Electromagnetic shielding coating material and preparation method thereof

A coating material and electromagnetic shielding technology, applied in conductive coatings, magnetic field/electric field shielding, coatings, etc., can solve the problems of low performance stability, large content, and non-environmental protection, and achieve high dispersion stability and film formation speed Fast, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

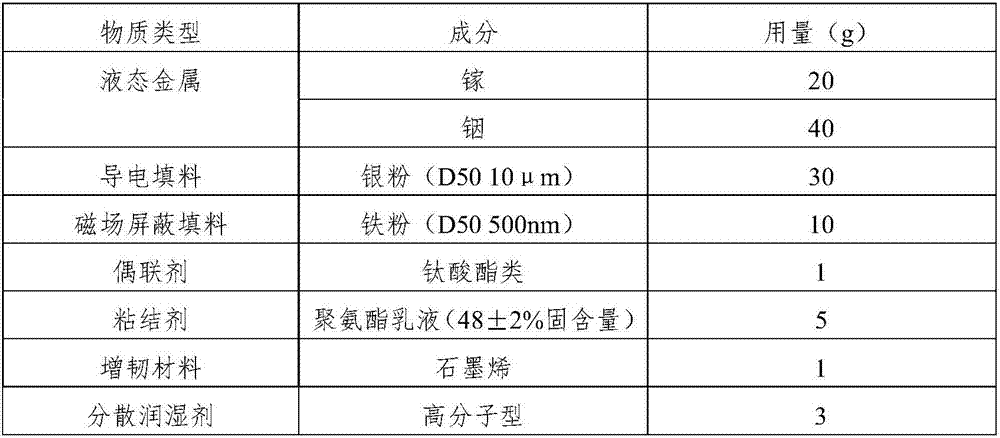

[0046] The formula composition of the environment-friendly high-performance liquid metal electromagnetic shielding coating material is shown in the following table:

[0047]

[0048] The preparation process of the present embodiment coating material is:

[0049] Step 1: The liquid metal raw materials (elemental gallium and elemental indium) are respectively subjected to reduction treatment in a hydrogen atmosphere using a reduction furnace to remove oxides on the surface of the raw materials. Sampling and weighing the reduced raw materials in proportion, put them together in a vacuum melting furnace for smelting. The molten alloy liquid is poured into ingots in a vacuum furnace.

[0050] Step 2: Weigh the required above-mentioned liquid metal alloy, under inert gas protection conditions, heat the liquid metal element or alloy to above the melting point (70°C), and stir for 50 minutes at 800r / min using an overhead disperser.

[0051] Step 3: Under inert gas protection cond...

Embodiment 2

[0055] In this embodiment, the conductive filler adopts copper powder with an average particle diameter of 300nm, and the magnetic field shielding material adopts nickel powder with an average particle diameter of 500nm. Other ingredients and preparation are the same as in Example 1.

Embodiment 3

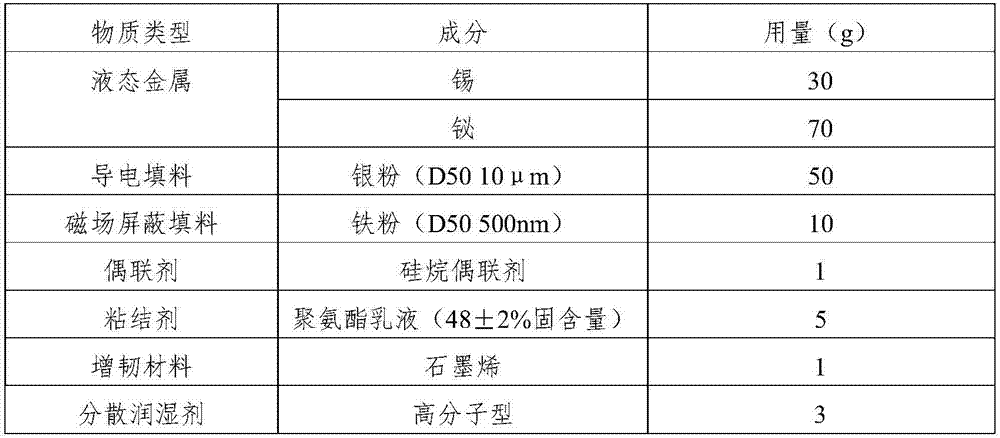

[0057] The formula composition of the environment-friendly high-performance liquid metal electromagnetic shielding coating material is shown in the following table:

[0058]

[0059] In the preparation process of the coating material of this embodiment,

[0060] Step 1: The elemental liquid metal raw materials (tin powder and bismuth powder) are respectively reduced by a reduction furnace in a carbon monoxide gas environment to remove oxides on the surface of the raw materials. Sampling and weighing the reduced raw materials in proportion, put them into a vacuum melting furnace for smelting. The smelted alloy liquid is filled into containers for standby use.

[0061] Step 2: Weigh the required above-mentioned liquid metal alloy, heat the liquid metal to the melting point (130°C) under the protection of inert gas, and stir for 50 min at 800 r / min with an overhead disperser.

[0062] Other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com