Matte photosensitive resin for photocuring quick molding and preparation method thereof

A matte photosensitive and photocuring technology, applied in the field of 3D printing, can solve the problem of no matte photosensitive resin, and achieve the effect of large-scale popularized production, easy operation, low process conditions and production equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

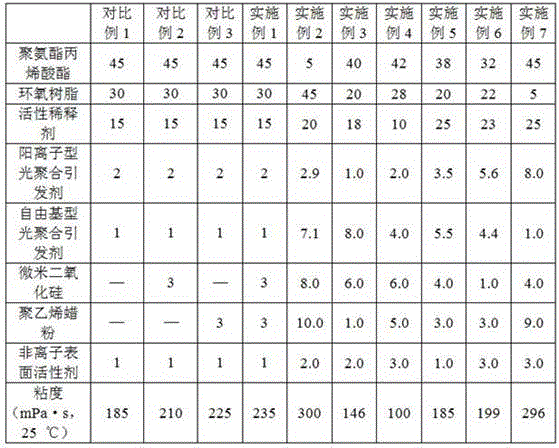

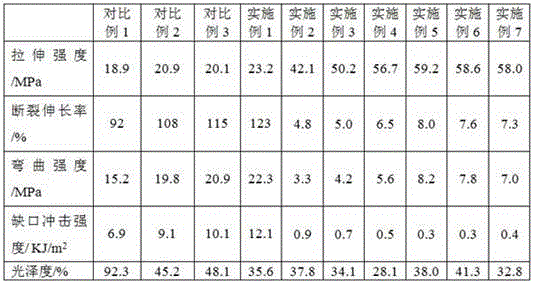

Embodiment 1

[0042] The matte photosensitive resin for photocuring rapid prototyping of the present embodiment is made of the following raw materials: 45 parts of polyurethane acrylate, epoxy resin (3,4-epoxy-6-methylcyclohexylcarboxylic acid- 3',4'-epoxy-6'-methylcyclohexyl methyl ester) 30 parts, reactive diluent (tripropylene glycol diglycidyl ether diacrylate) 15 parts, cationic photopolymerization initiator (diaryl iodonium hexafluorophosphate) 2 parts, free radical photopolymerization initiator (benzoin dimethyl ether) 1 part, micron silicon dioxide 3 parts, polyethylene wax powder 3 parts, nonionic surfactant (fatty alcohol polyoxygen Vinyl ether) 1 part.

[0043] The preparation method of the light-curing rapid prototyping matte photosensitive resin of the present embodiment is as follows:

[0044] According to the weight ratio, first stir the micron silica, polyethylene wax powder and nonionic surfactant, and then add the remaining polyurethane acrylate, epoxy resin, active dilue...

Embodiment 2

[0046] The matte photosensitive resin for photocuring rapid prototyping of the present embodiment is made of the following raw materials: 5 parts of polyurethane acrylate, 45 parts of epoxy resin (aliphatic glycidyl ether epoxy resin), reactive diluent ( Ethylene glycol diglycidyl ether diacrylate) 20 parts, cationic photopolymerization initiator (triarylsulfonium hexafluorophosphate) 1.0 parts, radical photopolymerization initiator (chlorinated benzophenone) 8 parts , 10 parts of micron silicon dioxide, 1 part of polyethylene wax powder, 2 parts of nonionic surfactant (polyoxyethylene sorbitan monostearate).

[0047] The preparation method of the light-curing rapid prototyping matte photosensitive resin of the present embodiment is as follows:

[0048] According to the weight ratio, first stir the micron silica, polyethylene wax powder and nonionic surfactant, and then add the remaining polyurethane acrylate, epoxy resin, active diluent, cationic photopolymerization initiator...

Embodiment 3

[0050] The matte photosensitive resin for photocuring rapid prototyping of the present embodiment is made of the following raw materials: 40 parts of polyurethane acrylate, 20 parts of epoxy resin (aliphatic glycidyl ether epoxy resin), reactive diluent ( Ethylene glycol diglycidyl ether diacrylate and tripropylene glycol diglycidyl ether diacrylate) 18 parts, cationic photopolymerization initiator (diaryliodonium hexafluorophosphate) 1 part, radical photopolymerization initiator 8 parts of agent (1-hydroxycyclohexyl benzophenone), 6 parts of micron silicon dioxide, 1 part of polyethylene wax powder, non-ionic surfactant (fatty acid methyl ester ethoxylate and polyoxyethylene sorbitan monohard Fatty acid ester) 2 parts.

[0051] The preparation method of the light-curing rapid prototyping matte photosensitive resin of the present embodiment is as follows:

[0052] According to the weight ratio, first stir the micron silica, polyethylene wax powder and nonionic surfactant, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com