Patents

Literature

43results about How to "Low dry heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

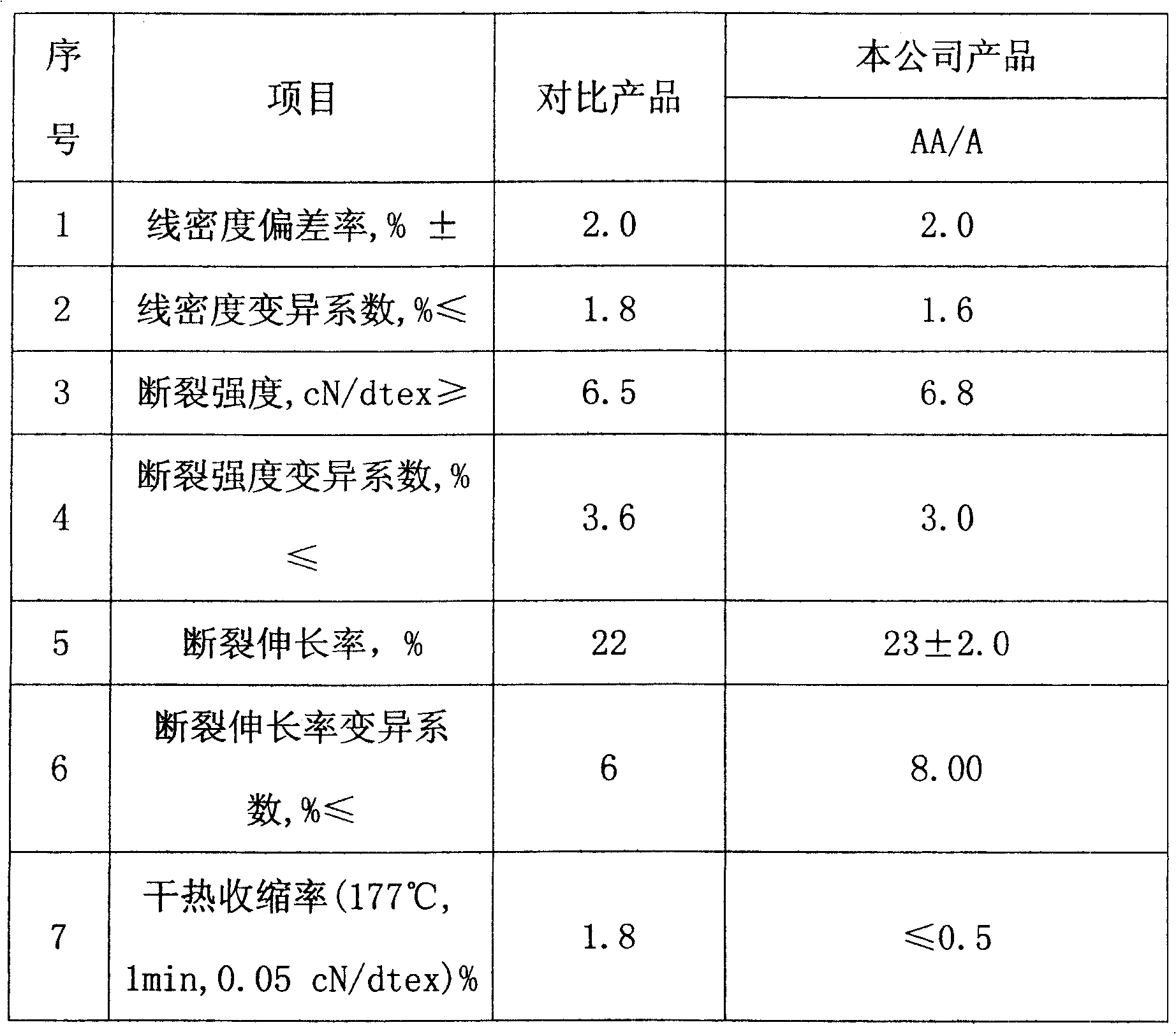

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN1904153AAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

High-extension and low-shrinkage polyester industrial filament and preparation method thereof

ActiveCN108130611AHigh elongation at breakLow dry heat shrinkageFilament/thread formingMonocomponent copolyesters artificial filamentShrinkage rateDiol

The invention relates to a high-extension and low-shrinkage polyester industrial filament and a preparation method thereof. Modified polyester is subjected to solid phase polycondensation tackifying,melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain the high-extension and low-shrinkage polyester industrial filament, wherein the high-extension and low-shrinkage polyester industrial filament is made of the modified polyester, and a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segmentand a diol chain segment with a branched chain; the central value of elongation at break of the finally prepared high-extension and low-shrinkage polyester industrial filament is 11.0-12.0%, and the dry-hot shrinkage rate under the conditions of 177 DEG C, 10 min and 0.05 cN / dtex is 6.5-13.5%. The method is simple and reasonable, and the prepared high-extension and low-shrinkage polyester industrial filament has the advantages of good mechanical properties, high elongation at break and low dry-hot shrinkage, and has excellent popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

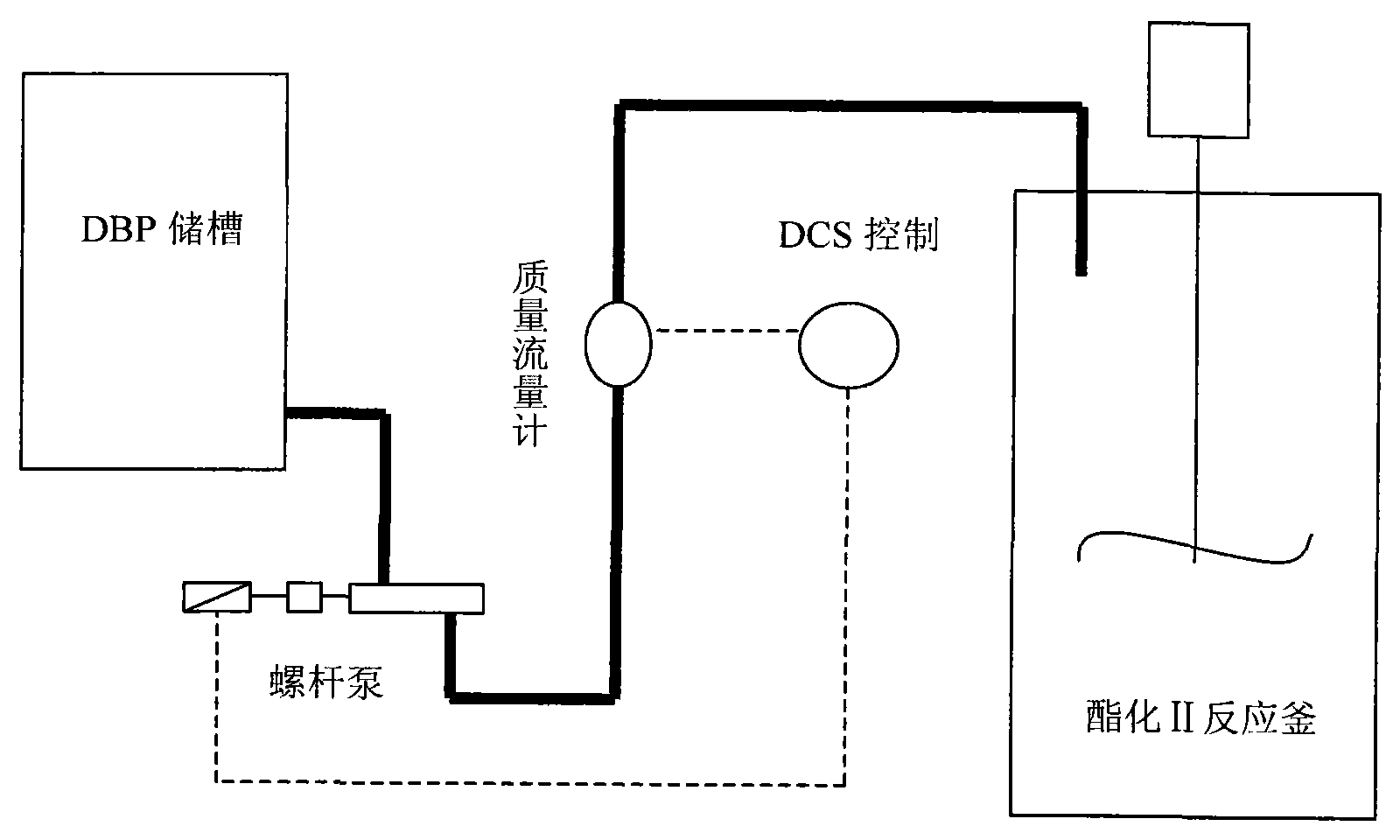

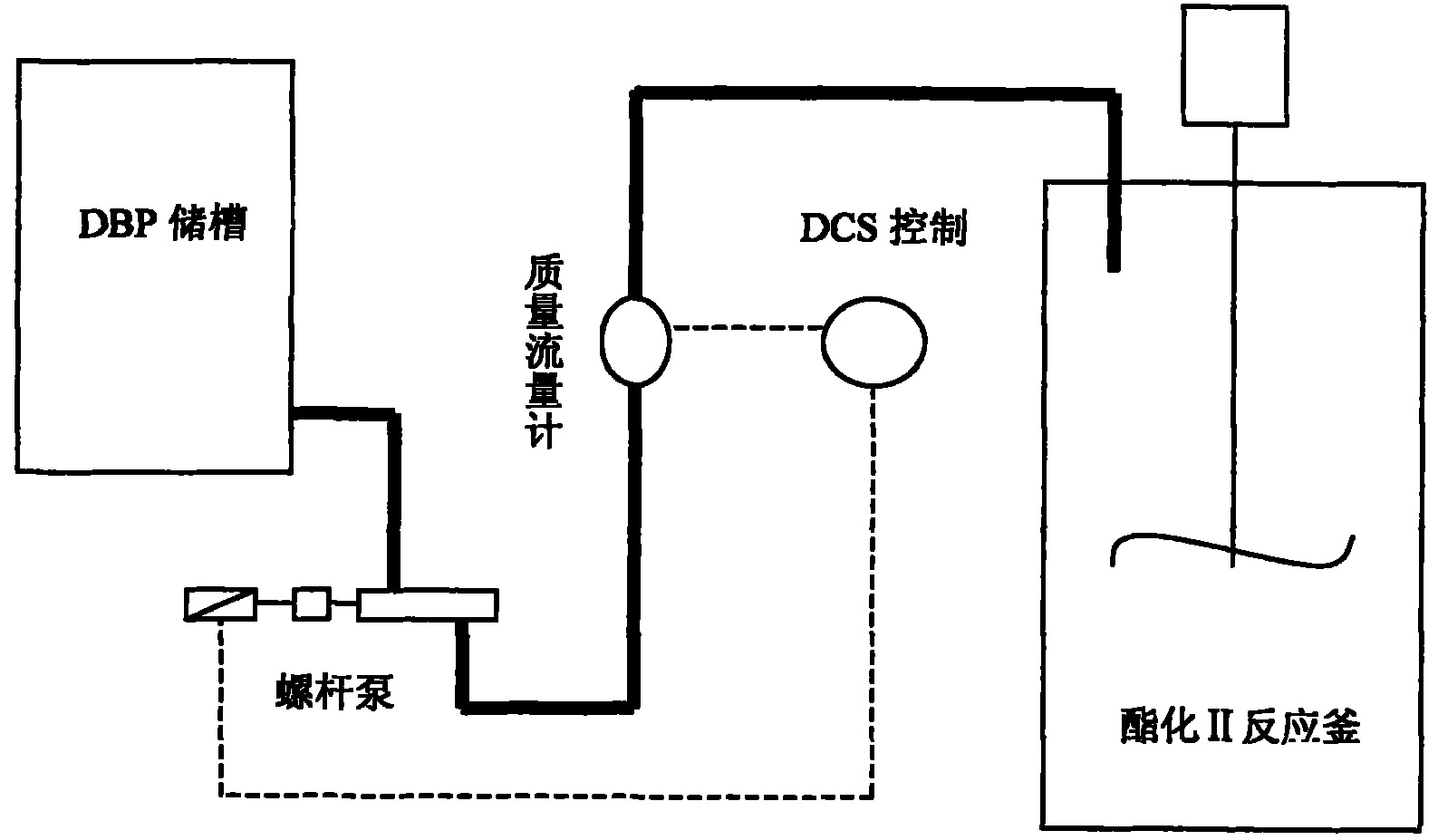

One-step method production process of ultra-low contract terylene industry fiber

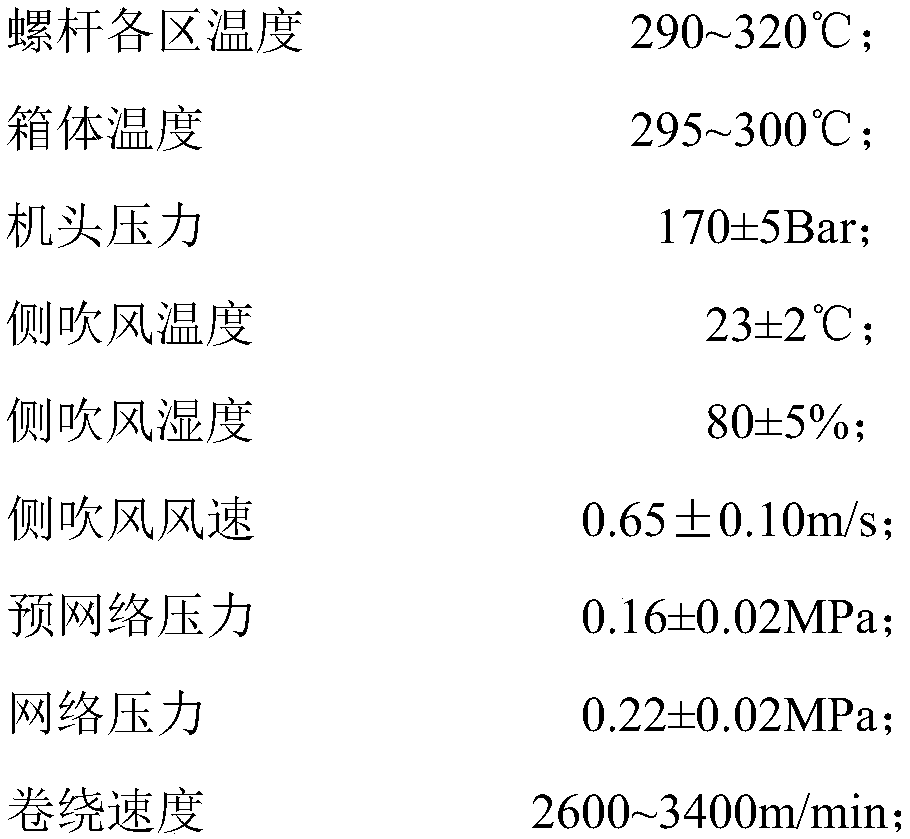

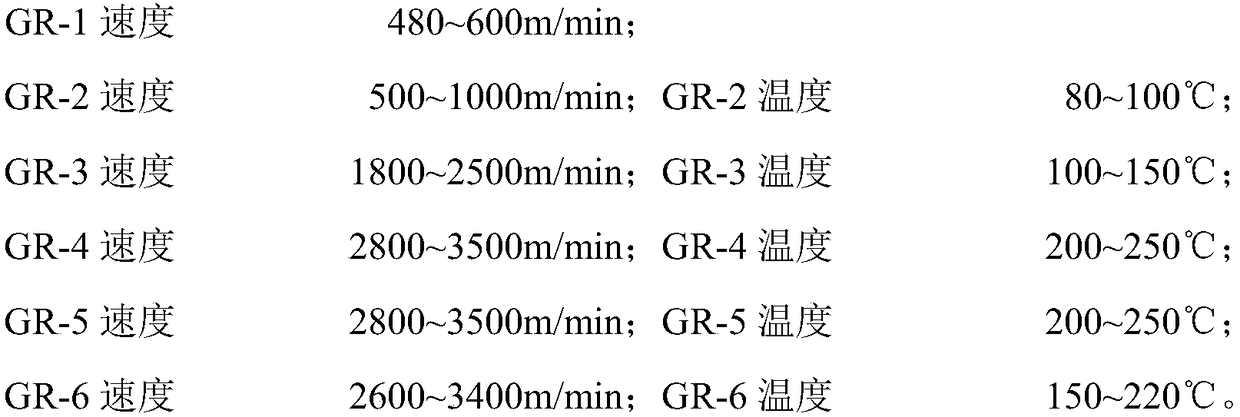

ActiveCN101407942AGuaranteed uniformityLow Dry Heat ShrinkageMelt spinning methodsFilament-forming treatmentSolid phasesMelt spinning

The invention discloses a one-step production technology of ultra-low shrinkage terylene industrial fibers, which comprises the steps as follows: A. the preparation of high-viscosity chips: the high-viscosity chips with the viscosity of 0.99 plus or minus 0.015 are obtained by the solid phase polymerization of low-viscosity chips; B. melt spinning: the high-viscosity chips are extruded by melting by a screw extruder in a spinning manifold, spun by a spinning component, and shaped by lateral blowing cooling, and pump oiling is carried out by adopting an ester leveling agent with the kinematic viscosity of 20 to 60mm<2> / s at the temperature of 30 DEG C, and the oiling rate is 0.6 plus or minus 0.15 percent; C. heat setting by drawing: heat setting by drawing is carried out firstly by a pre-tension roller, and sequentially by two groups of drawing rollers and three groups of hot rollers for shaping; and D. shaping by winding: products can be obtained by winding by a winding head after the obtained fibers pass through a main network device. In the invention, not only the technology has high production efficiency, but also the dry heat shrinkage value of the obtained ultra-low shrinkage terylene industrial fibers is low and has high strength and excellent combination property.

Owner:ZHEJIANG UNIFULL IND FIBER

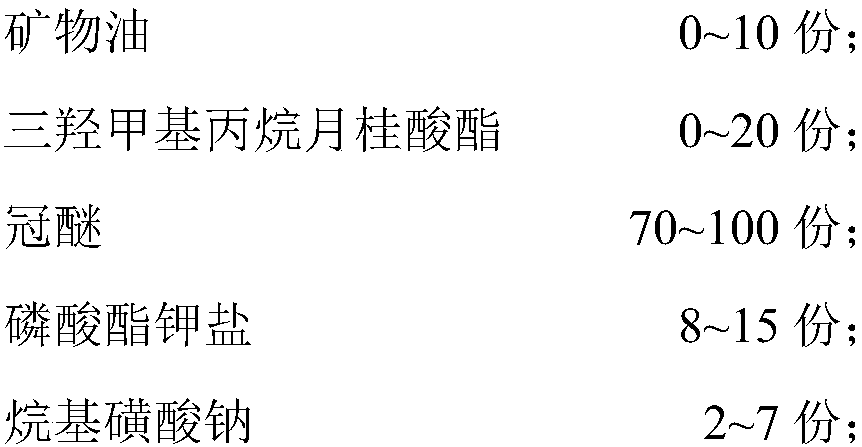

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

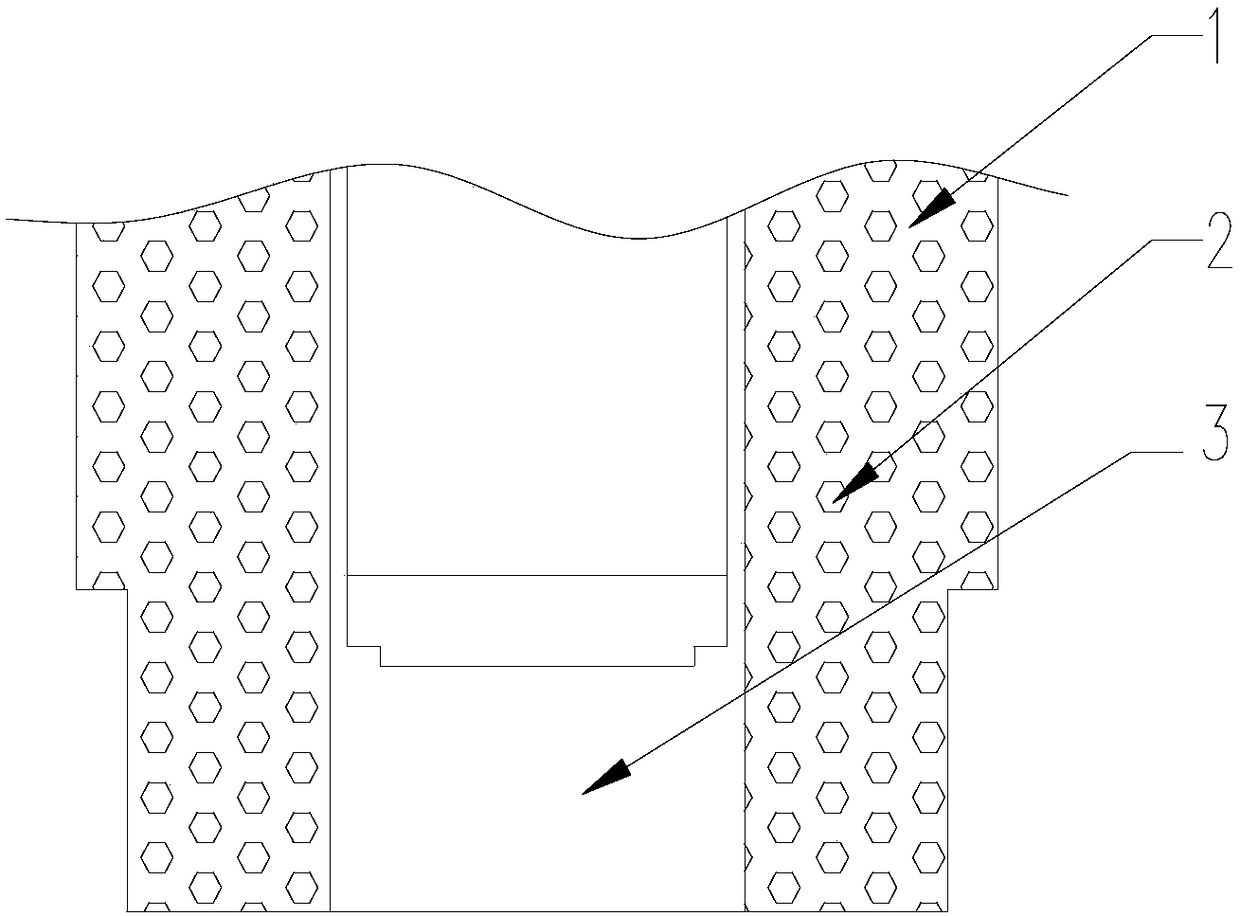

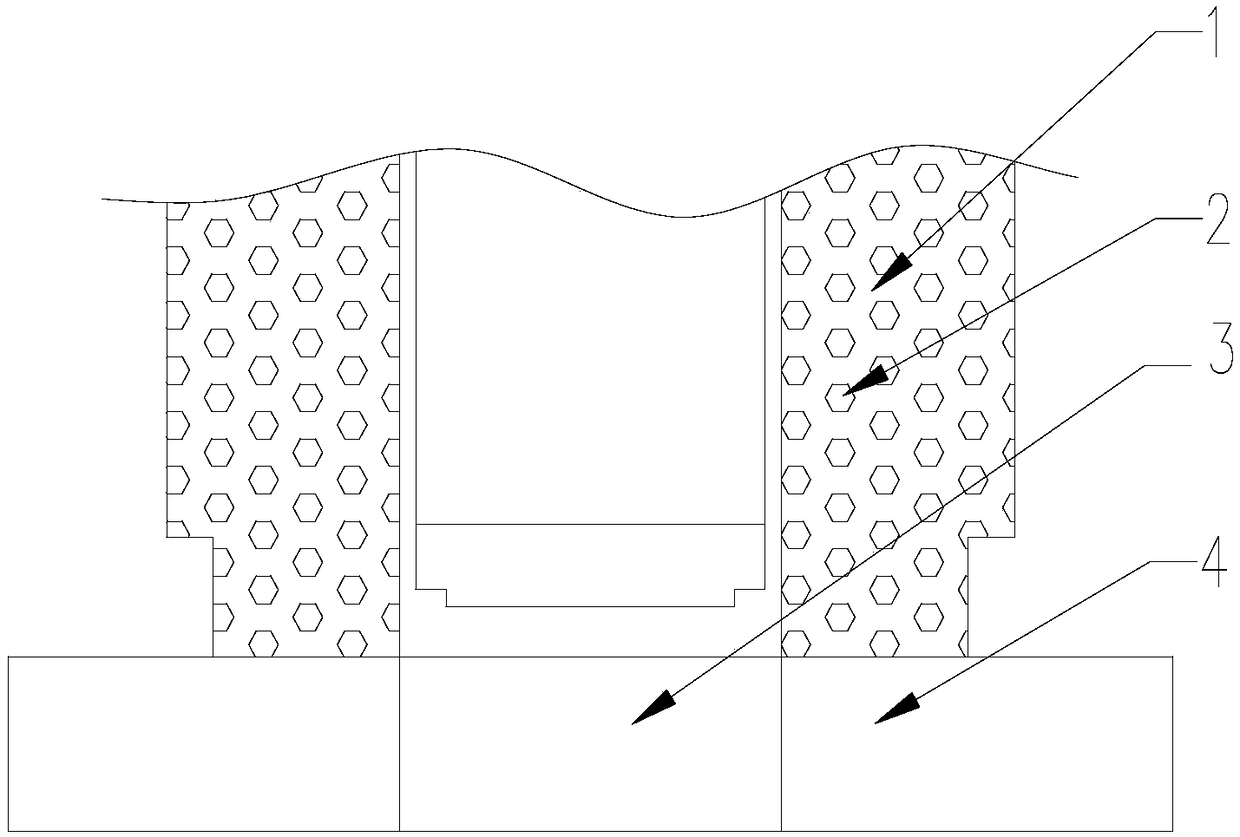

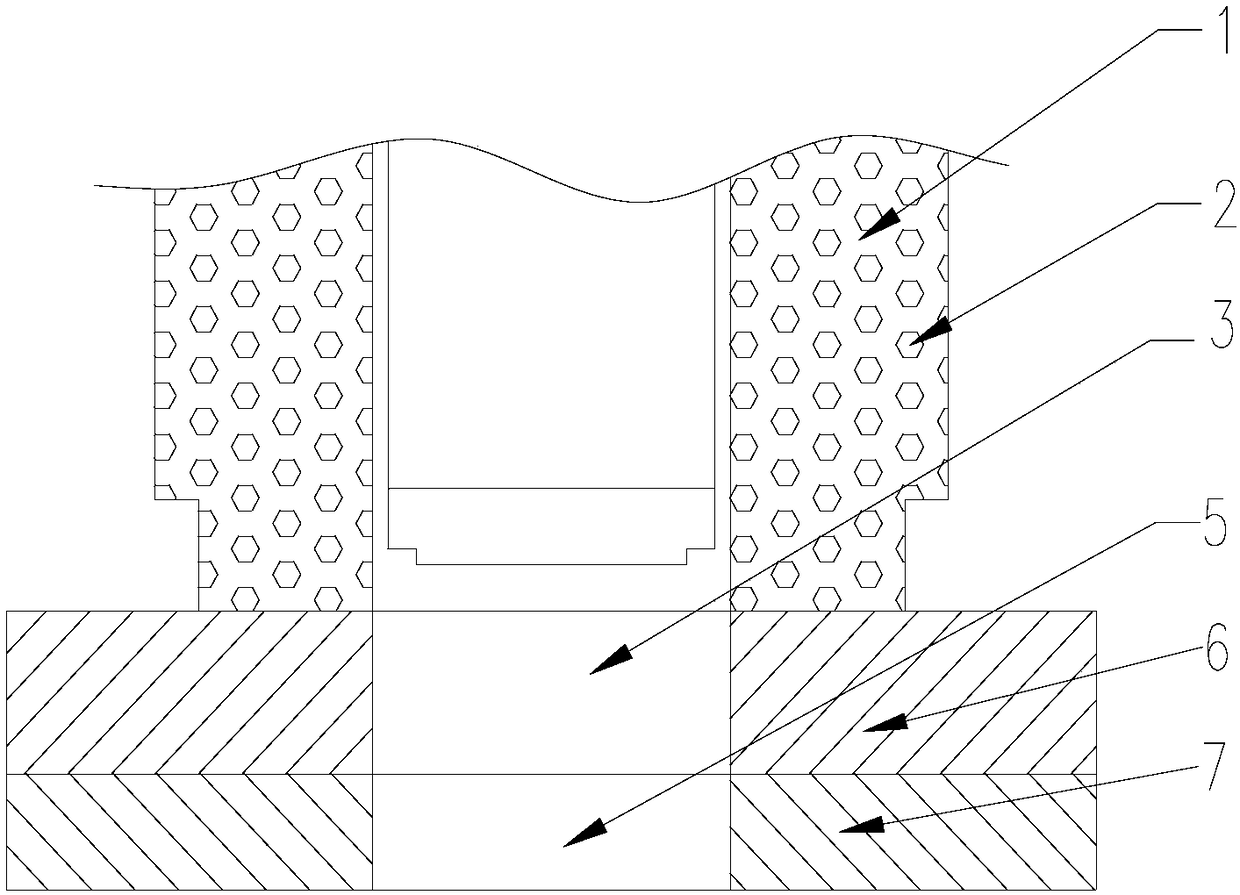

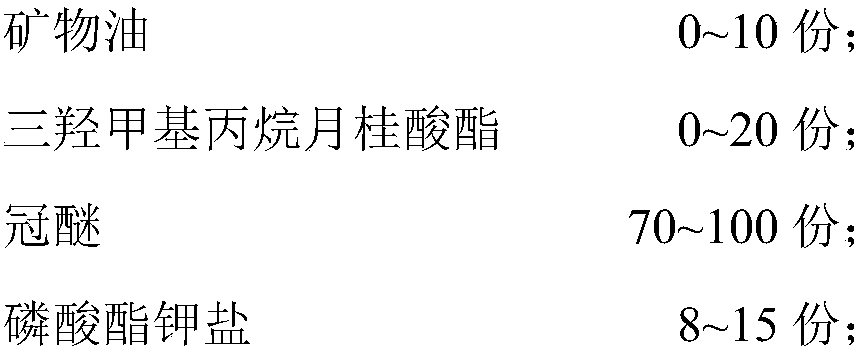

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

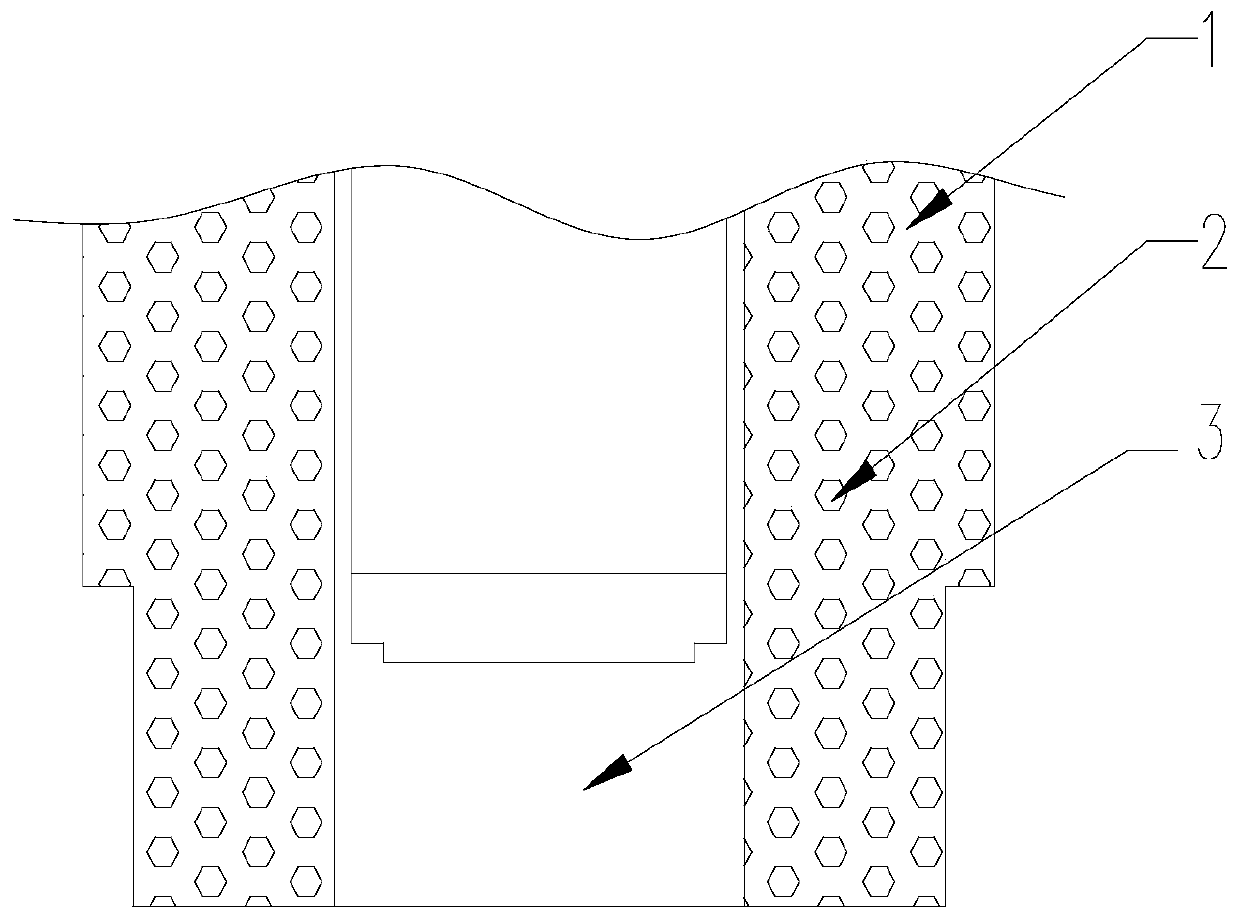

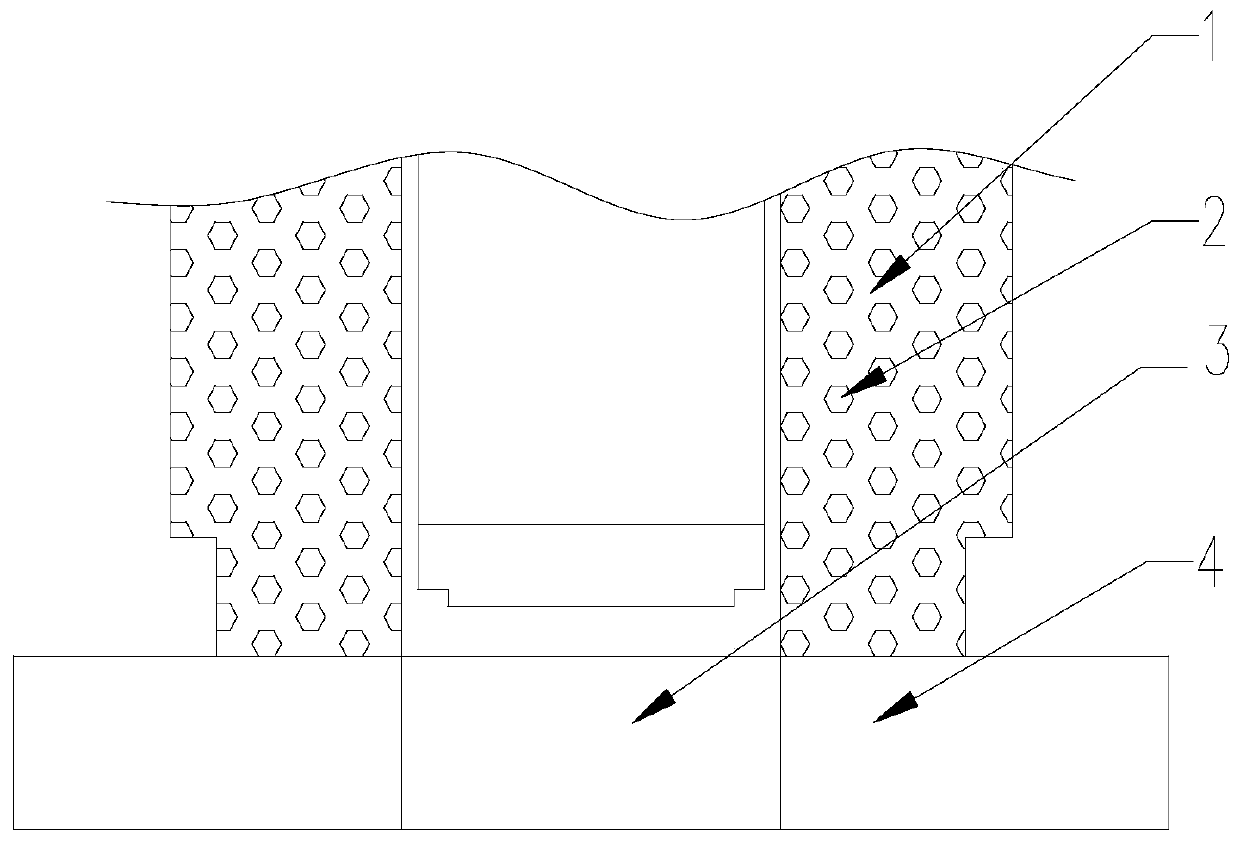

Manufacturing method for high-modulus low-shrinkage PET industrial yarn

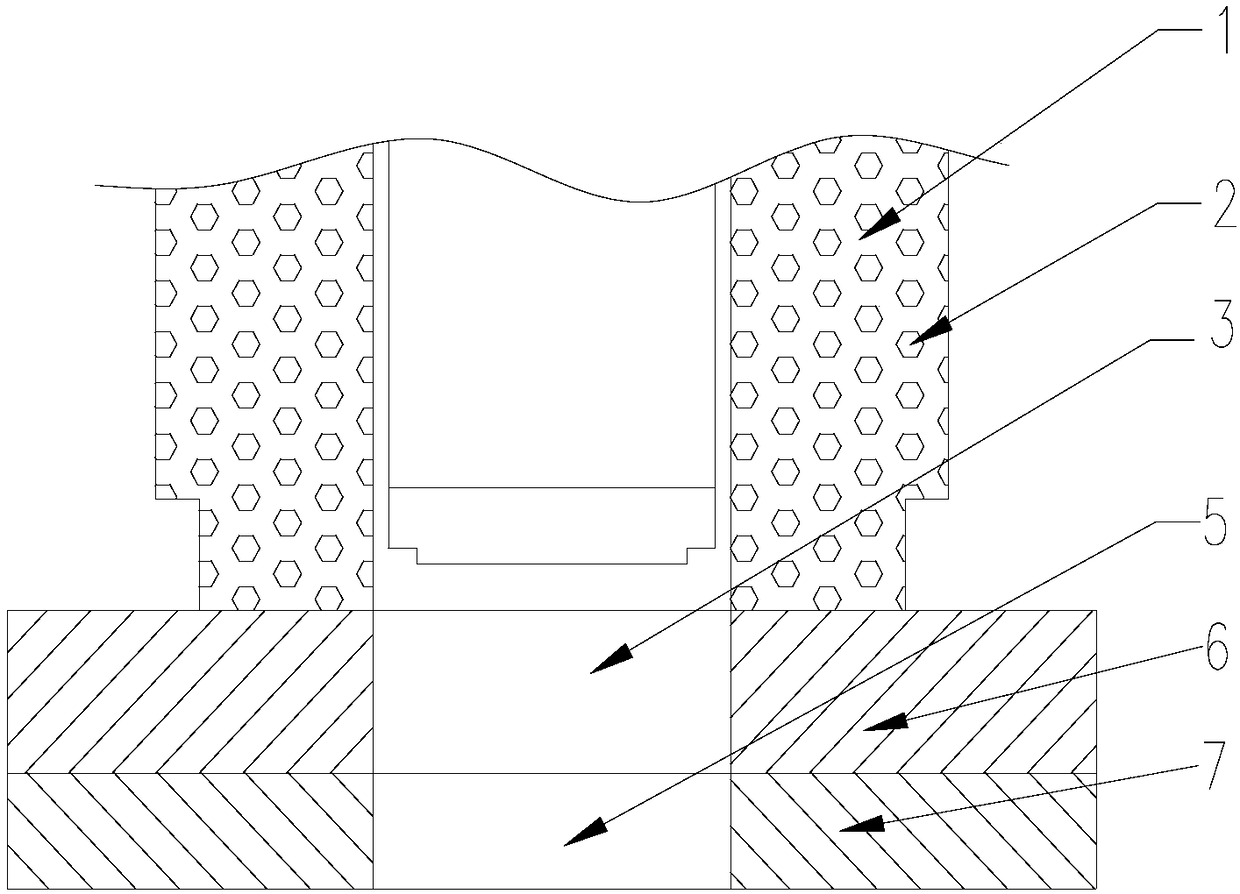

ActiveCN102797057AReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method for high-modulus low-shrinkage PET industrial yarn, and the technological process of the method is as follows: hyperviscous melting to polyester fiber raw materials, metering, spinning, cooling, oil applying, stretching, hot shaping and reeled forming, wherein the cooling process sequentially comprises four parts including slow-cooling, pre-cooling, calm zone cooling and blow cooling, and the pre-cooling part adopts a passive hollow ring-shaped belt device. Through the introduction of the pre-cooling device, the irregularity caused by tows quivering produced under the down moving of a solidification point of fiber can be reduced, the deviation ratio of linear density can be controlled within a lower range, the purpose of reducing orientation and crystallization of embryo fiber is achieved, finally high-modulus low-shrinkage PET industrial yarn can be obtained, the high-modulus low-shrinkage PET industrial yarn has the advantages of high modulus, low dry heat shrinkage percentage, low breaking elongation and low linear density deviation ratio, and practical application can be well met.

Owner:JIANGSU HENGLI CHEM FIBER

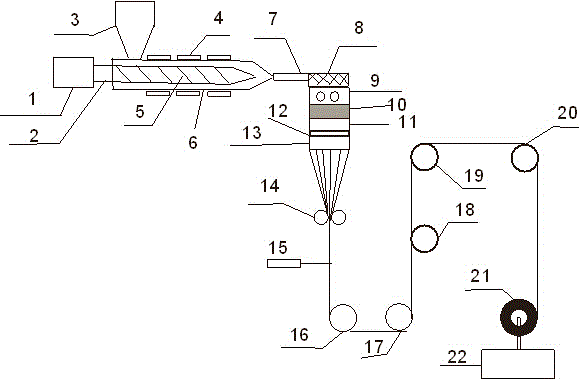

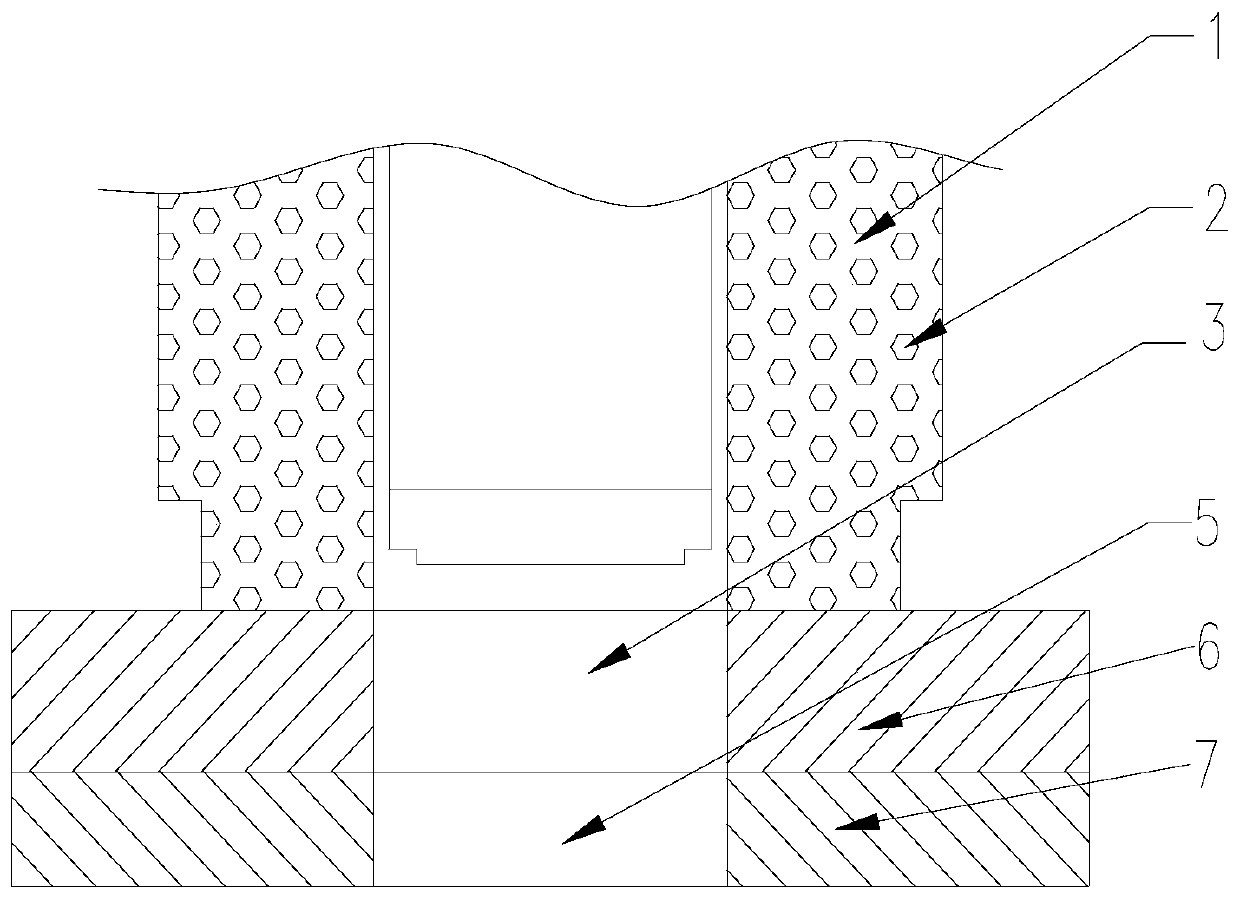

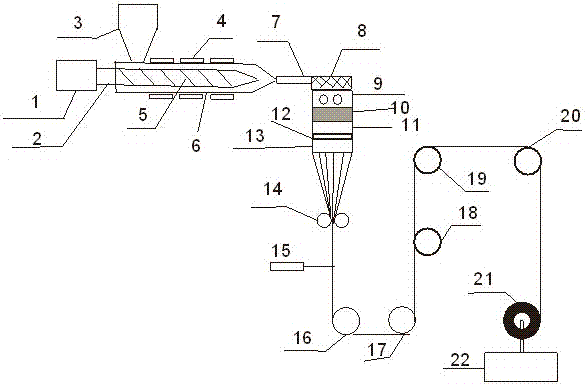

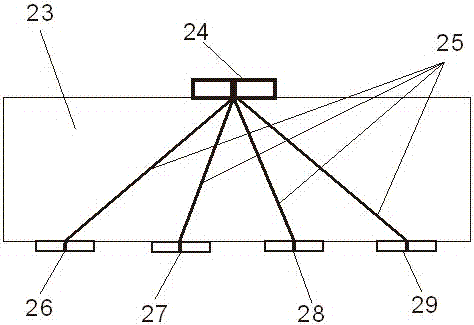

One-step method high-temperature and high-pressure melt spinning equipment and production method of polymer fiber

ActiveCN104313711AHigh crystallinityHigh densitySpinning head liquid feederMonocomponent synthetic polymer artificial filamentImidePolymer science

The invention discloses one-step method high-temperature and high-pressure melt spinning equipment and a production method of a polymer fiber and relates to the one-step method high-temperature and high-pressure melt spinning equipment. The spinning equipment is characterized by comprising a driving device, an extruder system and a spinning device, wherein the driving device comprises a driving motor and a speed reducing device; the extruder system comprises an extruder screw, a charging barrel, a loading hopper, an electric heater and an extruder head; the loading hopper and the electric heater are arranged on the charging barrel of an extruder; one end of the extruder screw is connected with the driving motor through the speed reducing device; the other end of the extruder screw is matched with the extruder head. The spinning equipment also comprises a melt filtering device, a metering pump, a spinning box body and a spinning component. The spinning device sequentially comprises the metering pump, the spinning box body, the spinning component, a spinneret plate, a coldness alleviating deice, a multifilament bundling device, an oiling device, a guide device, a hot roller drafting sizing device and a winding device. The high-temperature and high-pressure melt spinning equipment is special for melt spinning of polymers with high melting point, high melt viscosity and high performance, such as polyether-ether-ketone, polyaryletherketone and polyetherimide.

Owner:CHANGZHOU CHUANGYING NEW MATERIAL TECH

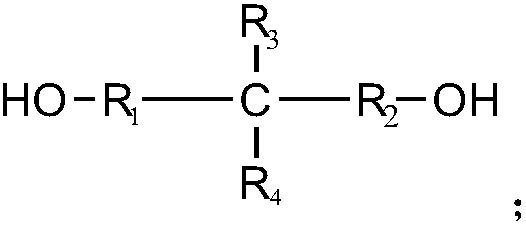

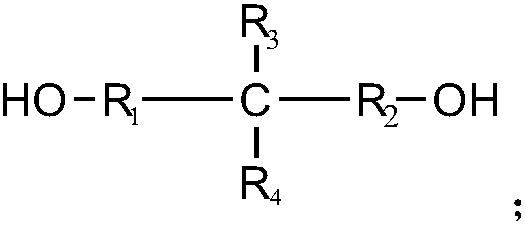

Low-shrinkage polyester industrial filament and preparation method thereof

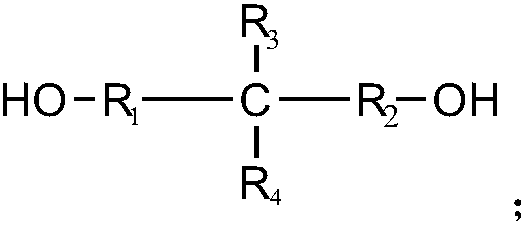

ActiveCN108130609ALow dry heat shrinkageSimple preparation processFilament/thread formingMonocomponent copolyesters artificial filamentStructural formulaConductor Coil

The invention relates to a low-shrinkage polyester industrial filament and a preparation method thereof. The preparation method comprises that modified polyester is subjected to solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding, wherein an oil agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58 wt%. The preparation method is simple and reasonable; the dry-hot shrinkage rate of the finally prepared low-shrinkage polyester industrial filament under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex is 2.5-4.7%. The low-shrinkage polyester industrial filament is made of the modified polyester, and a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5.

Owner:JIANGSU HENGLI CHEM FIBER

Method for producing cellulose fiber

InactiveCN1772983AHigh strengthIncrease elasticityMaterial nanotechnologyArtificial filaments from cellulose solutionsPolyvinyl alcoholCellulose fiber

The present invention provides a cellulose fiber having high strength, high modulus of elasticity, and low shrinkage properties, and excellent performance in preventing fibrillation and adhesion to rubber. It is produced by dissolving 0.1% to 10% by weight of salt and polyvinyl alcohol in a liquid concentrated NMMO solution to produce an NMMO solution; mixing, swelling, and dissolving the NMMO solution and cellulose powder to produce a cellulose solution Extrude and spin the cellulose solution through a spinning nozzle with 500 to 2000 spinneret holes, and then solidify it through an air layer and a coagulation bath to obtain multifilaments; wash the obtained multifilaments with water, Drying, oiling and coiling.

Owner:HYOSUNG ADVANCED MATERIALS CORP

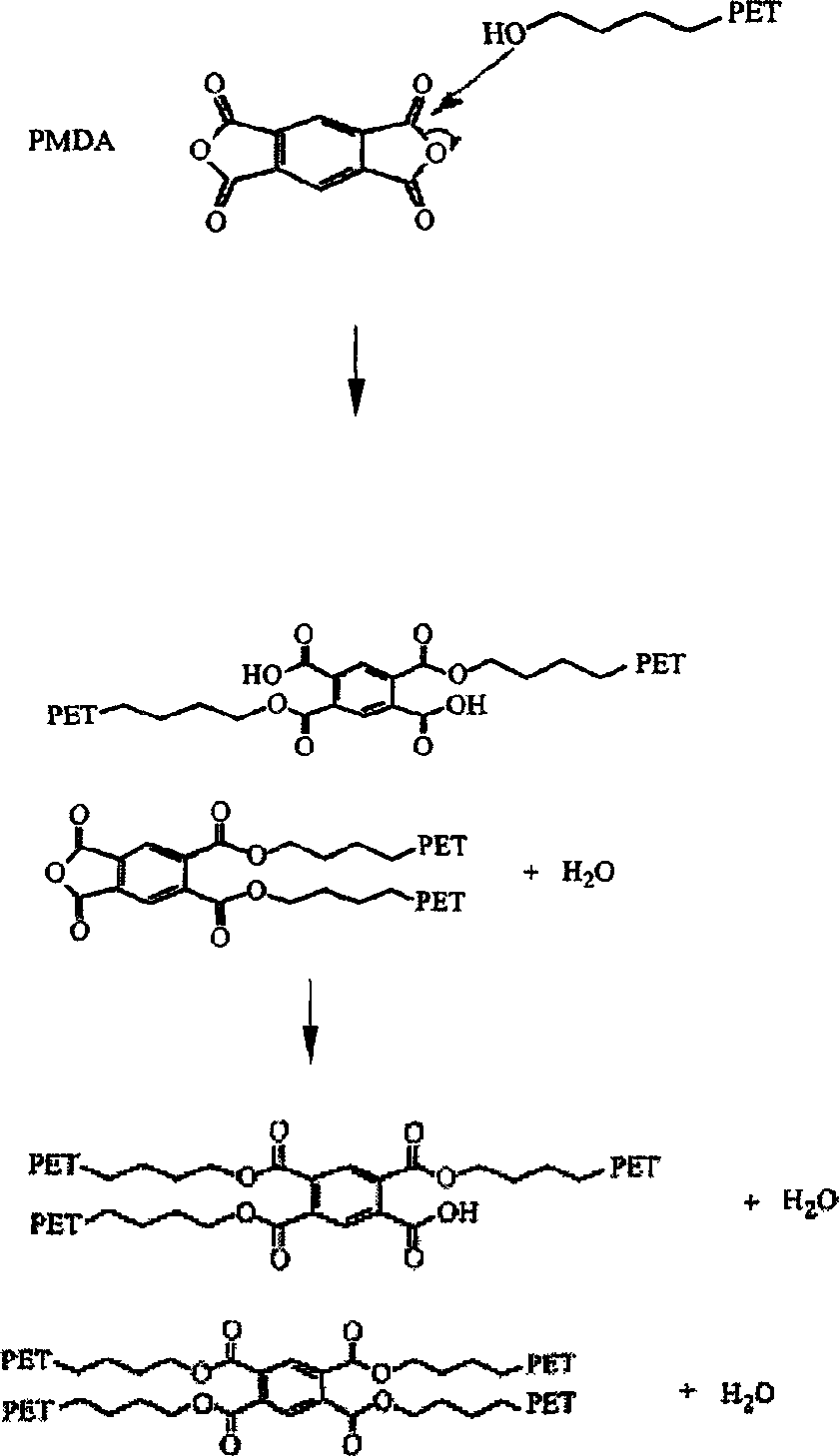

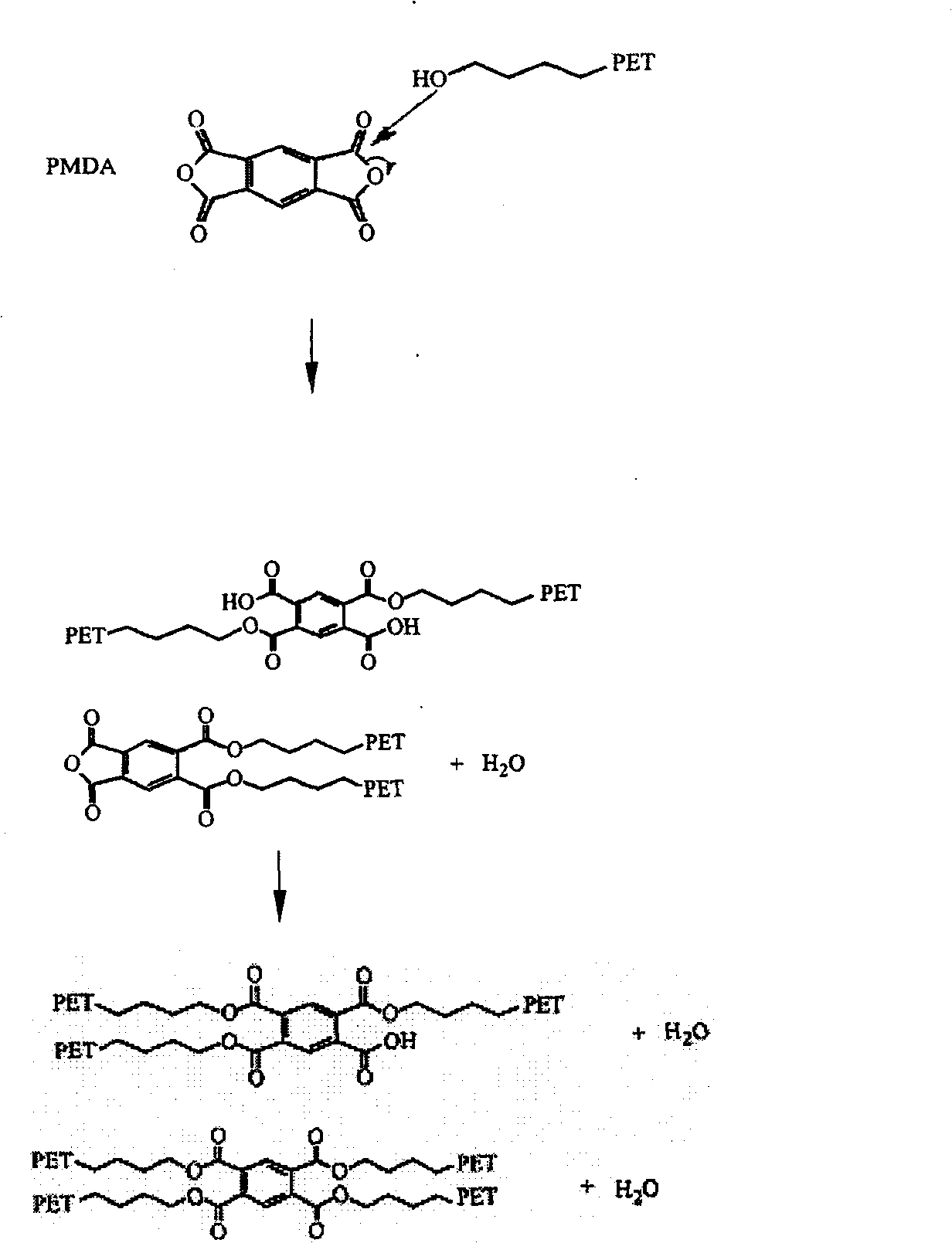

Method for preparing high-modulus super low shrinkage industrial yarn using pyromellitic dianhydride

InactiveCN1936122AHigh modulusHigh-modulus ultra-low shrinkage polyester industrial yarn will be high-strengthMelt spinning methodsMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to a method that uses equal benzene tetracarboxylic acid anhydride making high modulus ultralow shrinking industrial yarn that includes the following steps: sending normal polyethylene terephthalate or normal polyester precrystallization and drying into screw extruder, adding expanding agent, setting outlet pressure and heating temperature of screw extruder to gain high viscosity polyester melt; putting the polyester melt into spinning box to take spinning to make high modulus ultralow shrinking industrial yarn. By using the method, the device investing and producing cost would be lowered, and the polyester industrial yarn is high intention high modulus and ultralow shrinking.

Owner:JIANGNAN UNIV

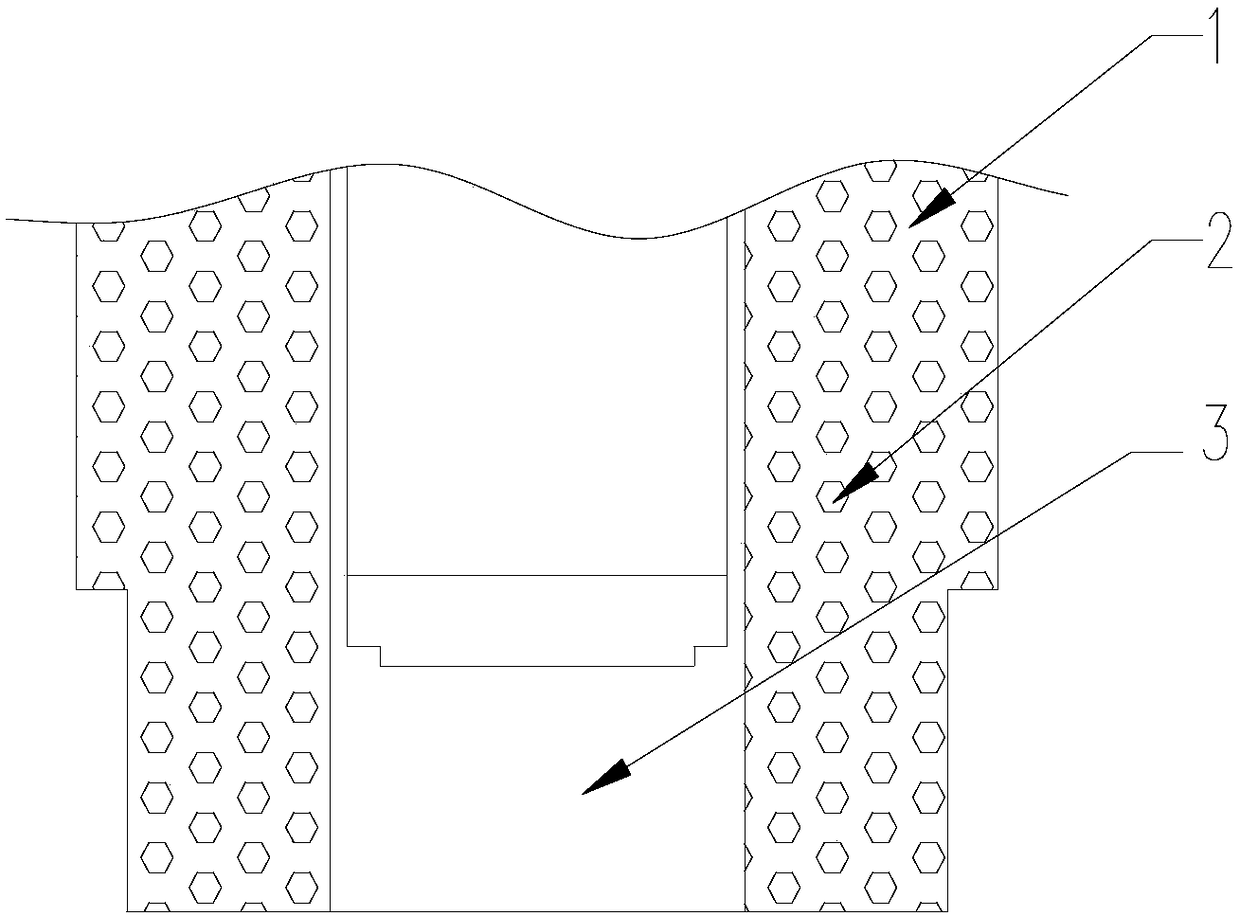

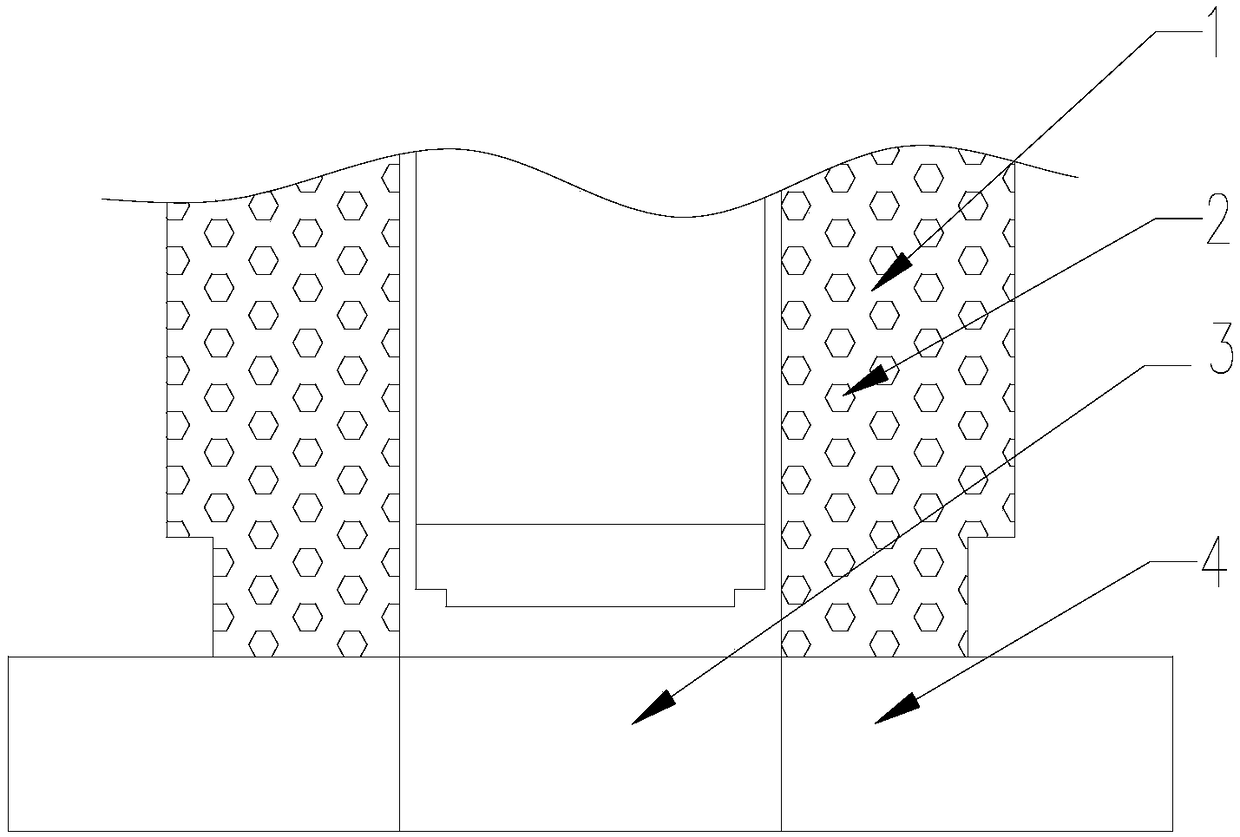

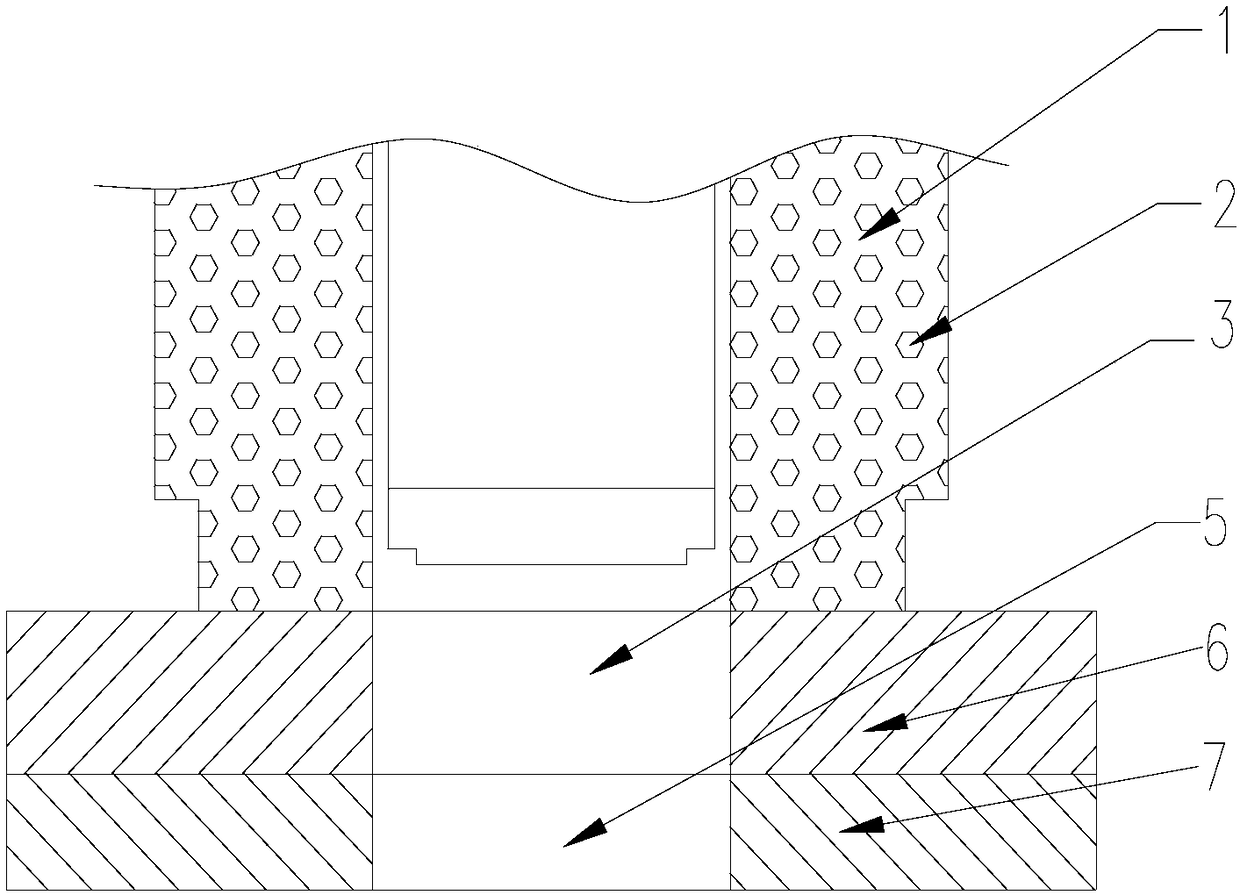

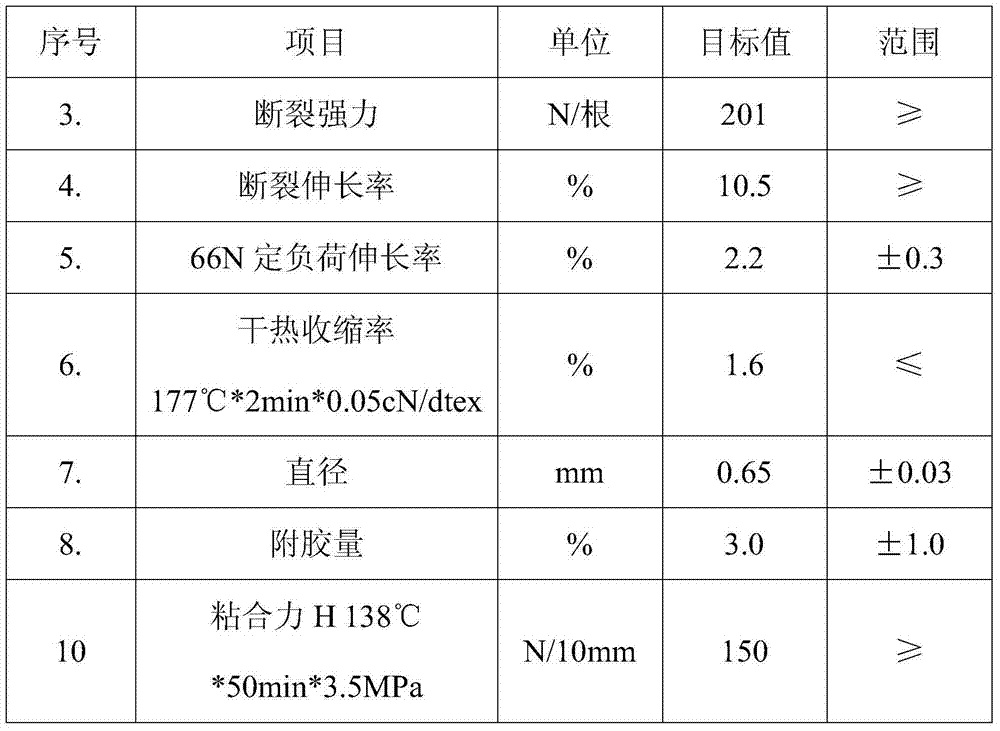

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

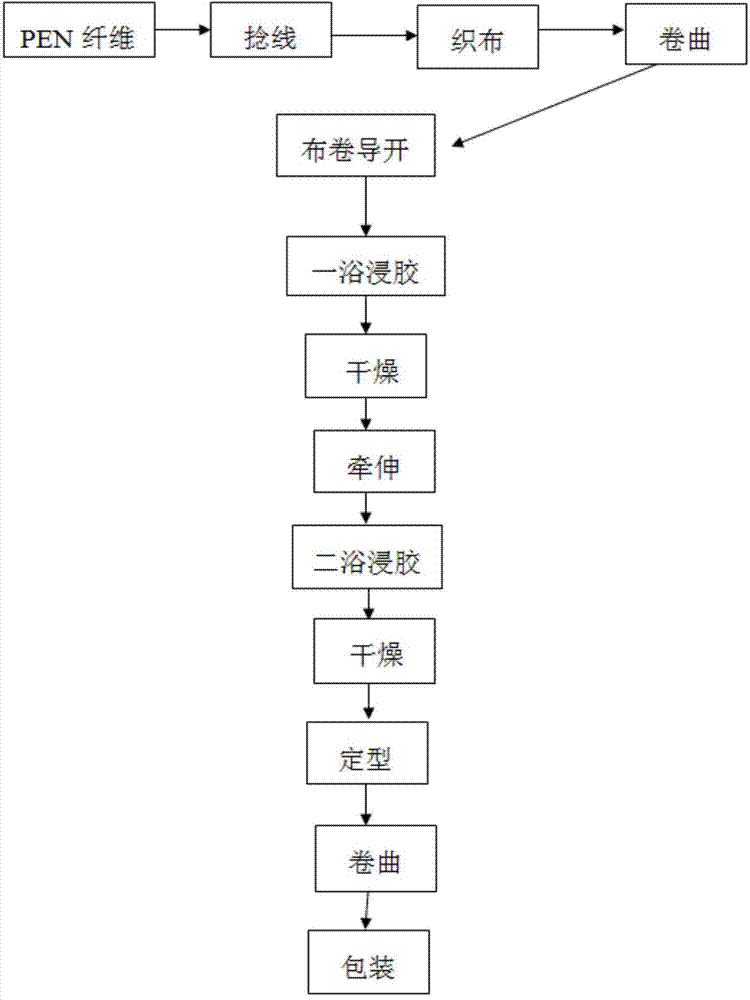

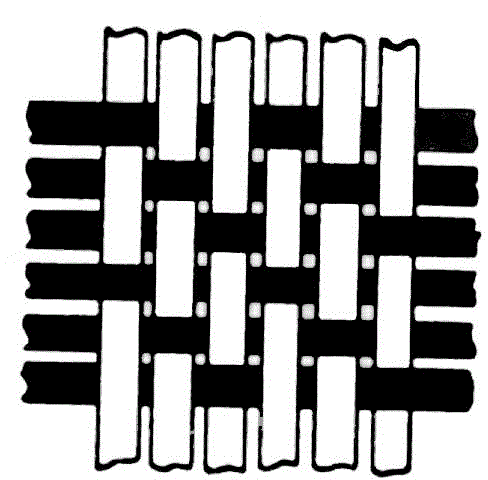

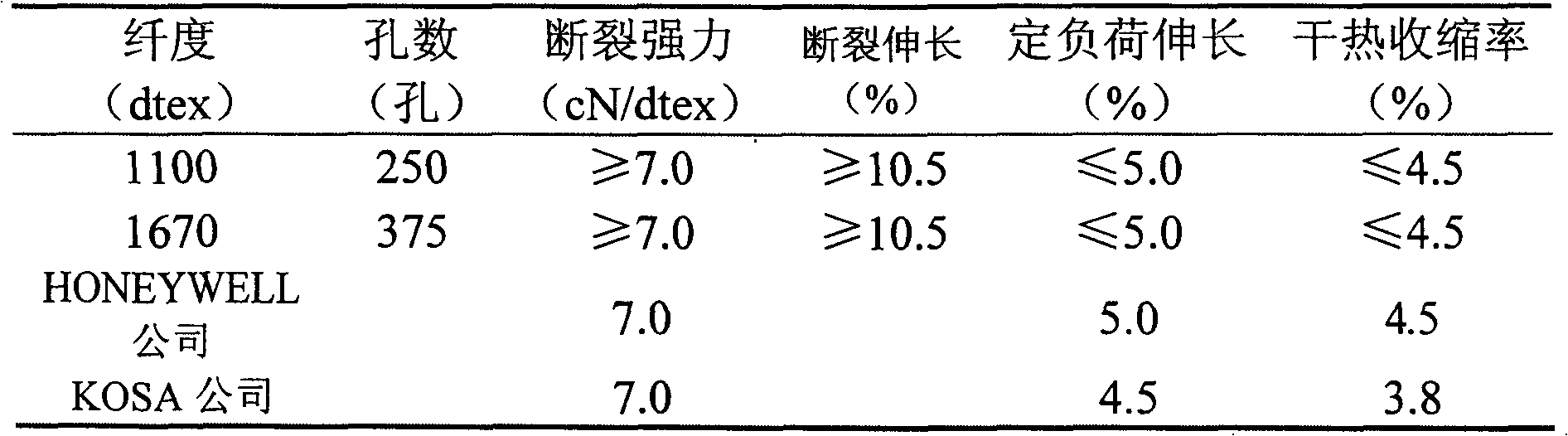

1670-dtex/2-PEN impregnation tire fabric used for taking radial tire cap ply and making method thereof

InactiveCN104746208AHigh modulusLow dry heat shrinkageFibre typesWoven fabricsMechanical engineeringComposite material

The invention discloses a making method of 1670-dtex / 2-PEN impregnation tire fabric used for taking radial tire cap ply. The making method specifically includes the steps of twisting, weaving, impregnating, winding and finished product making and obtaining. The invention further discloses the 1670-dtex / 2-PEN impregnation tire fabric used for the taking radial tire cap ply, the 1670-dtex / 2-PEN impregnation tire fabric used for the taking radial tire cap ply is obtained with the making method, and the drying shrinkage of the 1670-dtex / 2-PEN impregnation tire fabric used for the taking radial tire cap ply is smaller than or equal to 1.6% when the temperature is 177 DEG C. The 1670-dtex / 2-PEN impregnation tire fabric is high in modulus and free of creeping deformation, and has the better size stability.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Manufacturing method of large-diameter and high-viscosity polyester monofilament

InactiveCN103469326AOvercome appearanceOvercome strengthFilament forming substance formingArtificial thread manufacturing machinesPolyesterBreaking strength

The invention provides a manufacturing method of a large-diameter and high-viscosity polyester monofilament. The method comprises the working procedures of tackifying low-viscosity polyester chip raw material by polyester solid phase polycondensation to increase the intrinsic viscosity to be eta which is within the range of 0.9-1.0; drying the tackified polyester chip by a vacuum polyester dryer for crystallization, and enabling the water content of the polyester chip to be lower than 100ppm; melting the dried polyester chip to form polyester melt; evenly extruding the polyester melt by a metering pump, and forming primary monofilament by a mould; stretching the primary monofilament twice respectively in a prestretching way and an all-stretching way; shaping the stretched primary monofilament to form the large-diameter and high-viscosity polyester monofilament. The product obtained by the method can overcome the defects in the prior art, and avoids the phenomena of melt fracture and filament break increase caused by the overhigh intrinsic viscosity of the polyester chip raw material and the overlarge molecular weight of the polyester chip. Furthermore, by adopting the special drying procedure, the method reduces the dry heat shrinkage rate of the monofilament and improves the breaking strength of the monofilament.

Owner:XUZHOU SILK FIBER TECH

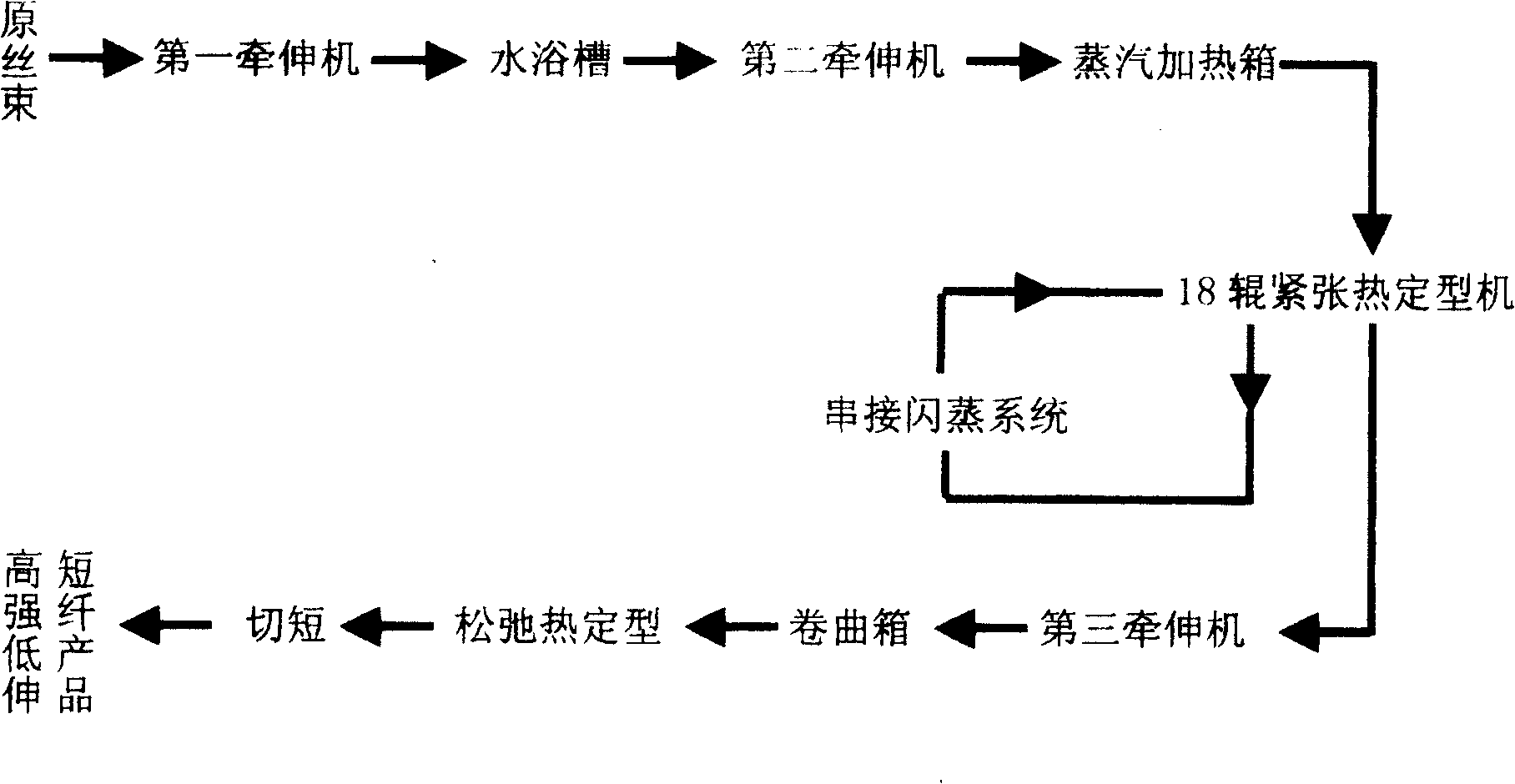

High-strength low-extension polyester staple fiber preparation method

ActiveCN100422400CGuarantee and meet the requirements of temperature uniformity and stabilityReduce consumptionArtificial filament heat treatmentMelt spinning methodsPolyesterWater baths

This invention relates to a terylene product technology, especially to a preparing method for short fabric with high strength and low elongation. This method uses the tow without drawing-off (short for original tow) for raw material, the working procedure for the production as follows: the first drawing-off, the second drawing-off, 18 roll tense thermoforming, the third drawing-off, curling, loose thermoforming, cutting off. Namely carrying out the first drawing-off through the water bath which between the thirst drafting machine and the second drafting machine; carrying out the second drawing-off through the steam heater which between the second drafting machine and the 18 roll tensely thermoforming machine; and then carrying out the thermoforming through the 18 roll tense thermoforming machine; carrying out the surplus drawing-off through the third drafting machine; curling through the curling machine; then drying through the loose thermoforming machine and cutting off after the thermoforming treatment. The original tow in this technology has a better drawing off, basically it hasn't the none-drawing off product, double long product and exceed long product, and the final product has the high strength, low elongation, and low thermal contraction and so on. The rupture strength >= 6.0CN / dtex, the rupture elongate rate 11-25%, the dry thermal contraction rate<8%.

Owner:上海太平洋二纺机化纤成套设备有限公司

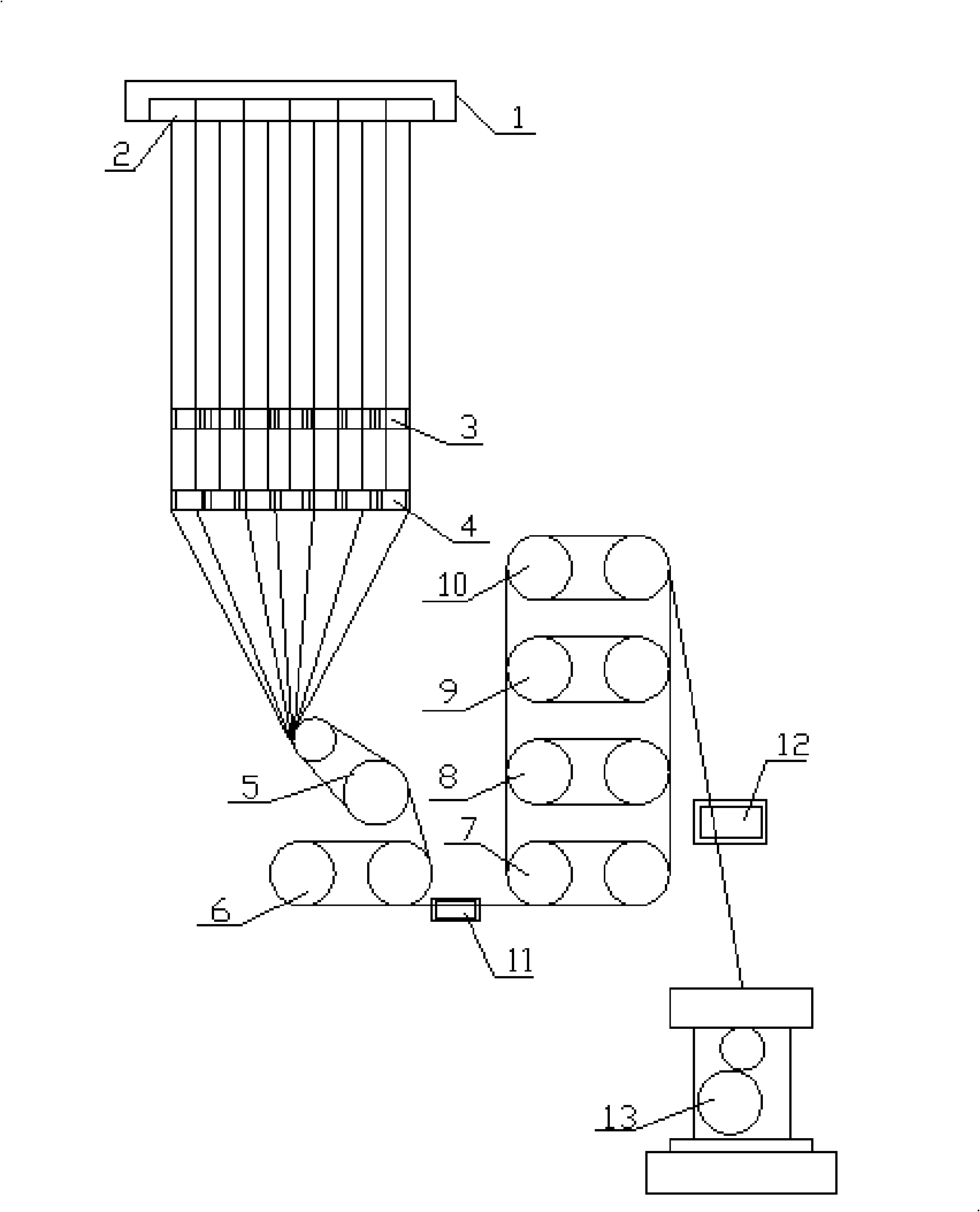

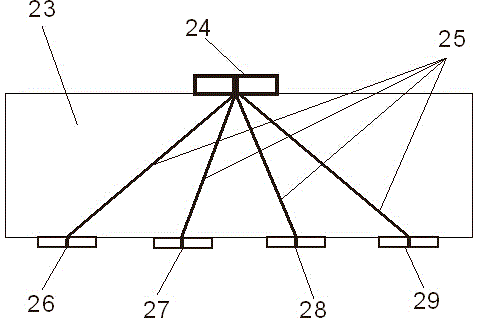

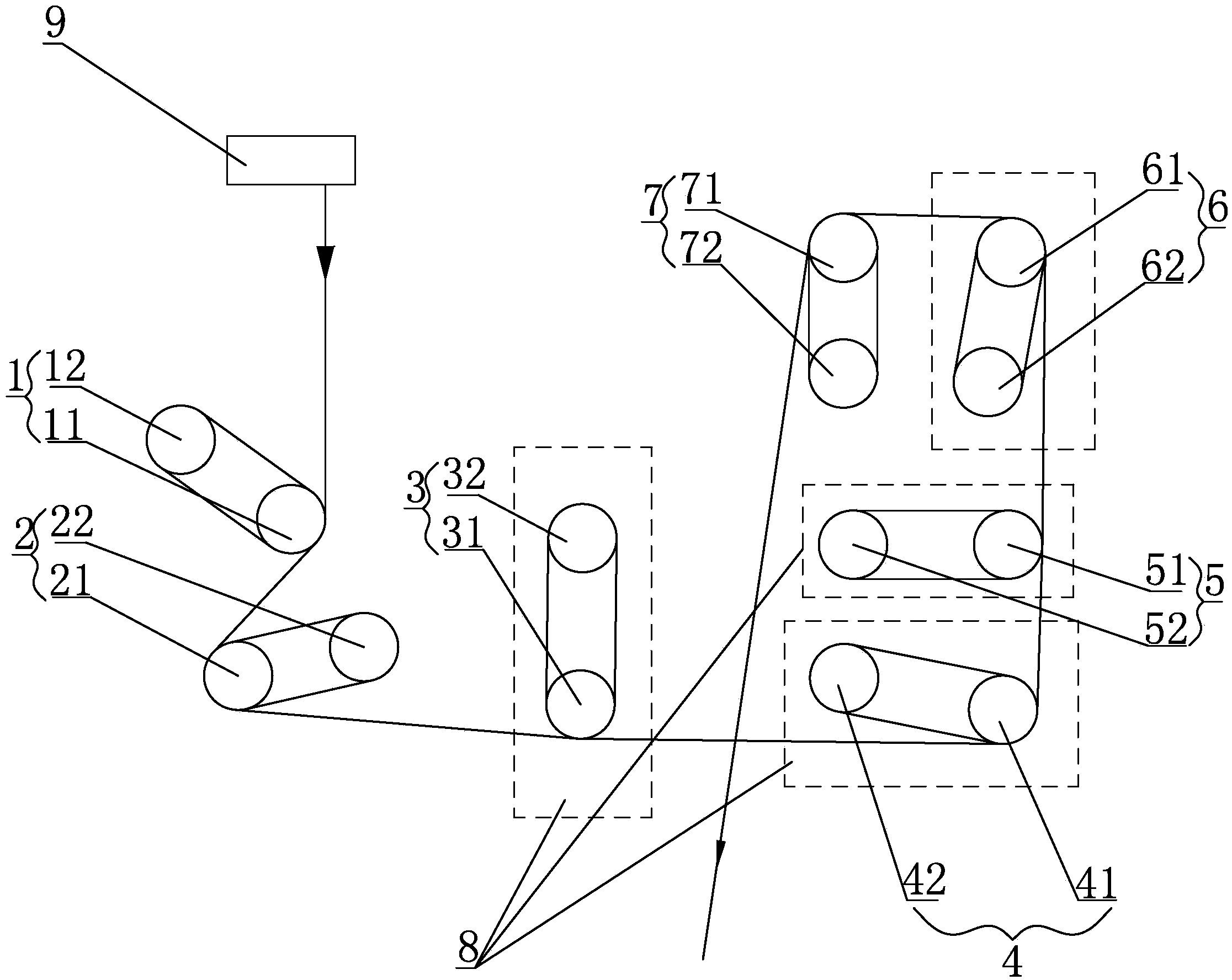

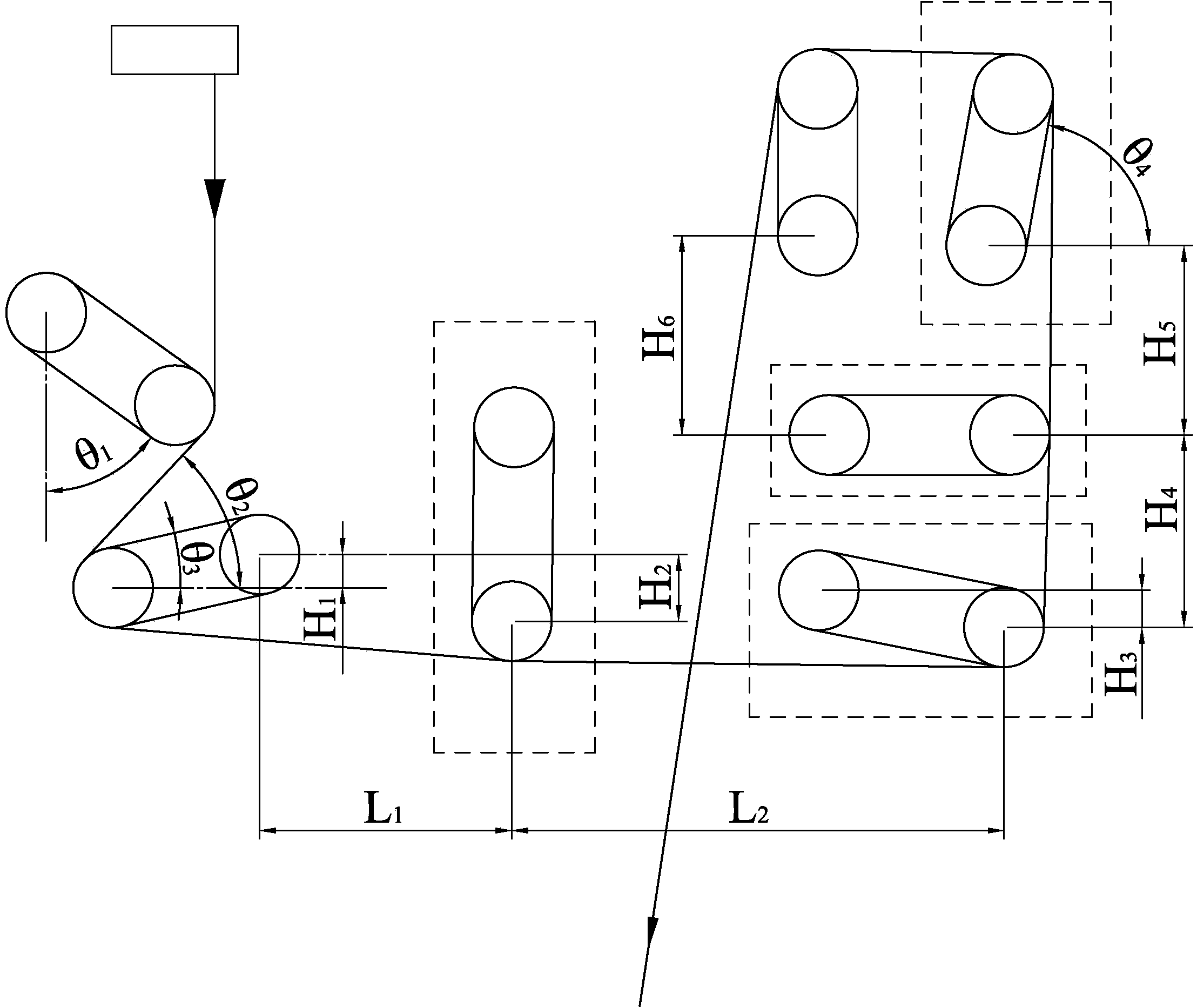

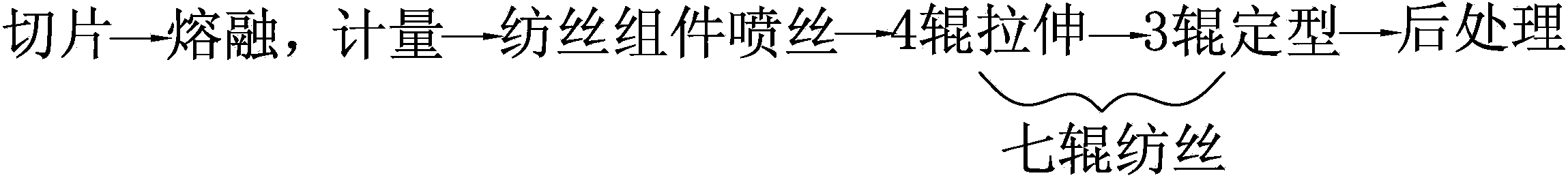

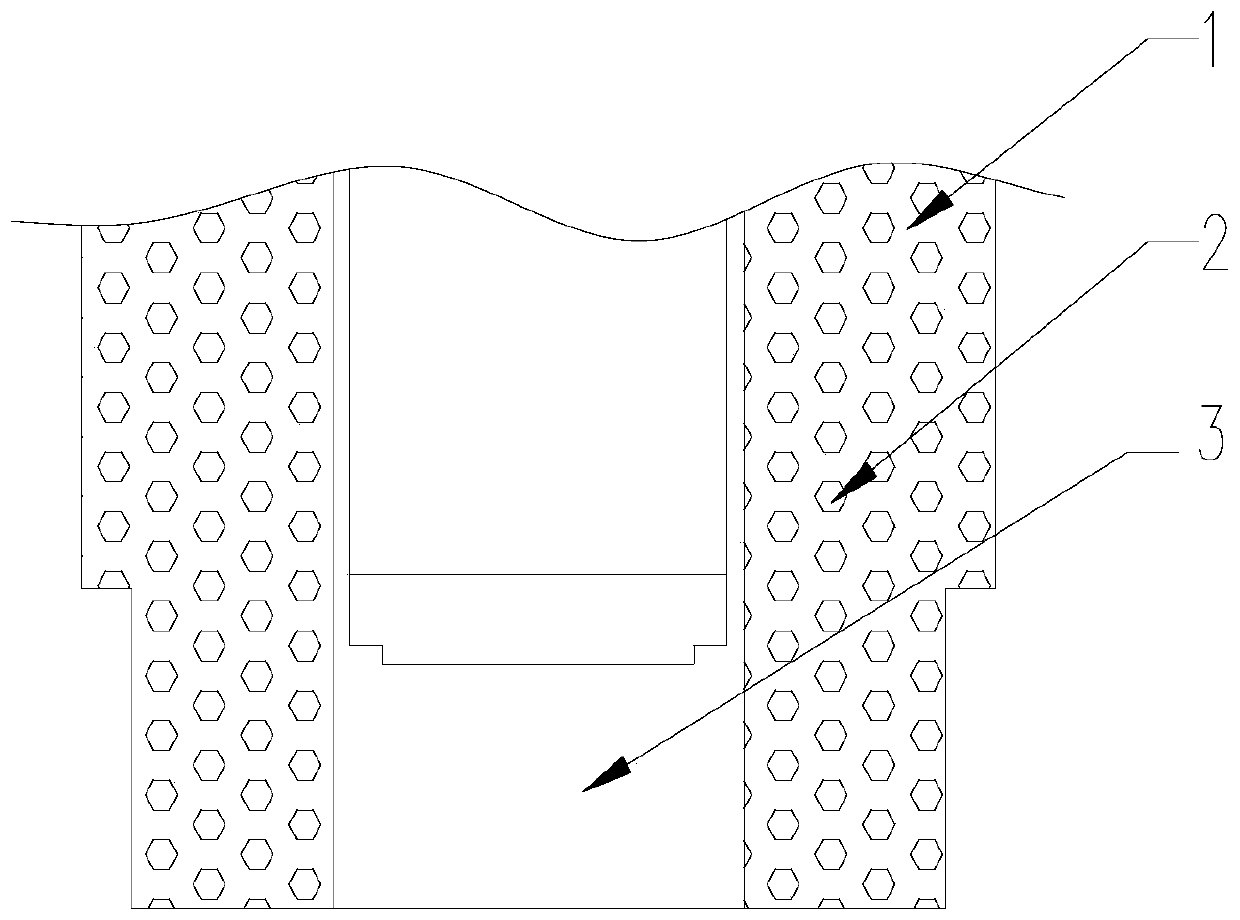

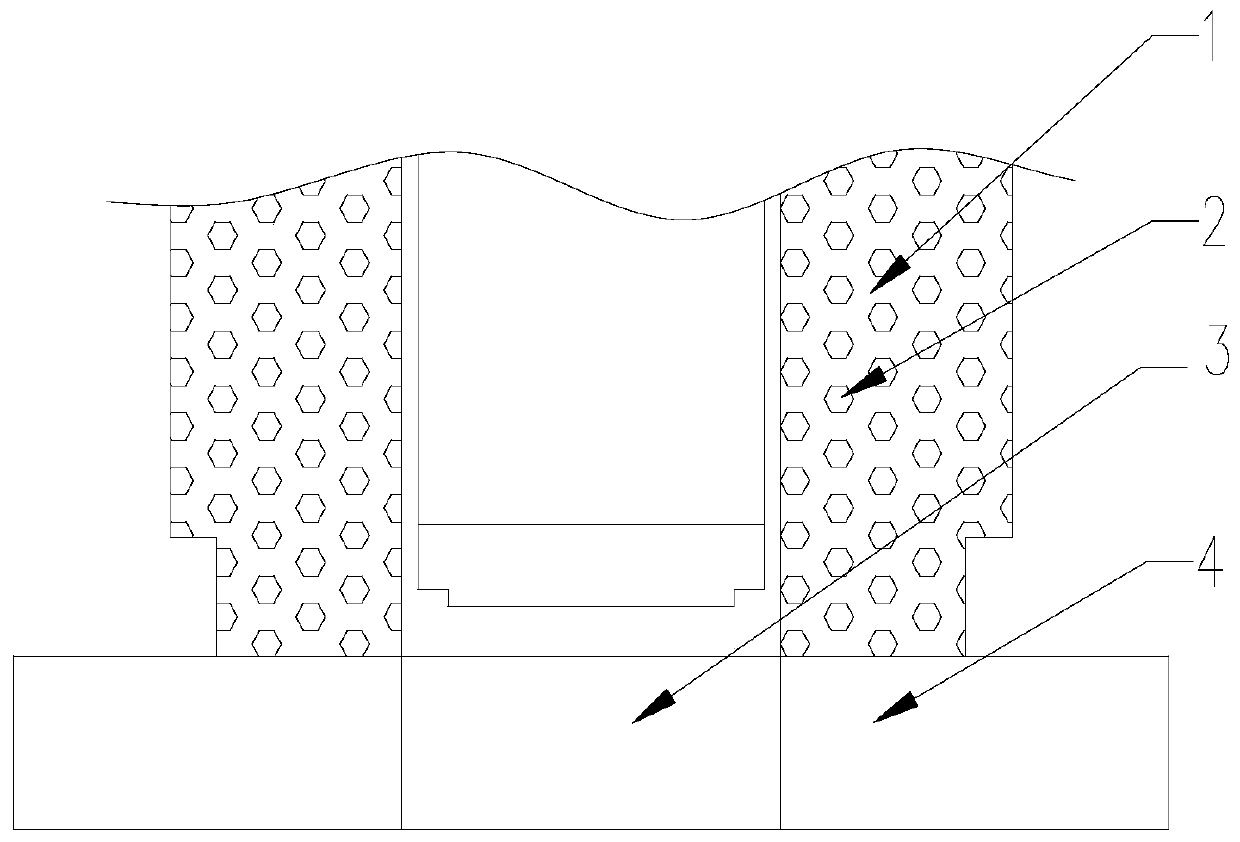

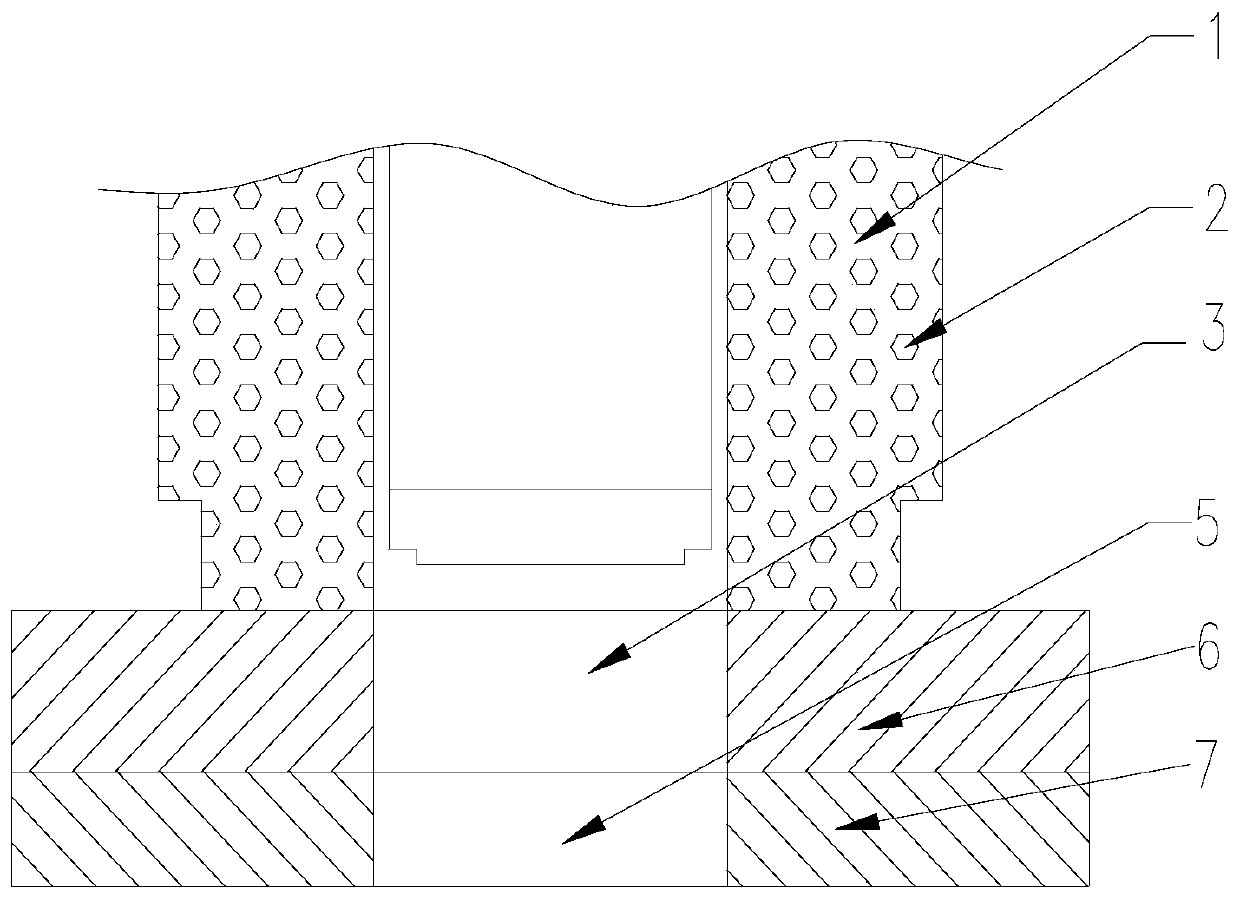

Spinning device with seven pairs of rollers and technology for producing terylene industrial yarns by adopting same

ActiveCN104264246AIncrease contact timeHeats and stretches evenlyArtificial filament heat treatmentStretch-spinning methodsYarnManufacturing engineering

The invention relates to a spinning device with seven pairs of rollers and a technology for producing terylene industrial yarns by adopting the same, and belongs to the technical field of production of terylene industrial yarns. The spinning device with the seven pairs of the rollers comprises a spinning component and seven pairs of the rollers arranged below the spinning component; each of the seven pairs of the rollers is composed of two rollers with the same center distance as 40-100 mm; the first pair of rollers is closest to the spinning component; the second pair of the rollers is located below the first pair of the rollers; the third pair of the rollers is located at the right side of the first and second pairs of the rollers; the fourth and fifth pairs of rollers are located at the right side of the third pair of the rollers. The spinning device with the seven pairs of the rollers can match with chip spinning and melt direct spinning respectively, the production way is flexible, and production of low-shrink terylene industrial yarns and common high-strength terylene industrial yarns can be realized through adjusting the roller speed, roller temperature and position setting of each pair of the rollers.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Heat-resistant impregnated synthetic fiber canvas and formula of impregnating adhesive solution needed by impregnation process

InactiveCN104669722ALow dry heat shrinkageImprove adhesionFibre typesSynthetic resin layered productsPolyesterPolymer science

The invention provides a heat-resistant impregnated synthetic fiber canvas and a formula of an impregnating adhesive solution needed by an impregnation process. The warp yarns refer to low shrinkage activated industrial polyester filaments, the weft yarns refer to high-strength polyhexamethylene adipamide fibers, the dry heat shrinkage of the finished canvas can reach a small value at the environment temperature of 175 DEG C, the adhesive force between the canvas layer and rubber at high temperature is enhanced by adopting a special impregnating adhesive solution formula, and separation between the adhesive layer and the canvas layer in the conveyor belt operating process is avoided.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

Regenerated polyester staple fiber and preparation method thereof

InactiveCN106835310AImprove spinnabilityImprove performanceStaple fibre formationMonocomponent polyesters artificial filamentFiberPolyester

The invention relates to a regenerated polyester staple fiber and a preparation method thereof. The preparation method mainly comprises the following steps of sorting recycled polyester bottles, removing tags, primarily cleaning, and crushing into PET (polyethylene terephthalate) slices; drying the PET slices, adding 0.01 to 0.015wt% of whitening powder, 0.05 to 0.09wt% of zinc oxide powder and 3 to 5wt% of polyester chain extender; melting, blending, spinning, drawing, drying and shaping. The regenerated polyester staple fiber and the preparation method thereof have the advantages that by controlling the technology conditions of temperature, time and the like in the processing and manufacturing process, and using the polyester chain extender, the dry heat shrinkage rate of the polyester staple fiber is reduced; the comprehensive property of the regenerated polyester staple fiber is better, and the spinning property of the regenerated polyester is effectively improved.

Owner:湖北泰峰实业有限公司

Method for preparing sewing-thread polyester filaments with high strength and low dry-heat shrinkage

InactiveCN101519811AIncrease production capacityIncrease manufacturing costMelt spinning methodsFilament-forming treatmentPolyesterDry heat

The invention discloses a method for preparing sewing-thread polyester filaments with high strength and low dry-heat shrinkage. The method is characterized in that common slices are tackified through solid-phase polymerization; the tackified common slices are dried to remove moisture and then enter a screw extruder so as to be melted; the obtained material is spun, cooled and oiled; and the obtained material is stretched through four times of hot rolling and then wound into a spinning cake. The polyester filaments with high strength and low dry-heat shrinkage, which are processed by the method, have the advantages of high strength, low dry-heat shrinkage, low boiling-water shrinkage, low elongation, few broken filaments, few broken ends and other good qualities, along with steady simple production operation and low production cost.

Owner:QINGDAO WEIFENG FIBER

Super-low shrinkage type sun shading cloth and preparation method thereof

ActiveCN108130743ALow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsCooling chamberSlow cooling

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN100427651CAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Production method of PET industrial yarns

InactiveCN107338488AHigh degree of polymerizationImprove breaking strengthSpinning head liquid feederMonocomponent copolyesters artificial filamentYarnEngineering

The invention discloses a production method of PET industrial yarns. The method comprises the technological steps of (1) preparation of high-viscosity slices, (2) spinning, (3) drafting and (4) winding, wherein at the step (3), drafting, thermal shaping and loosening are conducted by six pairs of drafting rollers under a certain spinning speed. The invention aims to provide the production method of the PET industrial yarns. The method is used to prepare the PET industrial yarns with good shrinkage characters. The method is applicable to production of wide fabrics; and demands for film structure materials can be satisfied.

Owner:桐乡守敬应用技术研究院有限公司

Ultra-low shrinkage sunshade cloth and preparation method thereof

ActiveCN108130743BLow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsPolymer scienceGlycol synthesis

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing high-modulus super low shrinkage industrial yarn using pyromellitic dianhydride

InactiveCN100432306CHigh modulusHigh-modulus ultra-low shrinkage polyester industrial yarn will be high-strengthMelt spinning methodsMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to a method that uses equal benzene tetracarboxylic acid anhydride making high modulus ultralow shrinking industrial yarn that includes the following steps: sending normal polyethylene terephthalate or normal polyester precrystallization and drying into screw extruder, adding expanding agent, setting outlet pressure and heating temperature of screw extruder to gain high viscosity polyester melt; putting the polyester melt into spinning box to take spinning to make high modulus ultralow shrinking industrial yarn. By using the method, the device investing and producing cost would be lowered, and the polyester industrial yarn is high intention high modulus and ultralow shrinking.

Owner:JIANGNAN UNIV

Low-shrinkage activated polyester industrial yarn and preparation method thereof

ActiveCN108385188ALow dry heat shrinkageLow wicking heightFibre typesFilament/thread formingYarnDry heat

The invention relates to a low-shrinkage activated polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, oiling with an activated oil agent, winding, and carrying out pre-activation treatment, wherein the oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58 wt%, and the material of the prepared polyester industrial yarn is the modified polyester withthe molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain. According to the present invention, the preparation method is simple and reasonable; and the dry heat shrinkage rates of the finally obtained low-shrinkage activated polyester industrial yarn respectively are 5.5+ / -0.8% and 2.8-5.8% at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex, and the wicking height is less than or equal to 5 mm.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method for regenerate polyester staple fiber

InactiveCN104562234AHigh elongation at breakLow dry heat shrinkageSevering to form staple fibresMelt spinning methodsPolyesterFiber

The invention relates to a preparation method for regenerate polyester staple fiber. The method improves elongation at break of the polyester staple fiber, and reduces shrinkage in hot air through control of technological conditions of temperature, time, and the like in a processing and preparation process, and improves dimensional pressed film thermal forming performance of the product (namely the regenerate polyester staple fiber).

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

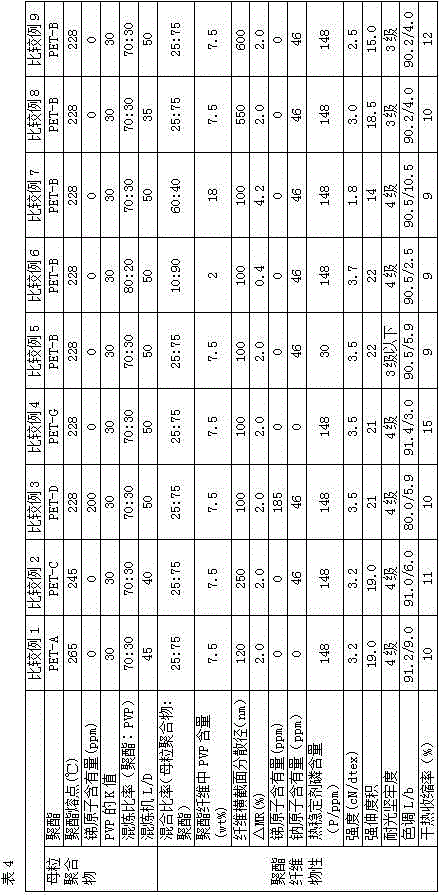

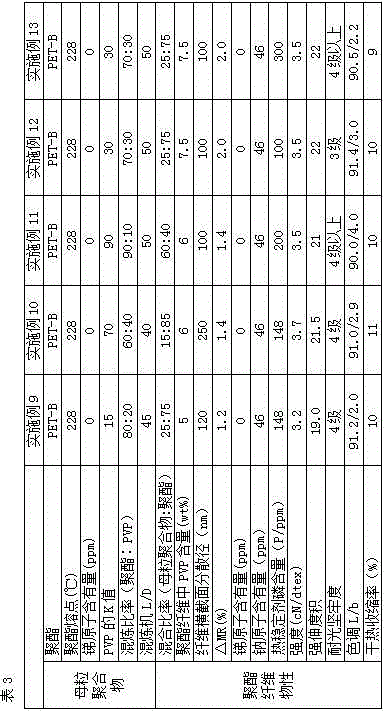

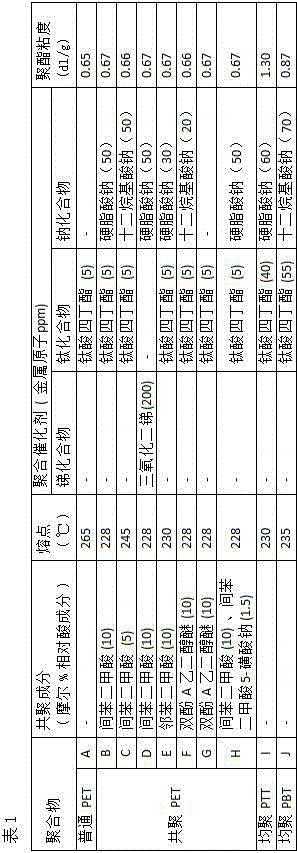

Polyester fiber with moisture absorption/desorption performance and preparation method thereof

InactiveCN105780188AGood hygroscopicityExcellent toneMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention discloses polyester fiber with moisture absorption / desorption performance and a preparation method thereof. The polyester fiber contains polyester with melting point being 200-240 DEG C, poly(N-vinyl lactam), a phosphorous heat stabilizer and a sodium nucleating agent, wherein poly(N-vinyl lactam) accounts for 3-15 wt% of weight of polyester fiber; weighed according to P element, the phosphorous heat stabilizer accounts for 50-500 ppm of weight of polyester fiber; weighed according to Na element, the odium nucleating agent accounts for 10-100 ppm of weight of polyester fiber; and content of antimony element in the polyester fiber is below 5 ppm. By adding a moisture absorption component, the phosphorous heat stabilizer and the sodium nucleating agent into polyester, the moisture-absorption polyester fiber which can be applied to materials for clothing such as underwear, sport suit and the like is obtained.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

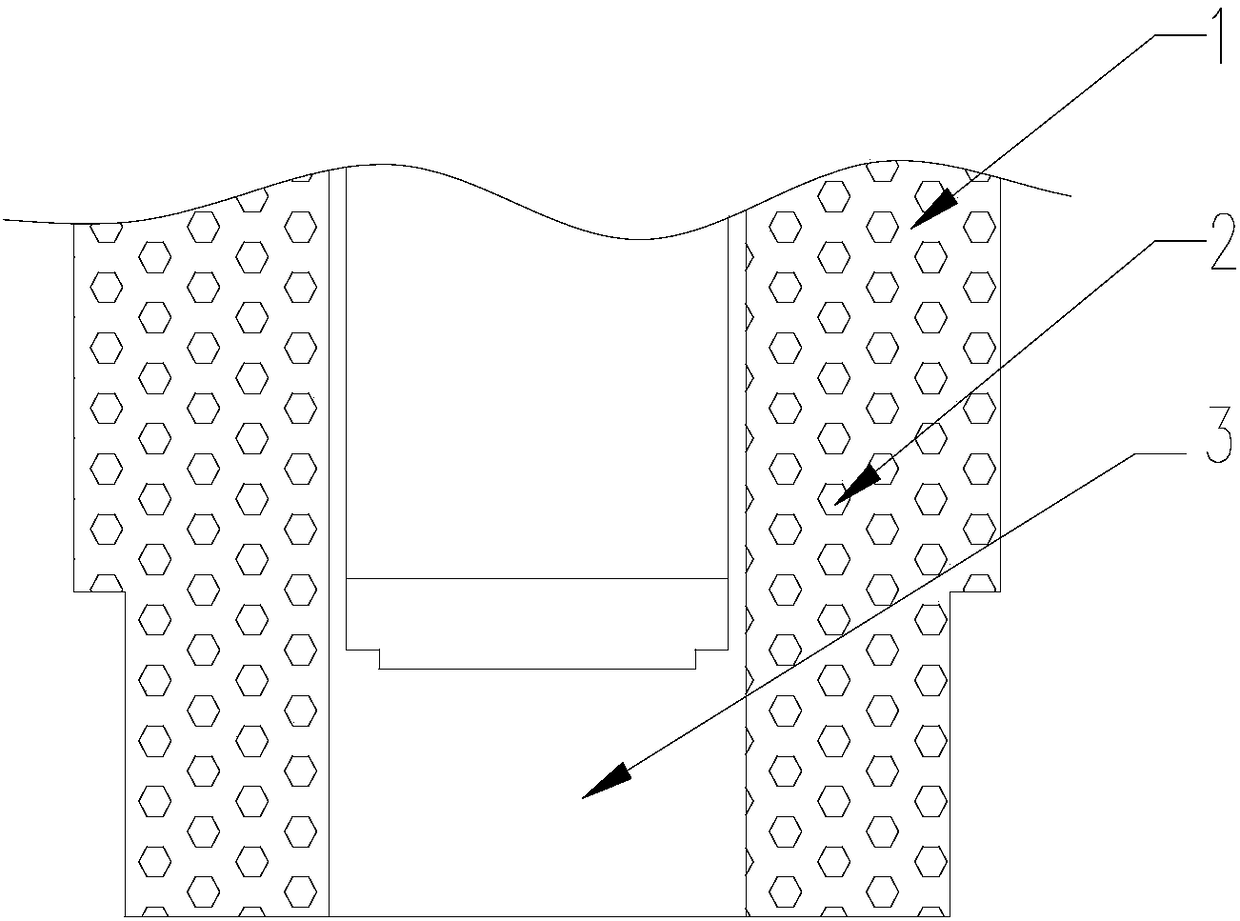

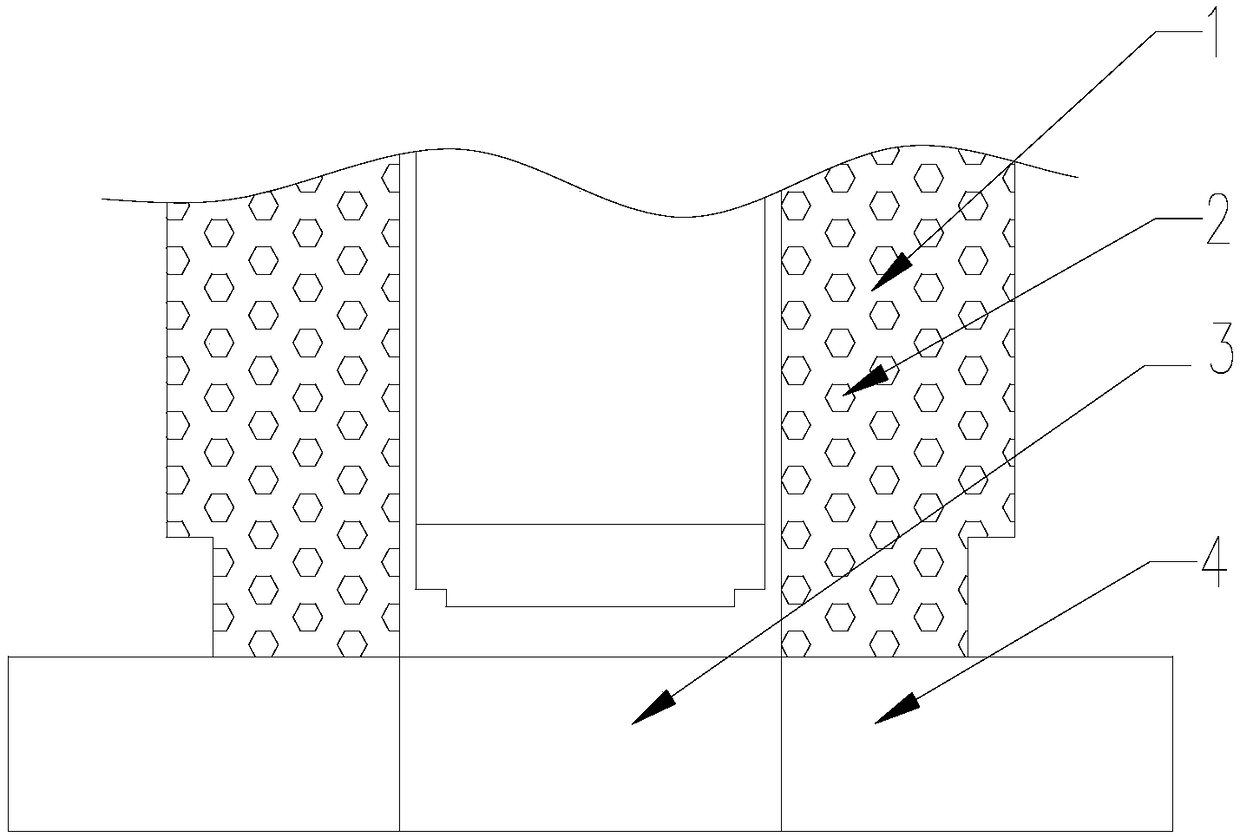

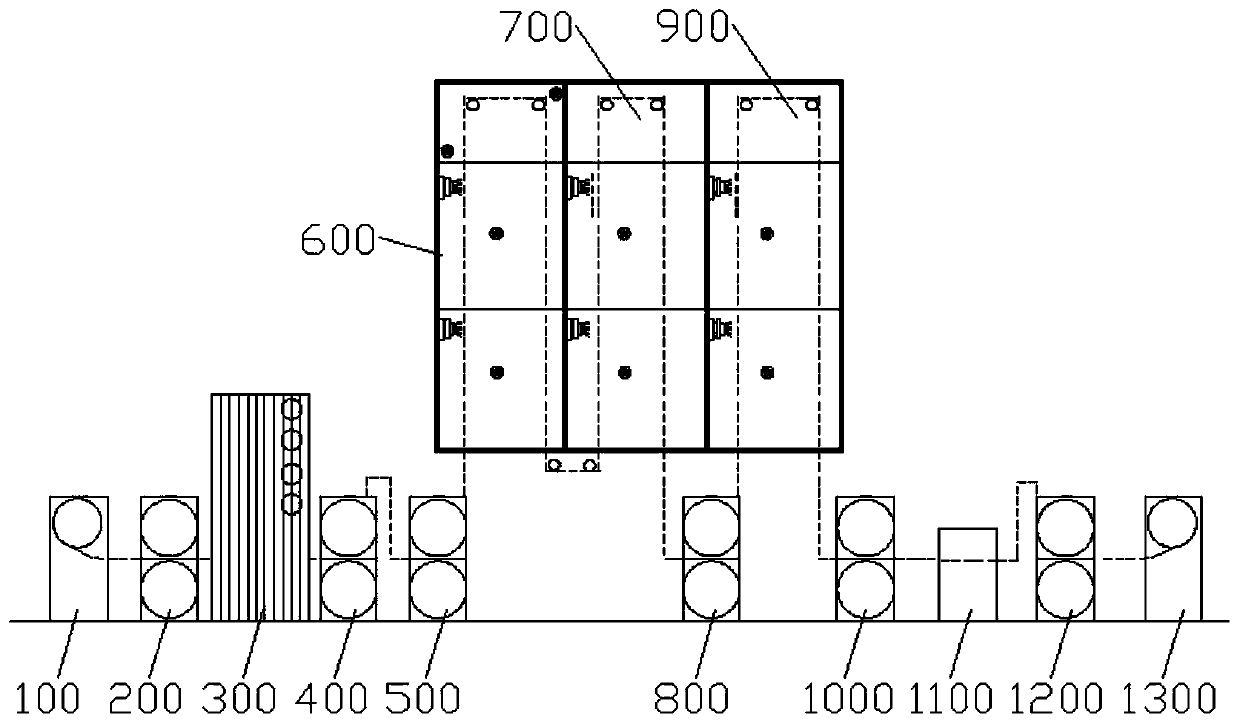

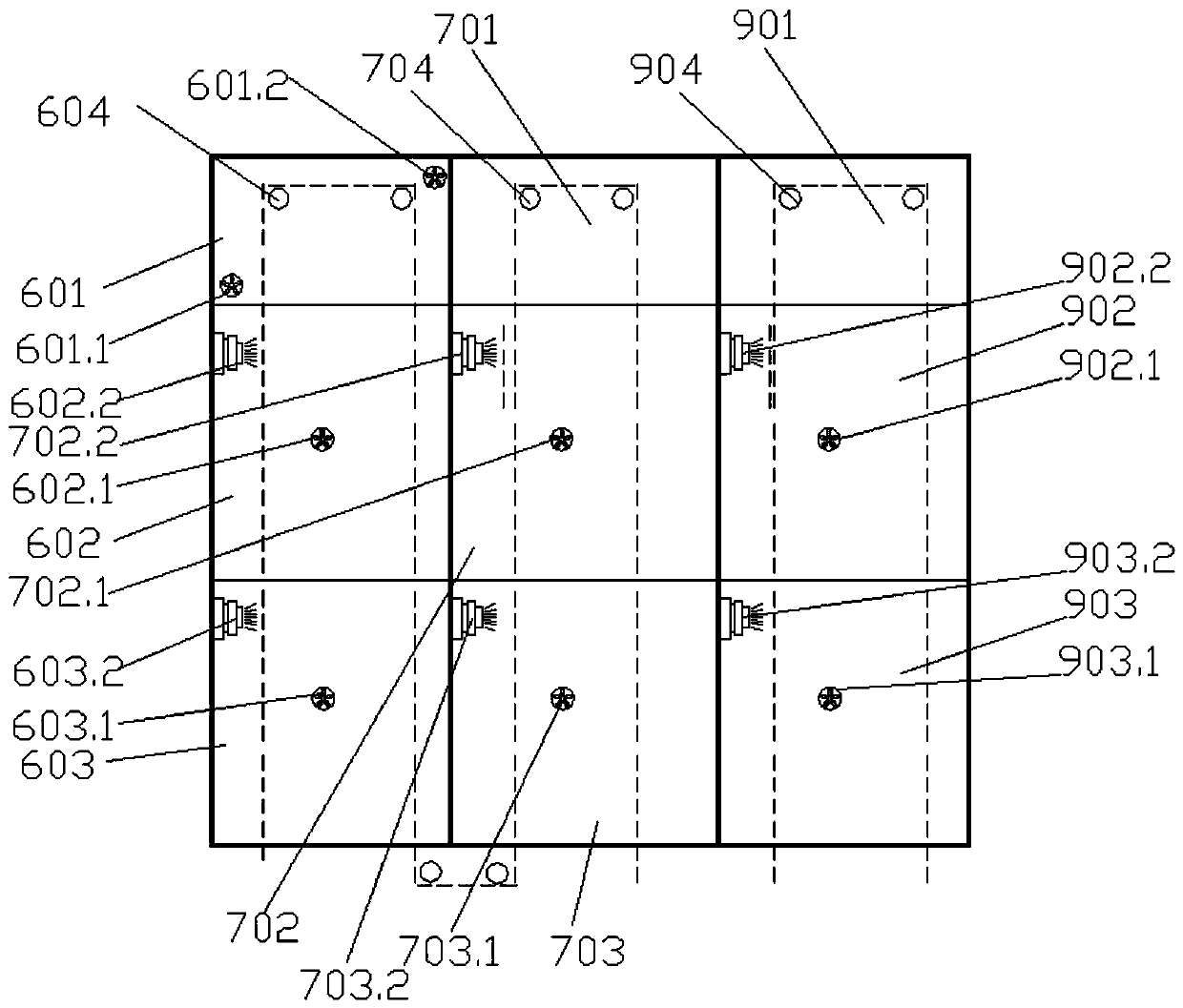

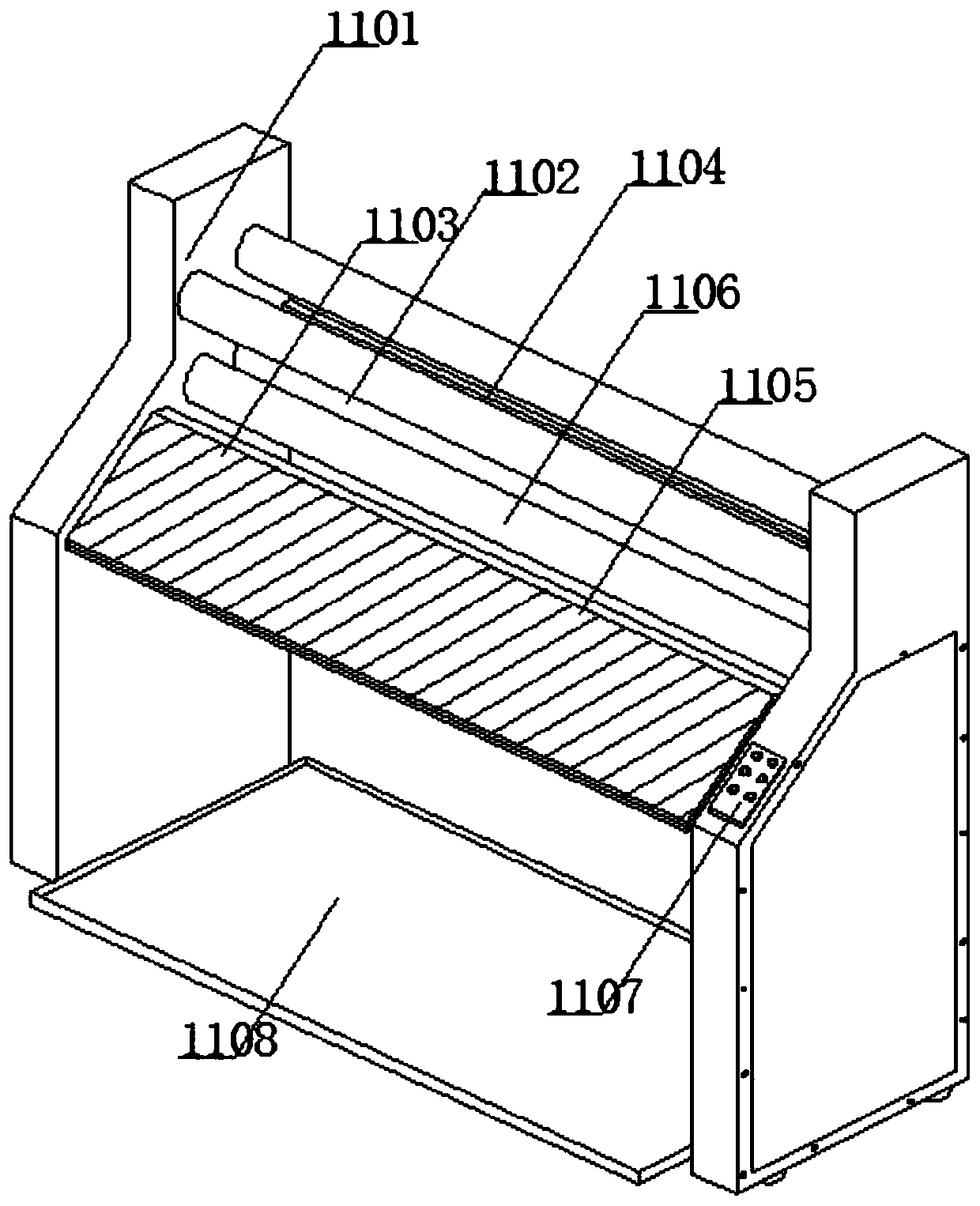

Multifunctional rubber dipping machine for preparing chinlon 6 cord fabric

PendingCN109811491AExtended service lifeStrong fatigue resistanceSucessive textile treatmentsLiquid/gas/vapor removalShrinkage rateHigh energy

The invention relates to a multifunctional rubber dipping machine for preparing a chinlon 6 cord fabric. The multifunctional rubber dipping machine is characterized in that the multifunctional rubberdipping machine comprises a system rack, the system rack sequentially comprises an unwinding device, a front traction device, a slow storage cloth device, a middle traction device, a dipping host, a front drying room, a rear drying room, a first roller set, a stretching drying room, a second roller set, a shaping device, a third roller set, and a winding device along the cord fabric from front toback. The multifunctional rubber dipping machine for preparing the chinlon 6 cord fabric has the advantages of high production efficiency, high energy utilization rate, and low product dry-heat shrinkage rate.

Owner:江阴市沙江纺织科技有限公司

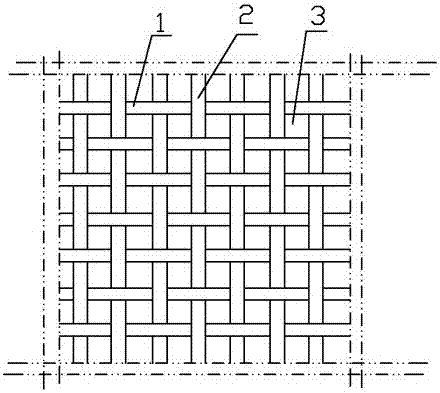

Ultra-high molecular weight polyethylene fiber filtering cloth

InactiveCN107983012AHigh precisionStrong loadHeating/cooling textile fabricsMembrane filtersFiberPolymer science

The invention discloses ultra-high molecular weight polyethylene fiber filtering cloth which is characterized by being prepared from ultra-high molecular weight polyethylene fiber warp and ultra-highmolecular weight polyethylene fiber weft in a woven manner, wherein filtering holes are formed between the ultra-high molecular weight polyethylene fiber warp and the ultra-high molecular weight polyethylene fiber weft. The ultra-high molecular weight polyethylene fiber filtering cloth is high in precision, high in loading capacity and good in tension resistance, the service life of the filteringcloth is 3 times or more than 3 times of that of a chemical fiber, the dry heat shrinkage rate of the filtering cloth is 2% or smaller than 2%, the acid / alkali resistance, the wearing resistance and the tension resistance are improved, the service life is prolonged, the use range of the filtering cloth is widened, the filtering quality is improved, and the filtering cost is reduced.

Owner:芜湖领航新材料科技有限公司

One-step high temperature and high pressure melt spinning equipment and production method of polymer fiber

ActiveCN104313711BHigh crystallinityHigh densitySpinning head liquid feederMonocomponent synthetic polymer artificial filamentPolyetherimideEngineering

Owner:CHANGZHOU CHUANGYING NEW MATERIAL TECH

Production method of special polyester staple fiber for high-strength medium-elongation nonwoven fabric

ActiveCN101487147BIncrease mobilityLow dry heat shrinkageMonocomponent polyesters artificial filamentPolyesterNonwoven fabric

Owner:JIANGYIN HUAHONG CHEM FIBER

A high-modulus low-shrinkage hard wire rope and its preparation method

ActiveCN108385418BLow dry heat shrinkageSimple preparation processFibre typesFilament/thread formingYarnPolymer science

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com