Method for producing laser hologram lining paper for cigarette packaging

A laser holography and production method technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of inability to obtain fine and clear laser patterns, eliminate potential harm to the environment and human body, reduce energy consumption and production Cost, saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

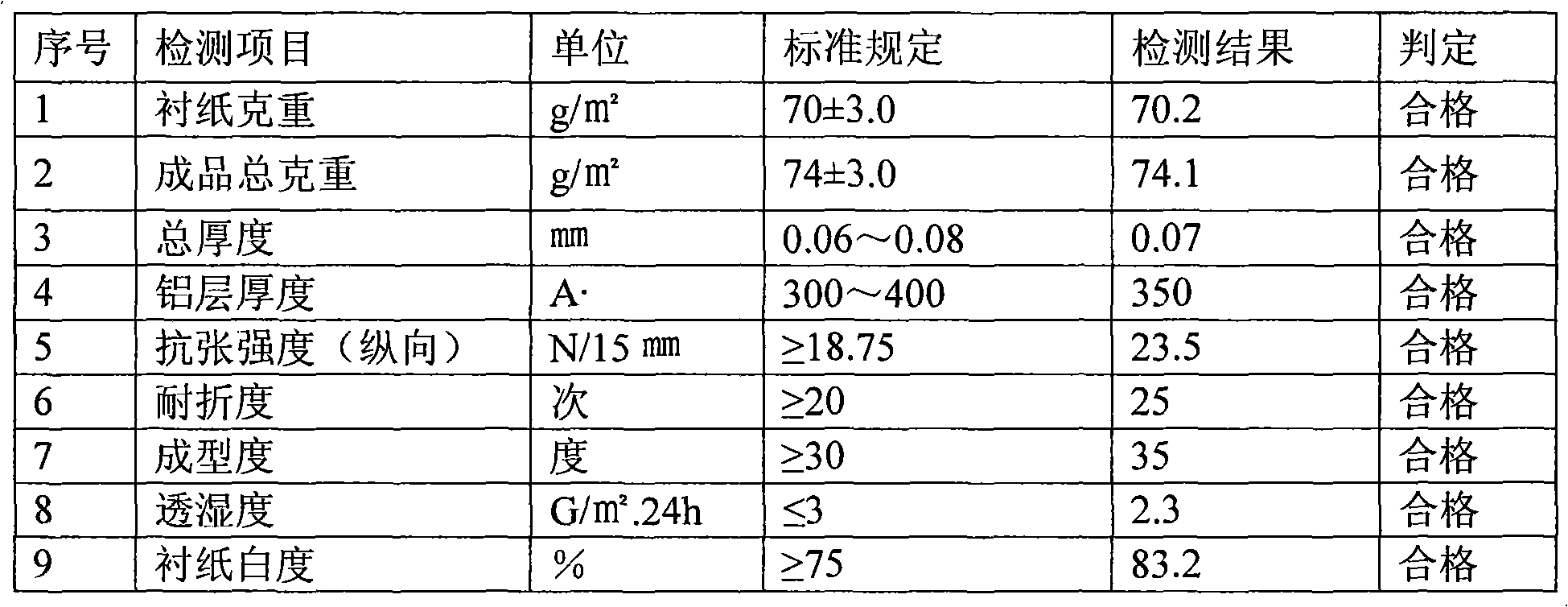

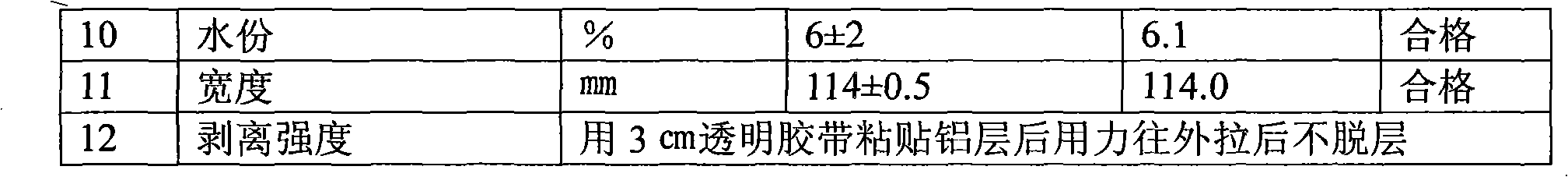

[0016] Produce a type of lining paper for "Zhonghua" brand soft pack cigarettes from Shanghai Cigarette Factory, the specification is 74g114mm, and the production quantity is 200 meters.

[0017] Carry out laser holographic laser molding on 0.2mm BOPP film, vacuum aluminum plating on the molding surface, and apply a coating to the aluminum layer on the roller coating equipment. The anilox roller used in the roller coating equipment is 150 mesh 65um, and the coating The paint formula weight ratio is as follows: 8% butyl methacrylate, 8% methyl methacrylate, 1% acrylic acid, 3% methyl acetate, 2% sodium lauryl sulfate, 1% super Composition of ammonium sulfate, 52% water and 25% ethanol.

[0018] After storage and curing at room temperature for 24 hours, a BOPP laser film is obtained.

[0019] Coat the adhesive on the coating layer of BOPP laser film or the base paper, roll the BOPP laser film and the base paper, and put it at room temperature for 24 hours to cure, and then peel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com