Super high strength polyester industrial filament and preparation method thereof

An ultra-high-strength, industrial yarn technology, applied in the direction of single-component polyester rayon, single-component copolyester rayon, filament/thread forming, etc., can solve the problem of poor mechanical properties of fibers and fiber quality No advanced problems, good mechanical properties, long replacement cycle, simple and reasonable preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

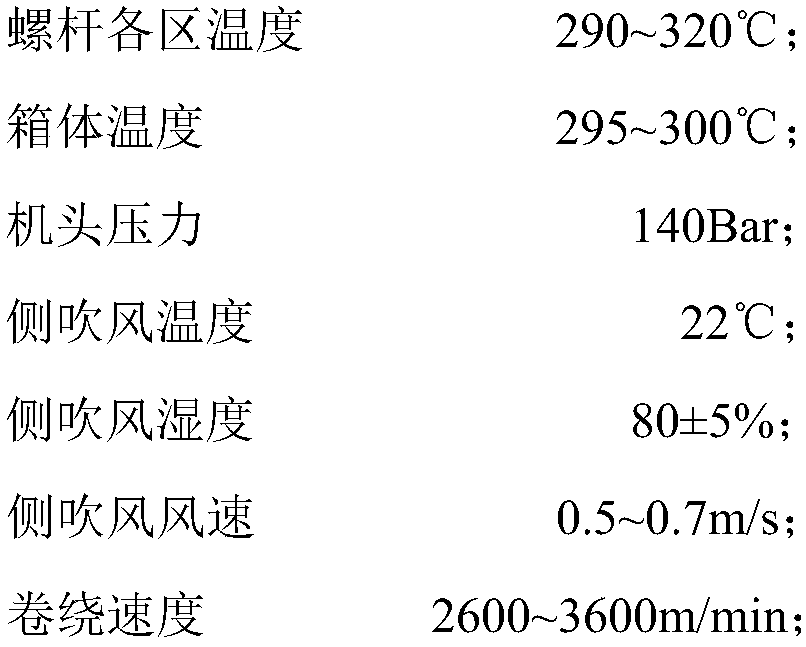

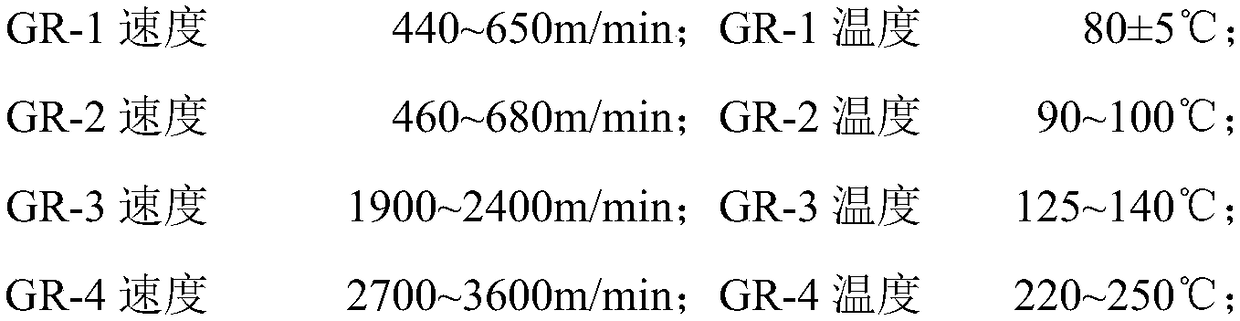

[0048] A preparation method of ultra-high-strength polyester industrial yarn, the steps are as follows:

[0049] (1) preparation of modified polyester;

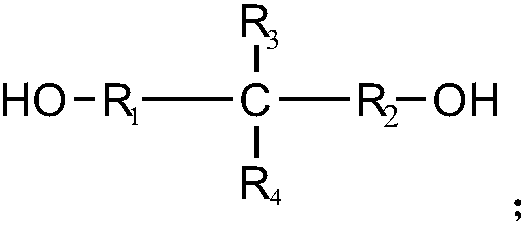

[0050] (a) Esterification reaction: terephthalic acid, ethylene glycol and 2-ethyl-2-methyl-1,3-propanediol in a molar ratio of 1:1.2:0.03 are made into a slurry, and antimony trioxide is added After mixing with triphenyl phosphate evenly, carry out the esterification reaction under pressure in a nitrogen atmosphere, the pressurized pressure is normal pressure, and the temperature of the esterification reaction is 250°C. 90% is the end point of the esterification reaction, wherein the addition of antimony trioxide is 0.01% of the weight of terephthalic acid, and the addition of triphenyl phosphate is 0.05% of the weight of terephthalic acid, wherein 2-ethyl- The structural formula of 2-methyl-1,3-propanediol is as follows:

[0051]

[0052] (b) polycondensation reaction; after the esterification reaction is over, start t...

Embodiment 2

[0056] A preparation method of ultra-high-strength polyester industrial yarn, the steps are as follows:

[0057] (1) preparation of modified polyester;

[0058] (a) Esterification reaction; prepare terephthalic acid, ethylene glycol and 2,2-diethyl-1,3-propanediol in a molar ratio of 1:1.3:0.04 into a slurry, add ethylene glycol antimony and phosphoric acid After the trimethyl ester is mixed evenly, the esterification reaction is carried out under pressure in a nitrogen atmosphere. The pressurized pressure is normal pressure, and the temperature of the esterification reaction is 260°C. When is the end point of the esterification reaction, the addition of ethylene glycol antimony is 0.02% of the weight of terephthalic acid, the addition of trimethyl phosphate is 0.03% of the weight of terephthalic acid, and 2,2-diethyl The structural formula of -1,3-propanediol is as follows:

[0059]

[0060] (b) polycondensation reaction; after the esterification reaction is over, start ...

Embodiment 3

[0064] A preparation method of ultra-high-strength polyester industrial yarn, the steps are as follows:

[0065] (1) preparation of modified polyester;

[0066] (a) Esterification reaction; terephthalic acid, ethylene glycol and 2-butyl-2-ethyl-1,3-propanediol in a molar ratio of 1:1.4:0.05 are made into a slurry, and antimony acetate and After the trimethyl phosphate is mixed evenly, carry out the esterification reaction under pressure in a nitrogen atmosphere. % is the end point of the esterification reaction, wherein the addition of antimony acetate is 0.03% of the weight of terephthalic acid, and the addition of trimethyl phosphite is 0.01% of the weight of terephthalic acid, wherein 2-butyl-2- The structural formula of ethyl-1,3-propanediol is as follows:

[0067]

[0068] (b) polycondensation reaction; after the esterification reaction is finished, start the polycondensation reaction in the low vacuum stage under negative pressure conditions, and within 40 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com