Ultraviolet curing aluminized transferring coating and preparation method and application thereof

A transfer coating and aluminizing technology, applied in paper coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high energy consumption, not getting rid of the influence of harmful solvent volatilization or residual, unfavorable energy saving, etc. The effect of less consumption, lower production cost and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of the above-mentioned UV-curable aluminized transfer coating, that is, adding an initiator and an auxiliary agent into the mixed film-forming material, stirring and dispersing evenly. In a specific implementation, the method that can be adopted includes the following steps:

[0037] Add the acrylate resin to the acrylate monomer and stir evenly, then add the initiator, and stir to make the initiator completely dissolved or evenly dispersed;

[0038] Add additives and continue stirring to disperse the additives evenly.

[0039] According to the above-mentioned preparation method, the operation that can also be adopted is:

[0040] (1) First add the acrylate monomer in the amount of the raw material formula into the batching tank (such as a reaction kettle);

[0041] (2) Add the acrylic resin of the raw material formula amount in the batching tank and stir evenly, then continue to add the initiator, stir to make ...

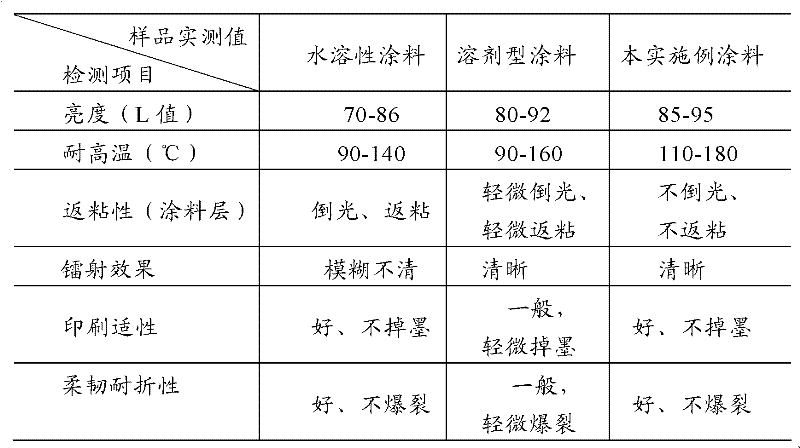

Embodiment 1

[0072] The preparation method of environment-friendly ultraviolet curing aluminized transfer coating comprises the following process steps:

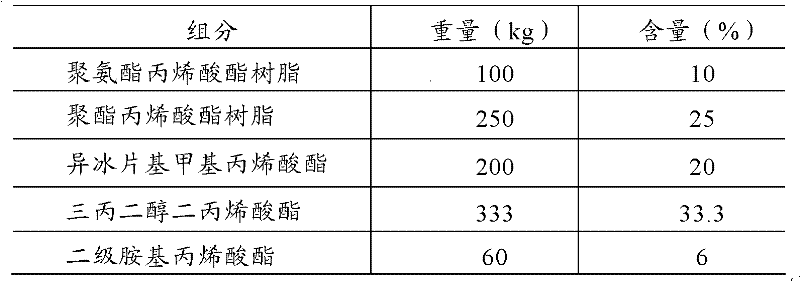

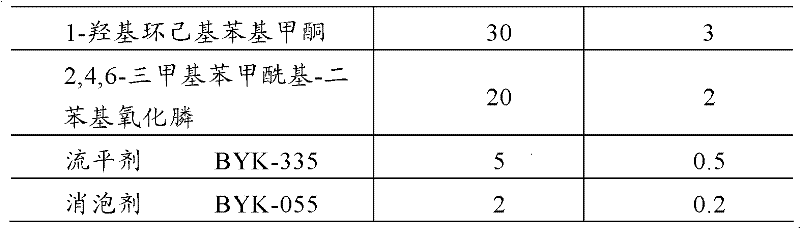

[0073] (1) prepare raw materials according to the following components and content (weight %):

[0074]

[0075]

[0076] Note: Both the leveling agent and the defoamer are commercially available from BYK, Germany, and the following examples are the same.

[0077] Among the above raw materials: polyurethane acrylate resin has a functionality of 2, a viscosity of 800-1000cps (25°C), and a molecular weight of MW n e is 1200, Tg value is 55°C; polyester acrylate resin has a functionality of 3, a viscosity of 1000-1500cps (25°C), and a molecular weight of MW n e It is 820, and the Tg value is 86°C; the viscosity of the secondary amino acrylate is 200-300cps (25°C), and the molecular weight is MW n e 540; the viscosity of isobornyl methacrylate is 15-100cps (25°C); the viscosity of tripropylene glycol diacrylate is 60-150cps (25°C)...

Embodiment 2

[0093] The preparation method of environment-friendly ultraviolet curing aluminized transfer coating comprises the following process steps:

[0094] (1) prepare raw materials according to the following components and content (weight %):

[0095]

[0096]

[0097] Among the above raw materials: polyurethane acrylate resin has a functionality of 2, a viscosity of 800-1000cps (25°C), and a molecular weight of MW n e It is 1500, Tg value is 50°C; polyester acrylate resin has a functionality of 2, a viscosity of 500-1000cps (25°C), and a molecular weight of MW n e is 750, Tg value is 82°C; epoxy acrylate resin has a functionality of 3, a viscosity of 2000-3000cps (25°C), and a molecular weight of MW n e It is 1520, and the Tg value is 110°C; the viscosity of the secondary amino acrylate is 200-300cps (25°C), and the molecular weight is MW n e It is 540; the viscosity of trimethylolpropane triacrylate is 80-250cps (25°C); the viscosity of tripropylene glycol diacrylate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tg value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com