One-step spun elastic composite filament and preparation method thereof

A composite yarn and elastic technology, applied in the direction of single-component polyester rayon, single-component copolyester rayon, etc., can solve the problems of color spots, difficult coloring, uneven dyeing, etc. The effect of good extensibility and maintaining dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of one-step spinning elastic composite yarn, concrete steps are as follows:

[0057] (1) prepare modified polyester;

[0058] (a) esterification reaction;

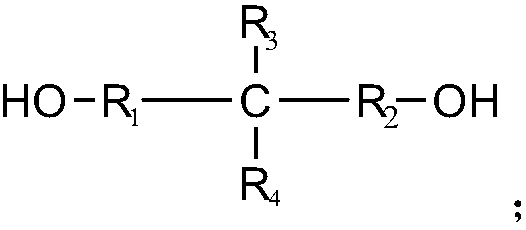

[0059] Prepare a slurry of terephthalic acid, ethylene glycol and 2-ethyl-2-methyl-1,3-propanediol with a molar ratio of 1:1.2:0.03, add antimony trioxide, titanium dioxide and triphenyl phosphate After mixing evenly, carry out the esterification reaction under pressure in a nitrogen atmosphere. At the end of the oxidation reaction, the addition of antimony trioxide is 0.01% of the weight of terephthalic acid, the addition of titanium dioxide is 0.20% of the weight of terephthalic acid, and the addition of triphenyl phosphate is 0.01% of the weight of terephthalic acid. 0.05%, wherein the structural formula of 2-ethyl-2-methyl-1,3-propanediol is as follows:

[0060]

[0061] (b) polycondensation reaction;

[0062] After the esterification reaction is over, start the polycondensati...

Embodiment 2

[0066] A kind of preparation method of one-step spinning elastic composite yarn, concrete steps are as follows:

[0067] (1) prepare modified polyester;

[0068] (a) esterification reaction;

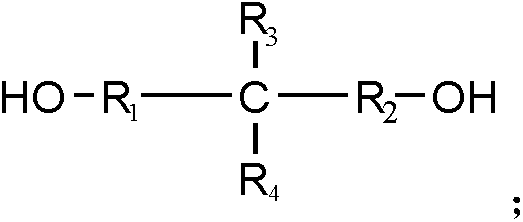

[0069] Prepare terephthalic acid, ethylene glycol and 2,2-diethyl-1,3-propanediol in a molar ratio of 1:1.3:0.04 to form a slurry, add antimony ethylene glycol, titanium dioxide and trimethyl phosphate and mix well Finally, the esterification reaction is carried out under pressure in a nitrogen atmosphere, the pressurized pressure is normal pressure, and the temperature of the esterification reaction is 260 ° C. When the amount of water distilled in the esterification reaction reaches 91% of the theoretical value, it is an esterification reaction. End point, wherein the addition of ethylene glycol antimony is 0.02% of the weight of terephthalic acid, the addition of titanium dioxide is 0.21% of the weight of terephthalic acid, and the addition of trimethyl phosphate is 0.03% of the weig...

Embodiment 3

[0076] A kind of preparation method of one-step spinning elastic composite yarn, concrete steps are as follows:

[0077] (1) prepare modified polyester;

[0078] (a) esterification reaction;

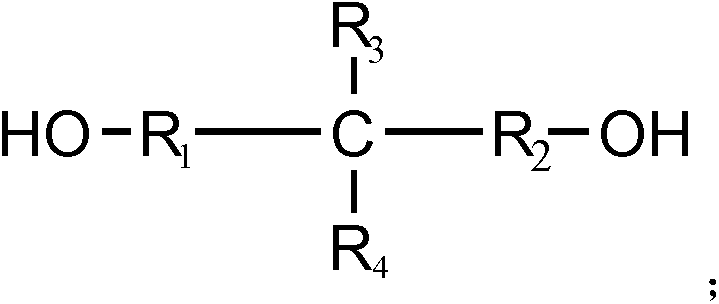

[0079] Prepare a slurry of terephthalic acid, ethylene glycol and 2-butyl-2-ethyl-1,3-propanediol with a molar ratio of 1:1.4:0.05, add antimony acetate, titanium dioxide and trimethyl phosphite to mix After uniformity, carry out esterification under pressure in a nitrogen atmosphere, the pressurized pressure is 0.1 MPa, the temperature of the esterification reaction is 252 ° C, when the amount of water distilled in the esterification reaction reaches 92% of the theoretical value, it is esterification At the end of the reaction, the addition of antimony acetate is 0.03% of the weight of terephthalic acid, the addition of titanium dioxide is 0.23% of the weight of terephthalic acid, and the addition of trimethyl phosphite is 0.01% of the weight of terephthalic acid , wherein the structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com