Patents

Literature

51results about How to "Change bond angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester DTY fiber and preparation method thereof

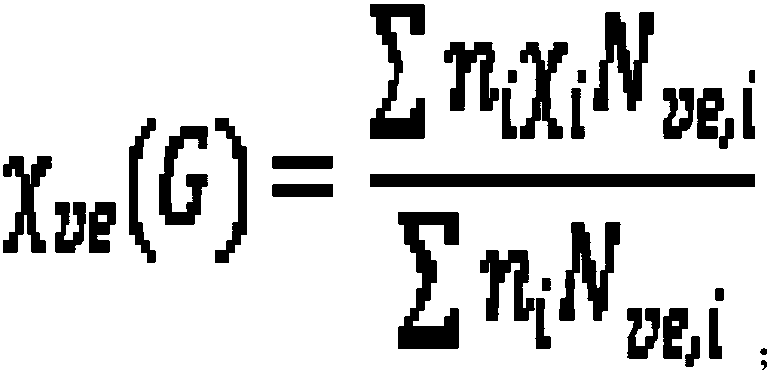

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

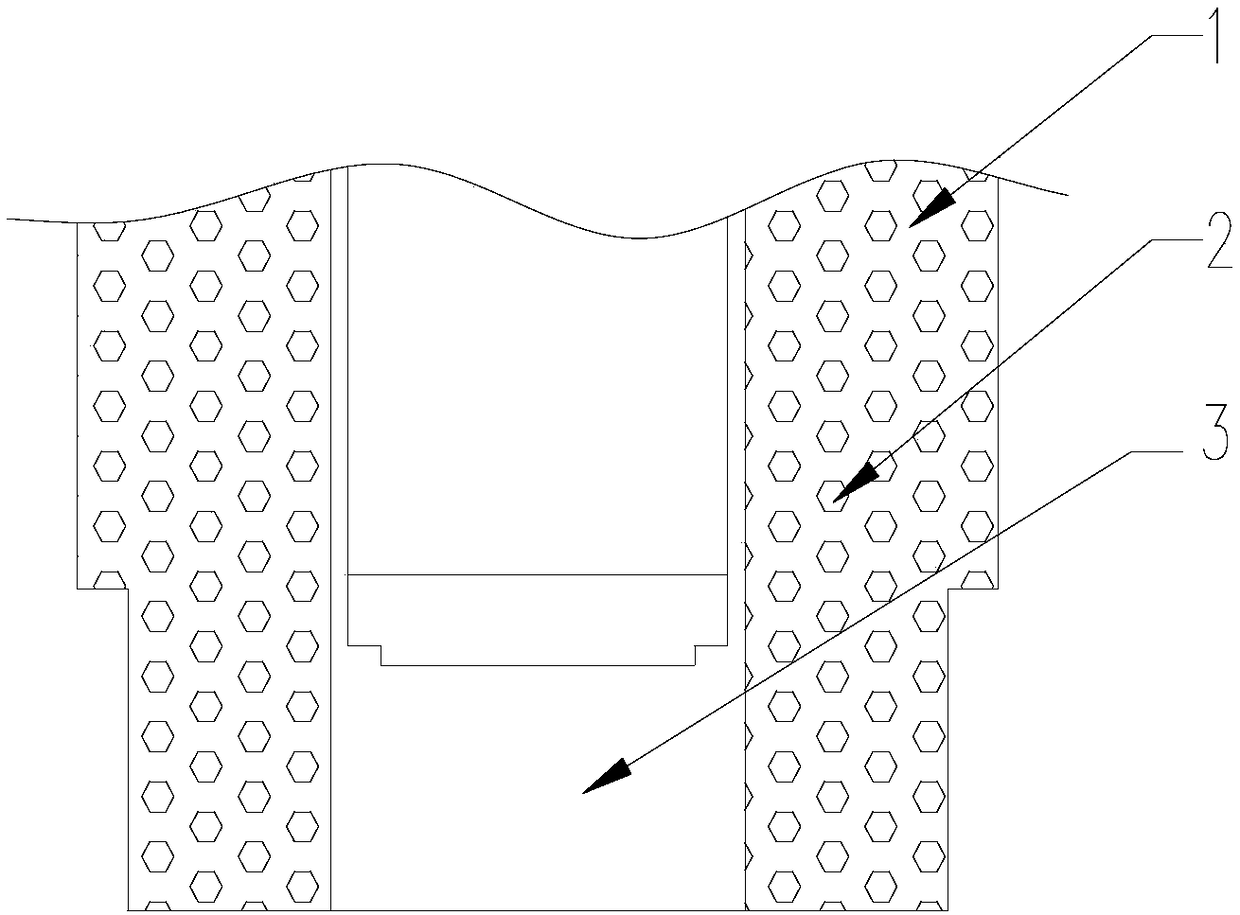

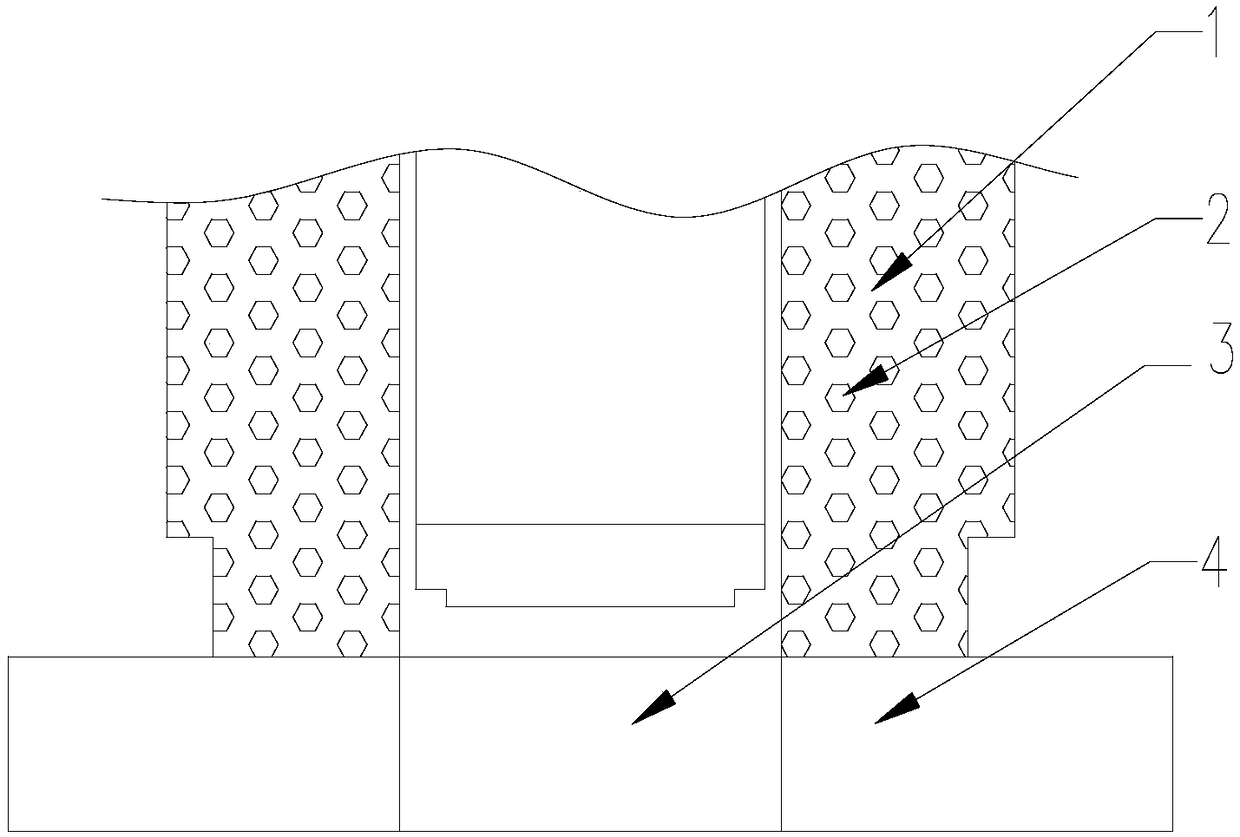

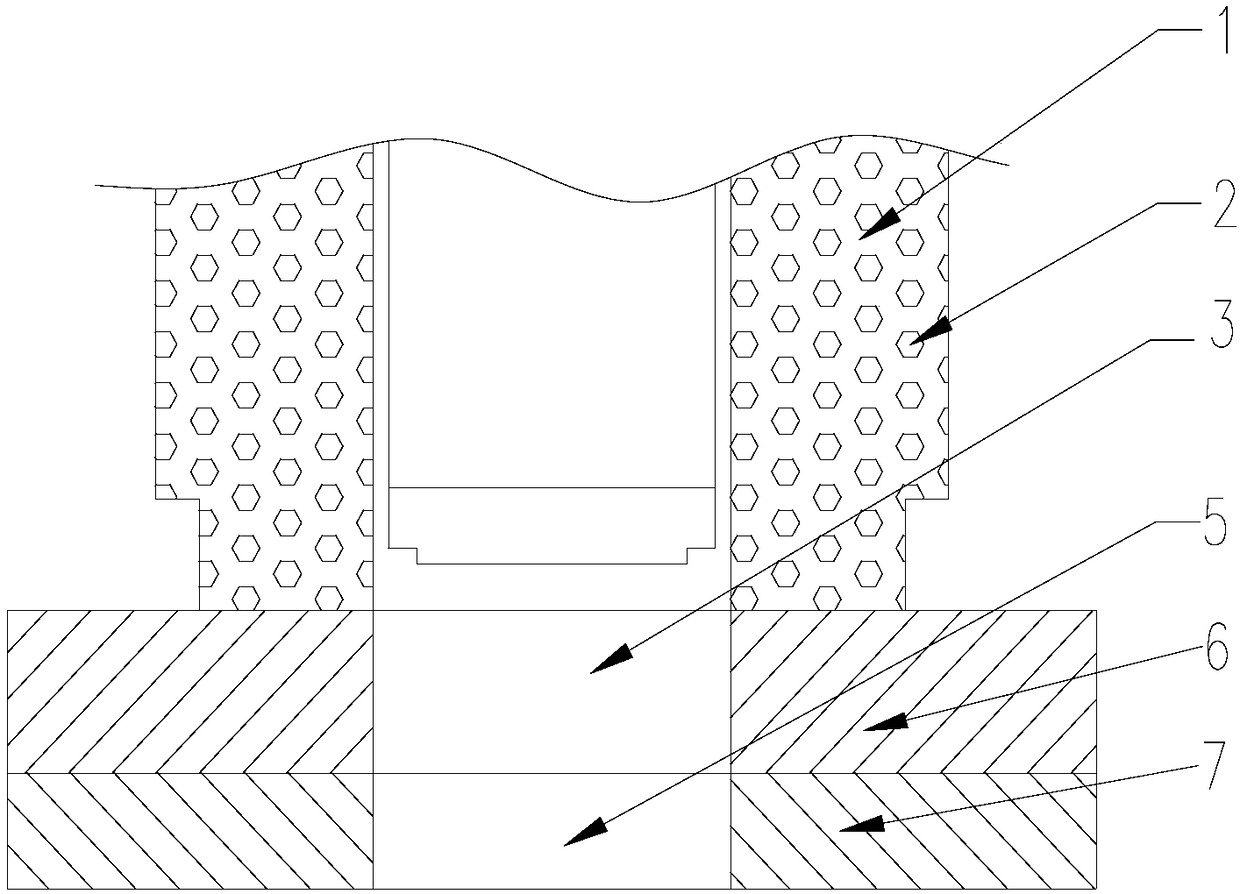

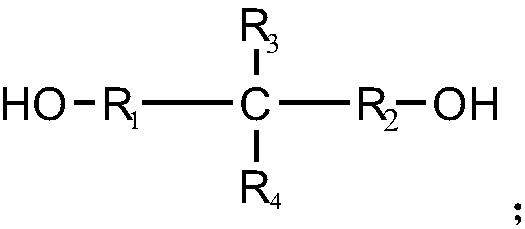

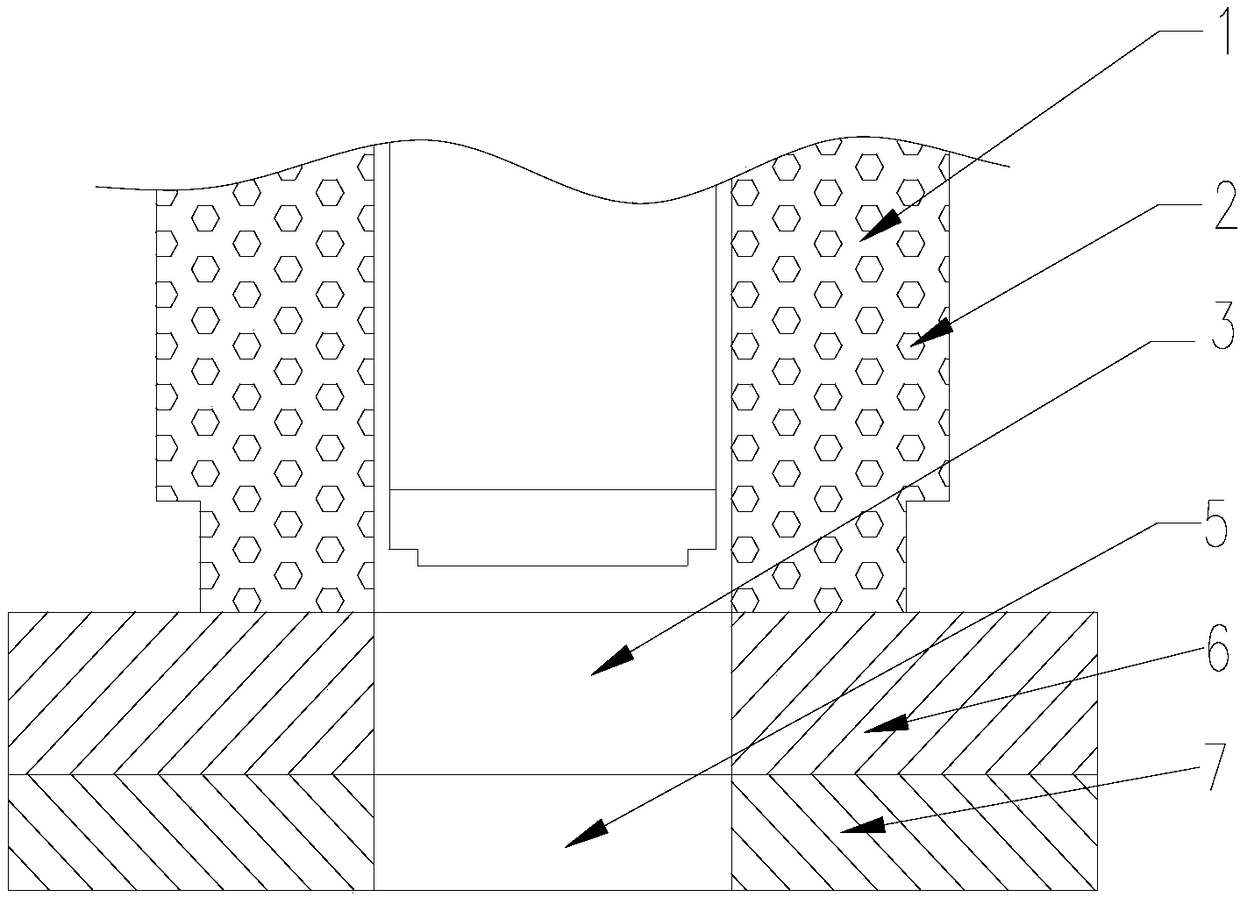

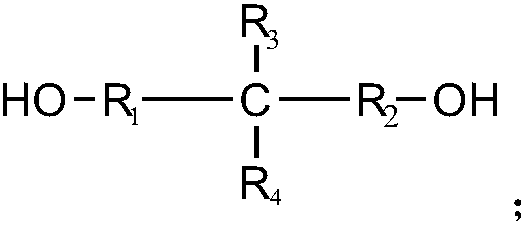

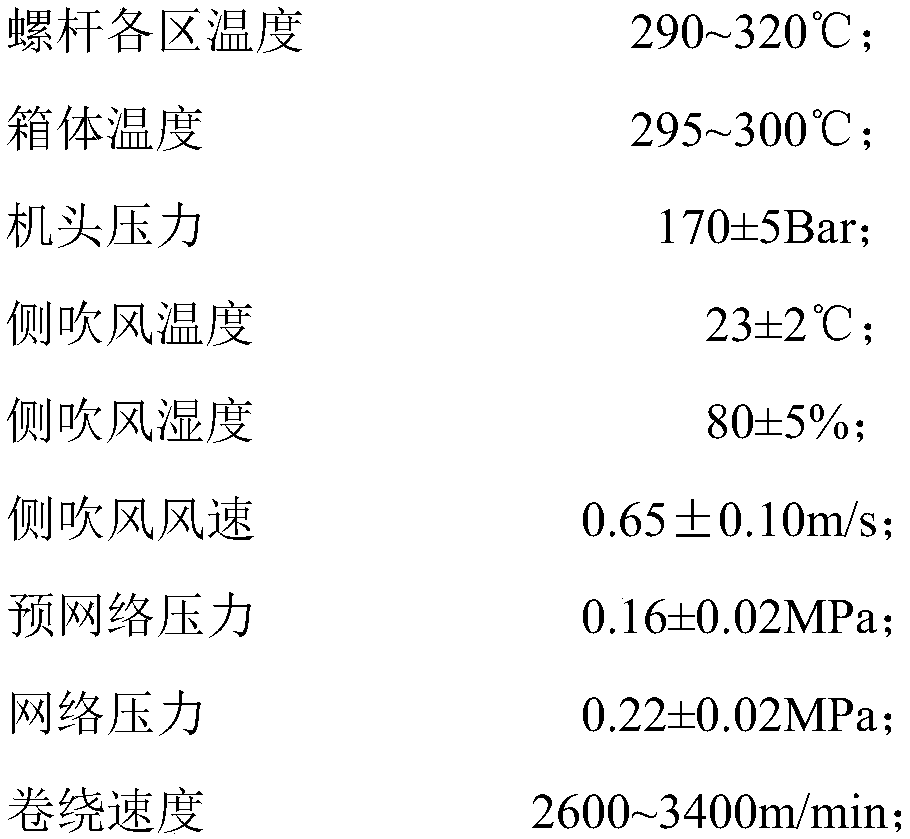

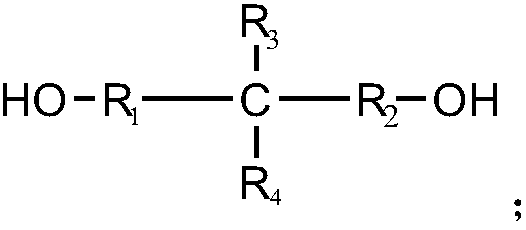

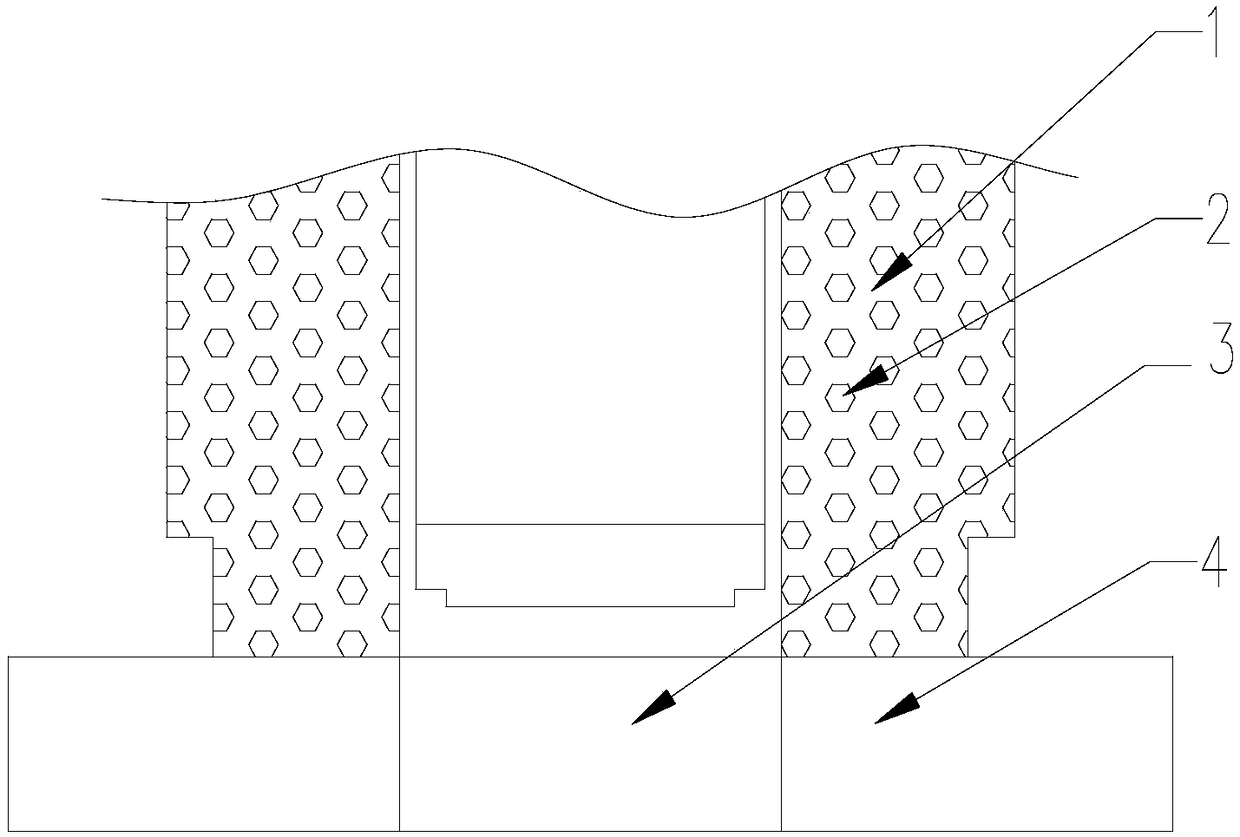

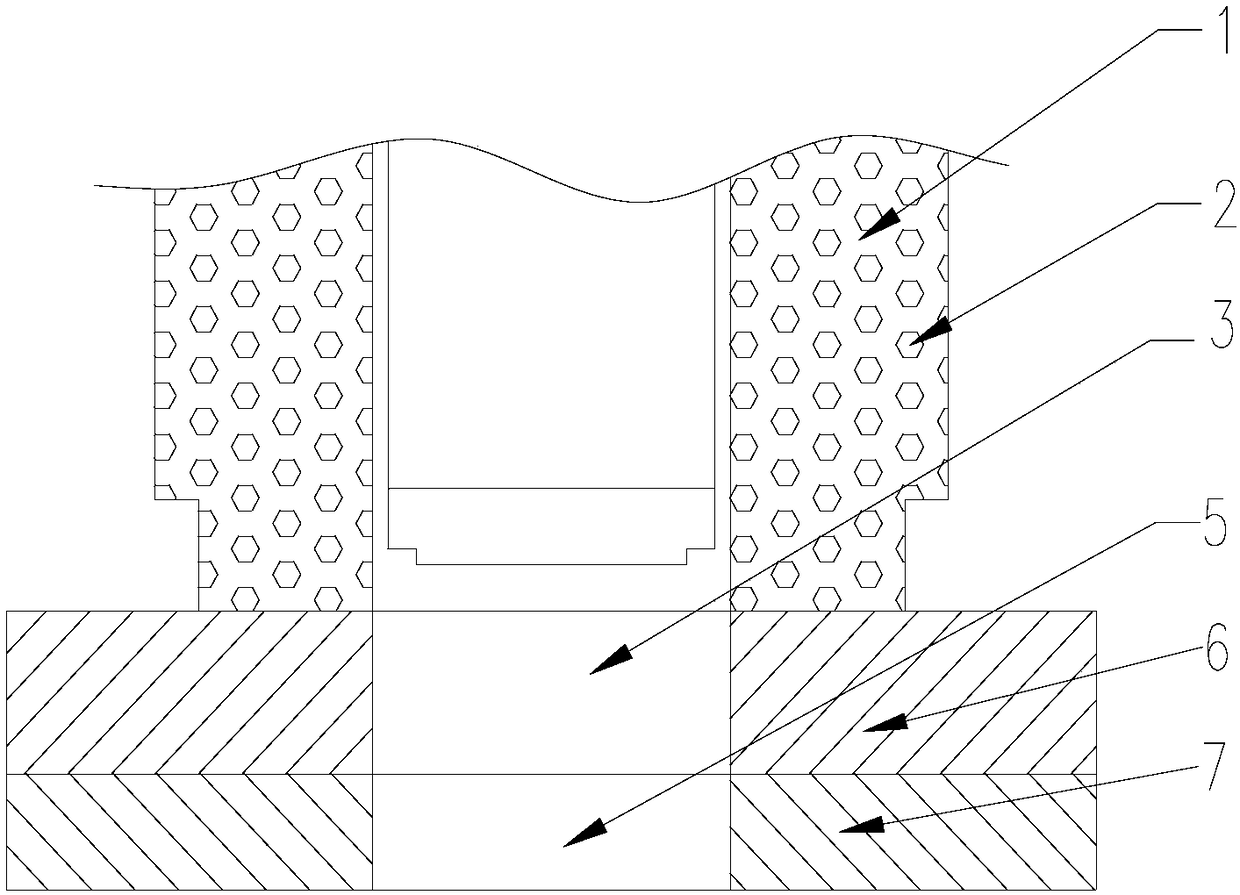

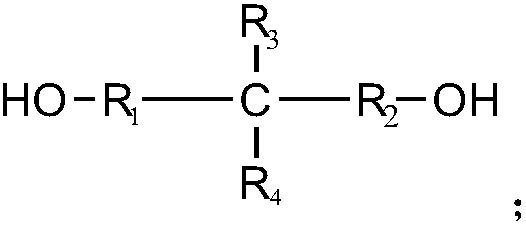

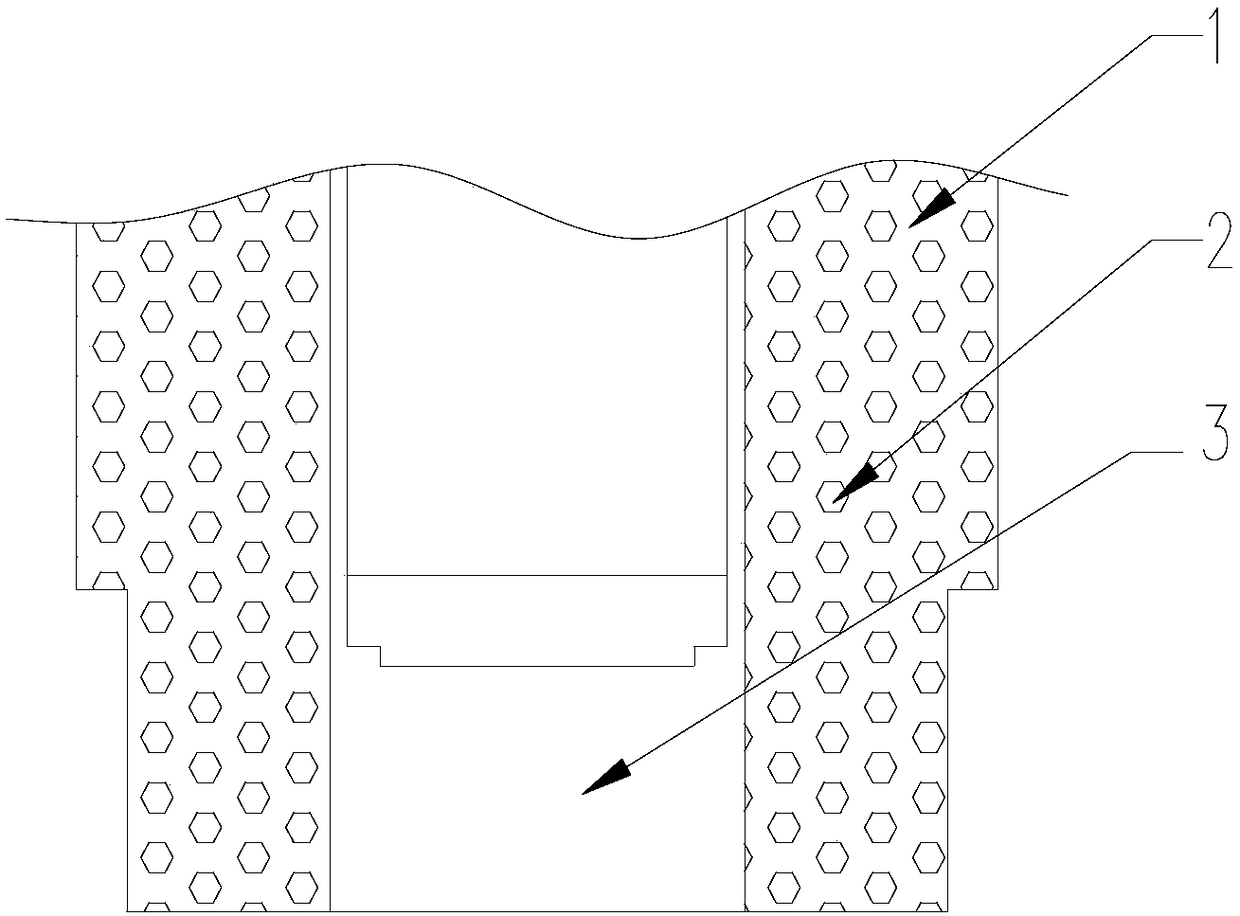

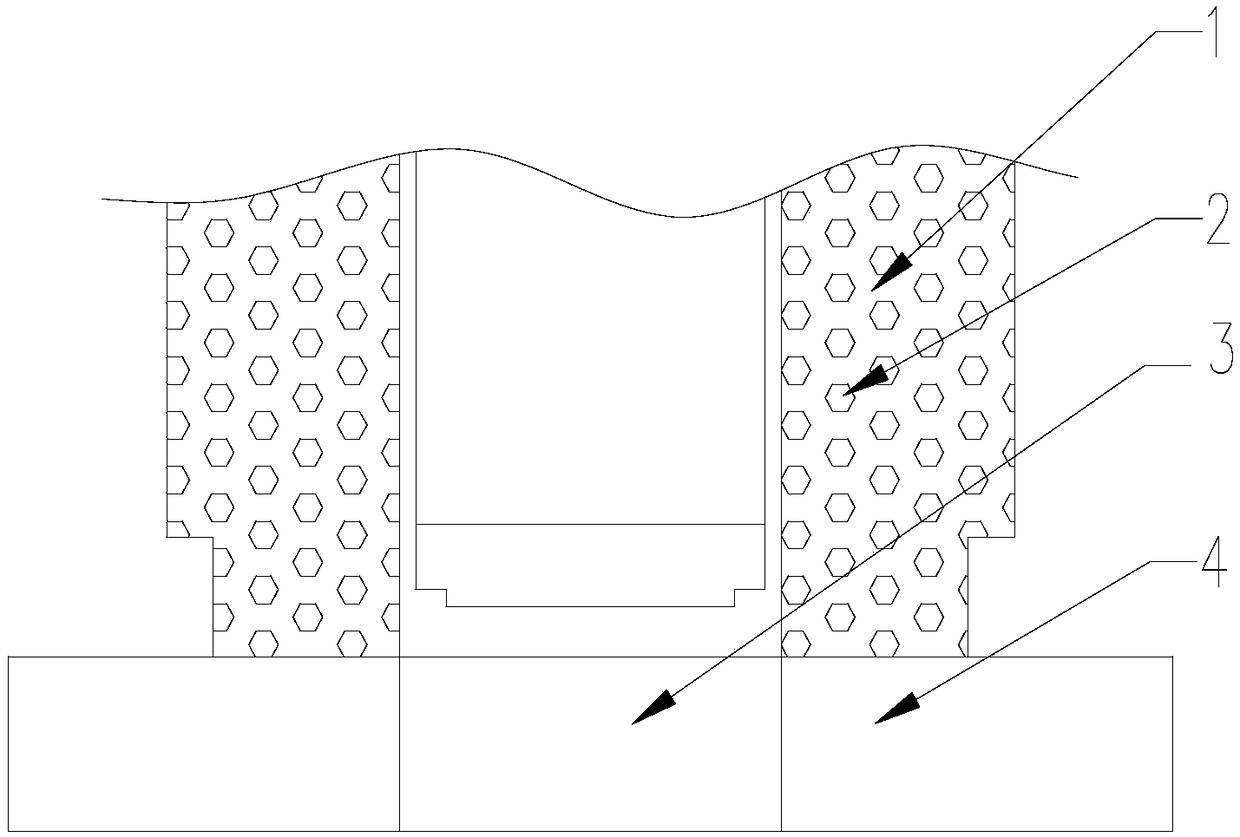

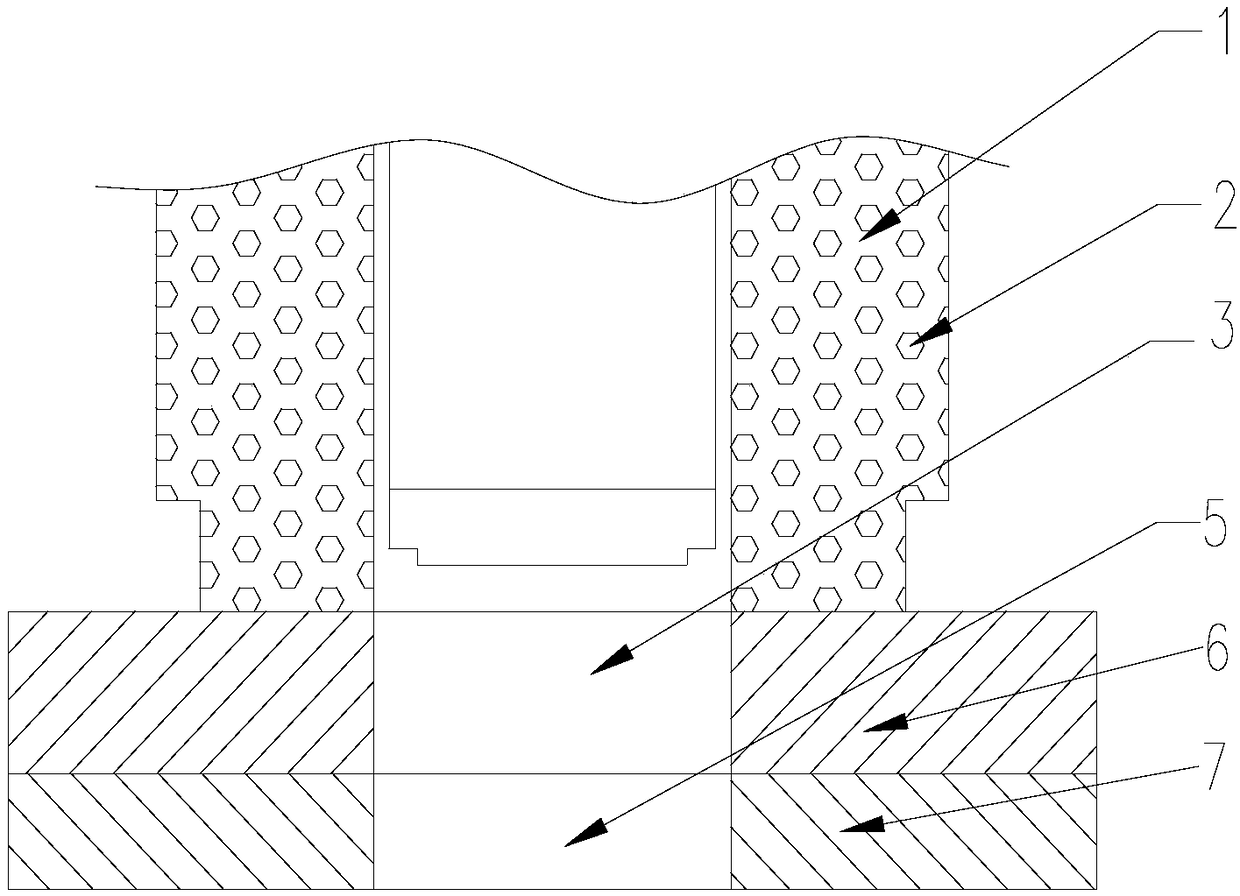

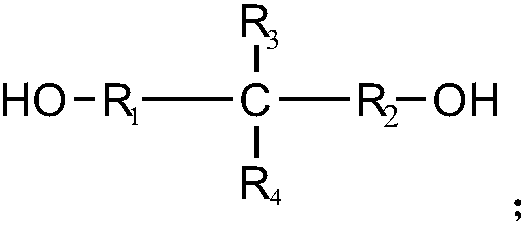

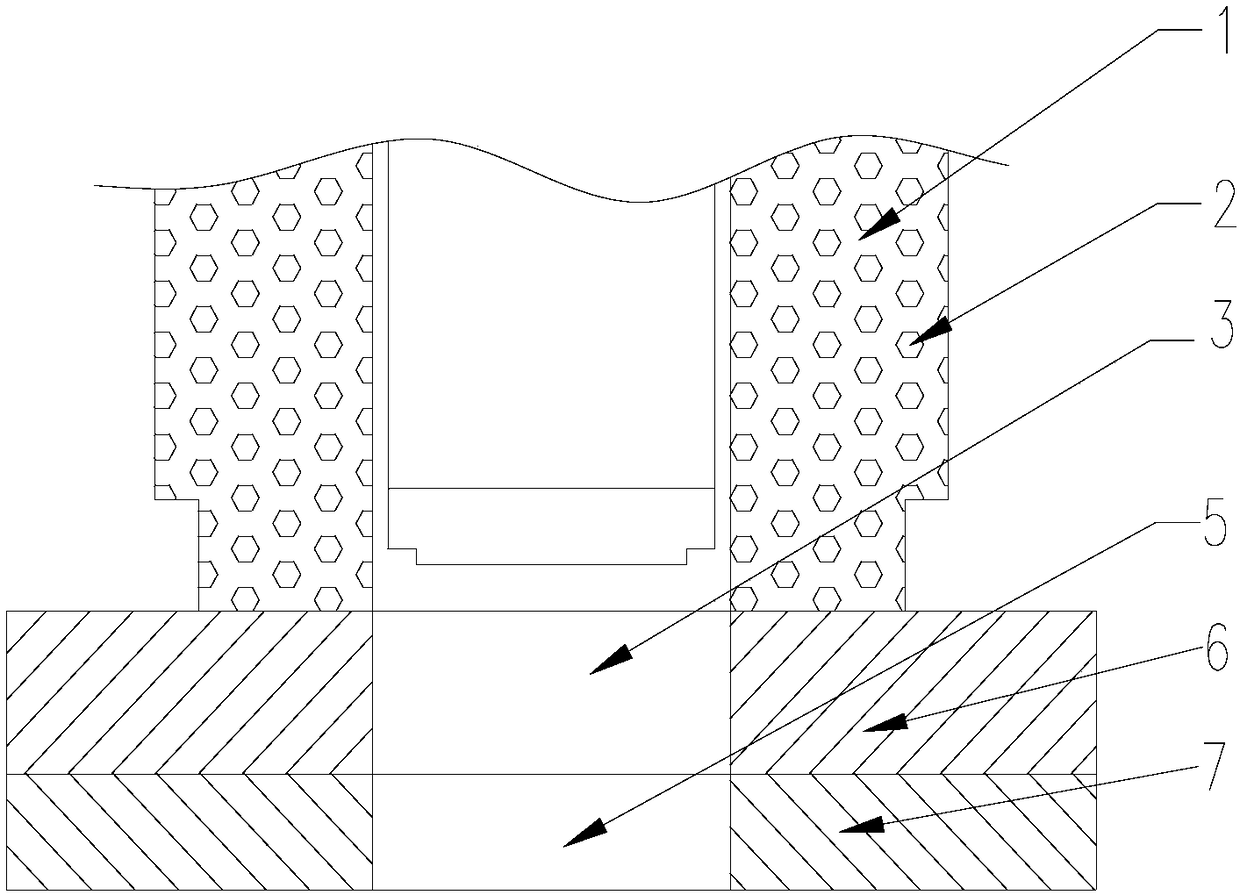

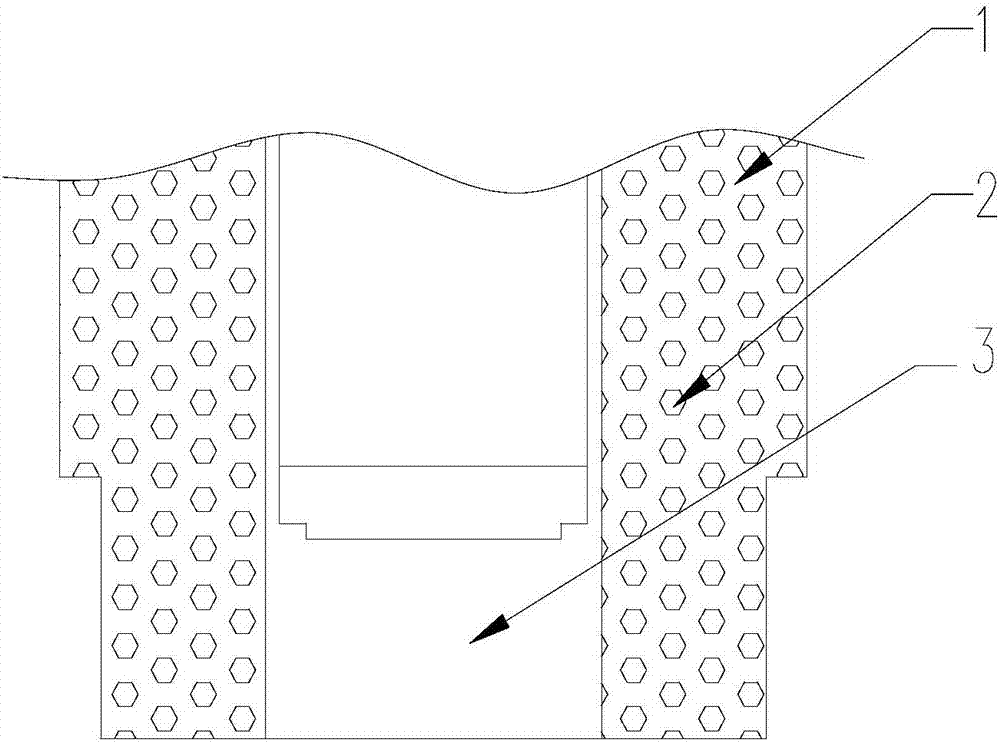

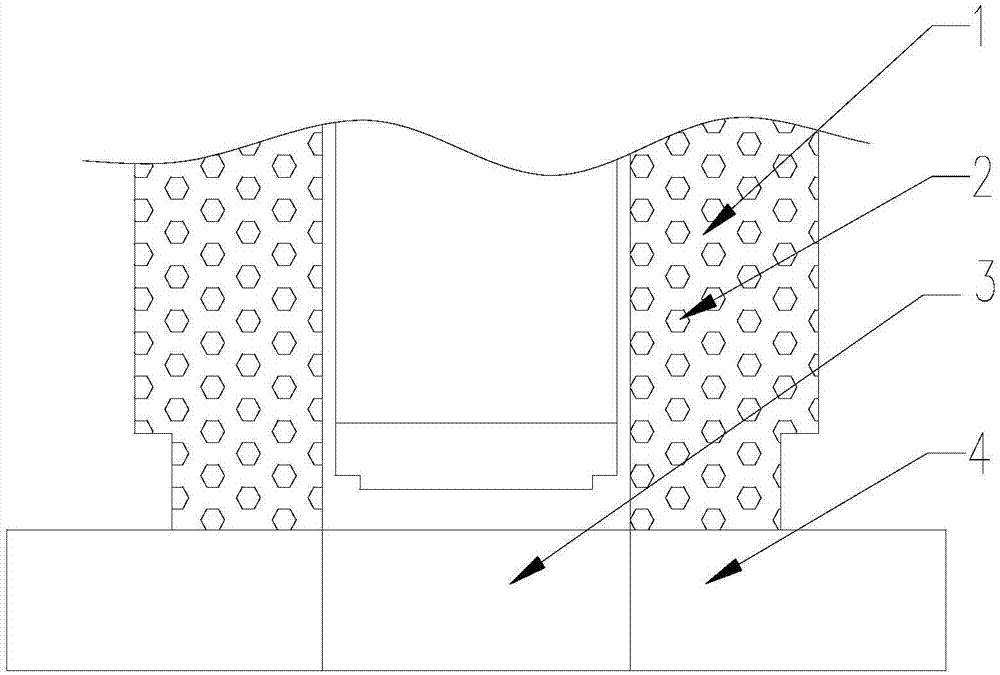

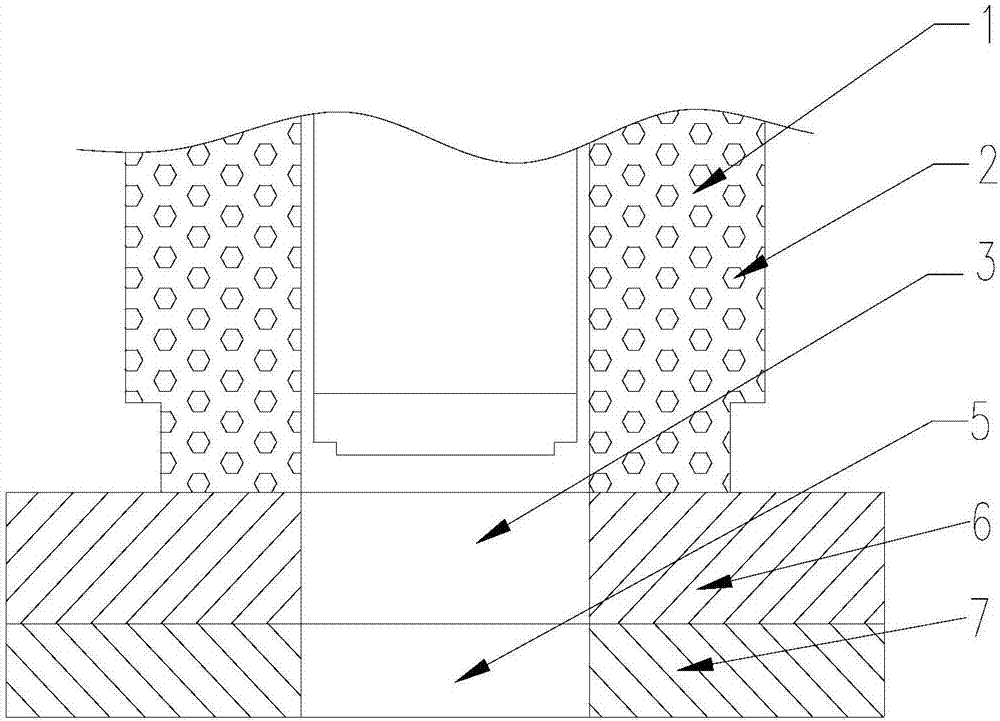

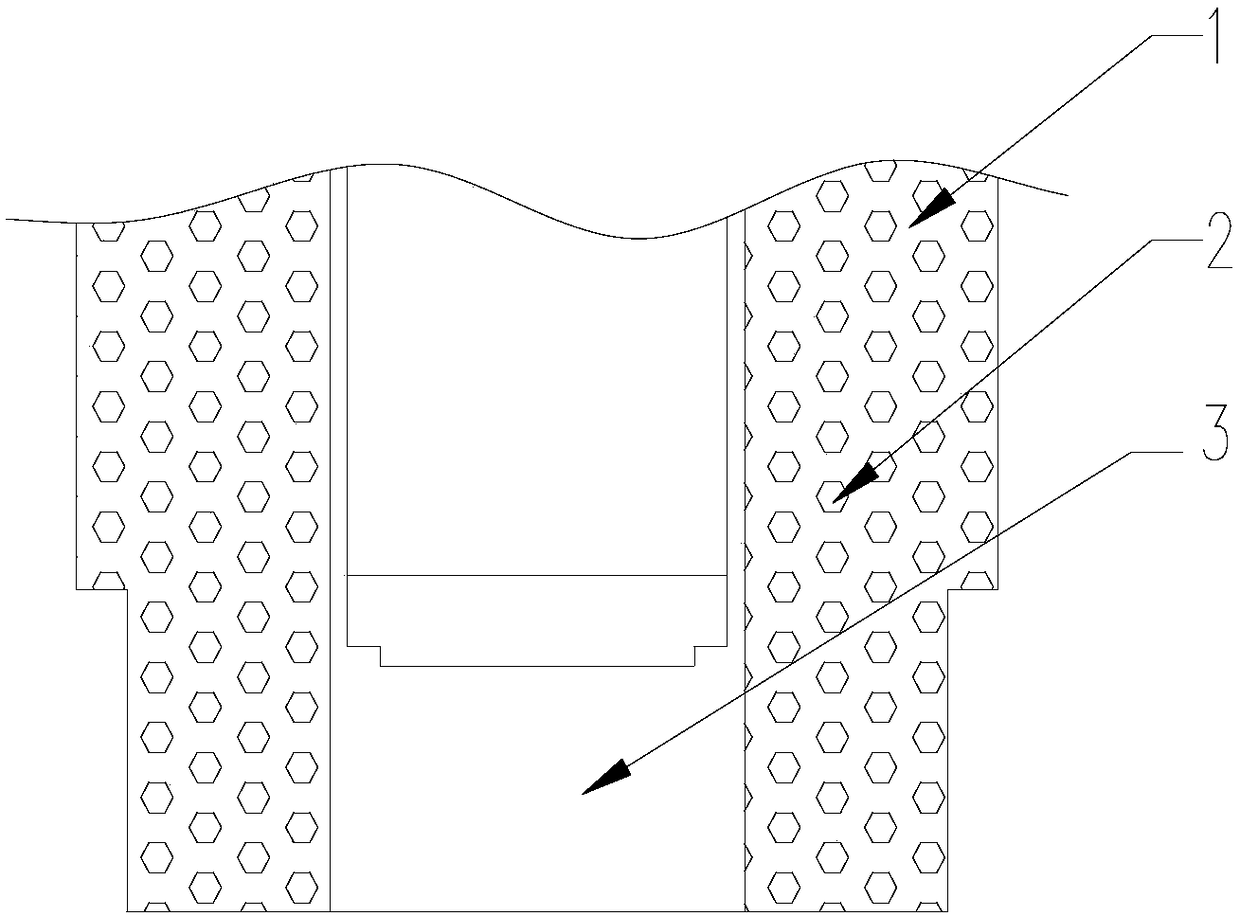

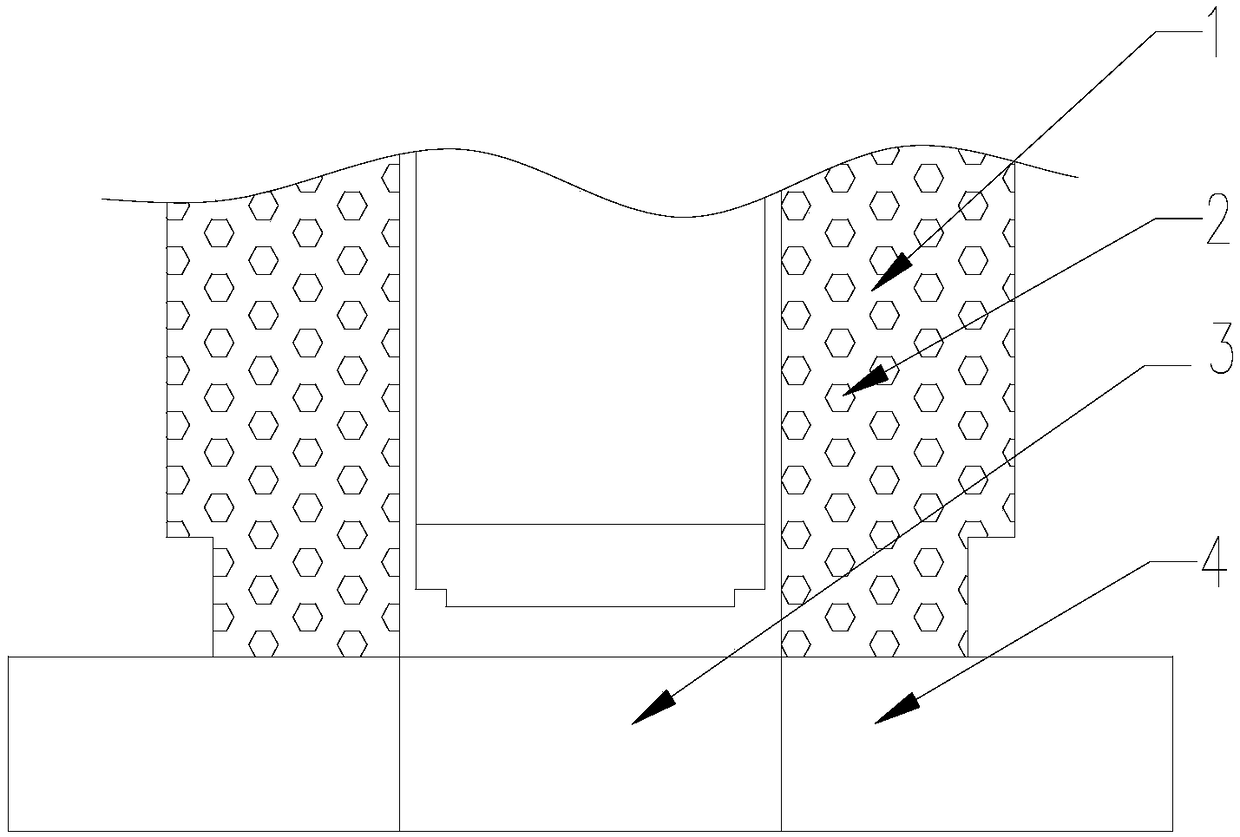

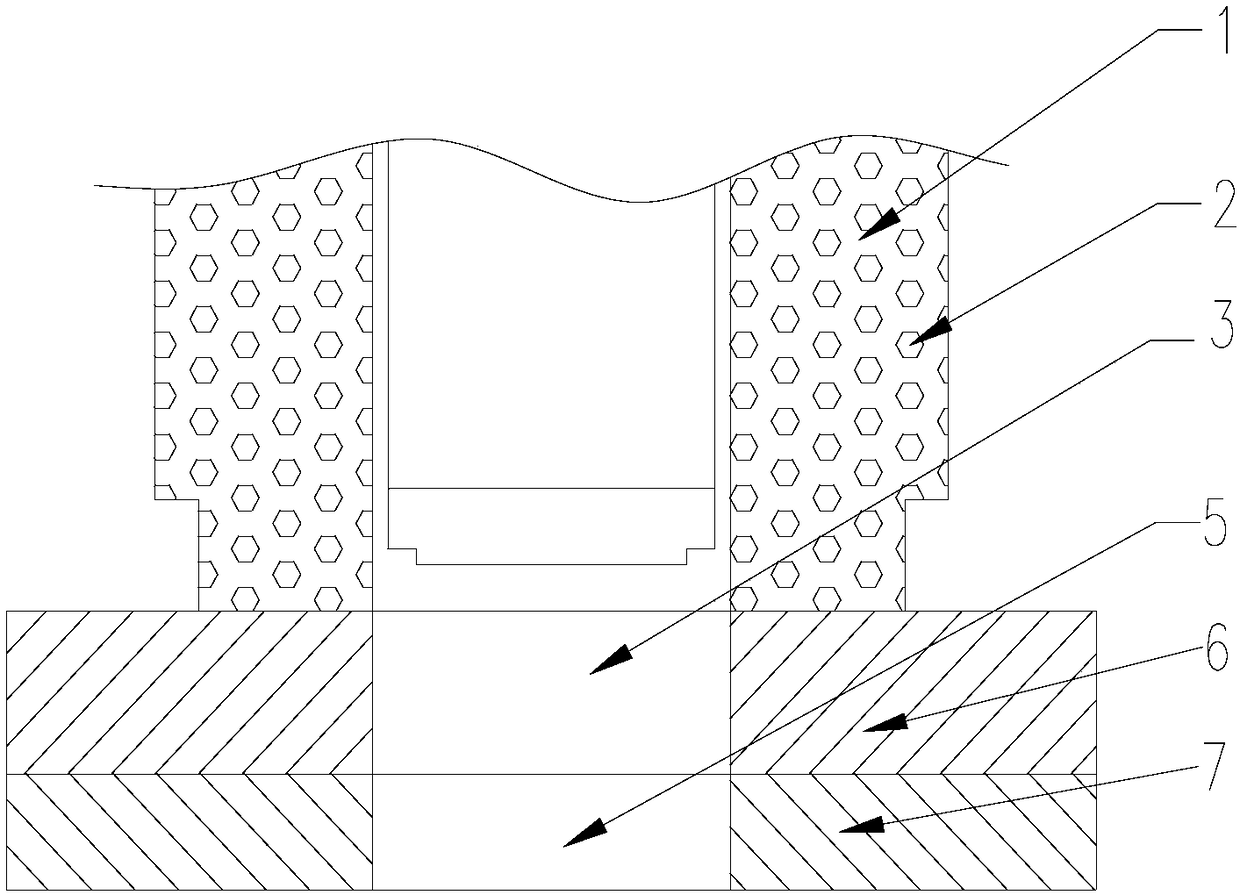

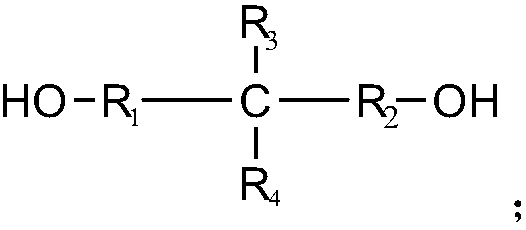

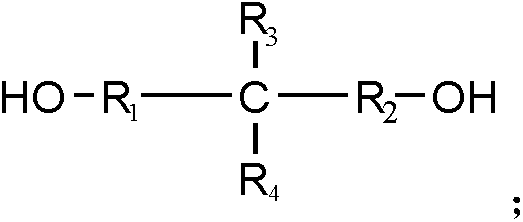

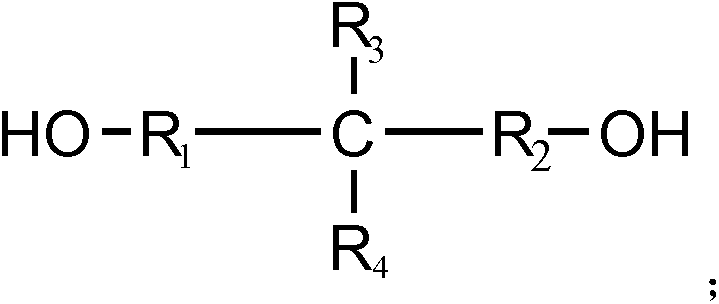

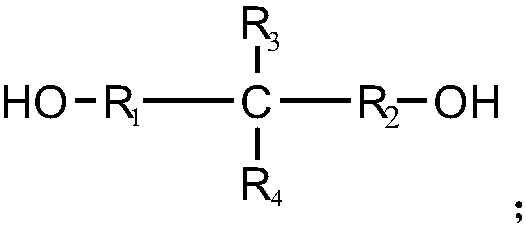

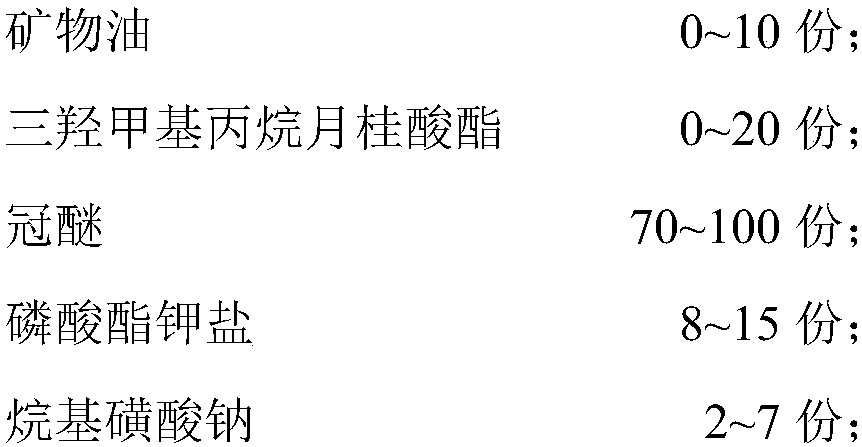

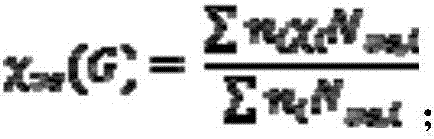

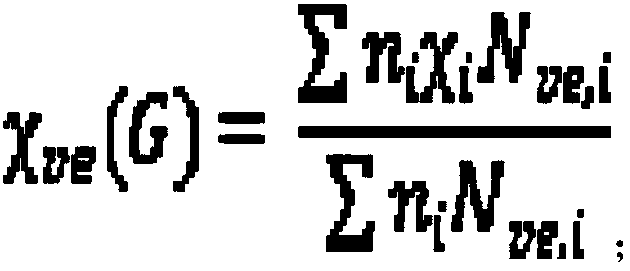

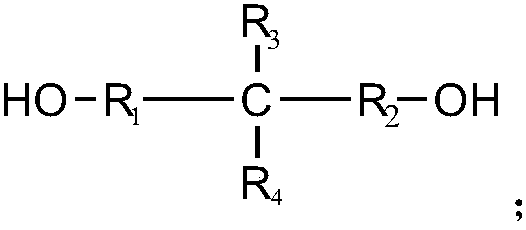

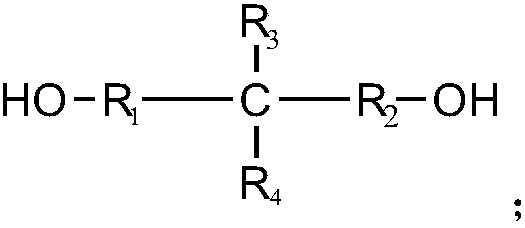

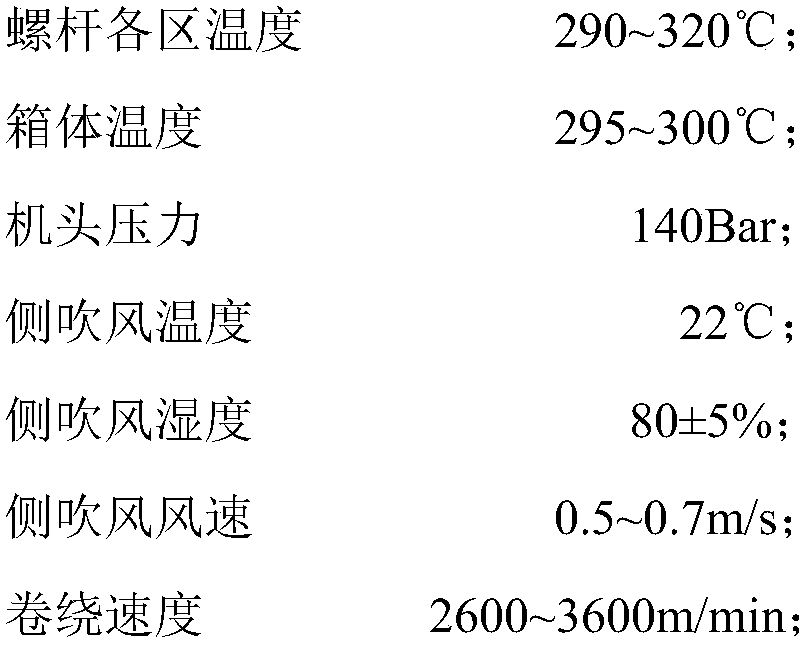

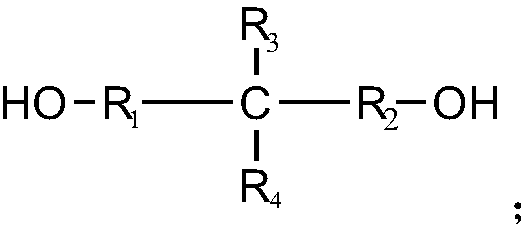

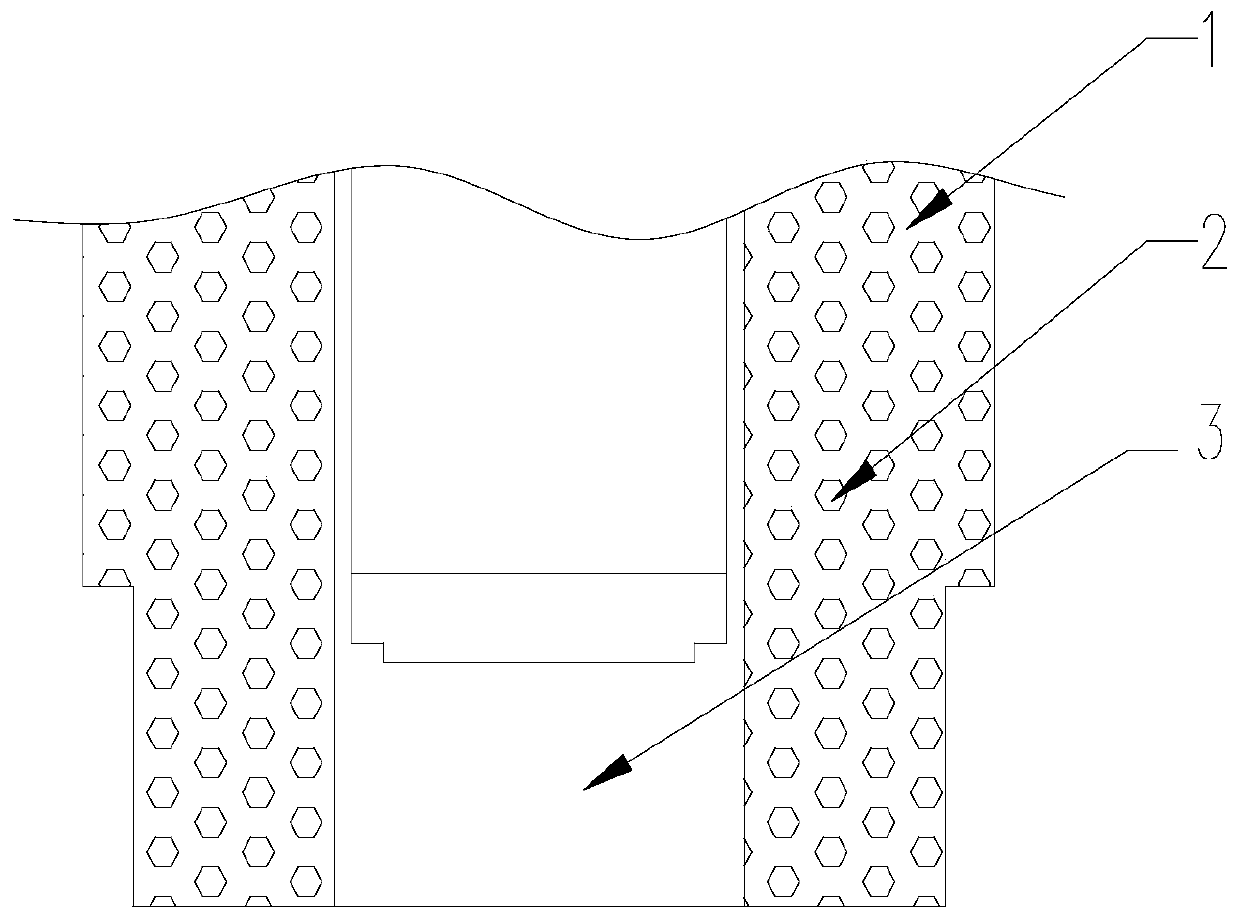

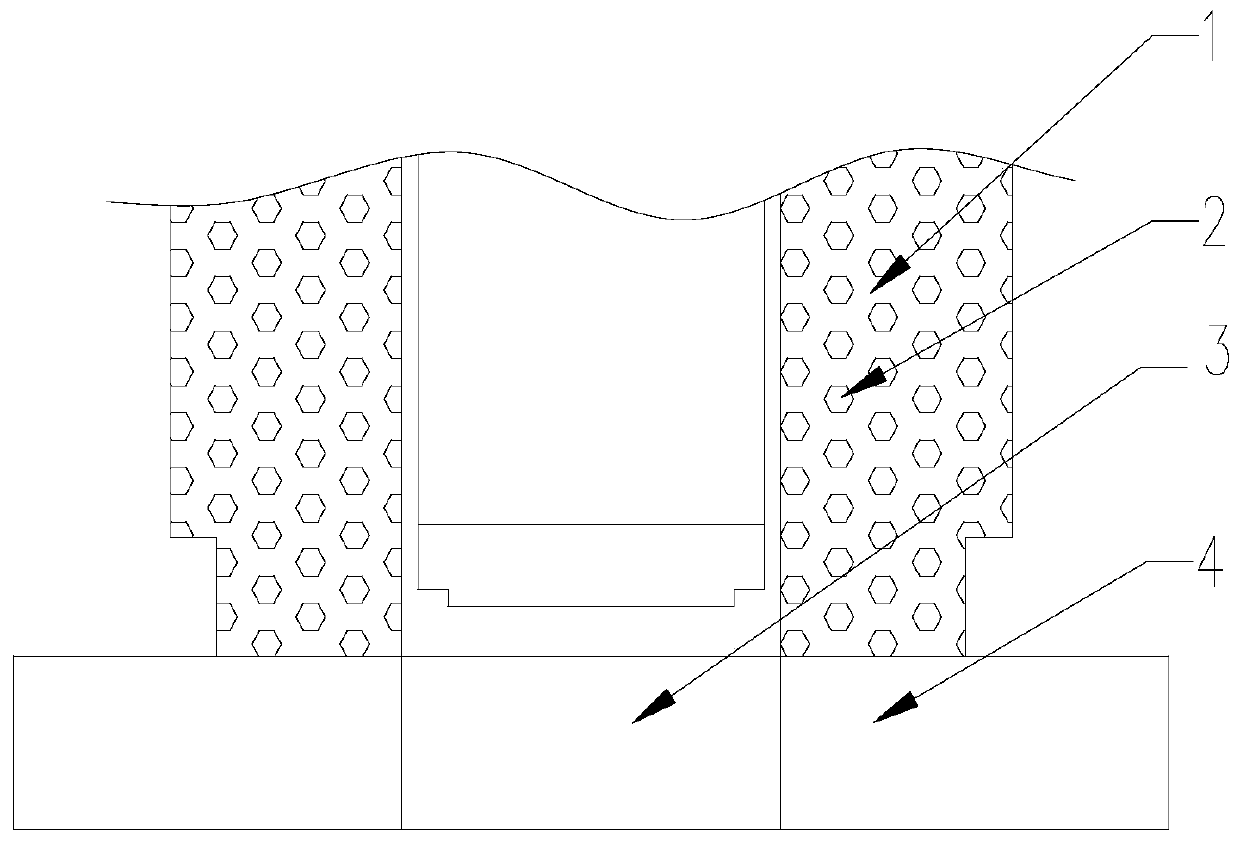

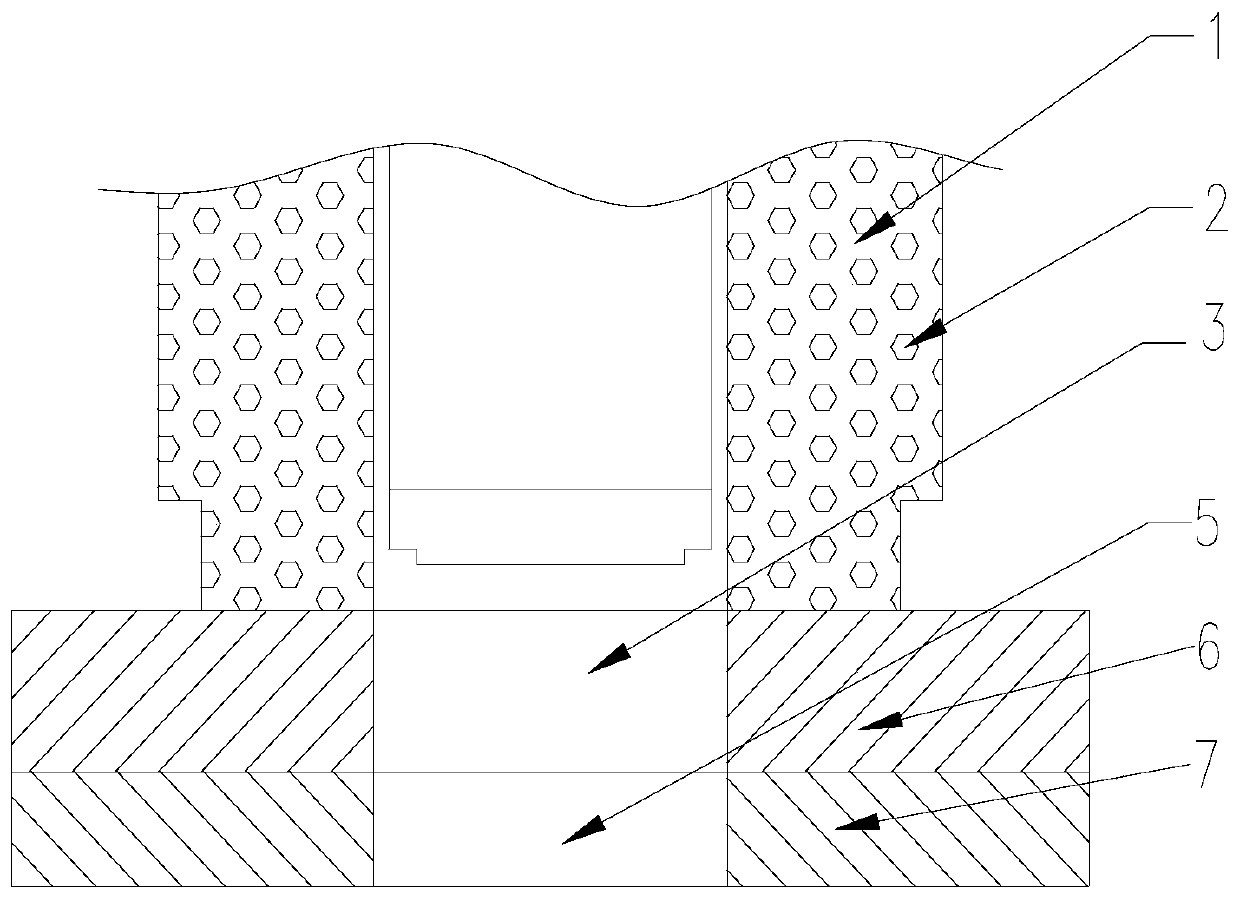

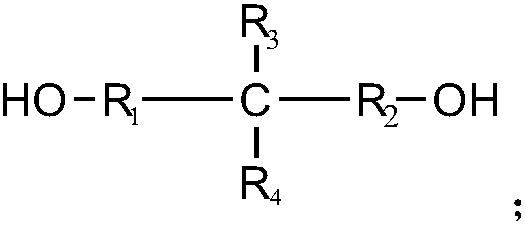

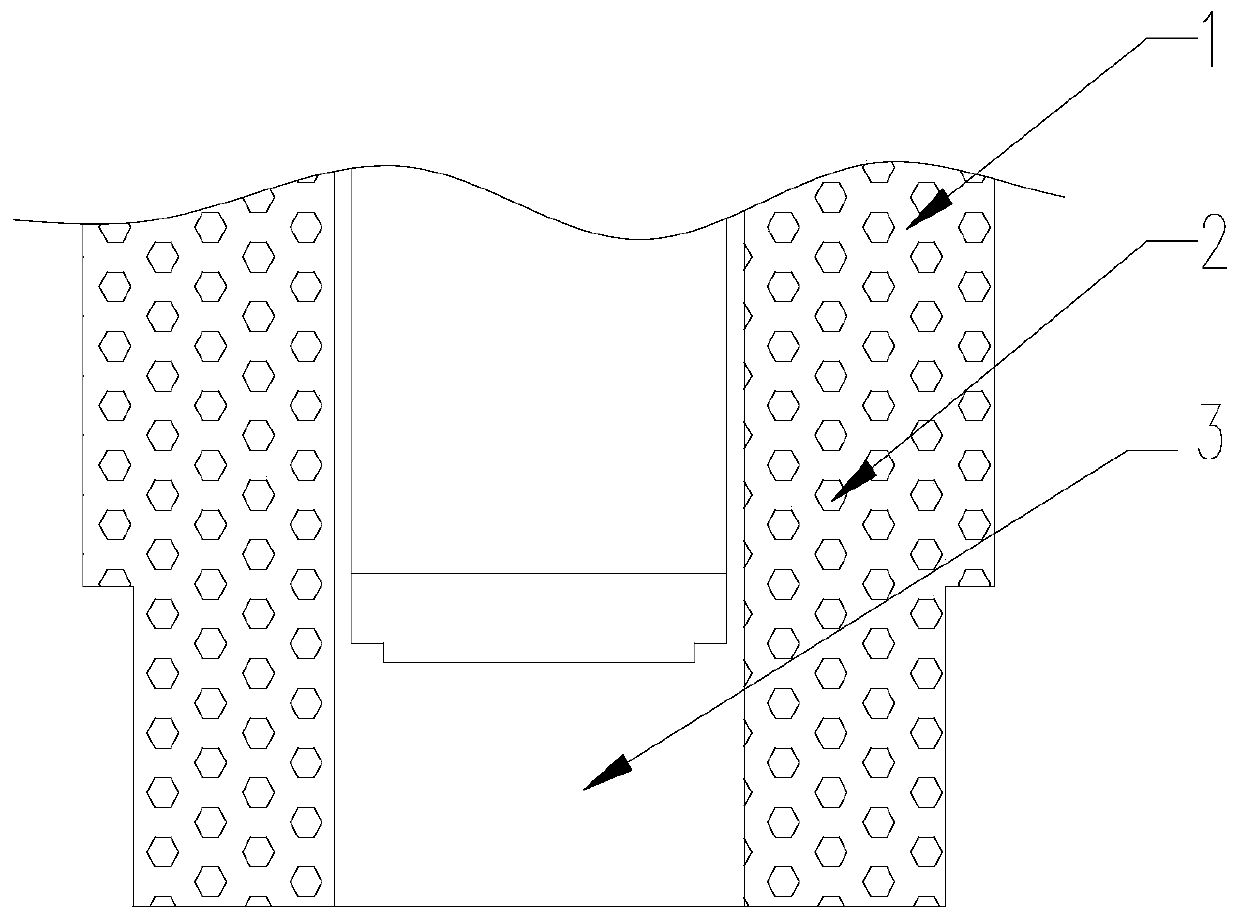

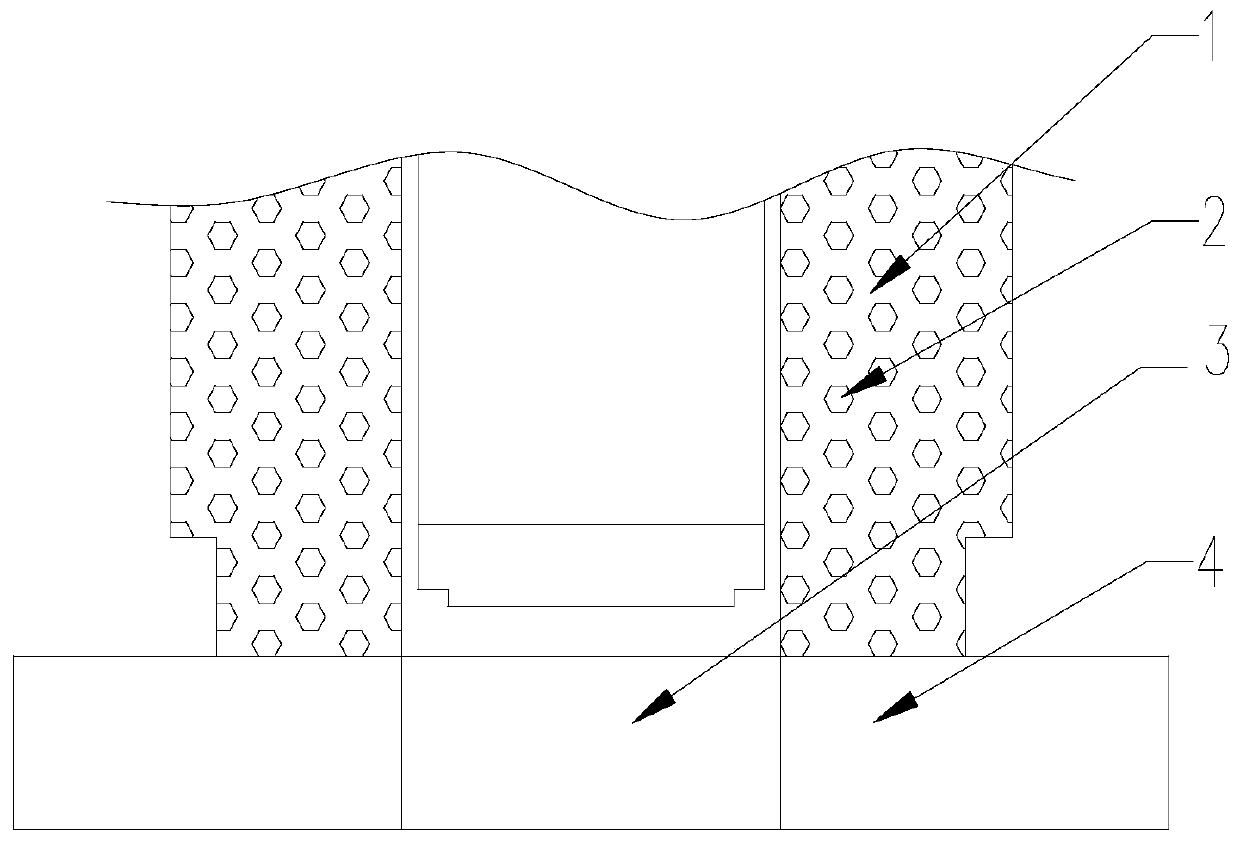

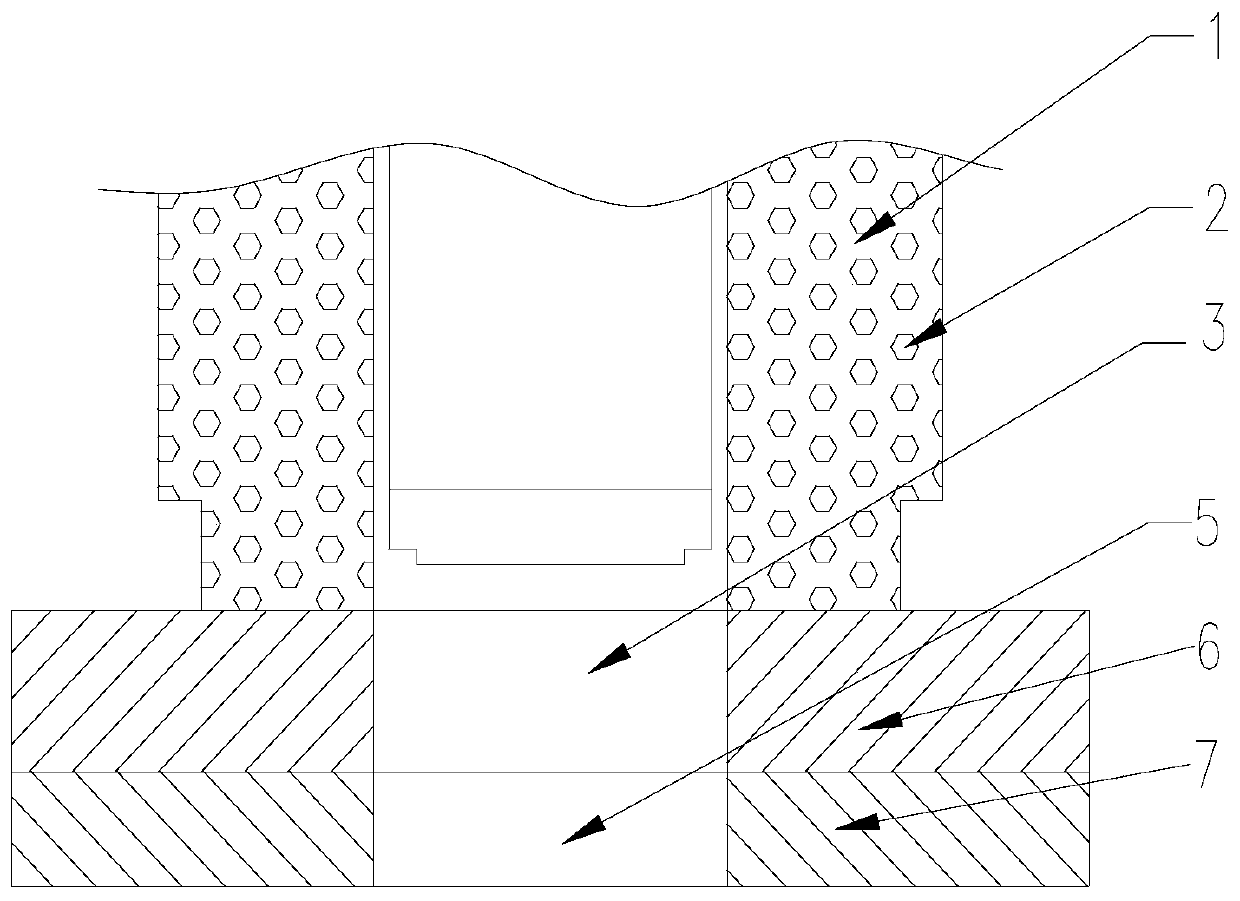

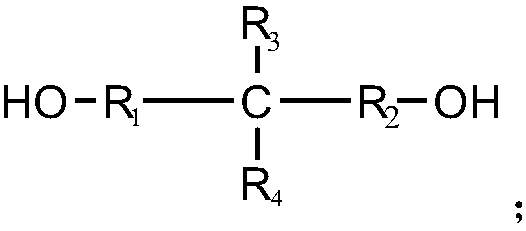

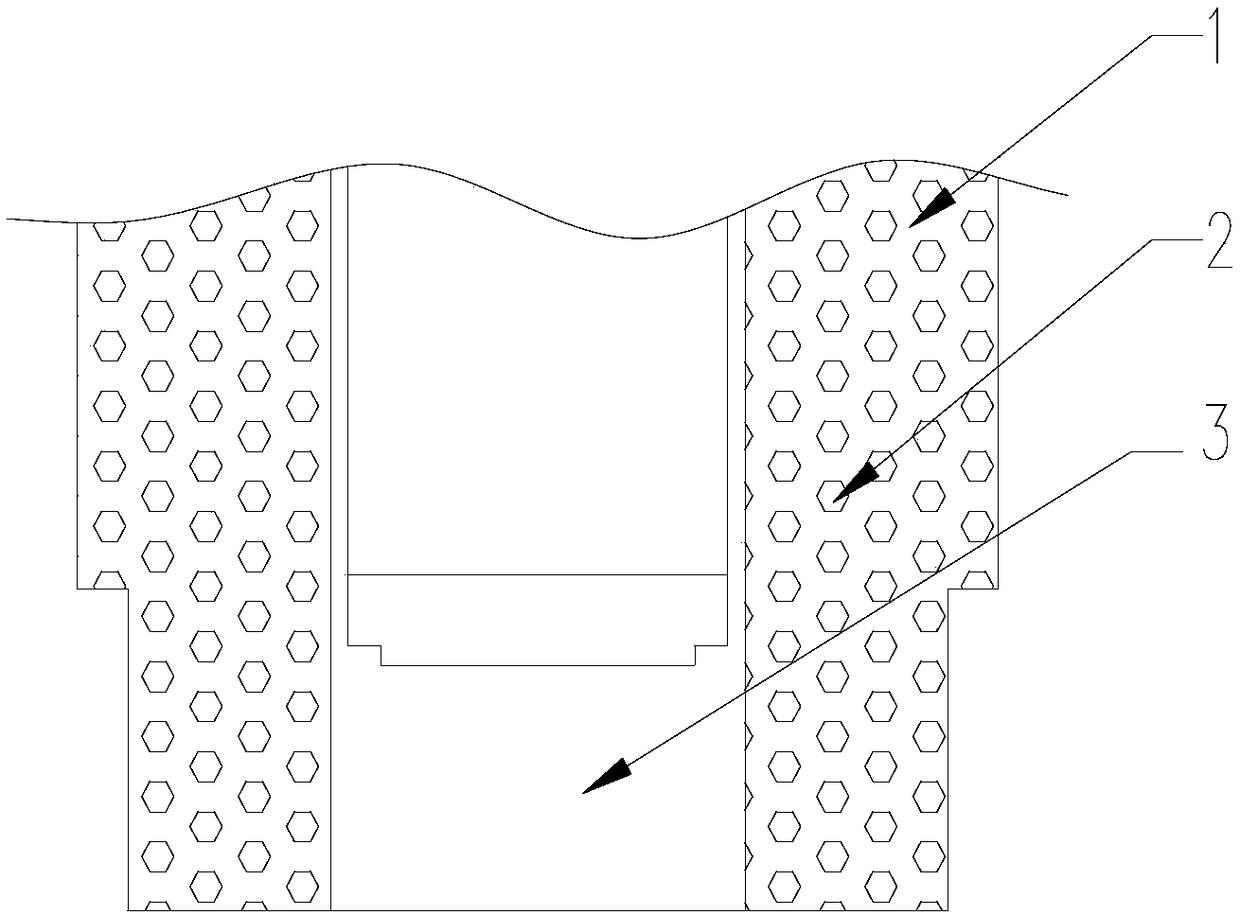

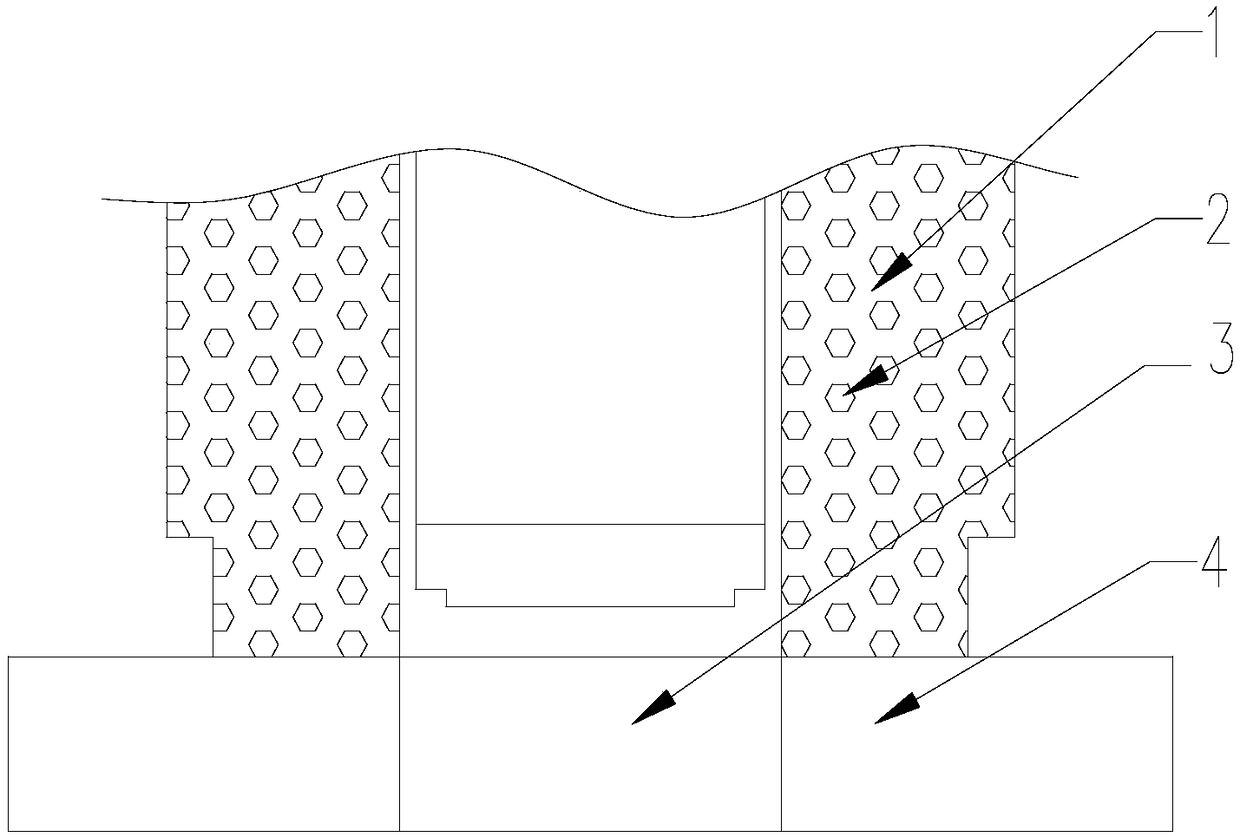

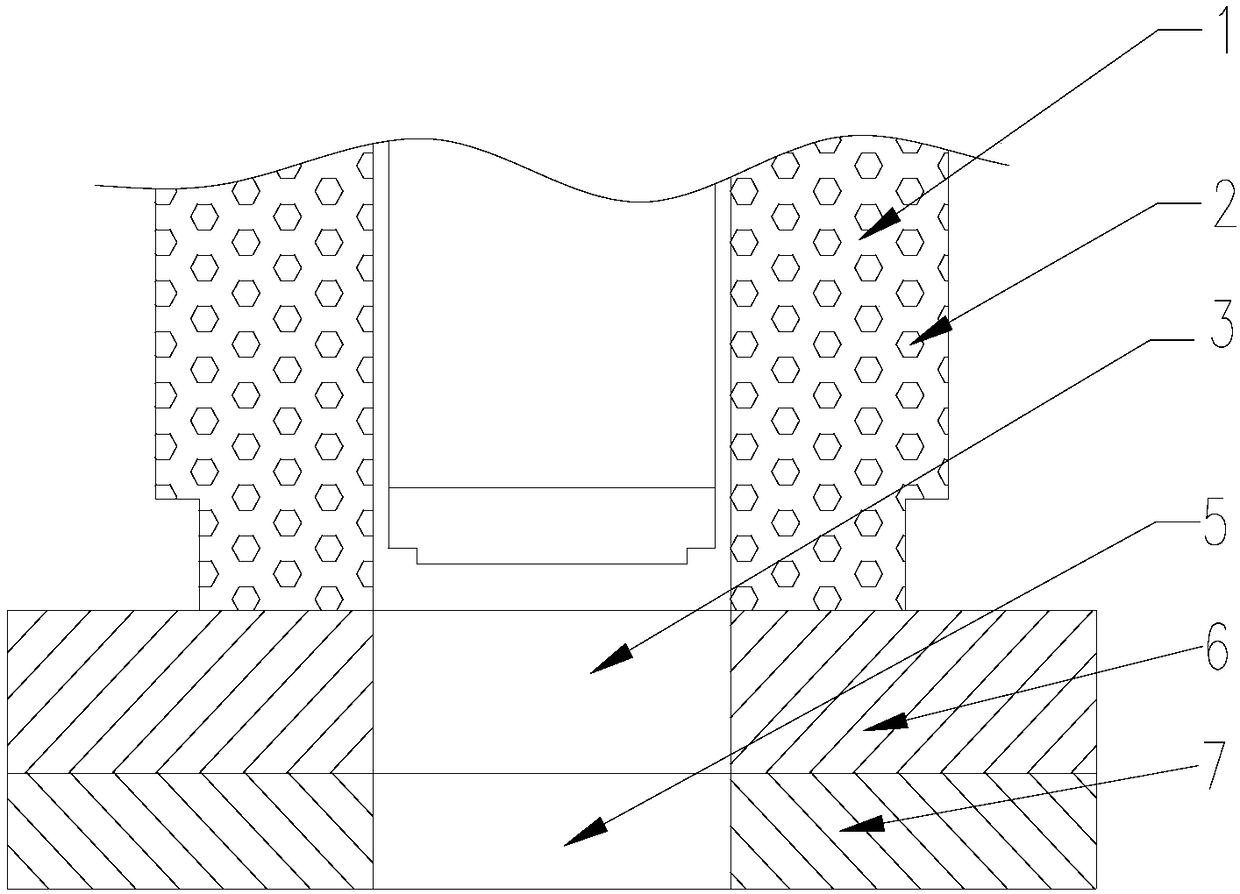

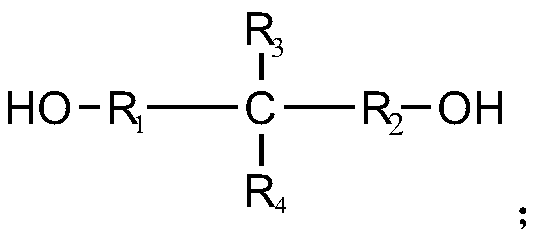

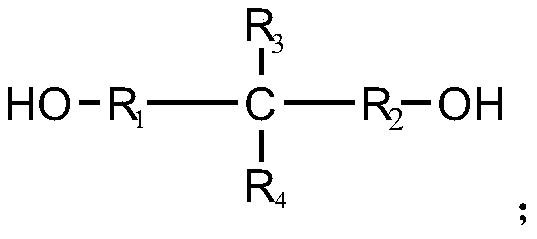

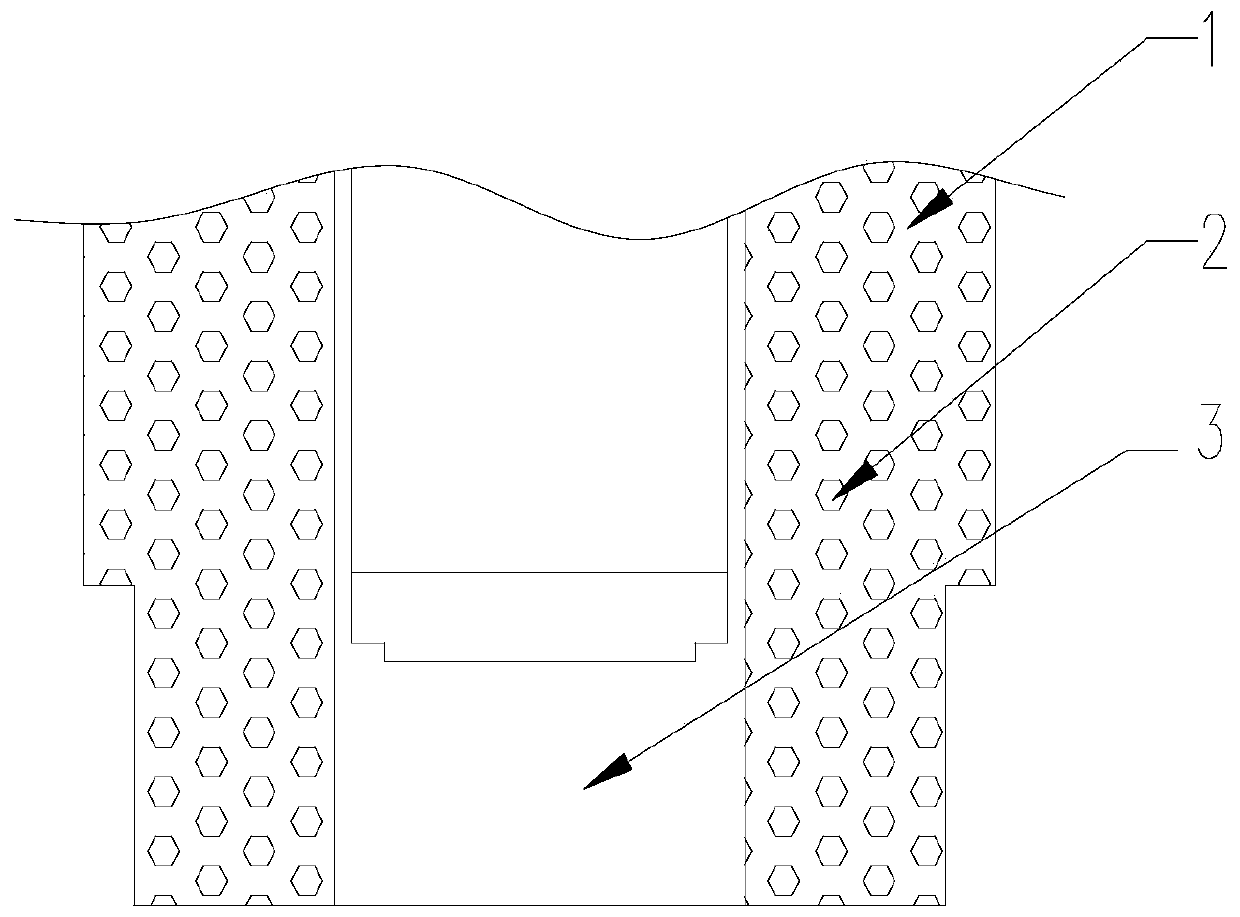

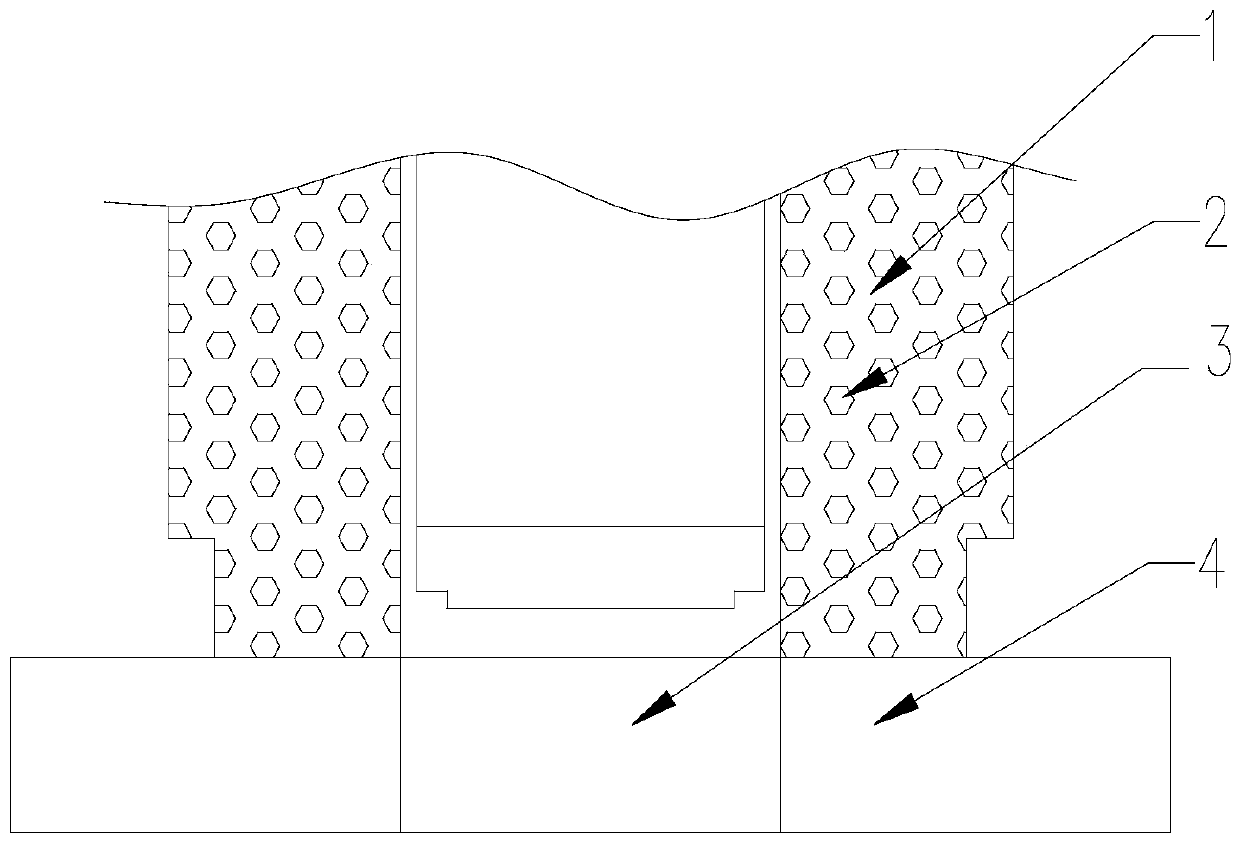

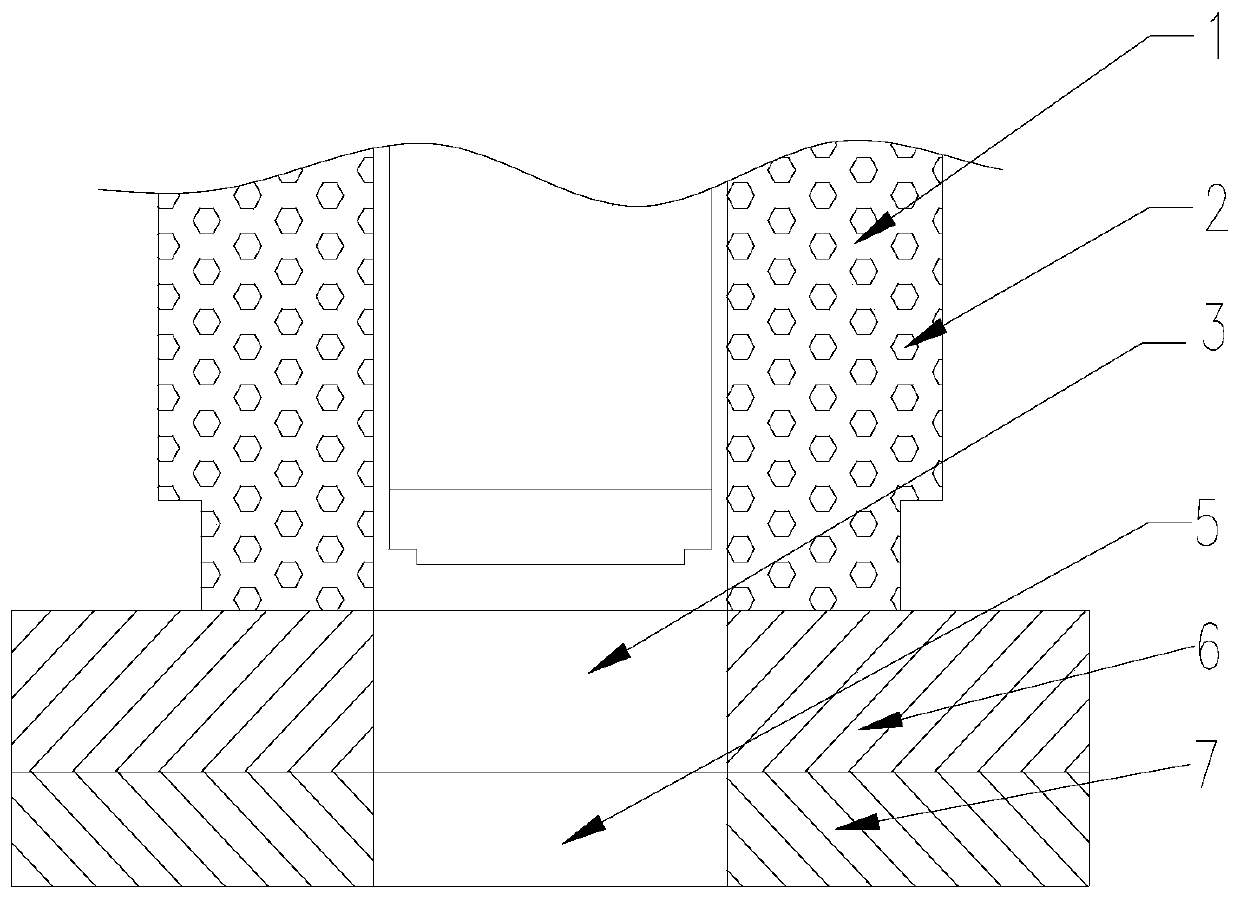

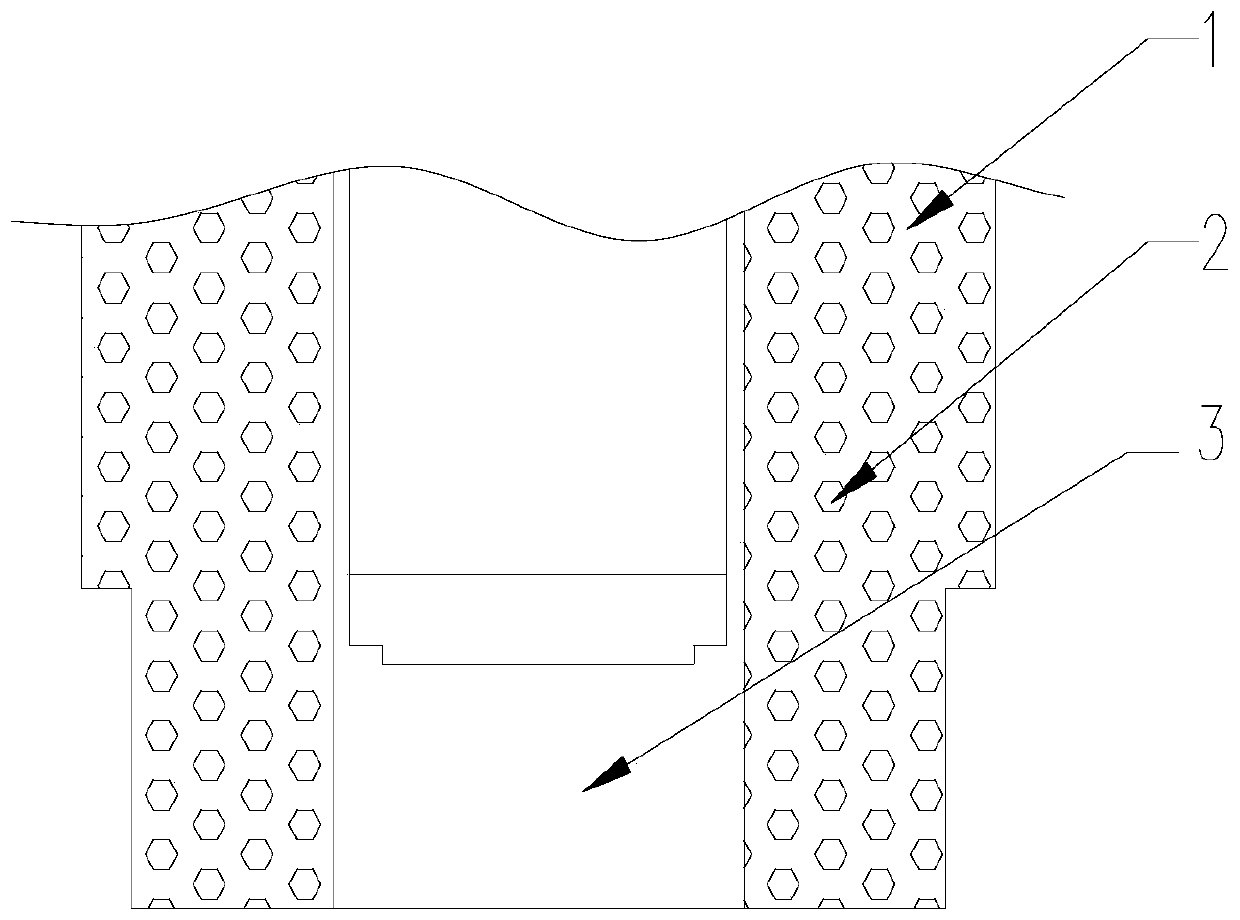

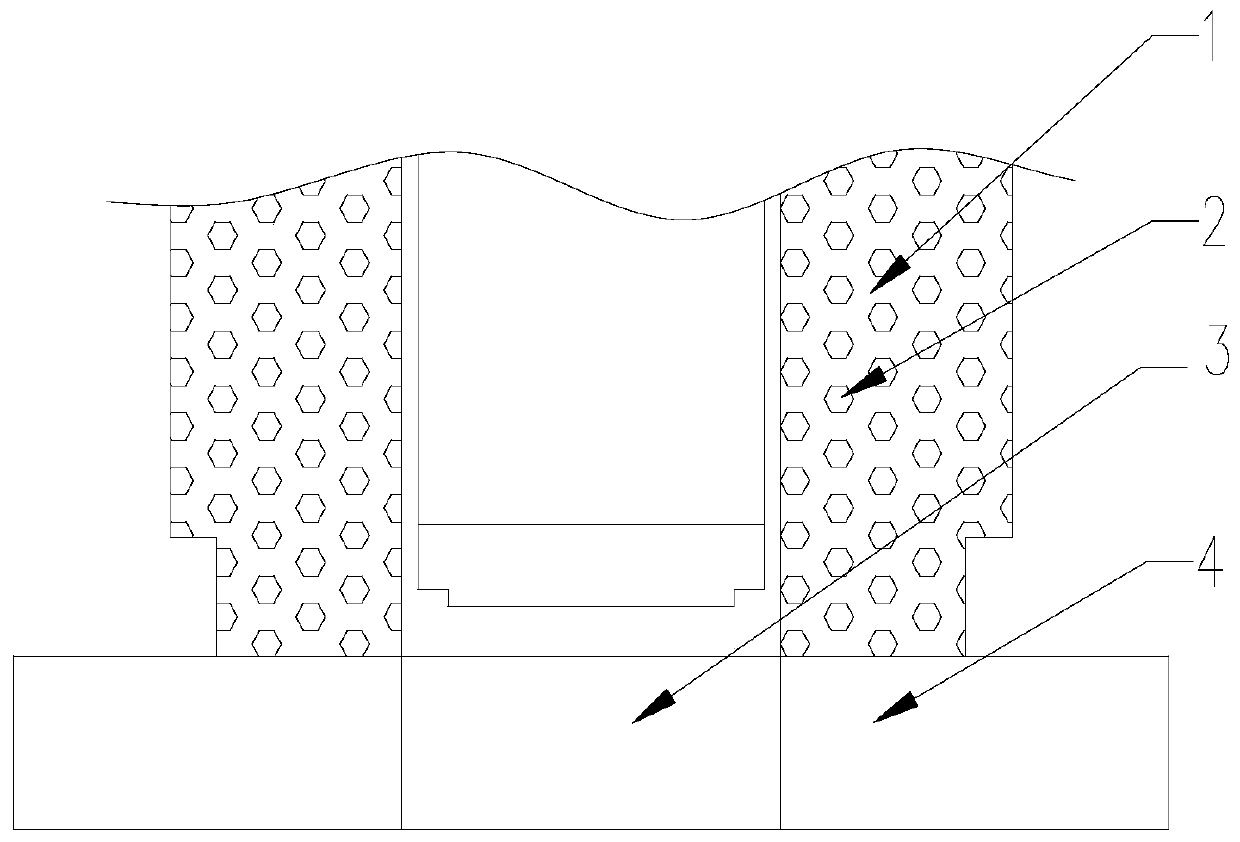

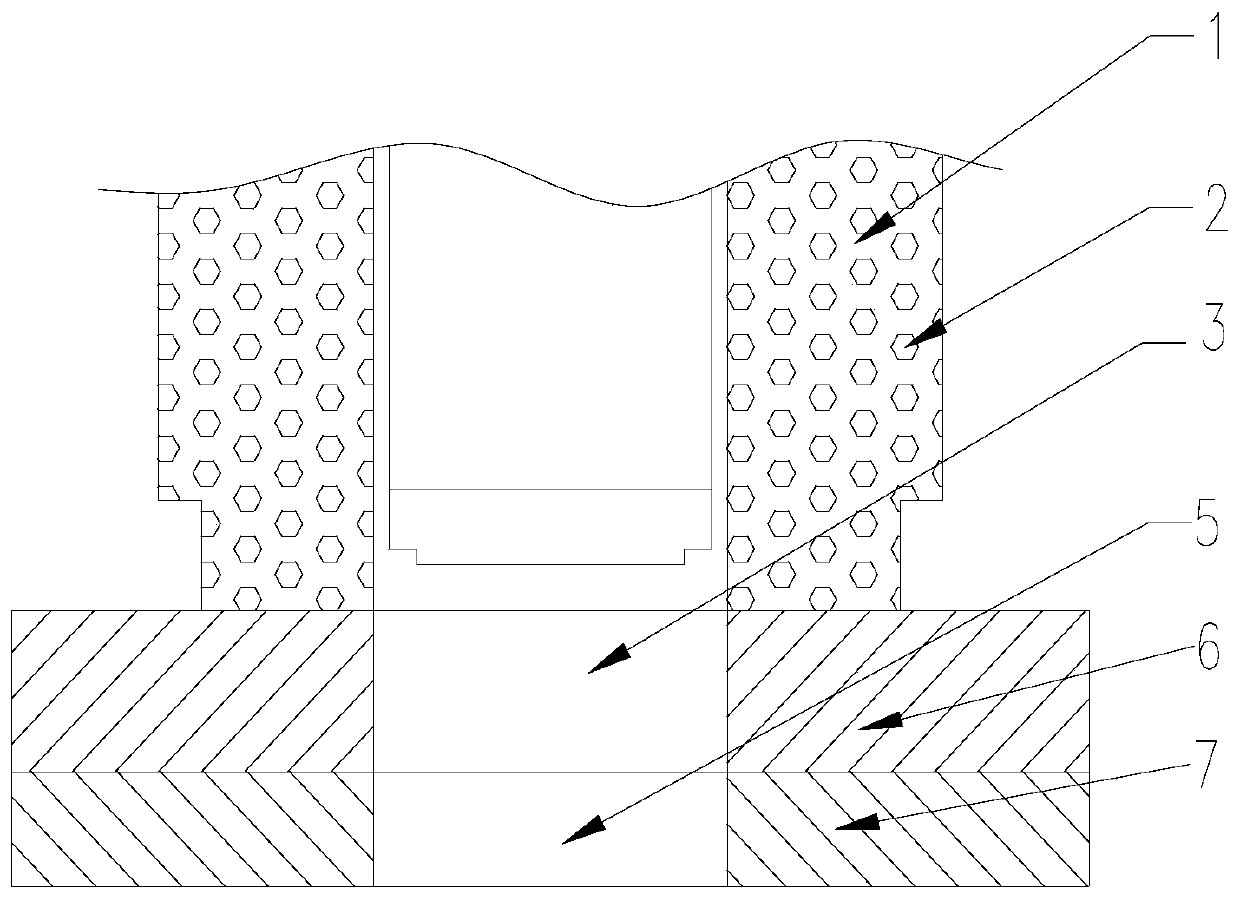

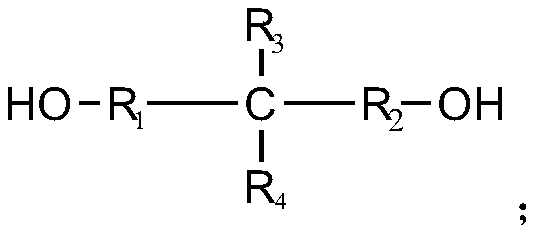

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester flax-like type different shrinkage composite yarn and preparation method thereof

ActiveCN108130624ASimple preparation processImprove fluffinessMelt spinning methodsConjugated synthetic polymer artificial filamentsYarnPolyester

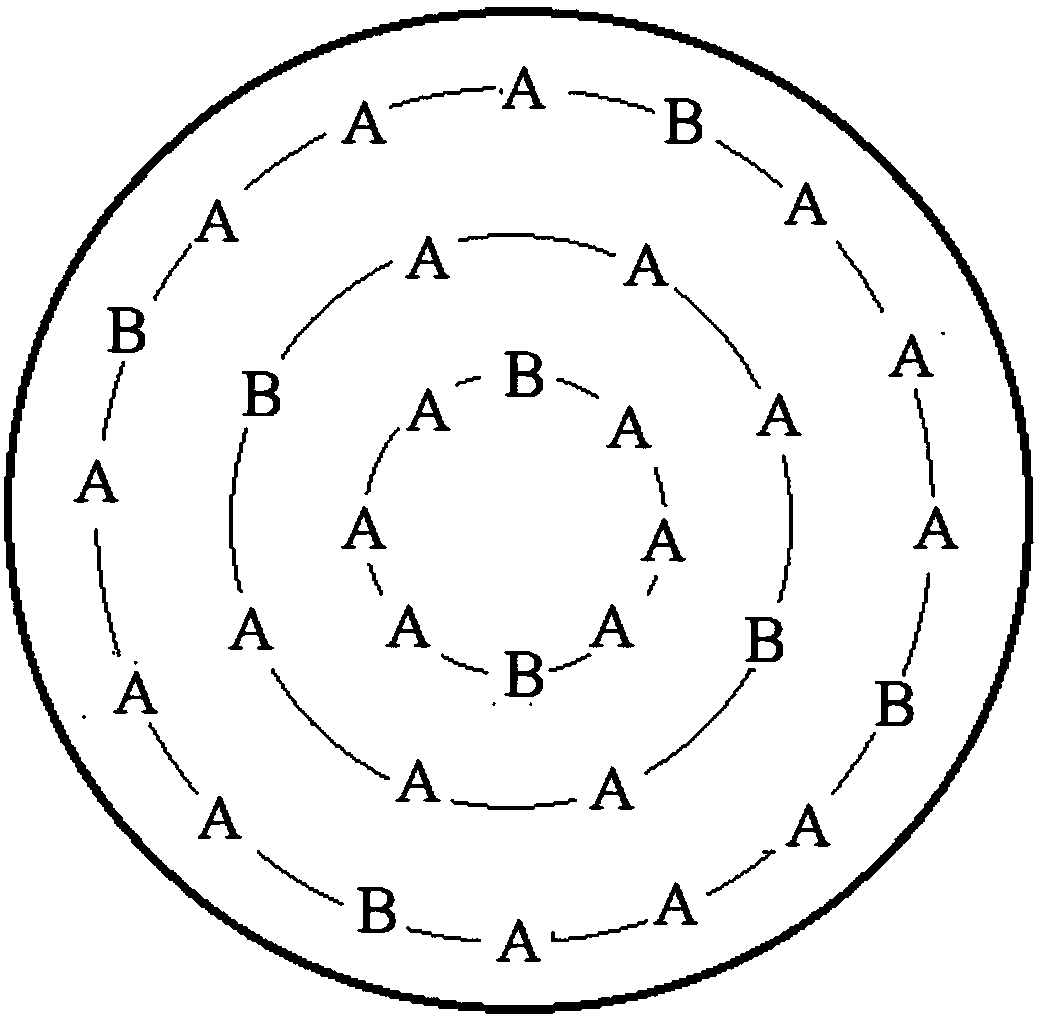

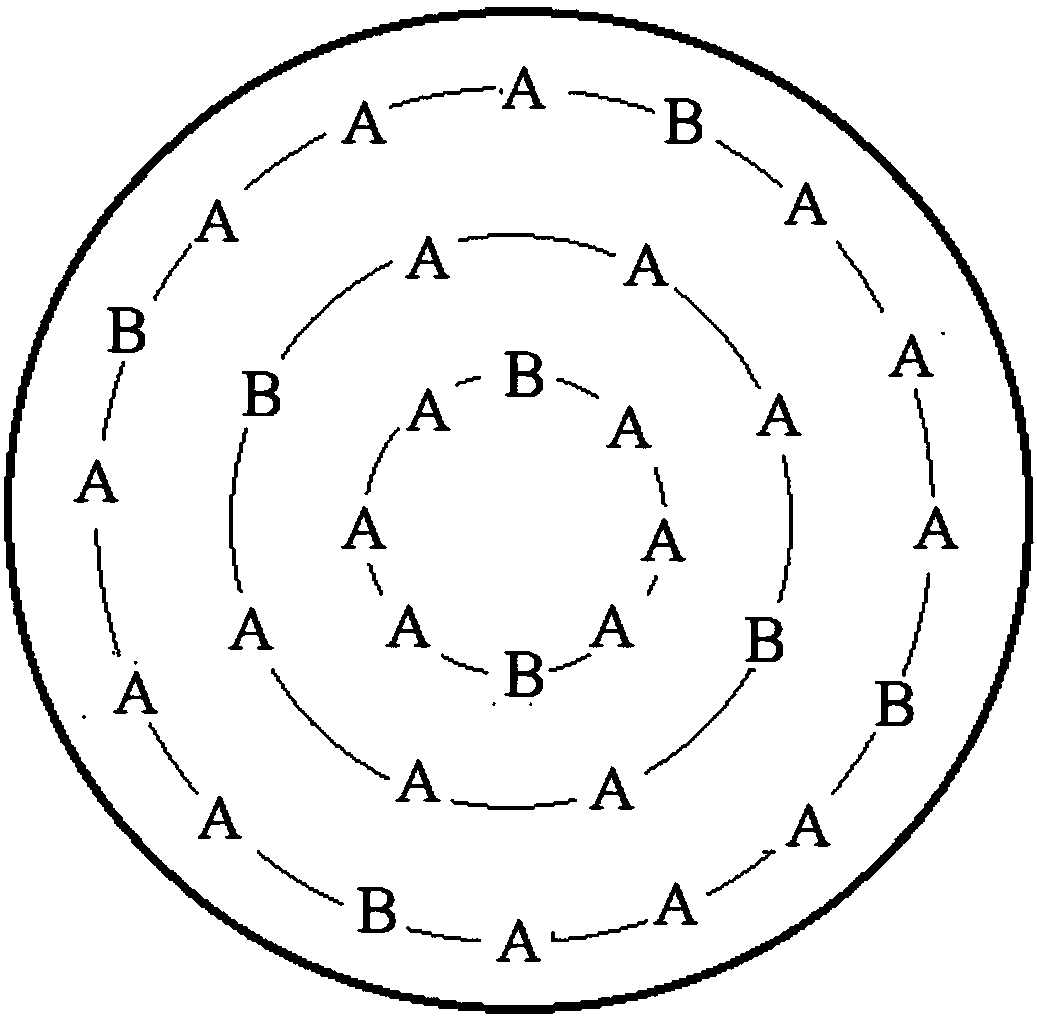

The invention relates to a polyester flax-like type different shrinkage composite yarn and a preparation method thereof. Firstly, a modified polyester yarn POY and a modified polyester yarn FDY are prepared respectively, then the modified polyester yarn POY and the modified polyester yarn FDY are compounded to prepare the polyester flax-like type different shrinkage composite yarn; the chromatic aberration [delta]E of the prepared polyester flax-like type different shrinkage composite yarn is less than 0.200; a bundle of the yarn POY or FDY extruded by a same spinneret plate contains a singleyarn shaped in a Chinese character 'wang' manner and a five-leaf single yarn; a molecular chain of modified polyester consists of a diol chain segment with a branched chain, and diol with the branchedchain has the structural formula defined in the specification, wherein R1 and R2 are straight-chain alkylene with the carbon atom number of 1-3 , R3 is alkyl with the carbon atom number of 1-5, and R4 is alkyl with the carbon atom number of 2-5. The method is simple and reasonable, and the prepared composite yarn has good fluffy property and moisture absorption and perspiration elimination properties.

Owner:JIANGSU HENGLI CHEM FIBER

Dyed polyester FDY fiber and preparation method thereof

ActiveCN108385194AExcellent performanceSimple preparation processSpinnerette packsFilament/thread formingThermal insulationSlow cooling

The invention relates to polyester FDY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, drawing, carrying out heat setting, and winding to prepare the polyester FDY fiber, wherein the unchanged longitudinal height is maintained during the cooling, the cross section area of the slow cooling chamber is increasedwhile the plate surface temperature of the spinning plate is maintained by using the thermal insulation method. According to the present invention, the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formulaof the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the prepared fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

High-extension and low-shrinkage polyester industrial filament and preparation method thereof

ActiveCN108130611AHigh elongation at breakLow dry heat shrinkageFilament/thread formingMonocomponent copolyesters artificial filamentShrinkage rateDiol

The invention relates to a high-extension and low-shrinkage polyester industrial filament and a preparation method thereof. Modified polyester is subjected to solid phase polycondensation tackifying,melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain the high-extension and low-shrinkage polyester industrial filament, wherein the high-extension and low-shrinkage polyester industrial filament is made of the modified polyester, and a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segmentand a diol chain segment with a branched chain; the central value of elongation at break of the finally prepared high-extension and low-shrinkage polyester industrial filament is 11.0-12.0%, and the dry-hot shrinkage rate under the conditions of 177 DEG C, 10 min and 0.05 cN / dtex is 6.5-13.5%. The method is simple and reasonable, and the prepared high-extension and low-shrinkage polyester industrial filament has the advantages of good mechanical properties, high elongation at break and low dry-hot shrinkage, and has excellent popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester wool-like different-shrinkage composite wire and preparing method thereof

ActiveCN108130605AConsistent extrusion speedGood moisture wickingArtificial filament heat treatmentMelt spinning methodsPolyesterAlcohol

The invention relates to a polyester wool-like different-shrinkage composite wire and a preparing method thereof. The method comprises the steps of firstly, modified polyester POY and FDY wires are produced separately; then, the POY and FDY wires are compounded to produce the polyester wool-like different-shrinkage composite wire, wherein the chromatic aberration delta E of the produced compositewire is smaller than 0.200. A bunchof POY or FDY wires extruded through the same spinneret plate contain double-cross single wires and trilobal single wires simultaneously, a modified polyestermolecular chain contains a dihydric alcohol chain section with a branch chain, and the structural formula of the dihydric alcohol chain section with the branch chain is shown in the description, wherein R1 and R2 are straight chain alkylidenes of which the number of carbon atoms is 1-3, R3 is an alkyl of which the number of carbon atoms is 1-5, R4 is an alkyl of which the number of carbon atoms is 2-5, and a matt agent in modified polyester is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or calcium carbonate and amorphous silicon dioxide. The preparing method is simple and reasonable, and the prepared composite wire has good fluffy and hygroscopic and sweat releasingperformance.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

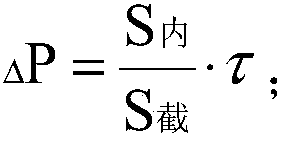

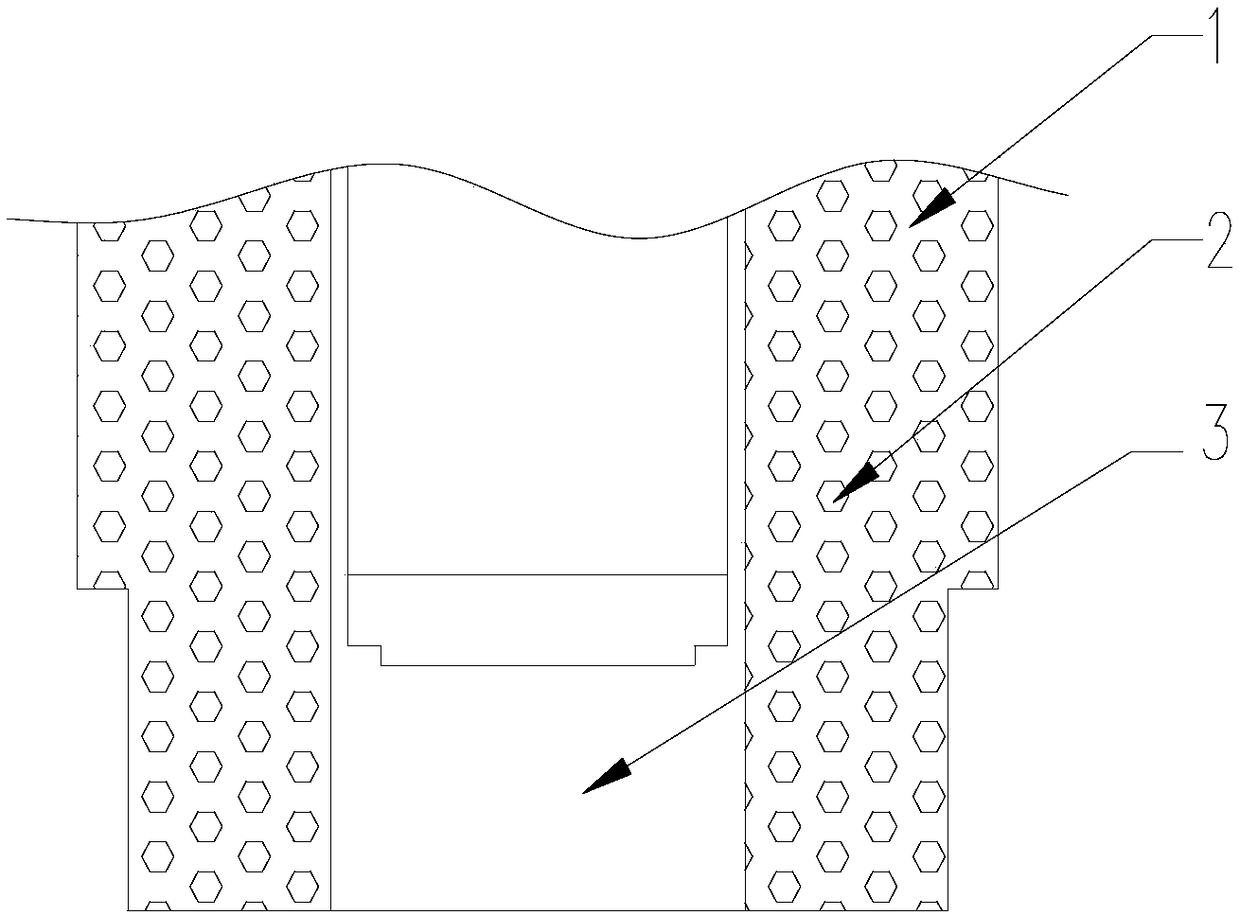

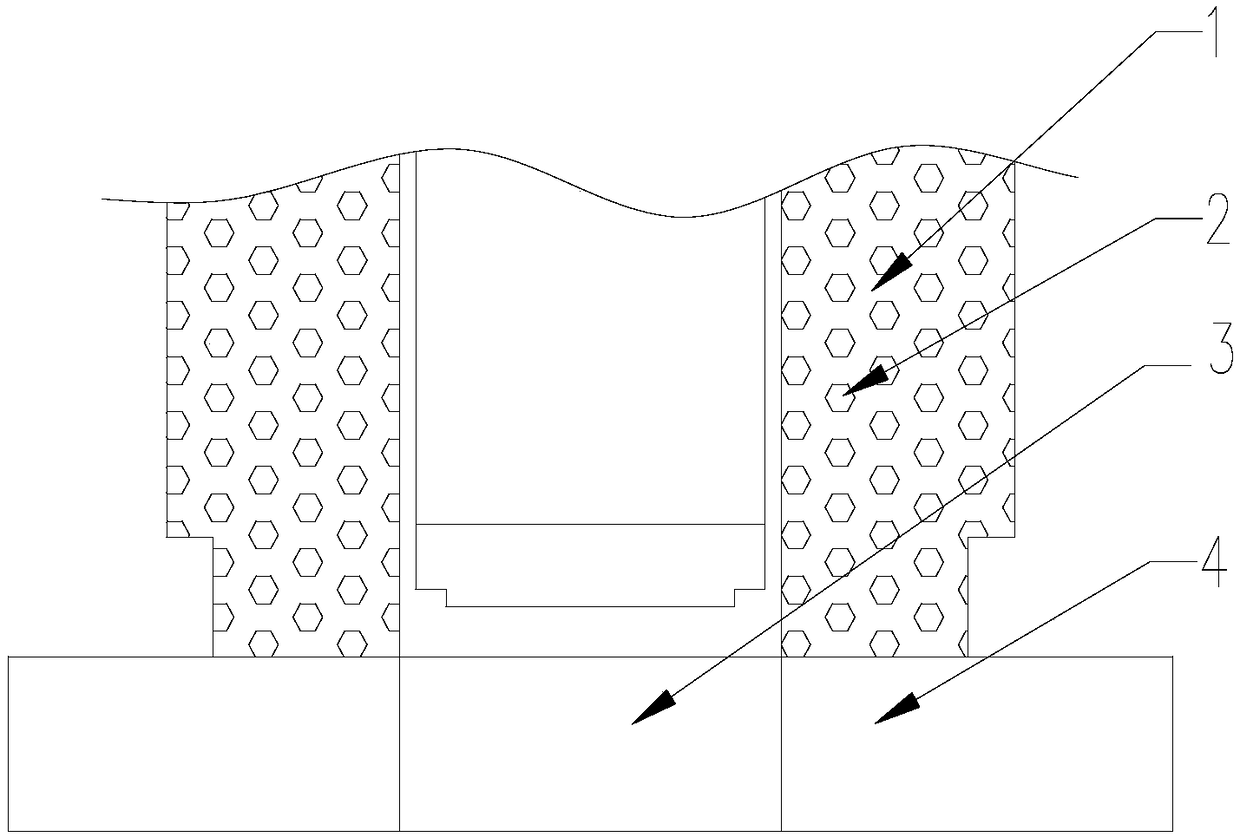

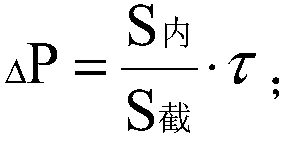

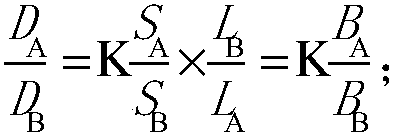

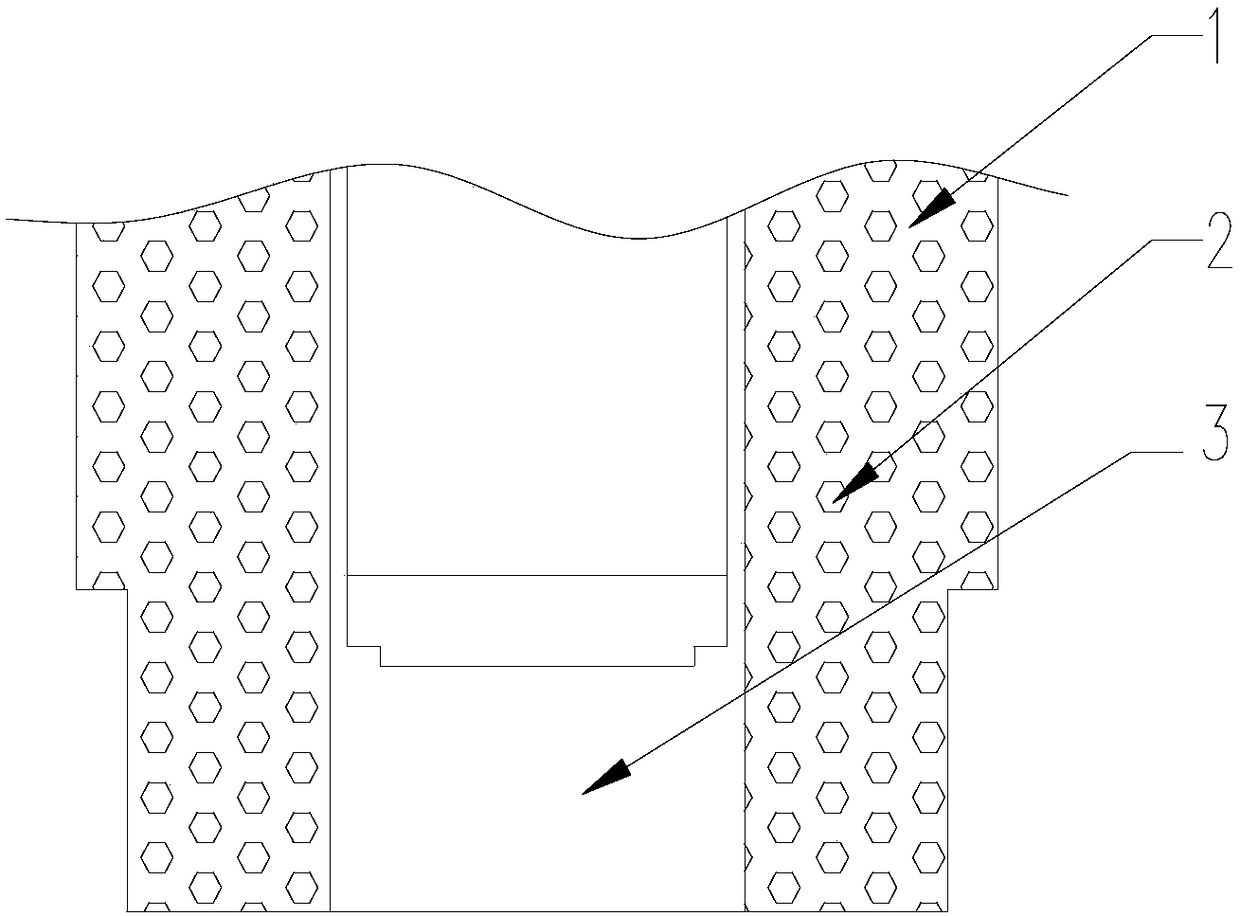

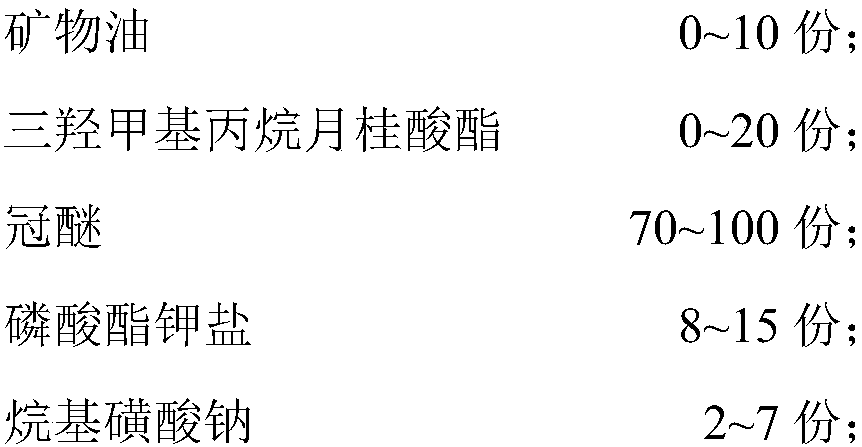

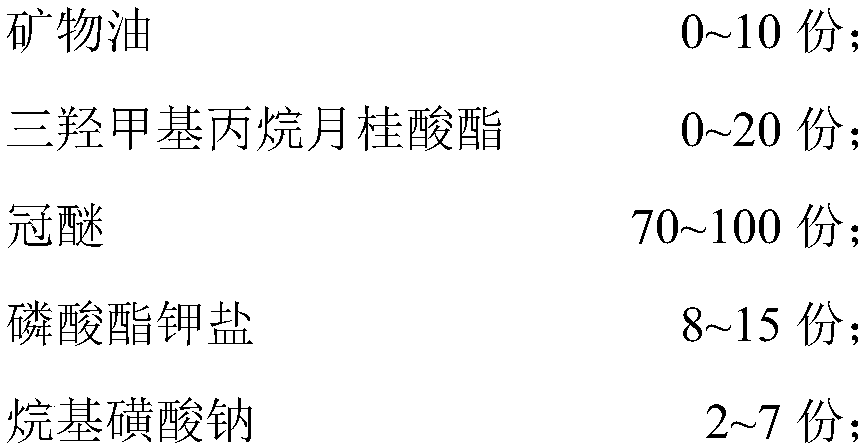

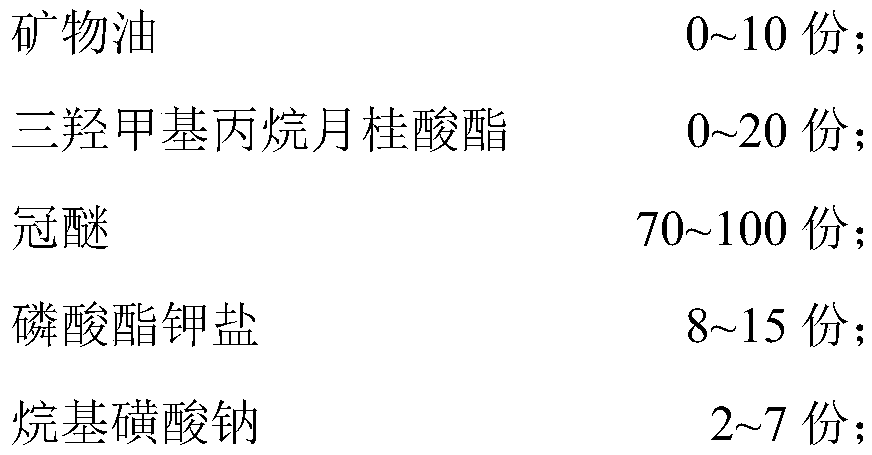

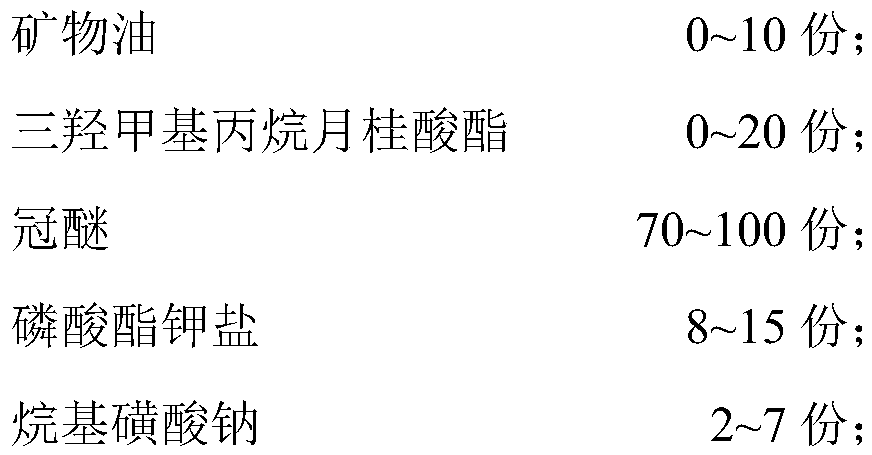

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

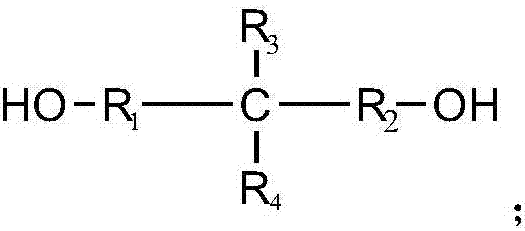

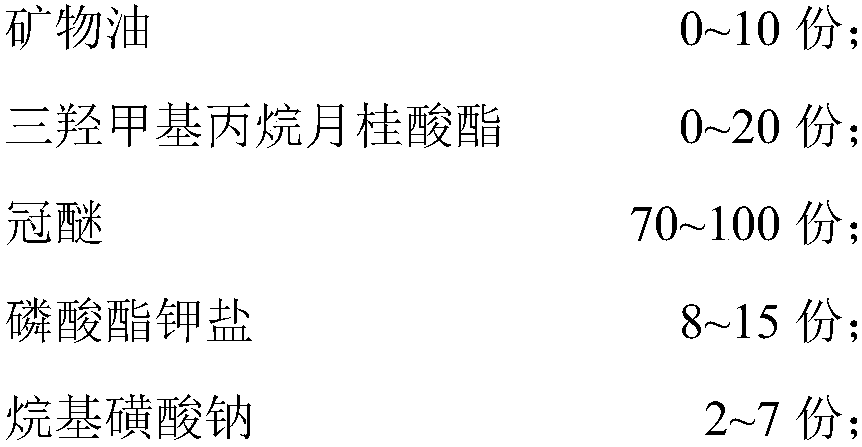

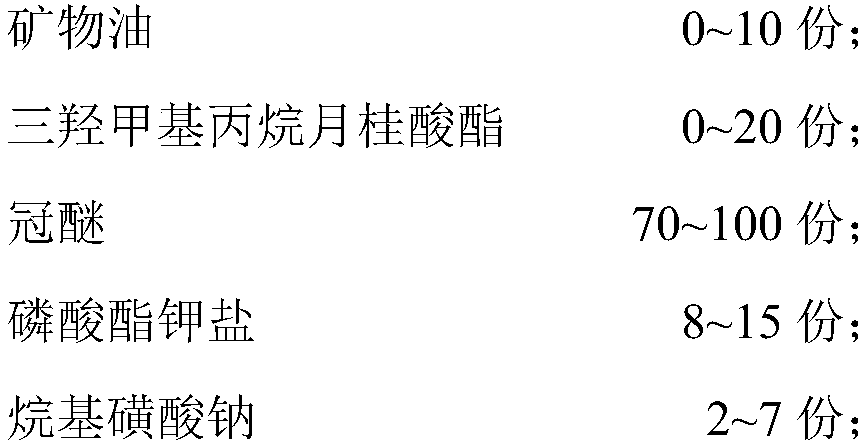

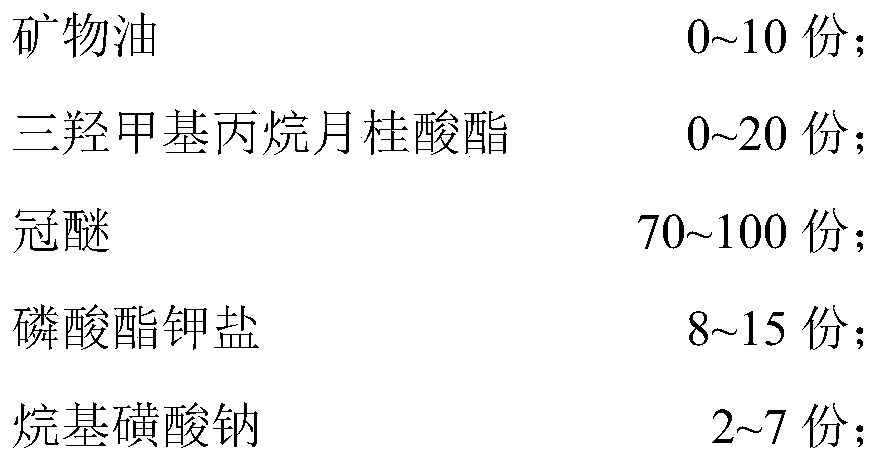

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage polyester industrial filament and preparation method thereof

ActiveCN108130609ALow dry heat shrinkageSimple preparation processFilament/thread formingMonocomponent copolyesters artificial filamentStructural formulaConductor Coil

The invention relates to a low-shrinkage polyester industrial filament and a preparation method thereof. The preparation method comprises that modified polyester is subjected to solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding, wherein an oil agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58 wt%. The preparation method is simple and reasonable; the dry-hot shrinkage rate of the finally prepared low-shrinkage polyester industrial filament under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex is 2.5-4.7%. The low-shrinkage polyester industrial filament is made of the modified polyester, and a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester DTY fiber and preparation method thereof

ActiveCN108385195AIncrease the cross-sectional areaReduce the temperatureFilament/thread formingArtificial filament heat treatmentThermal insulationDiol

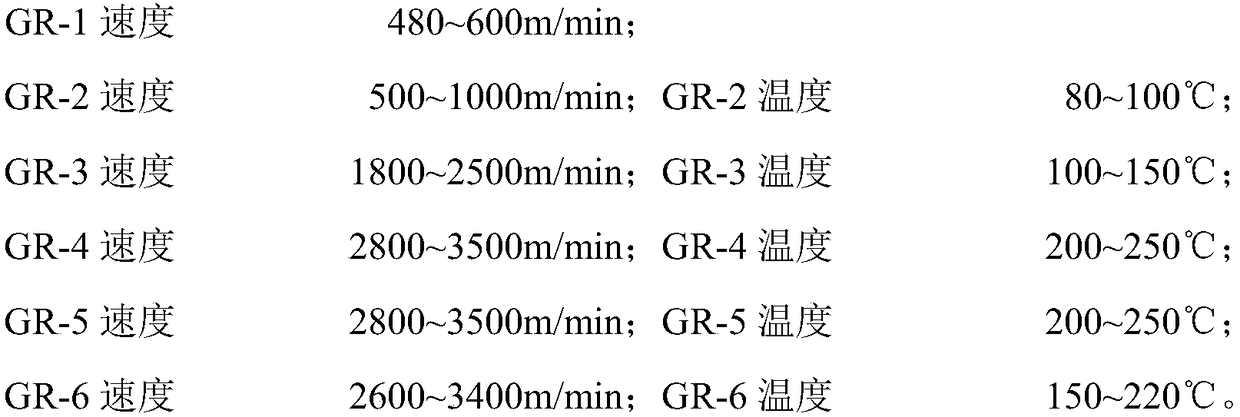

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, winding to prepare polyester POY fiber, and carrying out fiber conduction pipe, network, heating drawing, false twisting, heat setting and winding molding on the polyester POY fiber to obtain the polyester DTY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of thespinning plate is maintained by using the thermal insulation method; the material of the polyester POY fiber is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, and R4 is selected fromalkyl with a carbon atom number of 2-5; and the preparation method is simple, and the chromatic aberration [delta]E of the prepared fiber is less than 0.200.

Owner:JIANGSU HENGLI CHEM FIBER

Super high strength polyester industrial filament and preparation method thereof

ActiveCN108130610AExtended replacement cycleImprove stabilityFilament/thread formingMonocomponent copolyesters artificial filamentStructural formulaMechanical property

The invention relates to a super high strength polyester industrial filament and a preparation method thereof. Modified polyester is subjected to solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain the super high strength polyester industrial filament, wherein the super high strength polyester industrial filament ismade of the modified polyester, and a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branchedchain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5. The breaking strength of the super high strength polyester industrial filament is more than or equal to 8.8 cN / dtex. The method is simple and reasonable, and the prepared industrial filament has super high breaking strength and good mechanical properties.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester HOY fibers and preparation method thereof

ActiveCN108130614AHigh molecular weightMolecular weight narrowFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to polyester HOY fibers and a preparation method thereof. The preparation method comprises the steps of carrying out metering, extrusion, cooling, oiling and high-speed winding of a modified polyester melt to obtain the polyester HOY fibers, wherein the high-speed winding speed of the high-speed winding is more than or equal to 6000 m / min; during cooling, the vertical heightis kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the wayof heat preservation. The fibers are made of modified polyester having a molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the structural formula described in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3 , R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fibers is less than 0.200. The method is simple and reasonable in preparation process, and the prepared fibers have good properties.

Owner:JIANGSU HENGLI CHEM FIBER

Superfine dacron low stretch yarn and preparation method thereof

ActiveCN107988649AEasy to spreadImprove fiber qualityFibre typesMonocomponent copolyesters artificial filamentPolyesterYarn

The invention relates to a superfine dacron low stretch yarn and a preparation method thereof. Modified polyester fusant is subjected to metering, extrusion, cooling, oiling and winding to prepare POYyarns; the POY yarns are subjected to yarn guide tube passing, networking, heating stretching, false twisting, heat setting and winding formation to prepare DTY yarns, i.e., the superfine dacron lowstretch yarn is obtained. During cooling, the longitudinal height is kept unchanged; the cross section area of a slow cooling chamber is increased; meanwhile, the slow cooling chamber maintains the plate surface temperature of a spinneret plate in a heat insulation mode; an oil agent for oiling contains crown ether; the content of the crown ether is 67.30 to 85.58 weight percent; the dihydric alcohol chain segment with branched chain is introduced into modified polyester; the prepared superfine dacron low stretch yarn has the filament number being smaller than 0.3dtex; the crimp shrinkage is 8.0+ / -1.0 percent; the crimp stability is greater than or equal to 75 percent. The method is simple and reasonable; the prepared superfine dacron low stretch yarn has the advantage of low fiber number.

Owner:JIANGSU HENGLI CHEM FIBER

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

One-step spun elastic composite filament and preparation method thereof

ActiveCN108048939AIncrease elasticityDimensional stabilityMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentDiolStructural formula

The invention relates to a one-step spun elastic composite filament and a preparation method thereof. Two kinds of modified polyester with different viscosities are melted, metered, subjected to complex extrusion, cooled, oiled, stretched, heat-set and wound respectively, and the one-step spun elastic composite filament is prepared, wherein each of molecular chains of the two kinds of modified polyesters with different viscosities comprises a terephthalic acid chain segment, an ethanediol chain segment and a branched diol chain segment, and the structural formula of branched diol is as shown in the description. In the formula, R1 and R2 are independently selected from linear-chain alkylidene groups with 1-3 carbon atoms, R3 is selected from alkyl groups with 1-5 carbon atoms, and R4 is selected from alkyl groups with 2-5 carbon atoms. The elastic shrinkage of the prepared one-step spun elastic composite filament is higher than or equal to 35%. The method is simple and reasonable, and the prepared one-step spun elastic composite filament has the advantages of higher elasticity, good extensibility and the like, can also maintain dimensional stability and has excellent popularizationvalue.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-fine denier polyester drawn yarn and preparation method thereof

ActiveCN108035007ASimple preparation processSoft and delicateFibre typesMonocomponent copolyesters artificial filamentUltra fineFineness

The invention relates to an ultra-fine denier polyester drawn yarn and a preparation method thereof. A modified polyester is subjected to metering, extruding, cooling, oiling, stretching, heat settingand winding to obtain the ultra-fine denier polyester drawn yarn. An oiling agent used for oiling contains crown ether, and content of the crown ether is 67.30 to 85.58wt%. A modified polyester molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain. A structural formula of the ethylene glycol with thebranched chain is as follows: the structural formula is shown in the description. R1 and R2 are each independently selected from straight-chain alkylene groups with 1 to 3 carbon atoms, R3 is selected from alkyl groups with 1 to 5 carbon atoms, and R4 is selected from alkyl groups with 2 to 5 carbon atoms, and the resulting ultra-fine denier polyester drawn yarn is obtained. The single-filament fineness of the ultra-fine denier polyester drawn yarn is 0.2 to 0.3 dtex. The method is simple and reasonable, and the prepared ultra-fine denier polyester drawn yarn is soft and delicate, and has high quality.

Owner:JIANGSU HENGLI CHEM FIBER

Modified polyester and preparation method thereof

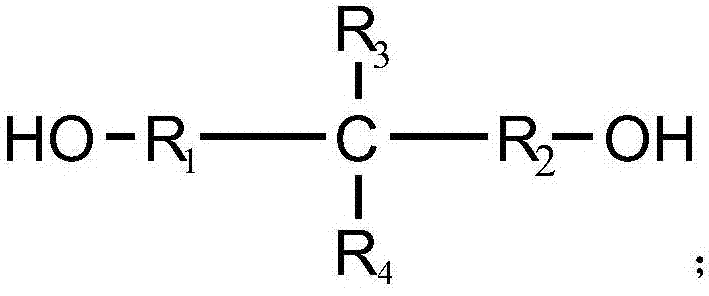

The invention relates to modified polyester and a preparation method thereof. Terephthalic acid, ethylene glycol and dihydric alcohol with branched chains are uniformly mixed and are then sequentiallysubjected to esterification reaction and condensation polymerization to obtain the modified polyester, wherein the dihydric alcohol with branched chains has the structural formula shown in the description; in the formula, R1 and R2 respectively and independently select straight chain alkylidene with the carbon number being 1 to 3; R3 selects alkyl with the carbon number being 1 to 5; R4 selects alkyl with the carbon number being 2 to 5. The molecular chain of the finally prepared modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with branched chains; the content of annular low polymers in the modified polyester is smaller than or equal to 0.6 weight percent. The method has the advantages that the content of the annular low polymers in the modified polyester can be obviously reduced; the influence on the performance of the polyester pre se cannot be caused; the prepared modified polyester has high molecular weight; the distribution is narrow; good popularization values are realized.

Owner:JIANGSU HENGLI CHEM FIBER

Melt directly-spun colored polyester fiber and preparation method thereof

ActiveCN108035011AHigh glossColorfulMelt spinning methodsPigment addition to spinning solutionPolymer scienceAlcohol

The invention relates to melt directly-spun colored polyester fiber and a preparation method thereof. The melt directly-spun colored polyester fiber is prepared by the steps of adding color master batch into modified polyester melt, metering, extruding, cooling, oiling, drawing, carrying out heat setting and winding; an oil agent for oiling contains crown ether, and the content of the crown etheris 67.30-85.58wt%. The preparation method is simple and reasonable, the glossiness of the finally-prepared melt directly-spun colored polyester fiber is more than or equal to 60%, the melt directly-spun colored polyester fiber is black, red, blue or yellow in color and is made of modified polyester with the molecular chain including a terephthalic-acid chain segment, an ethylene-glycol chain segment and a dihydric-alcohol chain segment with branch chains; the structural formula of dihydric alcohol is shown in the description, wherein R1 and R2 are independently and respectively selected from straight-chain alkylene with the number of carbon atoms being 1-3, R3 is selected from alkyl groups with the number of carbon atoms being 1-5, and R4 is selected from alkyl groups with the number of carbon atoms being 2-5. The melt directly-spun colored polyester fiber has the advantages of high glossiness and diversified color, so that the application prospect is very considerable.

Owner:JIANGSU HENGLI CHEM FIBER

High-strength colored polyester industrial yarn and preparation method thereof

ActiveCN108385196AImprove uniformitySimple manufacturing methodFibre typesMonocomponent polyesters artificial filamentYarnTerephthalic acid

The invention relates to a high-strength colored polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester and color masterbatch, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding to prepare the high-strength colored polyester industrial yarn, wherein the oil agent for oiling contains 67.30-85.58 wt% of crown ether, the main material of the industrial yarn is the modified polyester, the molecular chain of the modified polyestercomprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, R4 is selected from alkyl with a carbon atom number of 2-5, and the breaking strength of the prepared industrial yarn is more than or equal to 7.0 cN / dtex. According to the present invention, the method is simple and reasonable, and the obtained industrial yarn has advantages of high breaking strength and good uniformity.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester cotton-like type differential shrinkage composite yarns and preparation method thereof

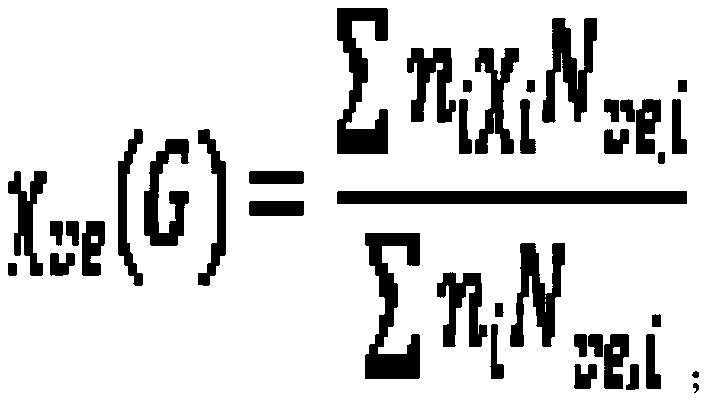

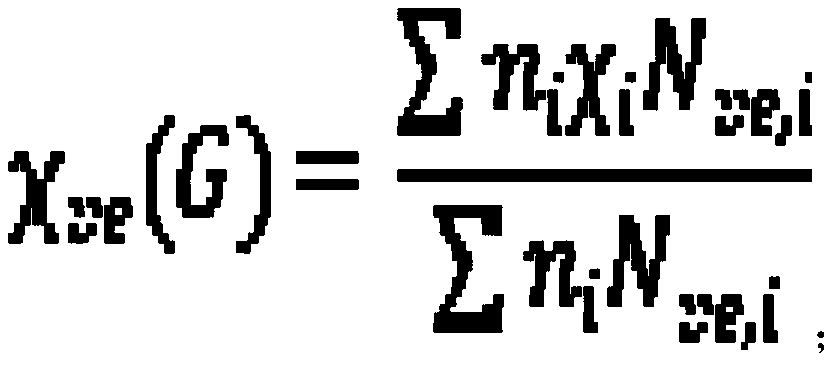

ActiveCN108385226AHigh molecular weightNarrow molecular weightFilament/thread formingYarnYarnPolyester

The invention relates to polyester cotton-like type differential shrinkage composite yarns and a preparation method thereof. The preparation method comprises the following steps: respectively preparing modified polyester POY (Pre-Oriented Yarn) and FDY (Fully Drawn Yarn) wires, and then compounding the POYs with the FDYs to prepare the polyester cotton-like type differential shrinkage composite yarns, wherein the color difference delta E of the prepared composite yarns is less than 0.200, a beam of POYs or FDYs extruded by the same yarn spraying plate simultaneously contains crossed single yarns and trefoiled single yarns; a molecular chain of the modified polyester comprises a branched diol chain segment, a structural formula of the branched diol is as follows: the formula (1) is shown inthe description; in the formula, R1 and R2 are straight-chain alkylene with carbon atomic number 1-3, R3 is alkyl with carbon atomic number 1-5, R4 is alkyl with carbon atomic number 2-5, and a matteagent dispersed in the modified polyester is amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and the amorphous silicon dioxide. The method disclosed by theinvention is simple and reasonable, and the prepared composite yarns have good fluffy, moisture absorption and perspiration performance.

Owner:JIANGSU HENGLI CHEM FIBER

Super-low shrinkage type sun shading cloth and preparation method thereof

ActiveCN108130743ALow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsCooling chamberSlow cooling

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-low shrinkage sunshade cloth and preparation method thereof

ActiveCN108130743BLow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsPolymer scienceGlycol synthesis

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Low-shrinkage activated polyester industrial yarn and preparation method thereof

ActiveCN108385188ALow dry heat shrinkageLow wicking heightFibre typesFilament/thread formingYarnDry heat

The invention relates to a low-shrinkage activated polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, oiling with an activated oil agent, winding, and carrying out pre-activation treatment, wherein the oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58 wt%, and the material of the prepared polyester industrial yarn is the modified polyester withthe molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain. According to the present invention, the preparation method is simple and reasonable; and the dry heat shrinkage rates of the finally obtained low-shrinkage activated polyester industrial yarn respectively are 5.5+ / -0.8% and 2.8-5.8% at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex, and the wicking height is less than or equal to 5 mm.

Owner:JIANGSU HENGLI CHEM FIBER

Superfine polyester low elastic yarn and preparation method thereof

ActiveCN107988649BSimple manufacturing methodSmall denierFibre typesMonocomponent copolyesters artificial filamentPolyesterPolymer science

The invention relates to a superfine dacron low stretch yarn and a preparation method thereof. Modified polyester fusant is subjected to metering, extrusion, cooling, oiling and winding to prepare POYyarns; the POY yarns are subjected to yarn guide tube passing, networking, heating stretching, false twisting, heat setting and winding formation to prepare DTY yarns, i.e., the superfine dacron lowstretch yarn is obtained. During cooling, the longitudinal height is kept unchanged; the cross section area of a slow cooling chamber is increased; meanwhile, the slow cooling chamber maintains the plate surface temperature of a spinneret plate in a heat insulation mode; an oil agent for oiling contains crown ether; the content of the crown ether is 67.30 to 85.58 weight percent; the dihydric alcohol chain segment with branched chain is introduced into modified polyester; the prepared superfine dacron low stretch yarn has the filament number being smaller than 0.3dtex; the crimp shrinkage is 8.0+ / -1.0 percent; the crimp stability is greater than or equal to 75 percent. The method is simple and reasonable; the prepared superfine dacron low stretch yarn has the advantage of low fiber number.

Owner:JIANGSU HENGLI CHEM FIBER

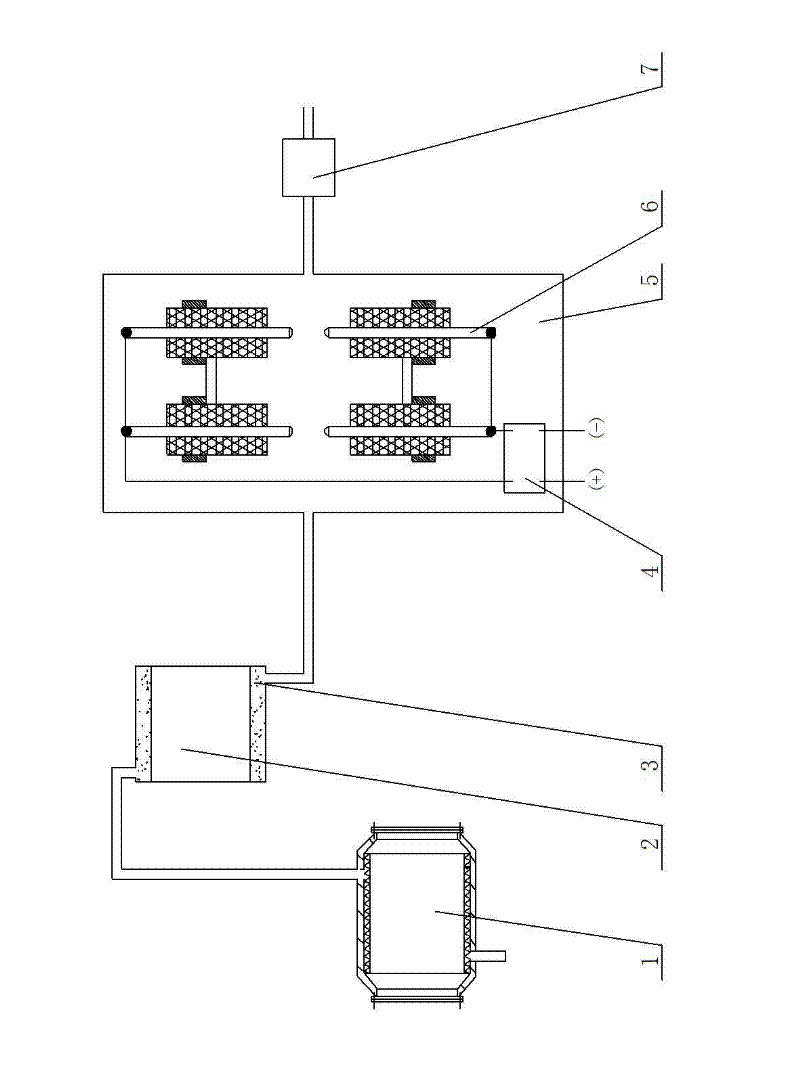

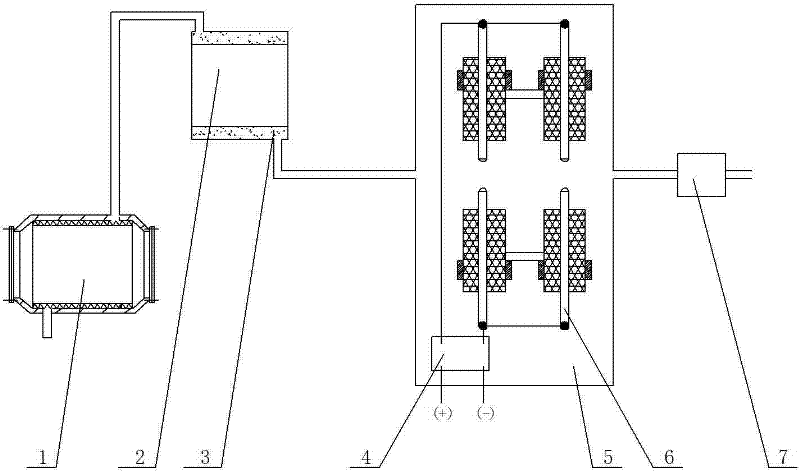

Method for decomposing water into hydrogen-oxygen mixed gas fuel

InactiveCN102020243BSpeed up decompositionSave energyHydrogen productionGaseous fuel burnerPtru catalystVapor generator

The invention relates to a method for decomposing water into a hydrogen-oxygen mixed gas fuel, which comprises the following steps: 1, vaporization: inputting water into a vapor generator, and vaporizing the water to form dry vapor; 2, catalysis: feeding the obtained dry vapor into a catalytic converter, wherein the dry vapor is activated by a manganese metal catalyst in the catalytic converter; 3, electric shock: feeding the activated dry vapor into a discharger to obtain a hydrogen-oxygen mixed gas of which the hydrogen-oxygen volume ratio is 2:1 and a small amount of dry vapor not subject to electric shock; and 4, separation of gas and water: passing the obtained hydrogen-oxygen mixed gas and the dry vapor not subject to electric shock through a gas-water separator to filter the dry vapor, thus obtaining the hydrogen-oxygen mixed gas. By using the method, water can be decomposed into the hydrogen-oxygen mixed gas which can be a new energy replacing fossil fuels, thereby achieving the purposes of energy conservation and emission reduction.

Owner:郎君羊 +1

Polyester large-aperture conveyor belt and preparation method thereof

ActiveCN108035156AReduce generationHigh breaking strengthFibre typesMonocomponent copolyesters artificial filamentSolid phasesChemistry

The invention relates to a polyester large-aperture conveyor belt and a preparation method thereof. According to the preparation method, high-strength polyester industrial yarns are obtained through solid phase polycondensation tackifying, melting, metering, extruding, cooling, oiling, stretching, heat setting and winding of the modified polyester, are then twisted and woven together to obtain a fabric layer, the fabric layer is coated with a synthetic polyurethane resin by two dipping and two rolling, and dried and baked to obtain the polyester large-aperture conveyor belt. An oiling agent used for oiling contains crown ether. The content of the crown ether is 67.30 to 85.58 wt%. The preparation method of the invention is simple and reasonable, and texture of the fabric layer of the polyester large-aperture conveyor belt finally obtained is a modified polyester with a molecular chain including a terephthalic acid chain segment, a glycol chain segment and a dihydric alcohol chain segment with g a branched chain, the breaking strength of the polyester large-aperture conveyor belt is equal to or more than 2900N, water pressure resistance is equal to or more than 100KPa, peel strengthis equal to or more than 9.0N / cm, when friction is equal to or more than 3500 times, coating does not change, and when temperature is equal to or less than -30 DEG C, the coating is crack-free.

Owner:JIANGSU HENGLI CHEM FIBER

High strength polyester industrial filament and preparation method thereof

ActiveCN108130616AIncrease the cross-sectional areaReduce the degree of cokingNew-spun product collectionArtificial filament heat treatmentCooling chamberStructural formula

The invention relates to a high strength polyester industrial filament and a preparation method thereof. Modified polyester is subjected to solid phase polycondensation tackifying, melting, metering,extrusion, cooling, oiling, stretching, heat setting and winding to obtain the high strength polyester industrial filament; during cooling, the vertical height is kept unchanged and the cross sectionarea of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation; a molecular chainof the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3 , R3 is selected from alkyl with thecarbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5. The fracture strength of the prepared high strength polyester industrial filament is more than or equal to8.1 cN / dtex. The method is simple and reasonable, and the prepared industrial filament has the advantages of high breaking strength and good mechanical properties.

Owner:JIANGSU HENGLI CHEM FIBER

Superfine denier polyester drawn yarn and preparation method thereof

ActiveCN108035007BSimple preparation processSoft and delicateFibre typesMonocomponent copolyesters artificial filamentPolymer scienceGlycol synthesis

The invention relates to an ultra-fine denier polyester drawn yarn and a preparation method thereof. A modified polyester is subjected to metering, extruding, cooling, oiling, stretching, heat settingand winding to obtain the ultra-fine denier polyester drawn yarn. An oiling agent used for oiling contains crown ether, and content of the crown ether is 67.30 to 85.58wt%. A modified polyester molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain. A structural formula of the ethylene glycol with thebranched chain is as follows: the structural formula is shown in the description. R1 and R2 are each independently selected from straight-chain alkylene groups with 1 to 3 carbon atoms, R3 is selected from alkyl groups with 1 to 5 carbon atoms, and R4 is selected from alkyl groups with 2 to 5 carbon atoms, and the resulting ultra-fine denier polyester drawn yarn is obtained. The single-filament fineness of the ultra-fine denier polyester drawn yarn is 0.2 to 0.3 dtex. The method is simple and reasonable, and the prepared ultra-fine denier polyester drawn yarn is soft and delicate, and has high quality.

Owner:JIANGSU HENGLI CHEM FIBER

Polyester large-diameter conveyor belt and preparation method thereof

ActiveCN108035156BHigh breaking strengthSimple preparation processFibre typesMonocomponent copolyesters artificial filamentYarnPolymer science

The invention relates to a polyester large-aperture conveyor belt and a preparation method thereof. According to the preparation method, high-strength polyester industrial yarns are obtained through solid phase polycondensation tackifying, melting, metering, extruding, cooling, oiling, stretching, heat setting and winding of the modified polyester, are then twisted and woven together to obtain a fabric layer, the fabric layer is coated with a synthetic polyurethane resin by two dipping and two rolling, and dried and baked to obtain the polyester large-aperture conveyor belt. An oiling agent used for oiling contains crown ether. The content of the crown ether is 67.30 to 85.58 wt%. The preparation method of the invention is simple and reasonable, and texture of the fabric layer of the polyester large-aperture conveyor belt finally obtained is a modified polyester with a molecular chain including a terephthalic acid chain segment, a glycol chain segment and a dihydric alcohol chain segment with g a branched chain, the breaking strength of the polyester large-aperture conveyor belt is equal to or more than 2900N, water pressure resistance is equal to or more than 100KPa, peel strengthis equal to or more than 9.0N / cm, when friction is equal to or more than 3500 times, coating does not change, and when temperature is equal to or less than -30 DEG C, the coating is crack-free.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of polyester hoy fiber and preparation method thereof

ActiveCN108130614BSimple preparation processImprove performanceFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to polyester HOY fibers and a preparation method thereof. The preparation method comprises the steps of carrying out metering, extrusion, cooling, oiling and high-speed winding of a modified polyester melt to obtain the polyester HOY fibers, wherein the high-speed winding speed of the high-speed winding is more than or equal to 6000 m / min; during cooling, the vertical heightis kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the wayof heat preservation. The fibers are made of modified polyester having a molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the structural formula described in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3 , R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fibers is less than 0.200. The method is simple and reasonable in preparation process, and the prepared fibers have good properties.

Owner:JIANGSU HENGLI CHEM FIBER

A high-modulus low-shrinkage hard wire rope and its preparation method

ActiveCN108385418BLow dry heat shrinkageSimple preparation processFibre typesFilament/thread formingYarnPolymer science

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

A Method for Reducing Hairiness of Polyester Yarn

The invention relates to a method for reducing polyester yarn hairness. According to the method, modified polyester is adopted, and polyester yarns are prepared by polyester fiber of an oil agent withthe crown ether content being 67.3 to 85.58 percent by weight used in the oiling link in the spinning process, wherein the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a diol chain segment with branched chains; the structure of the diol chain segment with the branched chains is as follows: (the formula is shown as the description); and in the formula, R1 and R2 are independently selected from straight chain alkylene with the carbon atom number being 2 to 5, R3 is selected from alkyl with the carbon atom number being 1 to 5,and R 4 is selected from alkyl with the carbon atom number being 2 to 5. The method for reducing the polyester yarn hairness, which is provided by the invention, is simple and reasonable, the number of the prepared polyester yarn hairness is 1.8 to 2.1 pieces / 10 km, the number of the prepared polyester yarn hairness is obviously reduced, the advantages of high uniformity, little hairness and highquality are achieved and great application prospect is achieved.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com