 3

[0067] A preparation method of an environment-friendly water-based matte aluminized paper primer, the method comprising the following steps:

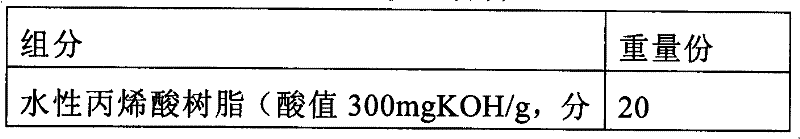

[0068] (1) Prepare materials according to the following components and content (parts by weight):

[0069]

[0070]

[0071] (2) An acrylic resin, a neutralizing agent, and 53.8 parts of water were mixed, and the temperature was raised to 70° C. to obtain an aqueous acrylate resin solution.

[0072] (3) Put the acrylate aqueous solution, acrylic acid emulsion, water-based polyester emulsion, and water-based wax slurry prepared in (2) into the reaction kettle, and stir evenly at a low speed of 300-500 rpm;

[0073] (4) After mixing the co-solvent and the remaining deionized water evenly, add it to the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0074] (5) Add a wetting agent into the reaction kettle, stir at a medium speed of 700-800 rpm for 10-20min;

[0075] (6) Add a defoamer to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com