Patents

Literature

77results about How to "Reduce hairiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

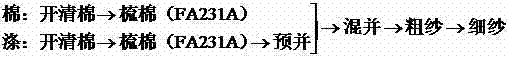

Production method of tight sirospun yarn of combed crystal cotton

InactiveCN102493064AHairiness value reductionImprove evennessContinuous wound-up machinesYarnCotton fibreCombing

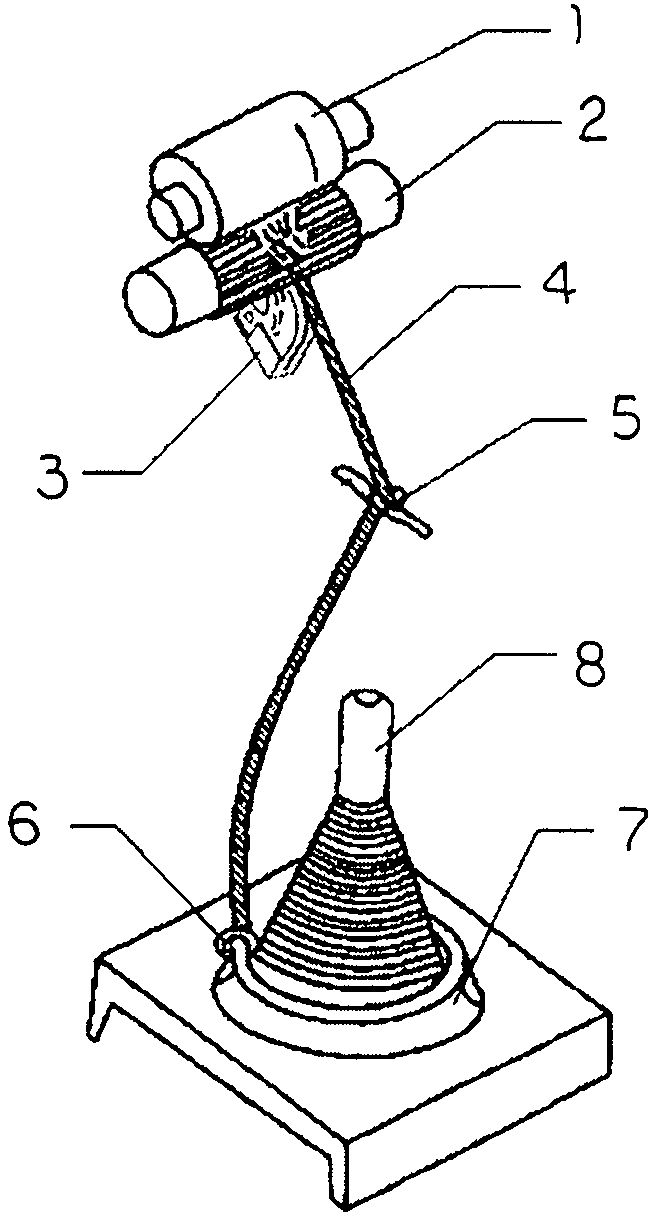

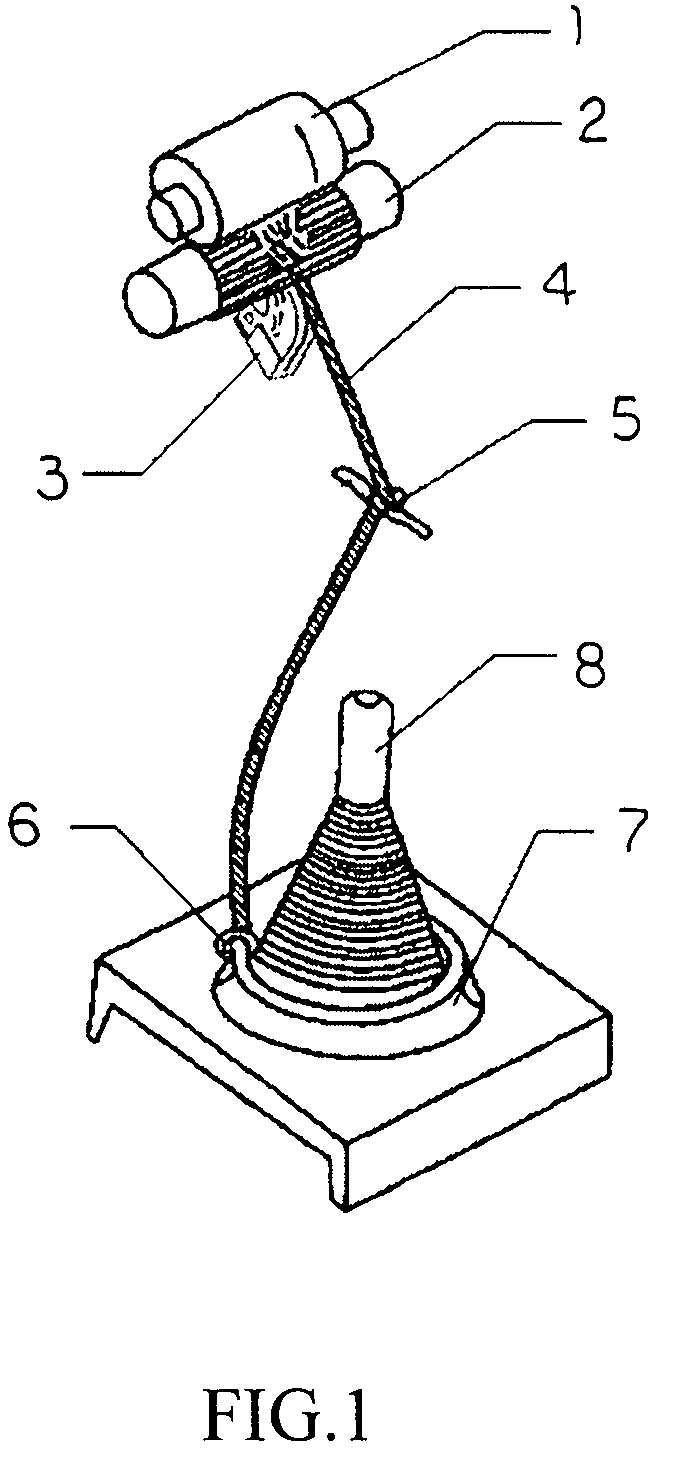

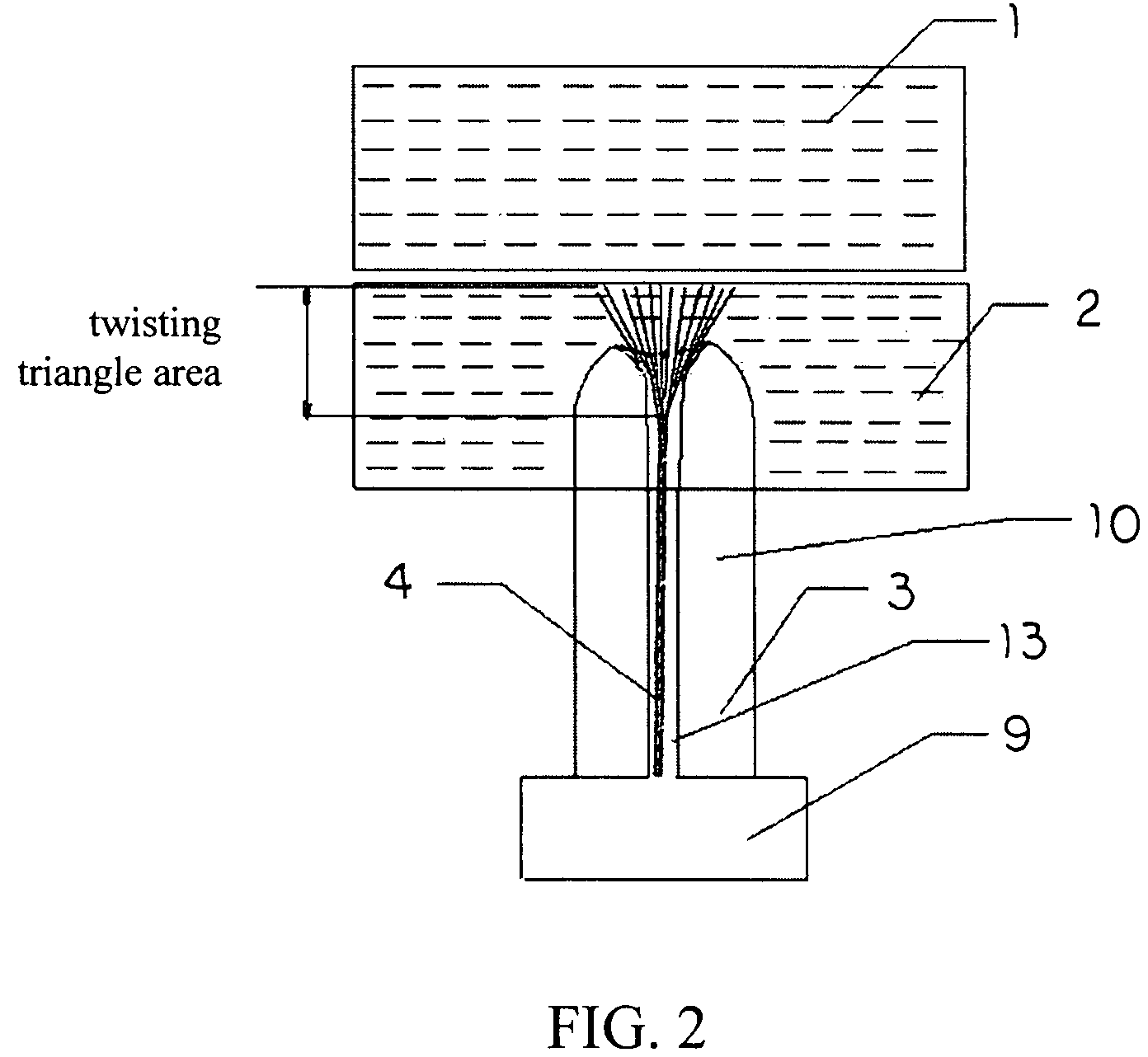

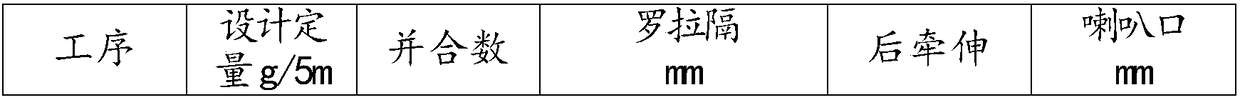

The invention relates to a production method of tight sirospun yarn of combed crystal cotton. The production method comprises the following sequential working procedures: combed cotton preparation; opening, cleaning and blending of combed cotton and crystal cotton; cotton combing; drawing; roving; mixing of sirospun yarn of nylon filament; and winding. According to the invention, crystal cotton fiber is blended with the combed cotton fiber, the tight sirospun yarn of the nylon filament is added during the spinning working procedure, and a double-rough-yarn feeding device and a tight spinning device are additionally installed on a traditional ring spinning frame, so that two threads of rough yarn are simultaneously fed to a drafting region, a certain spacing is reserved between drafted fiber strands, and the drafted fiber strands are gathered, converged and twisted at the downstream of the roller chop to obtain yarn. Under the action that the fiber strand twisting triangular region is canceled due to bundling action and two threads of fiber strands are combined, the filoplume value of single yarn is obviously reduced, the yarn evenness is significantly improved, the fracture strength is greatly increased and better resultant yarn quality is obtained; and functional yarn with high strength, high hygroscopicity, cleanness, high elasticity and bacteriostatic characteristic is produced by the equipment.

Owner:DANYANG DANSHENG TEXTILE

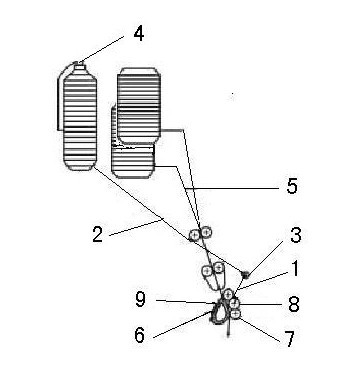

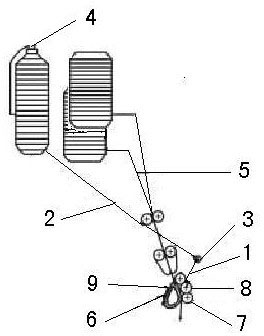

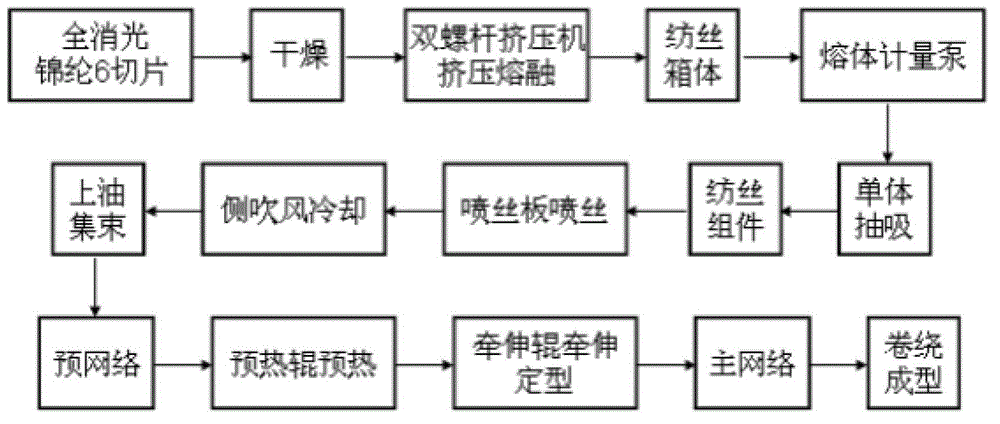

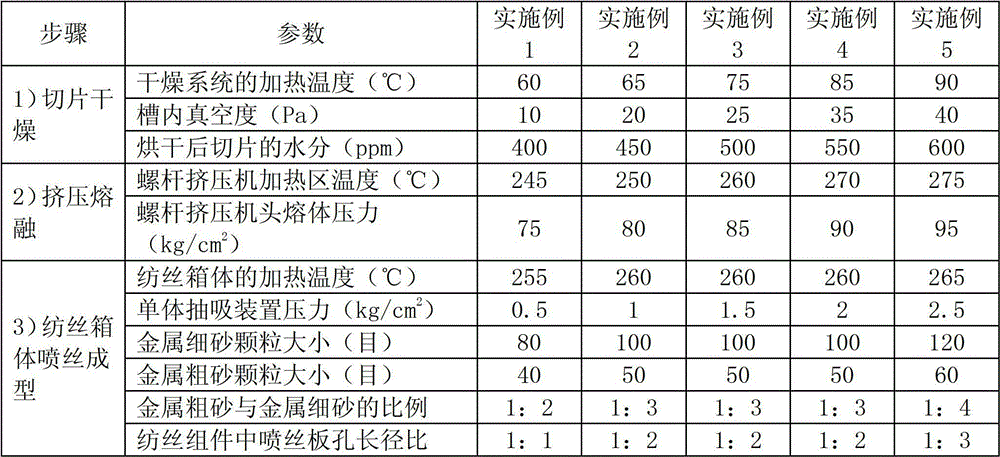

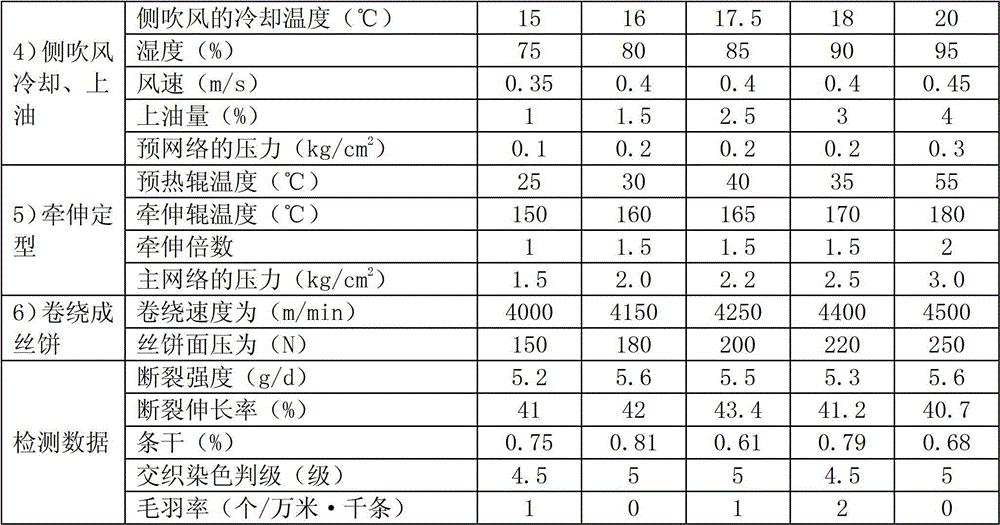

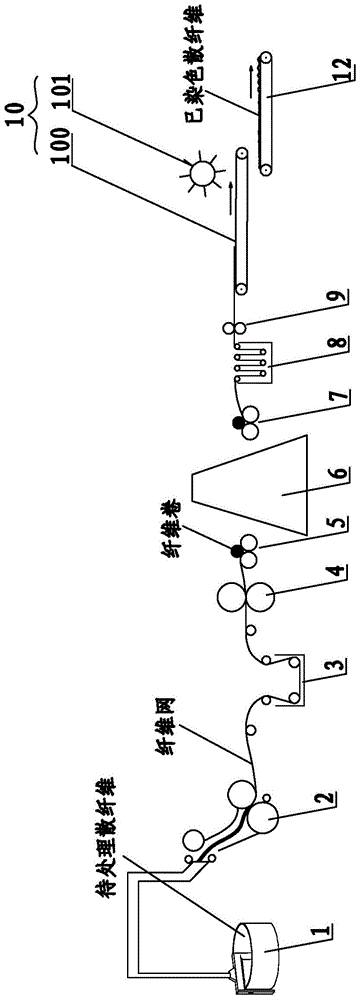

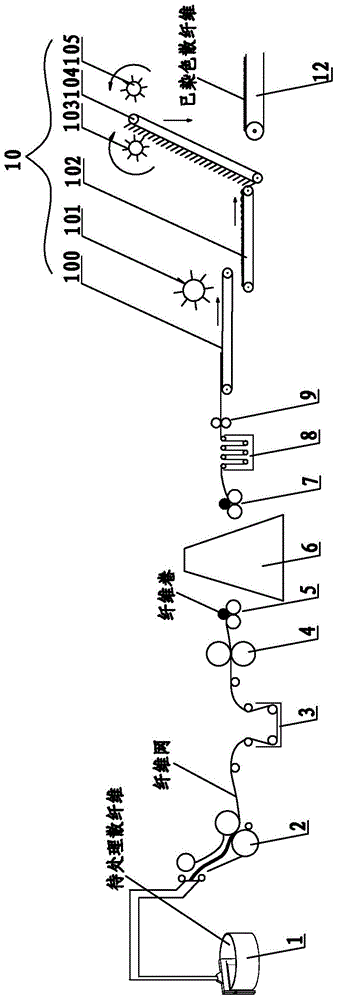

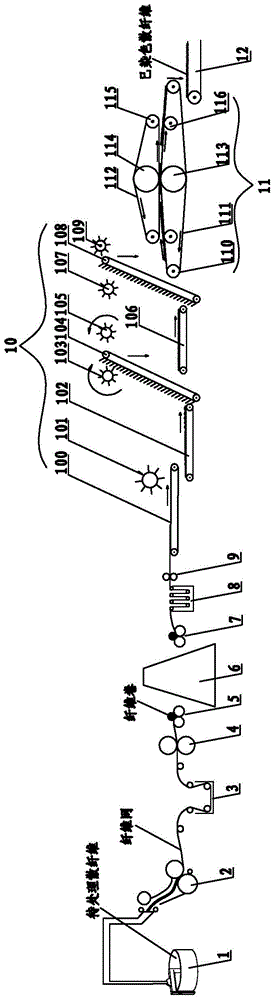

Production method for 20D/24F complete-extinction nylon 6 fully-drawn yarn

ActiveCN102747438ASimple processReduce processing costsFilament forming substance formingMelt spinning methodsYarnExtinction

The invention belongs to the field of synthetic fiber processing, relates to a preparation method for a nylon 6 fiber and discloses a production method for a 20D / 24F complete-extinction nylon 6 fully-drawn yarn. The production method comprises the following steps of: (1) slicing and drying until the water content is 400-600ppm; (2) extruding and melting by a twin-screw extruder; (3) extracting excessive monomer impurities by a single sucking device and performing spinneret and forming by a spinning manifold; (4) laterally blowing, cooling and oiling at constant temperature and humidity; (5) drafting and setting; and (6) winding to form a silk cake. The production method disclosed by the invention has the advantages of simple and feasible process and low processing cost as well as stable product quality, uniform evenness, low hairness ratio, favorable dyeing effect and excellent mechanical property by optimizing parameters.

Owner:浙江嘉华特种尼龙有限公司 +1

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

Environment-friendly and green secondary slurry of electronic-grade glass fiber cloth

InactiveCN101880964AGuaranteed tensile strengthImprove protectionFibre treatmentGlass fiberMetallurgy

The invention relates to secondary warp slurry used in the technical field of electronic-grade glass fiber cloth. The secondary slurry comprises the following components by weight percentage: 5-10 percent of main slurry starch, 0.5-1 percent of smoothing agent, 0.5-1 percent of binder, 0.01-0.05 percent of surfactant, and the balance of deionized water. The invention is warp slurry of electronic-grade glass fiber cloth for a printed circuit board with high-precision, high-uniformity and high-performance, the electronic-grade glass fiber cloth produced by the slurry formula has the advantages of excellent fabric appearance quality, smaller fabric thickness and energy saving and environment-friendly production process. The glass fiber cloth is applicable for insulation enhancing material of the printed circuit board, and is widely used in high-end products such as mobile phone boards, notebook computers, automotive sheets, digital cameras, digital players, navigation devices and the like.

Owner:SHANGHAI GRACE FABRIC

Flexible smooth yarn and production method thereof

The invention provides flexible smooth yarn and a production method thereof. The raw materials of the yarn is one or more of natural fibers or chemical fibers. The yarn is characterized in that compact siro spinning is combined with low-torsion spinning, two rough yarn parallel feeding is used during a spun yarn procedure, design twist coefficient of the yarn can be lowered at 280-300, fibers are tightly held together under action of a suction groove in a spinning trigonum, two completely drafted and gathered fiber bundles obtains more twisting before plying compared with common compact siro spinning due to the fact that false twist of low-torsion spinning is higher than intensive false twist of spun yarn formation twist, and more outstanding plying effect different from common compact siro spinning structures is achieved. The produced yarn is flexible and smooth, low in residual stress, and has plying effect, strength of the yarn is increased by 10-15%, hairness is lowered by 75-80%, evenness CV% is lowered by about 0.2%, and yarn twisting number is lowered by 20-30%.

Owner:RUGAO CITY DINGYAN TEXTILE

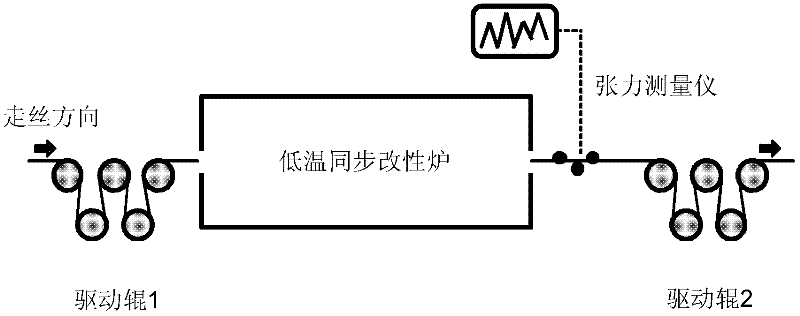

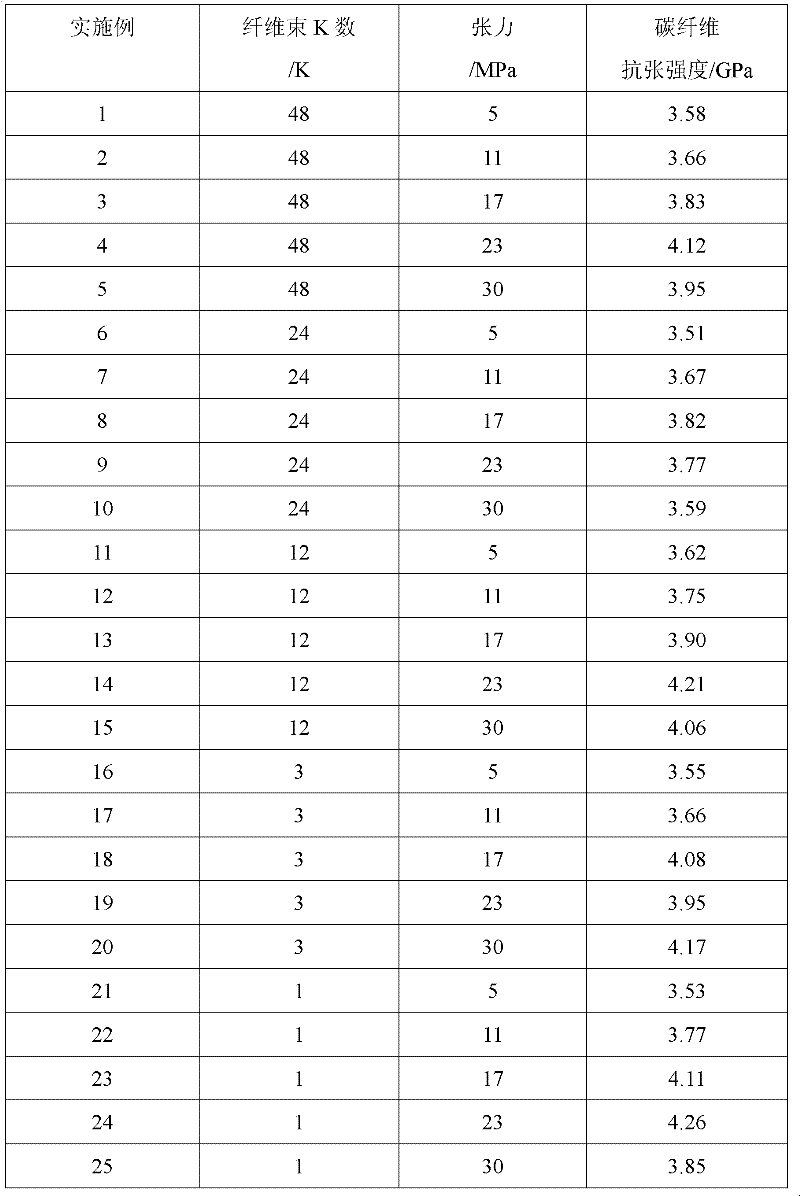

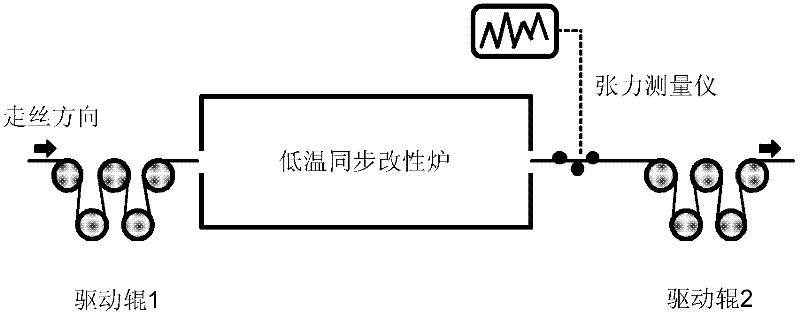

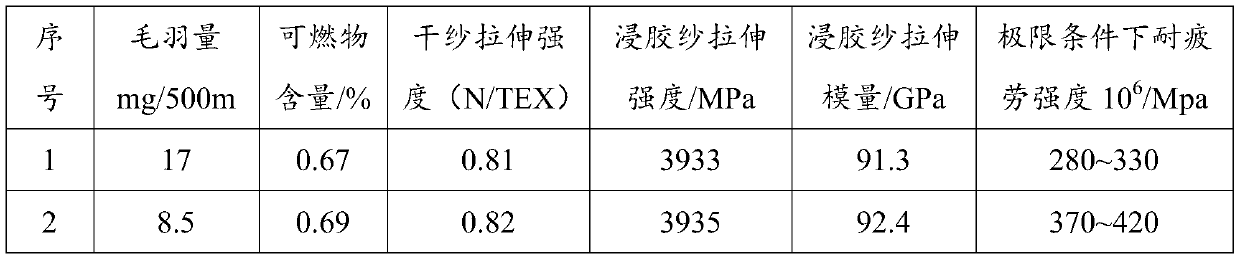

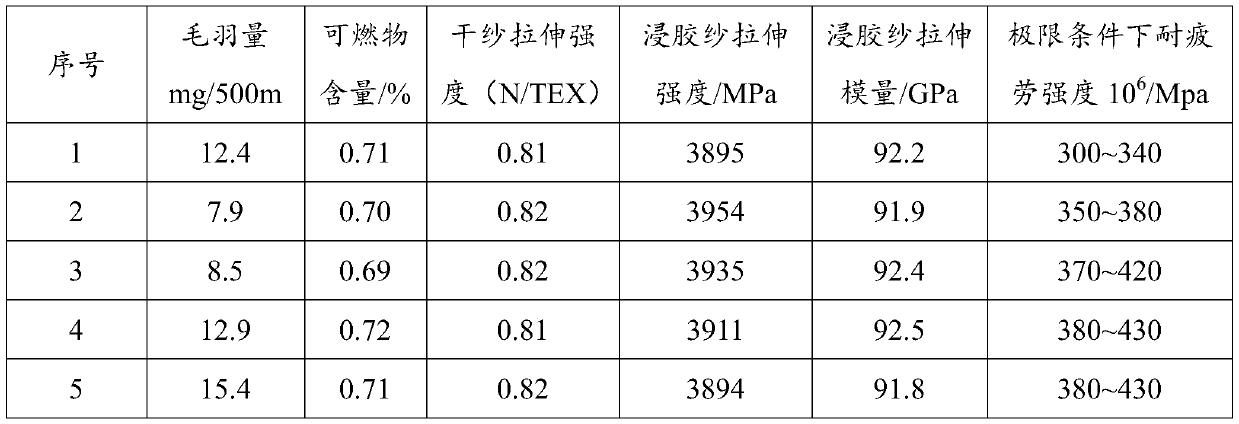

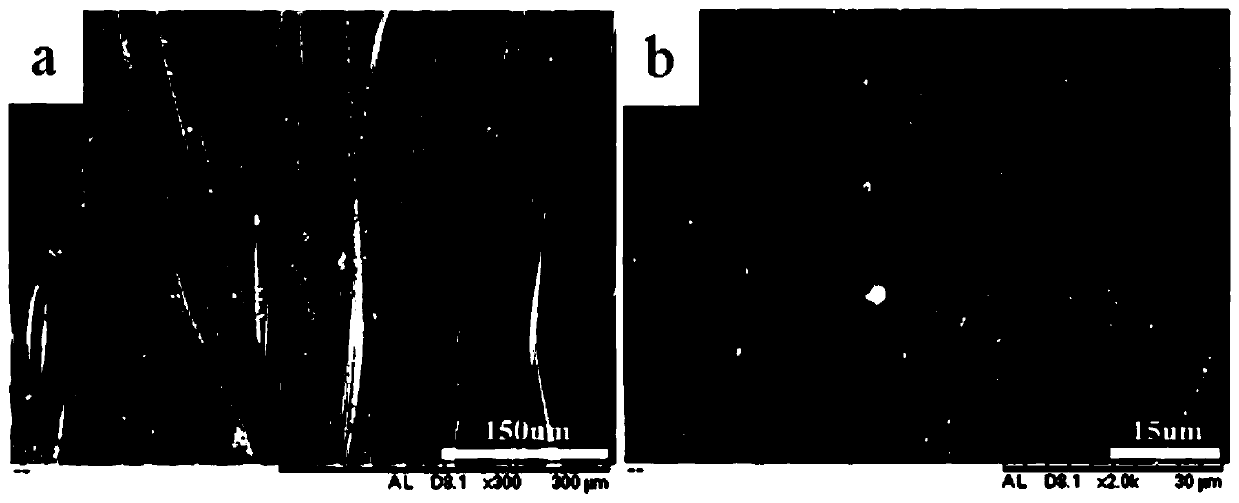

Method for preparing high performance carbon fiber by controlling tensile force

InactiveCN102505190AReduce hairinessImprove mechanical propertiesFibre chemical featuresDielectricCarbon fibers

A method for preparing high performance carbon fiber by controlling tensile force is characterized in that polyacrylonitrile copolymer fiber is placed in a thermal treatment furnace at the temperature ranging from 120 to 200 DEG C, 5 to 30 MPa of tensile force is exerted, and low temperature synchronous modification treatment is conducted for 2 to 10 minutes in the presence of air dielectric. Processed fiber is processed through thermal oxidation stabilization and carbonization to obtain carbon fiber. Tensile strength of the obtained carbon fiber is higher than 3.5 GPa.

Owner:BEIJING UNIV OF CHEM TECH

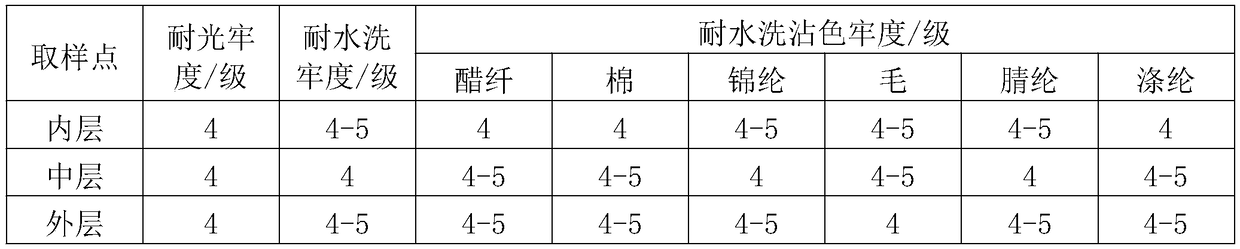

Production process of thin side-stretch fabric

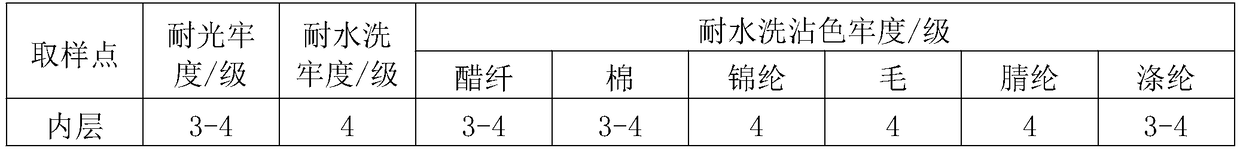

InactiveCN109505049AImprove comfortHigh color fastnessSingeingHeating/cooling textile fabricsPolyesterFiber

The invention discloses a production process of a thin side-stretch fabric. The production process comprises the following steps of S1 warping, S2 beam dyeing pretreatment, S3 beam dyeing, S4 soapingand color fixing, S5 foam slashing, S6 weft yarn unwinding, S7 weft yarn pretreatment, S8 weft yarn dyeing, S9 weft yarn soaping, S10 weaving and S11 after treatment. According to the production process of the thin side-stretch fabric, warp yarn is dacron spandex core-spun yarn, beam dyeing and sizing are adopted, weft yarn is subjected to cone yarn dyeing, stain fabric weave is adopted, and therefore polyester fibers are arranged on one face of the fabric, and blended tencel and Coolmax fibers are presented on the other face of the fabric. The polyester fibers have the advantages of being resistant to wear, high in brute force and the like, the face, in contact with the skin, of the tencel and Coolmax fibers has the functions of being good in hygroscopicity, resistant to static and bacteria and the like, and the comfort of the fabric is improved. Beam dyeing and sizing are adopted, fluff and nep on warp yarn can be reduced, and weaving is conducted smoothly.

Owner:浙江鸣春纺织股份有限公司

Flame-retardant coating fabric high in moisture-penetrability

The invention discloses a flame-retardant coating fabric high in moisture-penetrability. The flame-retardant coating fabric high in moisture-penetrability comprises a first base coating and a second base coating, wherein the first base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of a bridging agent, 1.6-2 parts of an accelerant, 1.4-1.6 parts of a washable agent and 9-11 parts of phosphate ester flame-retardant oil. The second base coating is obtained by drying a sizing agent which is prepared from the following components in parts by mass: 100 parts of polyurethane resin, 38-42 parts of bromoethane, 19-21 parts of diantimony trioxide, 4.5-5.5 parts of zinc borate, 4-5 parts of the bridging agent, 1.6-2 parts of the accelerant, 1.4-1.6 parts of the washable agent and 9-11 parts of phosphate ester flame-retardant oil. The flame-retardant coating fabric high in moisture-penetrability is small in smoke generation quantity, free of molten drop, high in flame-retardant effect and highly washable; the flame-retardant substance has a small possibility of hydrolyzing.

Owner:KUNSHAN HUAYANG NEW MATERIAL

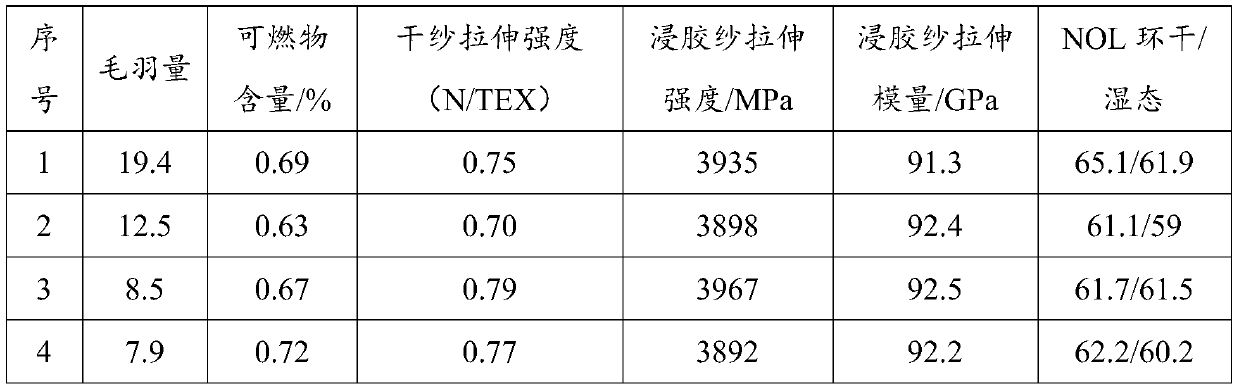

Film forming agent suitable for glass fibers, impregnating agent comprising same, and preparation method and applications of impregnating agent

The invention relates to the technical field of impregnating agents, and discloses a film forming agent suitable for glass fibers, an impregnating agent comprising the same, and a preparation method and applications of the impregnating agent. The film forming agent comprises emulsified bisphenol A type epoxy resin and polyester type polyurethane. Through the emulsification effect of a surfactant, the interfacial energy of a system is reduced, the stability of epoxy resin emulsion is improved, and thus the function of the epoxy resin emulsion can be better exerted. The polyester polyurethane film forming agent has a large molecular weight and a strong yarn-wrapping performance and easily forms a compact film on the surface of glass fibers, thus the glass fibers are isolated from the external environment, water will not enter the cracks of the glass fibers, the elasticity and wear resistant performance of yarns are improved, the anti-fatigue performance of yarns is strengthened, at the same time, the bundling force is high, and the phenomenon of yarns such as natural draping, non-uniform tension force, and the like, is effectively relieved.

Owner:SINOMA SCI & TECH

Yarn clearing device for yarn spool processing

InactiveCN111304796AImprove cleanlinessIncrease the scope of applicationDirt cleaningTextiles and paperYarnEngineering

The present invention relates to a yarn clearing device for yarn spool processing. The yarn clearing device comprises a working table, a yarn collecting device and a clearing device, wherein the rightend of the upper end surface of the working table is provided with the yarn collecting device, the front left side of the yarn collecting device is provided with the clearing device, and the lower end of the clearing device is mounted on the upper end surface of the working table. According to the yarn clearing device for yarn spool processing, defect points of impurities such as hairiness on thesurface of a yarn are cleared by adopting a design concept of multi-point clearing, and the impurities such as the hairiness in forward and reverse states on the yarn can be cleared, so that the yarnclearing degree is improved; and cutters with different sizes are adopted for adapting to yarns with different sizes and types, so that the application range and the utilization rate of the yarn clearing device are expanded and improved.

Owner:卫平山

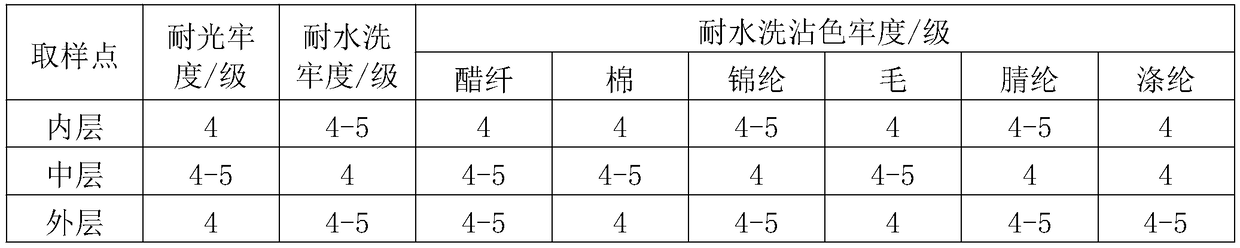

Production technology of beam-dyed double-layer two-way stretch fabric

The invention discloses a production technology of beam-dyed double-layer two-way stretch fabric. The production technology comprises the following steps: preparation of a surface beam, dyeing pretreatment of the surface beam, dyeing of the surface beam, soaping of the surface beam, foam slashing of the surface beam, preparation of a lining beam, pretreatment of the lining beam, dyeing of the lining beam, soaping of the lining beam, foam slashing of the lining beam, weaving and after finishing. According to the production technology of the beam-dyed double-layer two-way stretch fabric, the surface is formed by interweaving nylon fiber core spun yarn, and the lining is formed by interweaving corn spun yarn taking tencel and Coolmax as a coating layer. According to the double double-layer two-way stretch fabric, the surface has wear resistance of nylon fiber, the lining has moisture absorption and removal effect of the tencel and the Coolmax fiber, and the creativity and durability of the fabric are improved. Besides, yarn hairiness and neps on warp can be reduced by beam dyeing sizing, so that weaving is performed smoothly. The process of the production technology can be shortened and production efficiency can be improved.

Owner:浙江鸣春纺织股份有限公司

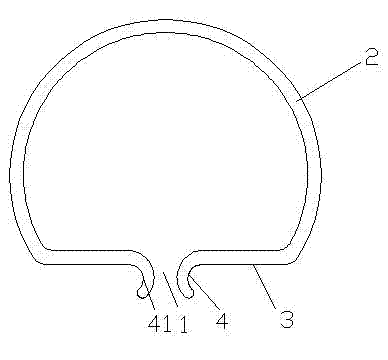

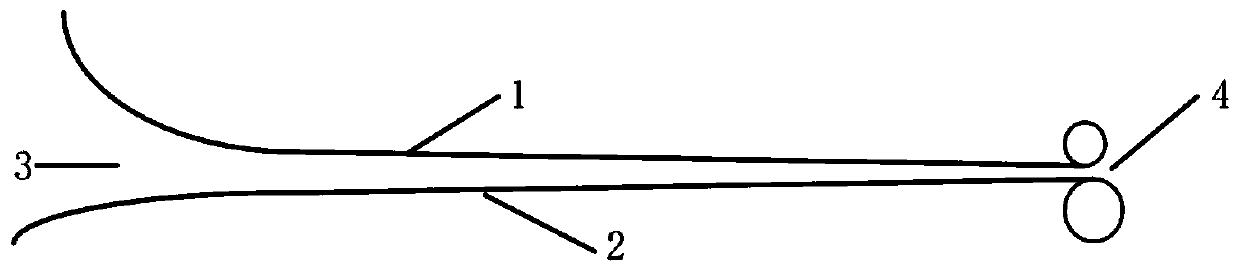

Method and apparatus for producing high quality yarn on a ring-spinning machine

A method of producing a high quality of yarn by an iron-heating apparatus, including the steps of: guiding a yarn to pass between upper and lower rollers, wherein the yarn is exited at a front nip in a twisting triangle area; guiding the yarn to enter to a groove of a heating main body of the iron-heating apparatus; heating the yarn along the groove to reduce a rigidity of the yarn so as to allow the yarn to be easily twisted to form an improved yarn with high quality; and enwrapping the improved yarn on a spun yarn tube. In addition, a counter frictional force is applied at the yarn through walls of the groove such that fiber on a surface of the yarn is further twisted to the yarn for minimizing hairiness.

Owner:WUHAN TEXTILE UNIV

Formula and production method of impregnating agent for low-cost electronic-grade glass fiber yarns

A production method of an impregnating agent for low-cost electronic-grade glass fiber yarns is designed in the invention. The impregnating agent mainly comprises 93-95 parts of softened water, 1.8-2.4 parts of unmodified high-amylase corn starch, 1.8-2.4 parts of modified potato starch, 1.3-1.7 parts of a vegetable oil elusion, 0.1-0.3 parts of a plasticizing agent and 0.2-0.4 parts of a cationic softening agent, and the production method is completed through a certain preparation method. Electronic-grade glass fiber yarns produced through using the impregnating agent have the advantages of excellent performances, low cop hairiness rate, uniform yarn stiffness, and complete satisfaction of subsequent operation use performances, and the cost of the impregnating agent for 1t of yarns is low, so the production cost of 1t of the yarns is saved.

Owner:JUSHI GRP CO

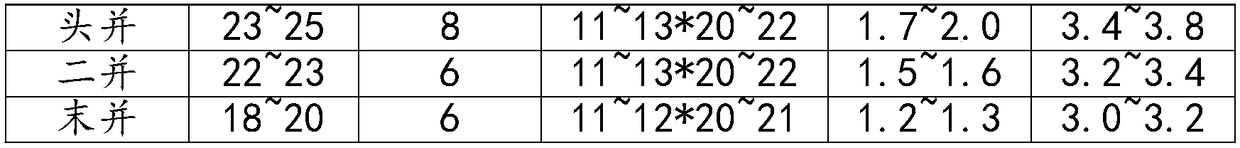

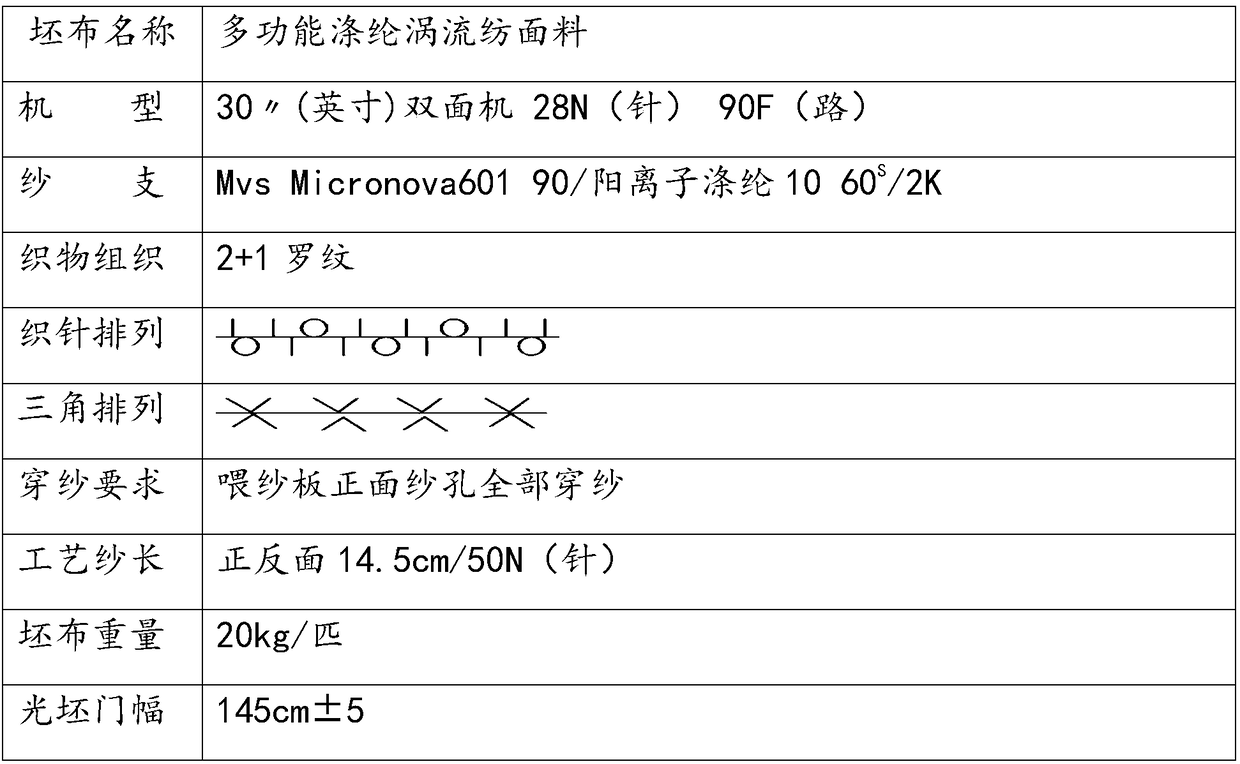

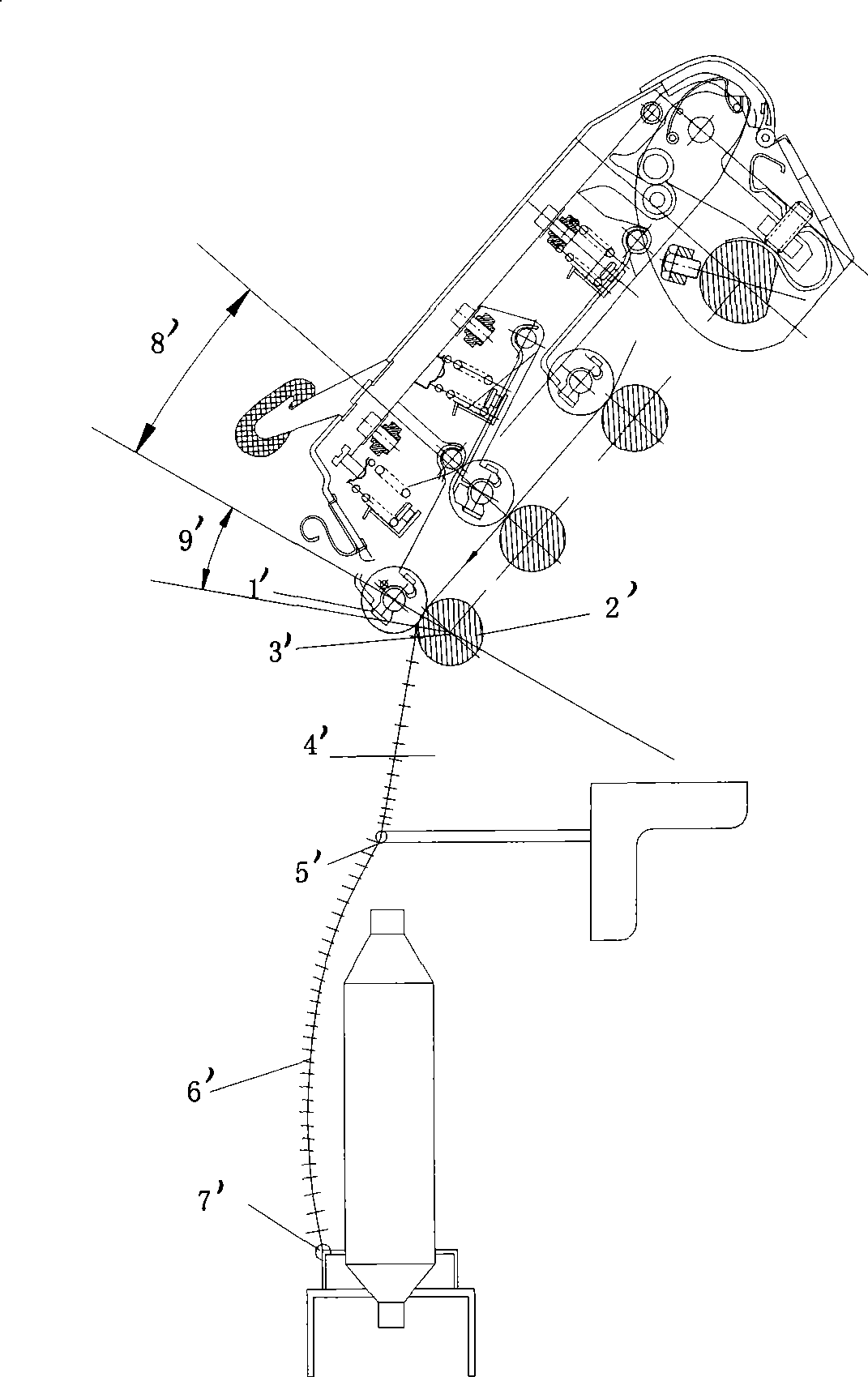

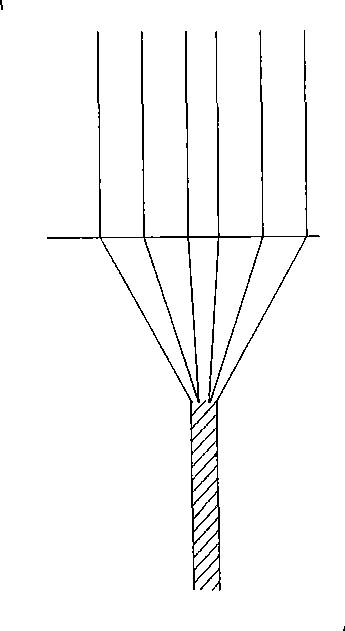

Multifunctional polyester vortex spinning fabric and production method thereof

InactiveCN108468146AFast turning speedShorten speedWeft knittingContinuous wound-up machinesYarnPolyester

The invention provides a multifunctional polyester vortex spinning fabric and a production method thereof. The fabric is woven by Micronova fiber and blended cation polyester; the production method comprises the steps that the multifunctional polyester vortex spinning fabric is finally obtained after spinning, weaving and finishing are conducted on the Micronova fiber taking up the dry weight ratio of 88.5%-91.5% and the blended cation polyester taking up the dry weight ratio of 8.5%-11.5%, wherein the spinning step comprises opening picking, cotton carding, drawing, Murata vortex spinning anddouble twisting, the weaving step comprises yarn steaming, waxing and machine weaving, and the finishing step comprises knitted fabric singeing, boiling and bleaching, dyeing, soft winding processing, dehydrating, drying and finishing. By means of the method, the antibacterial, wear resistant and ultraviolet resistant fabric with light and soft fabric surface and better permeable preventing performance can be obtained.

Owner:江苏悦达棉纺有限公司

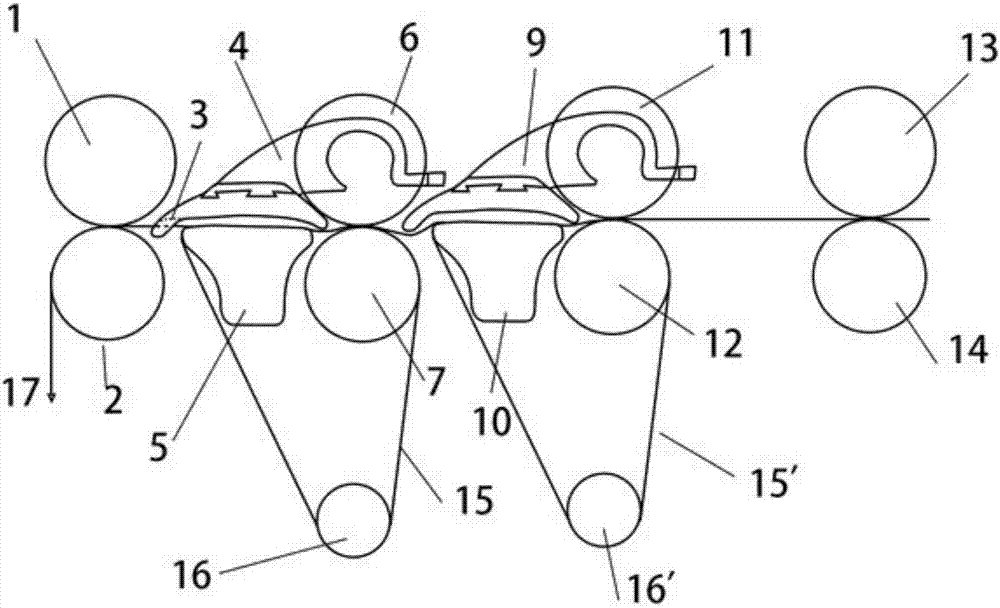

Frame spinning semi-tight spinning process

InactiveCN101457416AAvoid influenceReduce formationDrafting machinesContinuous wound-up machinesYarnIngot

The invention relates to a ring-spinning semi-compact spinning process. Rough yarn is drawn and twisted by a front bottom roller nip of an original ring-spinning machine; a semi-compact spinning device which can regulate the length of a drawing area and the length of a weak twisting area is arranged at the downstream of a front rubber roll and a front bottom roller of the original ring-spinning machine; wherein, the semi-compact spinning device comprises a doffing roller, a doffing rubber roll, aprons and a device base; the aprons are sleeved at the outside of the front bottom roller of the original ring-spinning machine and the doffing rubber roll of the semi-compact spinning device; the doffing roller and the doffing rubber roll are arranged on the device base; the device base is fixed with a rack of the original ring-spinning machine, and the rough yarn is transmitted to a doffing roller nip after being drawn by the front bottom roller nip of the original ring-spinning machine and drawn out from the position between the doffing roller and the doffing rubber roll, thereby preparing twisted yarn. The ring-spinning semi-compact spinning process has the advantages that the spun yarn evenness is improved and the hairiness is greatly reduced, thereby greatly reducing the defects of fabric neps and color neps and significantly improving the anti-pilling grade of fabric.

Owner:ZHEJIANG LANBAO WOOL SPINNING GROUP +1

High-moisture-penetrability waterproof fabric

ActiveCN104015445AHigh strengthReduce hairinessFibre treatmentSynthetic resin layered productsOxidePhosphate

The invention discloses a high-moisture-penetrability waterproof fabric which comprises basic cloth and a coating layer positioned on one side of the basic cloth, wherein a second priming coating is obtained by drying slurry consisting of the following components by weight percent: 100 percent of polyurethane resin, 38-42 percent of bromoethane, 19-21 percent of antimonous oxide, 4.5-5.5 percent of zinc borate, 4-5 of a bridging agent, 1.6-2 percent of a promoting agent, 1.4-1.6 percent of an anti-washing agent and 9-11 percent of phosphate antiflaming fuel; a surface coating is obtained by drying slurry consisting of the following components in percent by weight: 100 percent of polyurethane resin, 9-11 percent of bromoethane, 4.5-5.5 percent of antimonous oxide and 0.9-1.1 percent of zinc borate; antiflaming acrylic yarns consist of the following components in percent by weight: 4 percent of acrylic, 3.5-4.5 percent of cotton and 0.9-1.1 percent of aramid fibers; the bridging agent is isocyanic acid ester; the promoting agent is an organic ammonia salt; the anti-washing agent is trimethylolpropane poly-material. The high-moisture-penetrability waterproof fabric is long in antiflaming time, small in smoke generation amount, and good in antiflaming effect and has the washing-resistant effect, and the hydrolysis of antiflaming substances is avoided.

Owner:南通东屹纺织科技有限公司

Spinning method combining embedding spinning with compact siro spinning

The invention relates to a cotton spinning industry spinning method, and especially relates to a spinning method combining embedding spinning with compact siro spinning; in a compact siro spinning process, two chemical fiber filaments are respectively fed on two yarn fiber strands by a control jaw between a front roller and an abnormity gather pipe. The novel spinning method can utilize cotton yarns of short fiber length, has lower requirements for yarn fiber length, thus reducing production cost; the method is high in efficiency, low in consumption, short in process, saves energy, thus solving the problems that dissolved chemical fibers are low in intensity, flurry and complex in fibers, and fabrics is poor in wear resistant performance and tearing fastness; the method is simple in technology.

Owner:湖北孝棉实业集团有限责任公司

Production process of polyester viscose corn-spun yarn

Provided is a process for producing polyester viscose corn-spun yarn. Ordinary polyester medium-length fibers, viscose medium-length fibers, high-strength polyester medium-length fibers and spandex filaments are adopted as the raw materials, the ratio of the polyester medium-length fibers to the viscose medium-length fibers is 65:35, and the ratio of the ordinary polyester medium-length fibers to the high-strength polyester medium-length fibers is 60:5; polyester fibers are subjected to scutching, cotton carding and drawing to be prepared into drawn slivers A and rough yarn; the viscose medium-length fibers are subjected to scutching, cotton carding and drawing to be prepared into drawn slivers B and rough yarn; the drawn slivers A and the drawn slivers B which are subjected to roving are mixed with the spandex filaments to be prepared into drawn slivers C, and drawn slivers C are subjected to spinning and automatic winding to be prepared into yarn, and the yarn is inspected, packed and warehoused. The obtained yarn is straight, clean, good in toughness and good in dimension retainability.

Owner:山东正凯新材料股份有限公司

Cotton polyester yarn sizing agent

The invention discloses a preparation method of a novel cotton polyester yarn sizing agent. The method includes the steps that firstly, materials are weighed, wherein the materials include, by weight, 4-5 parts of starch, 0.5-0.8 part of soybean protein, 0.3-0.4 part of collagen, 0.6 part of hydrolyzed wheat peptides, 0.1-0.3 part of trehalose, 0.5 part of glycerin and 88-90 parts of water; secondly, three kinds of collagen are added into 20 parts of water, dissolved and evenly stirred, starch and trehalose are added, the mixture is heated in a water bath boiler, the temperature is raised to 60 DEG C, glycerin and a smoothening agent are added, the temperature is preserved for 1 h, and components which are not dissolved are filtered out, wherein magnetic stirring speed is 20 r / min. The provided cotton polyester yarn sizing agent is natural and environmentally friendly, hardness and inclusion force of yarn can be effectively enhanced, firmness is high, quality is stable, and the hairiness degree of the cotton polyester yarn is greatly reduced.

Owner:湖州天鑫皮革涂饰剂厂

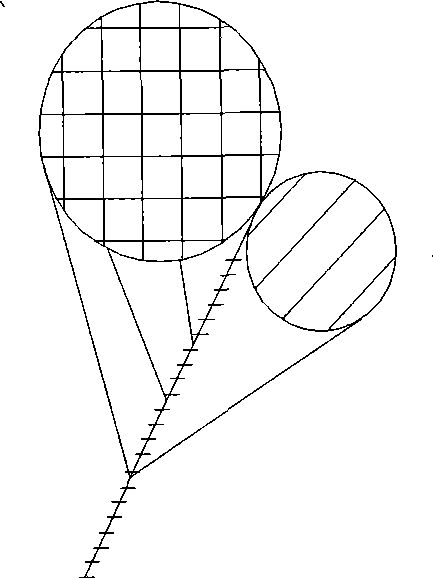

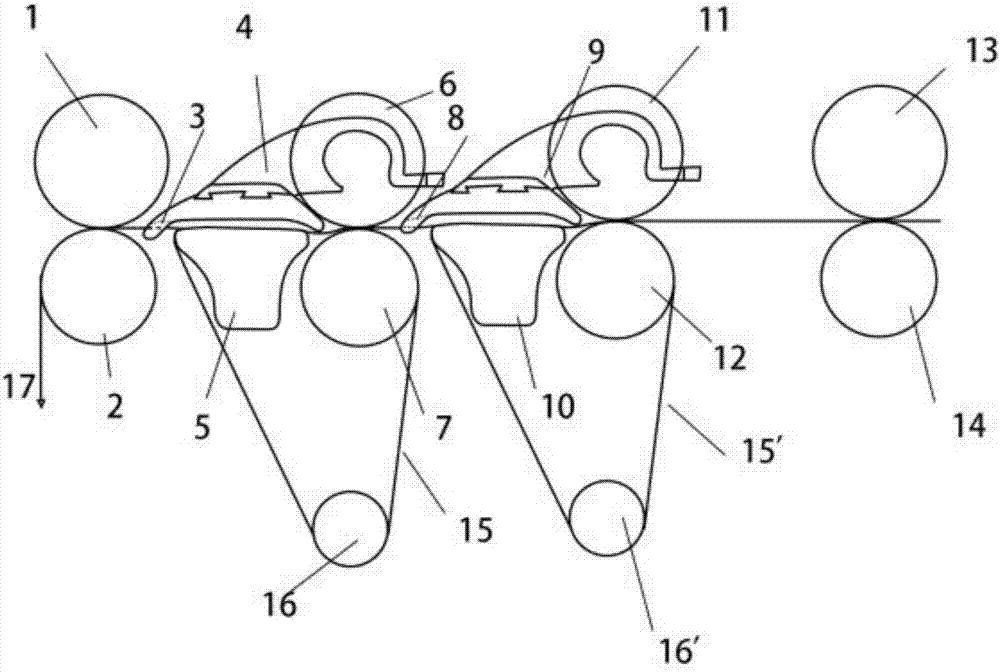

Aggregated type spun yarn super large drafting device and spinning technology

The invention relates to an aggregated type spun yarn super large drafting device and a spinning technology. The aggregated type spun yarn super large drafting device at least comprises two main drafting areas and one post drafting area, and a fiber strand passes through the post drafting area and then enters the two main drafting areas, respectively a rear main drafting area and a front main drafting area in sequence in the running direction of the fiber strand; rollers / leather rollers are arranged in the front and back of all the areas, and the main drafting areas are further provided with main drafting area upper / lower pins, leather rings and tension rollers, wherein aggregation grooves are formed in the adhering surfaces of the fiber strands of the front main drafting area upper pins, the groove width is reduced in the running direction of the fiber strands, and the groove depth is increased in the running direction of the fiber strands. A drawn sliver firstly enters the post drafting area and is subjected to pre-drafting, then enters a rear main drafting area to be subjected to primary drafting, afterwards enters a front main drafting area to be aggregated, and finally is rolled into spun yarn after being twisted. In the aggregated type spun yarn super large drafting device and the spinning technology, super large drafting is achieved by reducing the length of a floating area and adding a main drafting area, the roving procedure is omitted, the technological procedure is shortened, the yarn quality and resultant yarn efficiency are improved, and the aggregated type spun yarn super large drafting device have the advantages of being simple in structural technology, easy to operate and low in cost.

Owner:DONGHUA UNIV

Production method of photoelectronic polyester combed cotton compact yarn

The invention discloses a production method of photoelectronic polyester combed cotton compact yarn. Based on weight percentage, the method comprises the steps of combed cotton preparation, blowing mixing of combed cotton and photoelectronic polyester, cotton carding, drawing, roving, spinning and spooling. According to the invention, the photoelectronic polyester fiber and Xinjiang first-class raw cotton are blended and subjected to compact spinning in the spinning process; due to the bundling effect, the strand twisting triangle area is canceled; the hairiness value of single yarn is obviously reduced, and the evenness is remarkably improved; and since the combed cotton is used as a raw material for re-spinning, the neps are remarkably reduced, the quality of the resultant yarn is better, and the functional yarn with brightness, high grade and cooling antibacterial healthcare effect is produced.

Owner:DANYANG DANSHENG TEXTILE

A kind of preparation method of graphene oxide antibacterial mildew-proof medical bandage

ActiveCN105497959BSimple preparation processEasy to operateEther separation/purificationAbsorbent padsEscherichia coliStaphylococcus aureus

The invention relates to a preparing method of a graphene oxide antibacterial mildew-resistant medical bandage. The method includes evenly spraying gauze with a prepared antibacterial mildew-resistant agent through a spraying process to obtain the antibacterial mildew-resistant medical bandage. Antibacterial mildew-resistant and peculiar smell-removing effects of the bandage are significantly improved through synergistic effects of nanometer graphene oxide, a wild lily bulb extract and nanometer metal-supported graphene oxide. The mildew-resistant level of the bandage is the zero level. The bacteriostatic rate of the bandage for staphylococcus aureus is 99.91%, the bacteriostatic rate of the bandage for escherichia coli is 99.23%, the bacteriostatic rate of the bandage for helicobacter pylori is 99.0%, the bacteriostatic rate of the bandage for candida albicans is 98%, and the bacteriostatic rate of the bandage for mould is 100%. For the gauze sprayed with the antibacterial mildew-resistant agent, nanometer particles penetrate into the gauze and inner cohesiveness of the gauze is enhanced, and therefore hairiness is greatly reduced, and secondary wounds when the bandage is used by a patient are avoided.

Owner:张建刚

Flexible smooth yarn and production method thereof

The invention provides flexible smooth yarn and a production method thereof. The raw materials of the yarn is one or more of natural fibers or chemical fibers. The yarn is characterized in that compact siro spinning is combined with low-torsion spinning, two rough yarn parallel feeding is used during a spun yarn procedure, design twist coefficient of the yarn can be lowered at 280-300, fibers are tightly held together under action of a suction groove in a spinning trigonum, two completely drafted and gathered fiber bundles obtains more twisting before plying compared with common compact siro spinning due to the fact that false twist of low-torsion spinning is higher than intensive false twist of spun yarn formation twist, and more outstanding plying effect different from common compact siro spinning structures is achieved. The produced yarn is flexible and smooth, low in residual stress, and has plying effect, strength of the yarn is increased by 10-15%, hairness is lowered by 75-80%, evenness CV% is lowered by about 0.2%, and yarn twisting number is lowered by 20-30%.

Owner:RUGAO CITY DINGYAN TEXTILE

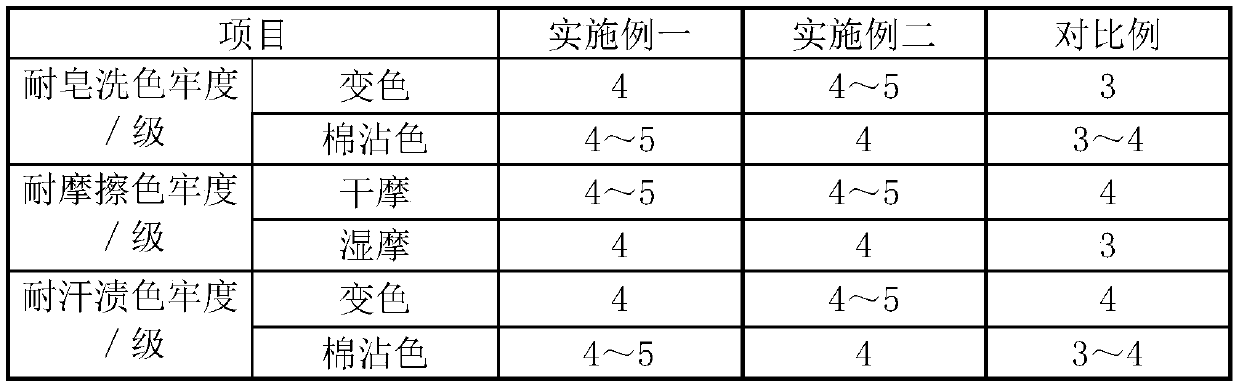

A cationic polyester blended fabric with antibacterial function and its preparation process

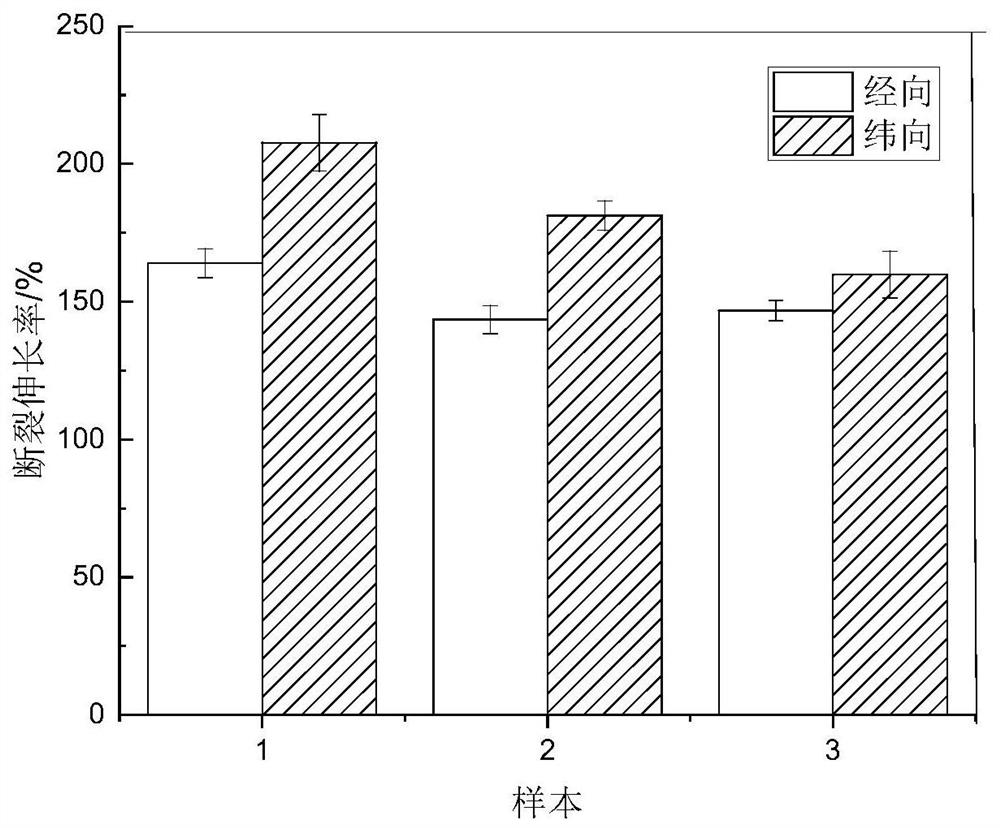

ActiveCN110318147BGood moisture absorption and air permeabilityImprove mechanical propertiesWeft knittingBiochemical fibre treatmentPolyesterYarn

The invention relates to an antibacterial functional cationic polyester blended fabric and a preparation process thereof. The preparation process includes the step of weaving antibacterial functionalcationic polyester blended yarn to obtain the antibacterial functional cationic polyester blended fabric. The antibacterial functional cationic polyester blended yarn is prepared by carding cationic polyester fibers obtained after plasma treatment, cotton fibers and chitosan fibers separately, carrying out mixing, and then sequentially carrying out the procedures of drawing, roving, spinning and winding, wherein according to the parameters of the winding procedure, the winding speed is 850-1200 m / min, and the tension is 5-8 cN; the finally prepared antibacterial functional cationic polyester blended fabric is excellent in elasticity, soft and comfortable in hand feeling and good in moisture absorption and air permeability. The blended fabric solves the problems that cationic polyester fibers are poor in antibacterial property, chitosan fibers are low in breaking strength, high in rigidity and low in cohesive force, and thus the spinnability is poor. The obtained fabric has good antibacterial function, great mechanical performance, high moisture absorption and air permeability and low hairiness number.

Owner:苏州麦克成纺织有限公司 +1

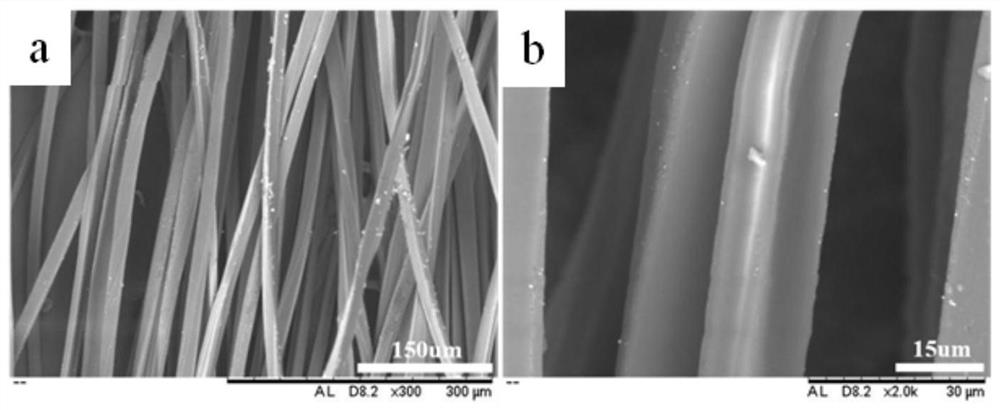

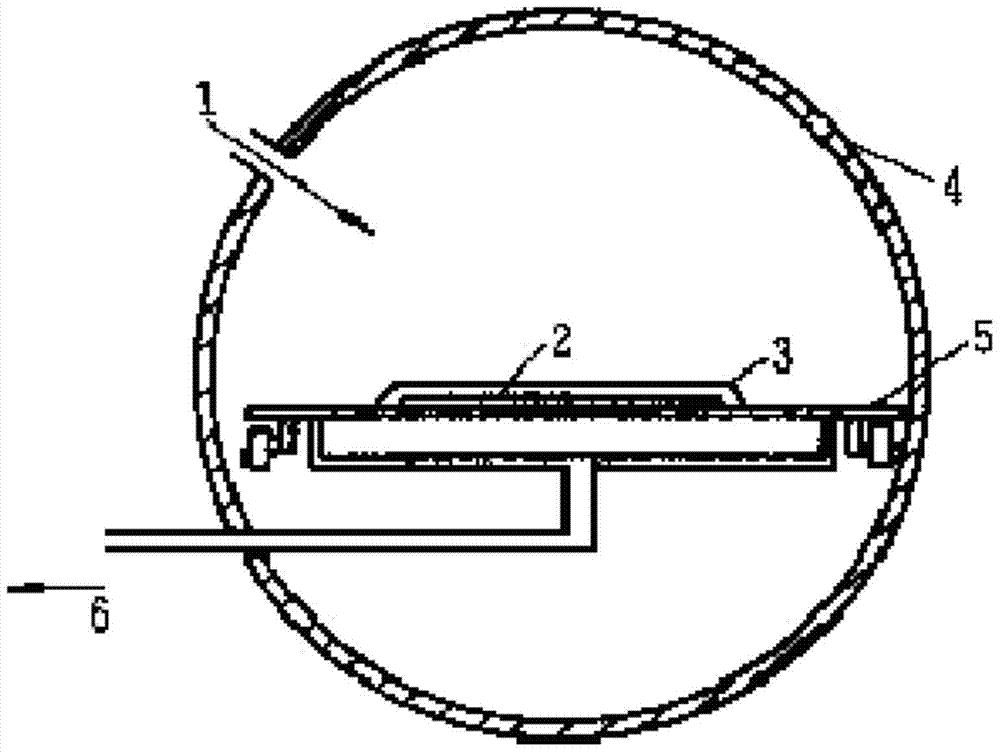

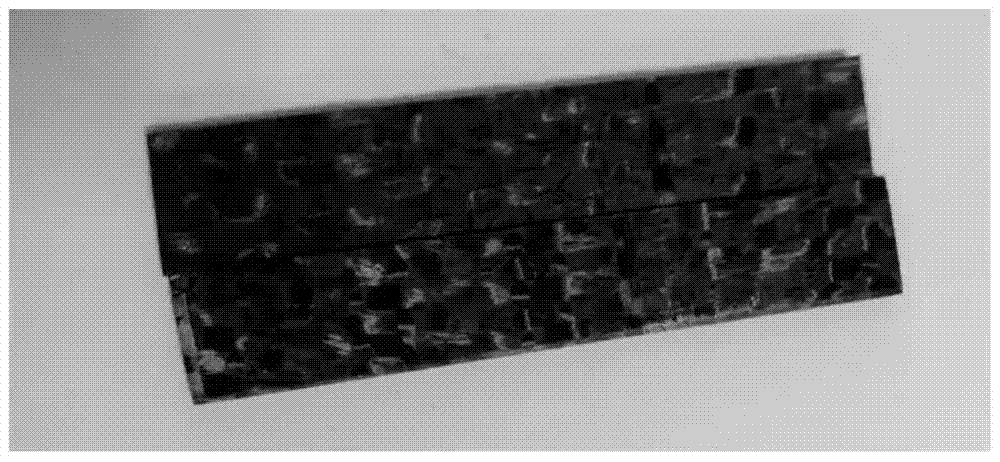

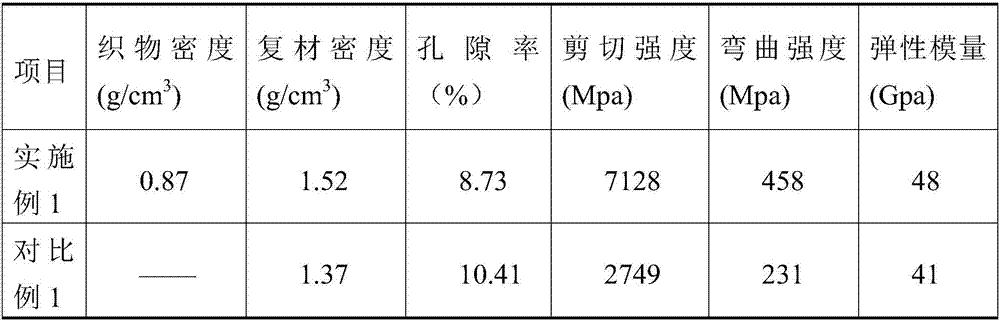

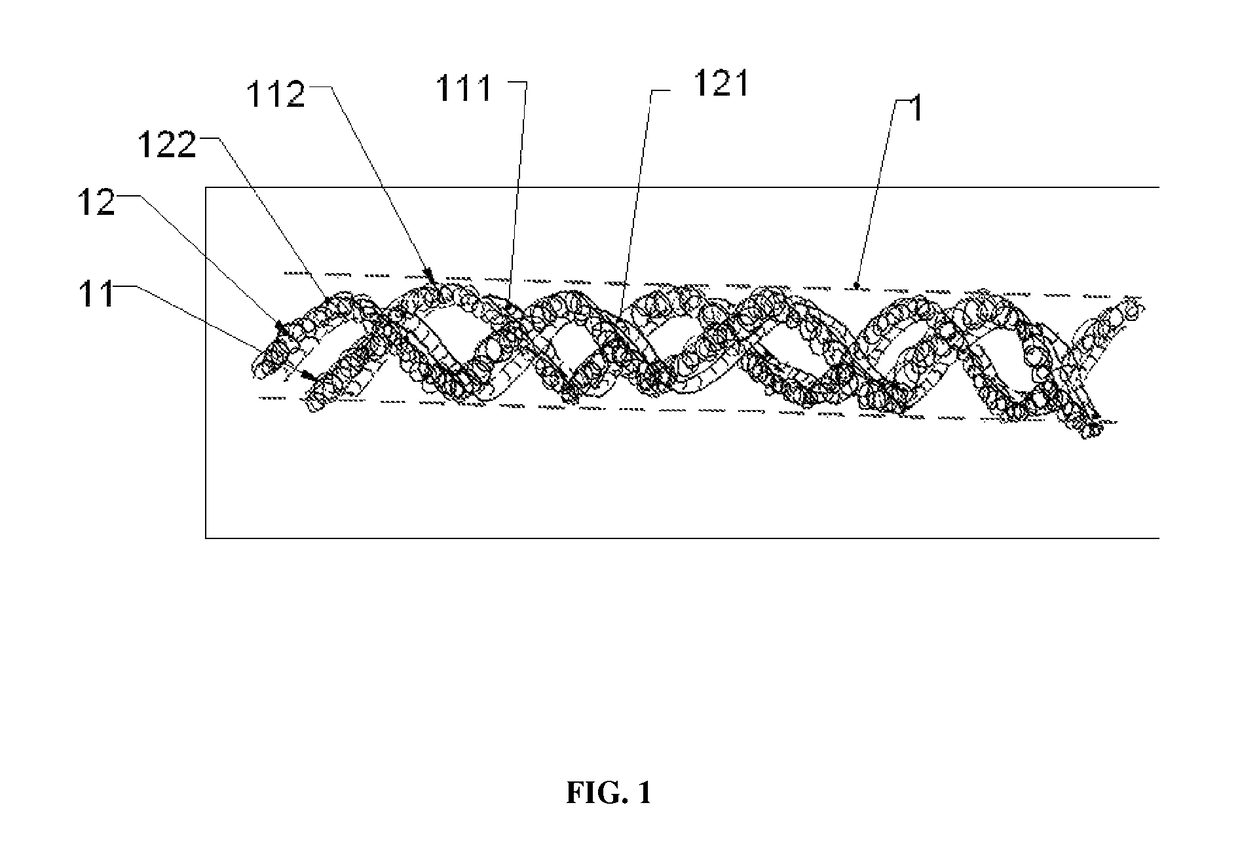

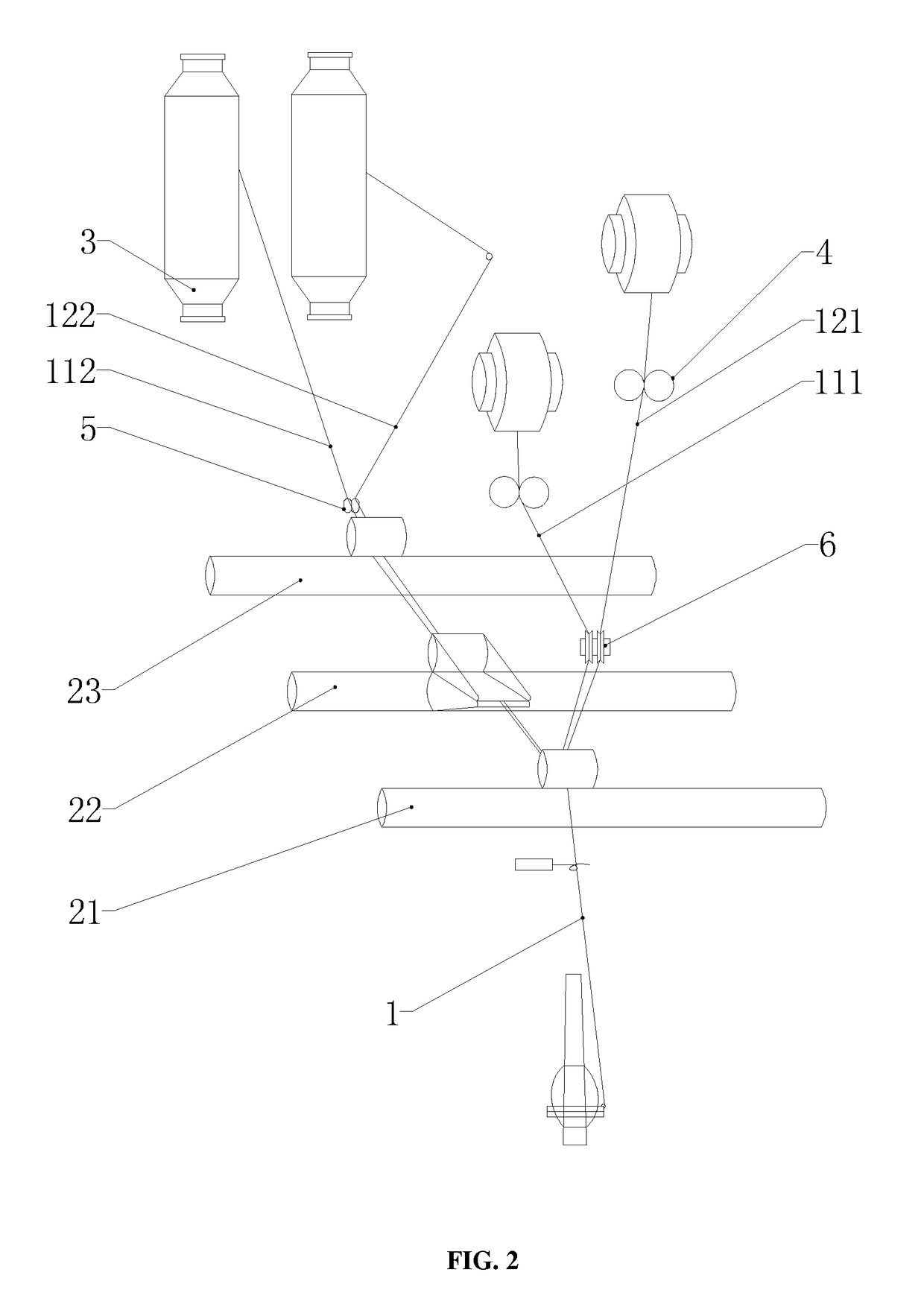

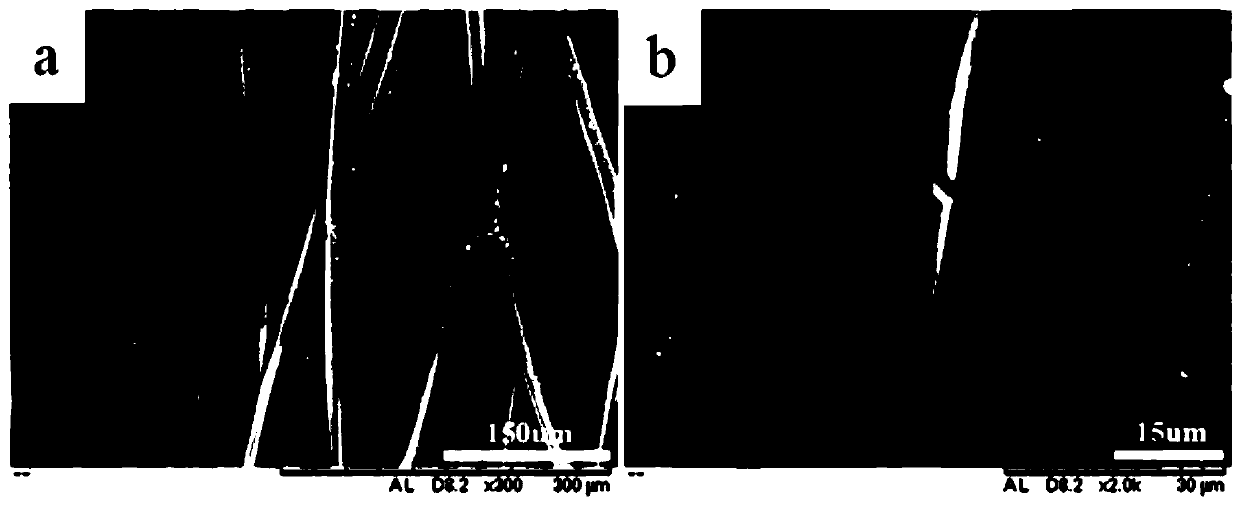

A 2.5-dimensional carbon fiber woven preform reinforced resin-based friction material

The invention discloses a 2.5 dimensional carbon fiber woven prefabricated part reinforced resin matrix friction material. The friction material is formed by combining and curing 2.5 dimensional carbon fiber woven prefabricated parts serving as reinforced structures and matrix resin glue. The specific preparation process comprises the steps of pretreatment of carbon fibers, preparation of the 2.5 dimensional carbon fiber woven prefabricated parts, preparation of the matrix resin glue and preparation of the friction material. According to the friction material, the carbon fibers are subjected to the pretreatment, and thus the carbon fibers are excellent in strength elongation property and weavability. Attachment warps penetrate through the material in the whole thickness direction, three-dimensional structures are formed, the delaminating problem is solved, the interlaminar shear strength is improved, the mechanical properties are outstanding, and the service life is prolonged; meanwhile, the preparation process is simple, and a product is low in porosity, uniform and compact, flat and clean in surface, low in production cost and easy to popularize.

Owner:JIANGNAN UNIV

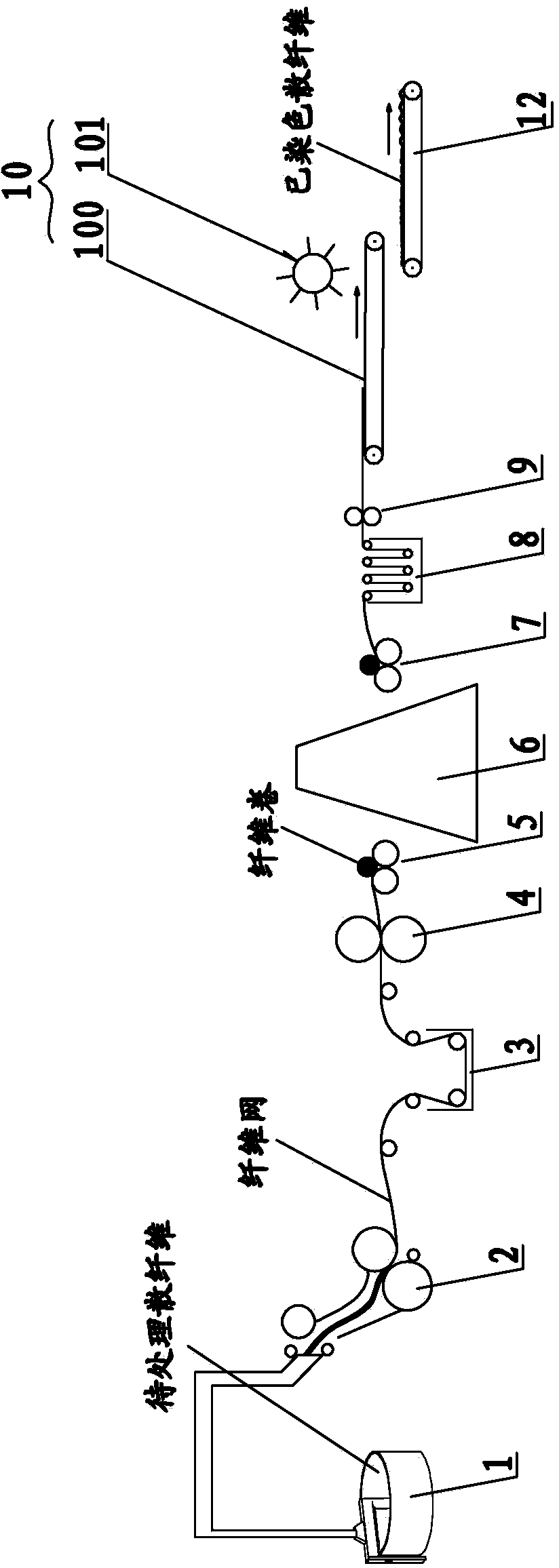

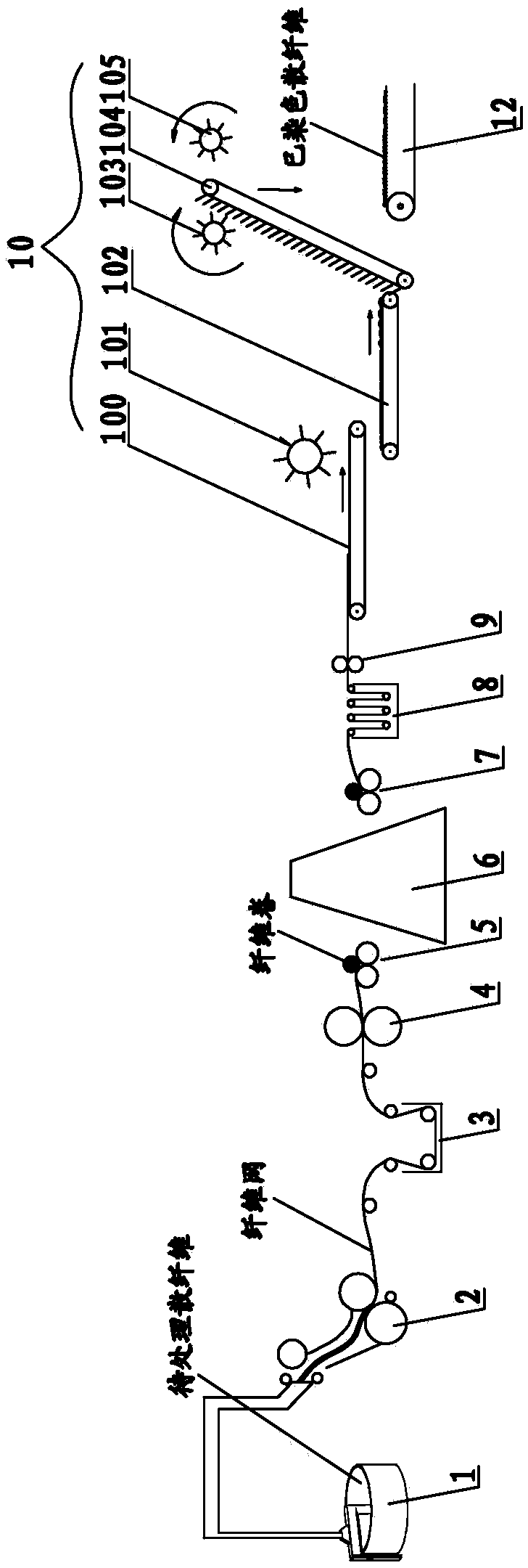

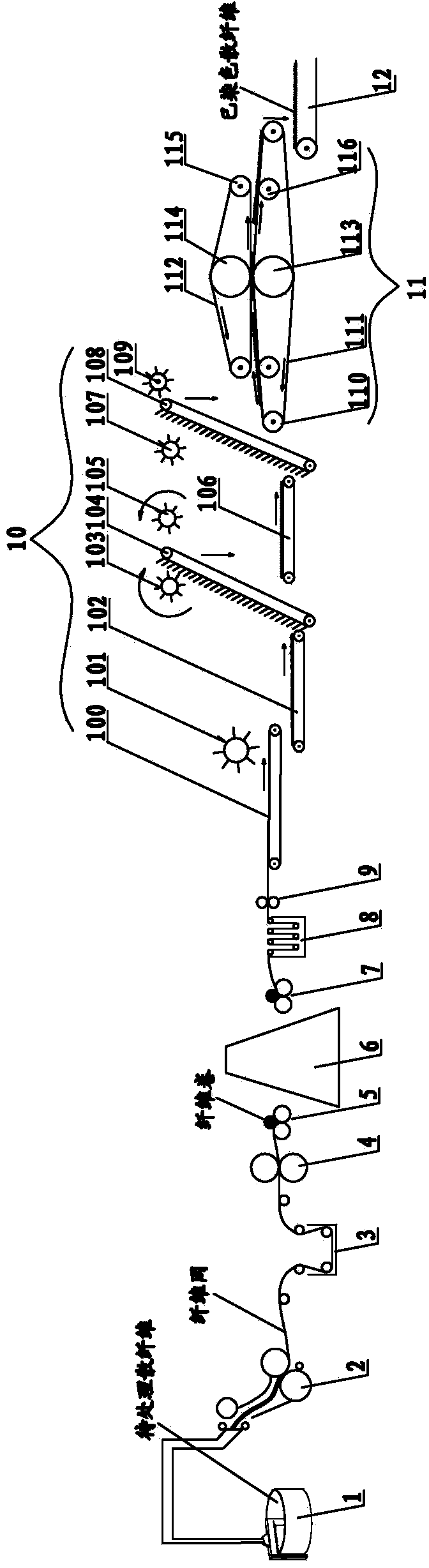

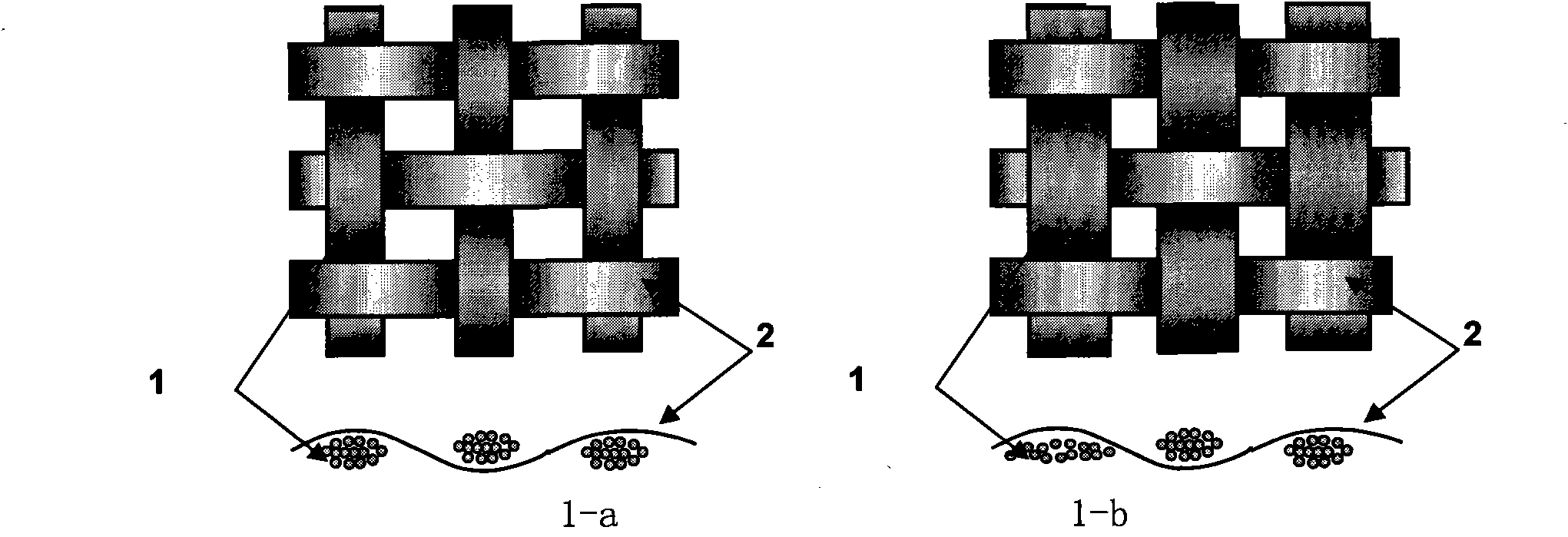

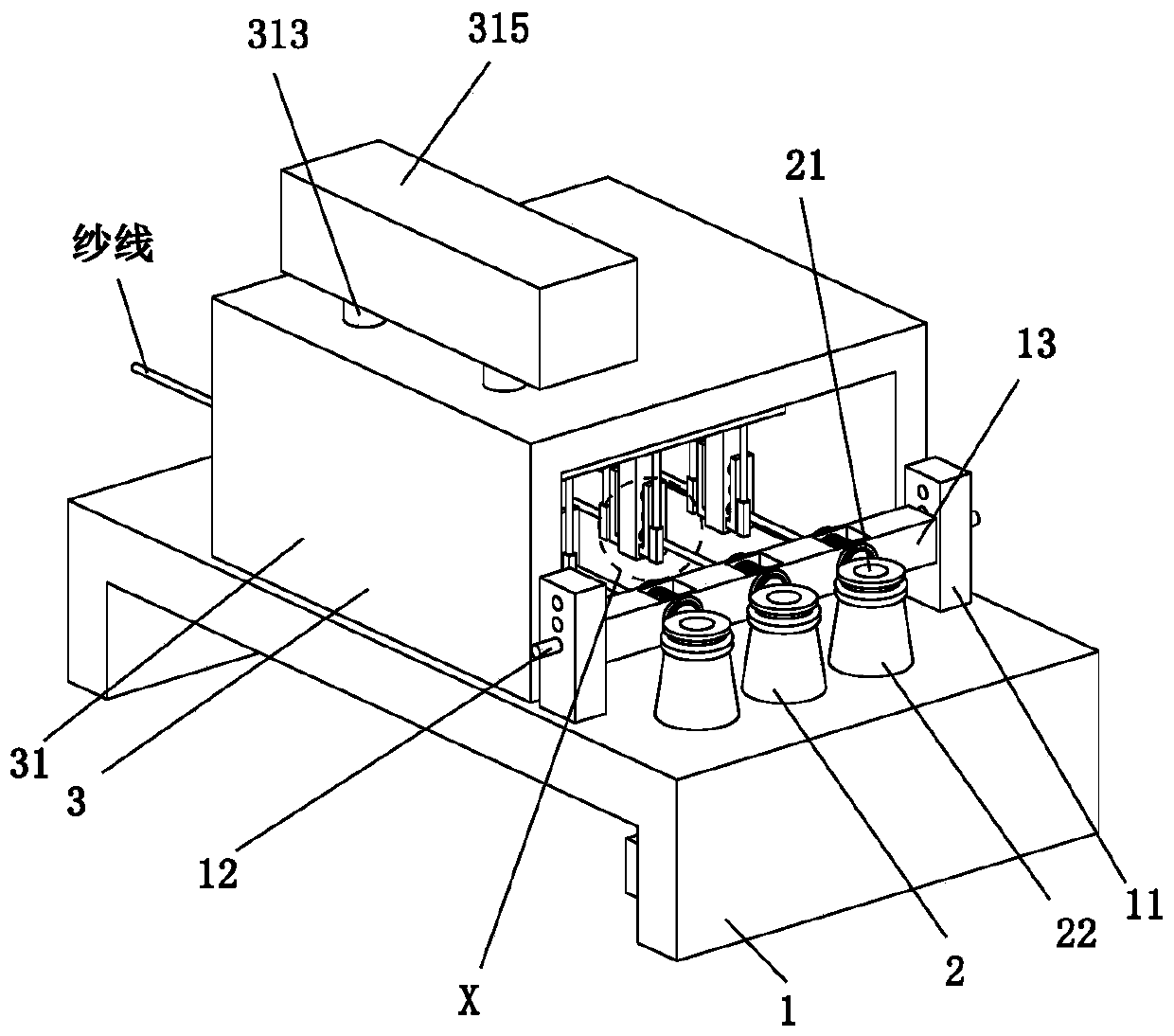

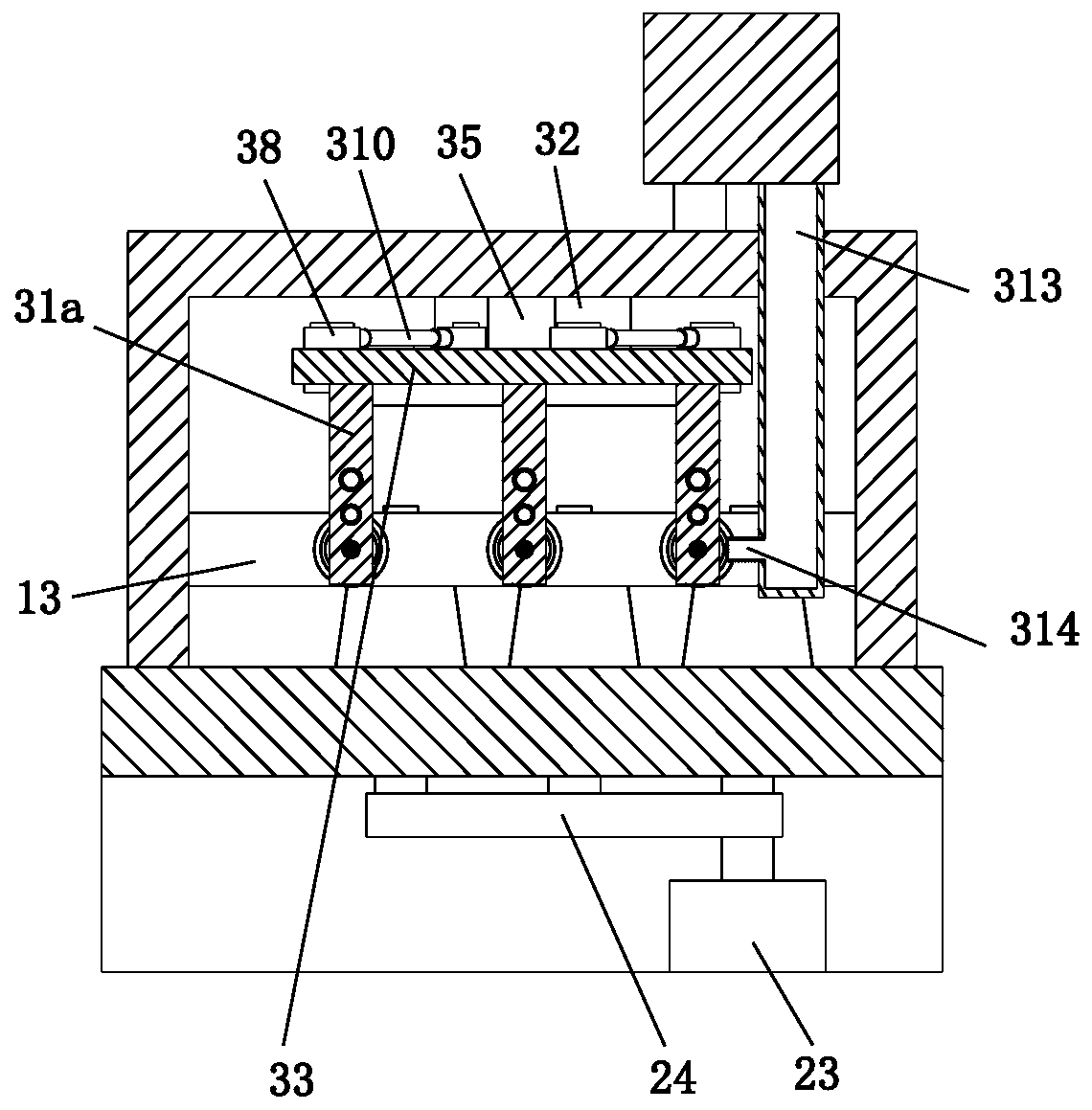

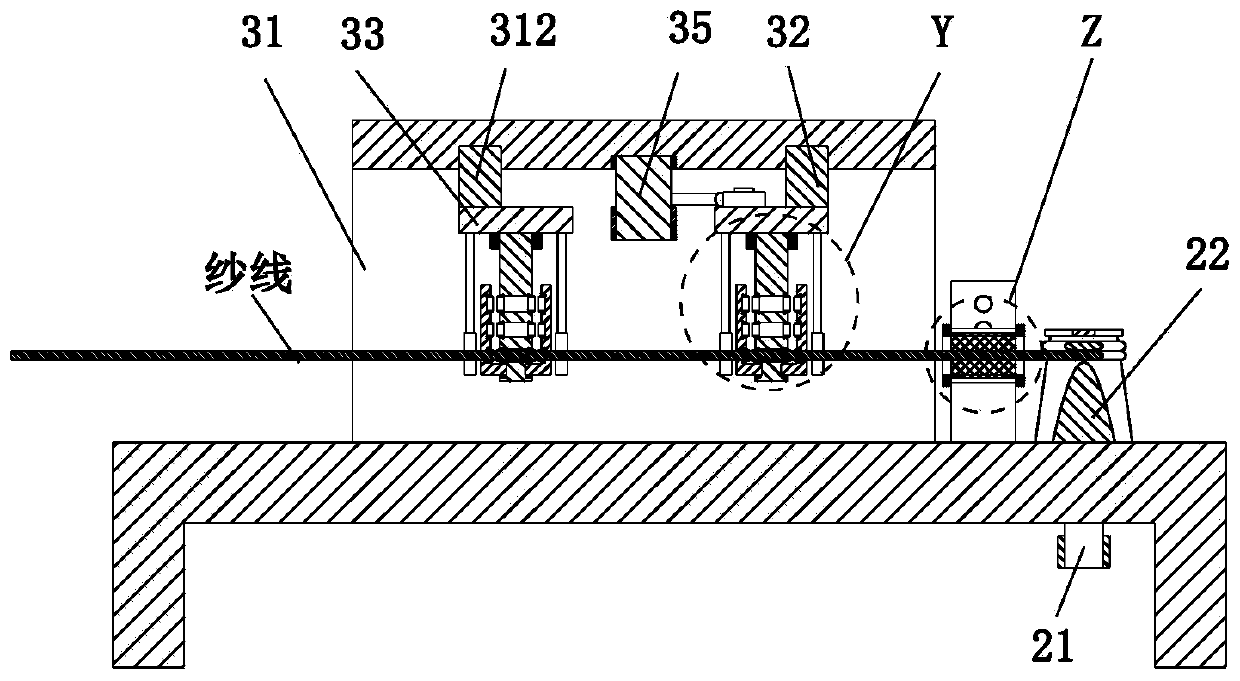

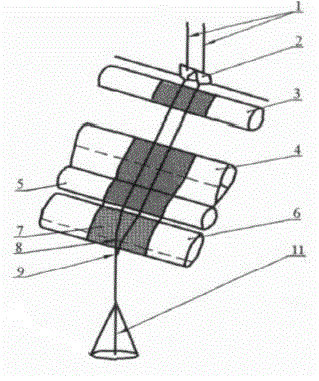

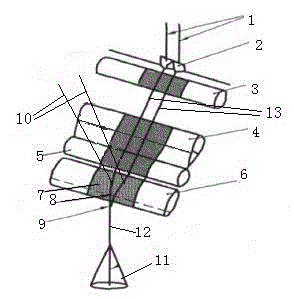

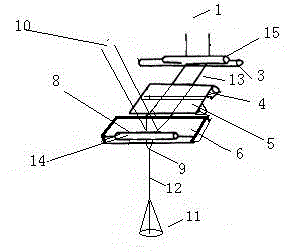

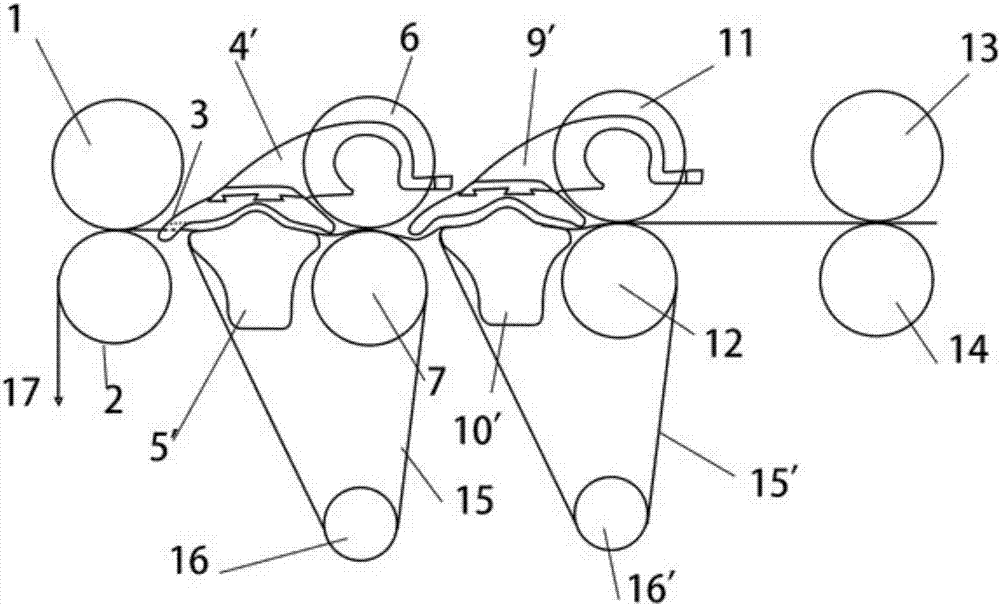

Multi-component elastic yarn, textile fabrics and method of making and apparatus thereof

The invention discloses a multi-component elastic yarn comprises two fiber rovings and two core filaments, wherein each core filaments is elastic, low-elastic or inelastic filaments or any combination thereof. The invention also discloses preparation method and apparatus. The multi-component elastic yarn of the present invention is featured by smooth surface, low hairiness, fiber does not falling off easily, high strength and good wearing resistance. The textile fabrics made from the present yarn have a smooth surface, low hairiness, good wearing resistance, high tensile and tear strength, soft and smooth hand feeling and high elastic recovery rate. The apparatus of the present invention has strong applicability, is easy to maintain and high cost-effective.

Owner:TVN INVESTMENT LTD

Antibacterial positive ion polyester blended yarn and preparation process thereof

The invention relates to an antibacterial positive ion polyester blended yarn and a preparation process thereof. The preparation process includes the steps: mixing plasmas treated positive ion polyester, cotton fibers and chitosan fibers; sequentially performing opening and picking, carding; secondary drawing, roving, spinning and spooling on mixture to prepare antibacterial positive ion polyesterblended yarn. Parameters of a spooling process include that spooling speed is 950-1100m / min, tension is 6-8cN, the count of the finally prepared antibacterial positive ion polyester blended yarn is 20-60Ne, breaking strength is 165.2-369.6cN, breaking elongation is 8.19-17.69%, moisture regain is 3.29-6.75%, and escherichia coli and staphylococcus aureus resisting ratio can reach 70% or more. Thepreparation process solves the problems of poor antibacterial capability of positive ion polyester and spinning property of the chitosan fibers, and the prepared yarn has less hairiness and excellentantibacterial functions.

Owner:SUZHOU UNIV +1

Corrosion-resistant spinning machine ring traveler

InactiveCN102953178ANot easy to corrodeImprove the lubrication effectTextiles and paperEngineeringMechanical engineering

The invention discloses a corrosion-resistant spinning machine ring traveler. The corrosion-resistant spinning machine ring traveler is characterized in that: the corrosion-resistant spinning machine ring traveler is a multi-section steel ring with an opening, and a fluorine plating layer is arranged on the surface of the steel ring. Since the surface of the corrosion-resistant spinning machine ring traveler is provided with the fluorine plating layer, the ring traveler cannot be easily corroded, does not need an anti-corrosion measure even if the ring traveler is in the damp environment, is easy to store, and saves the storage cost. When the corrosion-resistant spinning machine ring traveler is in use, the good lubricity of the surface of the ring traveler reduces the friction of spun yarns and a ring and breakage or hairness, and prolongs the service life.

Owner:WUJIANG RUNLEI TEXTILE

Method for producing non-woven fabric through gas-stimulation reinforced fiber web

InactiveCN110453376AWide variety of sourcesImprove production environmentNon-woven fabricsProduction lineManufacturing technology

The invention belongs to the technical field of non-woven fabric production and manufacturing, and particularly relates to a method for producing a non-woven fabric through gas-stimulation reinforcedfiber web. Gas-stimulation reinforcement is conducted on the fiber web through airflow, a non-woven fabric is produced; the fiber web is obtained through at least one of four web formation modes of carding web formation, airflow web formation, spinning web formation and melt-blowing web formation; fiber of the fiber web is natural fiber or conventional chemical fiber or differential fiber or functional fiber or high-performance fiber. Compared with a spunlaced non-woven fabric, the whole process of the method does not need water, energy conservation and environmental friendliness are better achieved, the method is updating and upgrading of the spunlaced process, production can be conducted by transforming equipment on an exiting non-woven production line, and the method is suitable for scale production; compared with a spunlaced non-woven fabric, defects of oil stains formed by gas-stimulation reinforcement, and the method has the advantages of being hygienic and environmentally friendly.

Owner:SHENZHEN PURCOTTON TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com