Method for preparing holography sputtering internal lining paper

A paper-lined, holographic technology, applied in the direction of machining/deformation, metal coating, special visual effect coating, etc., can solve the problem of poor surface quality, achieve high product quality, simple process steps, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

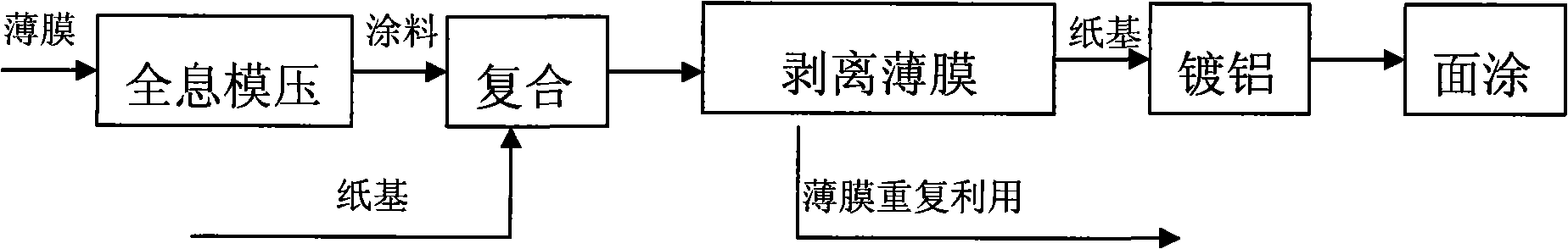

[0029] The preparation method of a kind of holographic direct-plating lining paper in this embodiment refers to figure 1 , is a new process method formed after improving the ordinary vacuum aluminum plating method, including the following processes

[0030] The holographic direct plating lining paper of the present invention comprises the following steps:

[0031] (1) Provide a commercially available polypropylene film (BOPP film) coated with an isolation layer on the surface;

[0032] (2) Carry out laser holographic embossing treatment on the above-mentioned film. The embossing process is to emboss the laser holographic pattern on the surface of the film that is coated with the isolation layer. Copying on the surface of the film coated with the isolation layer, the molding speed is 20-50 m / min;

[0033] (3) Coat a layer of composite adhesive paint on the side of the above film with a holographic layer, and then compound it with the inner lining paper base. The inner lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com