Method for preparing high performance carbon fiber by controlling tensile force

A carbon fiber, high-performance technology, applied in the field of preparation of high-performance carbon fiber, can solve the problem of aggravating carbon fiber wool, achieve the effect of reducing the degree of wool and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

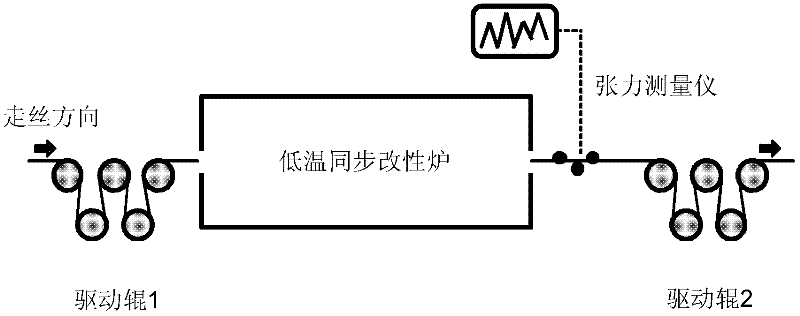

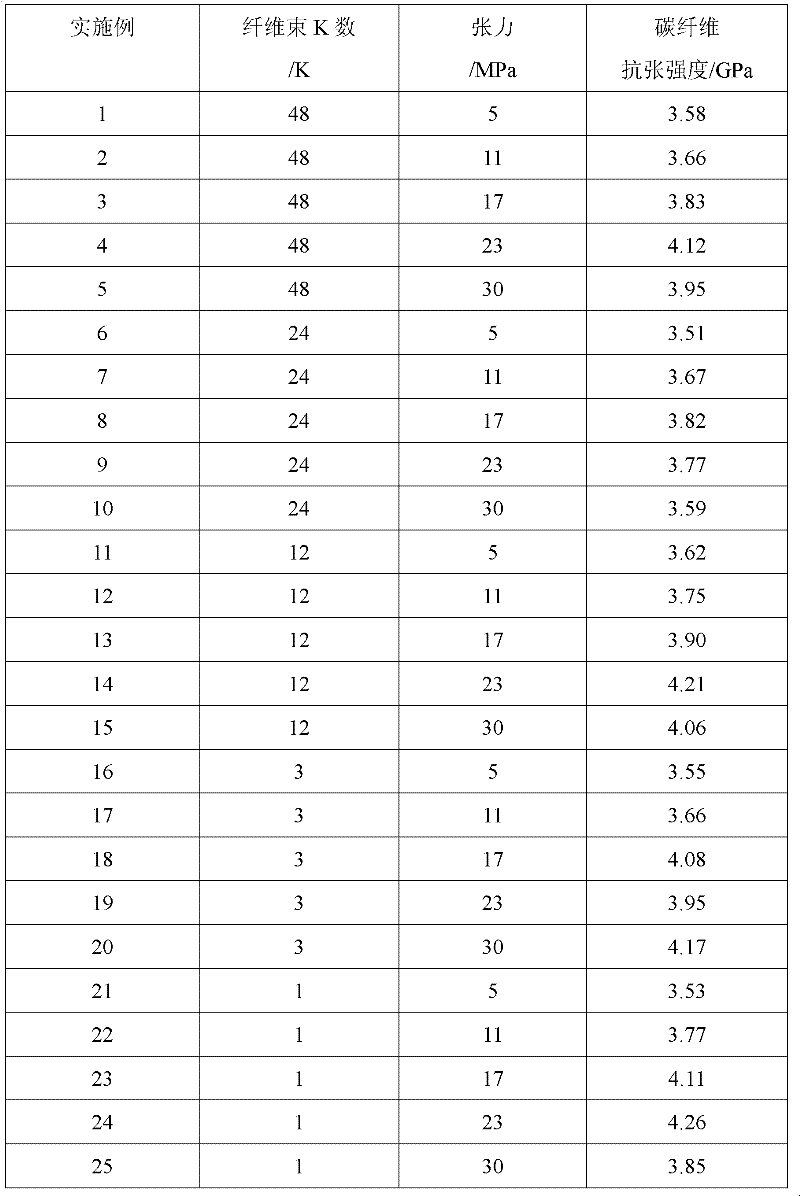

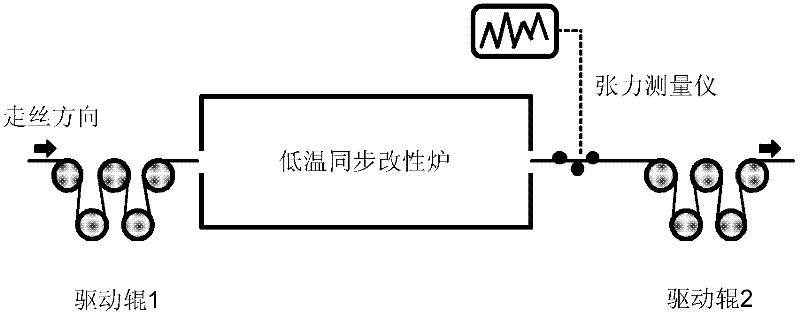

Embodiment 1

[0012] The 48K polyacrylonitrile copolymer fiber produced by Asahi Kasei Co., Ltd. of Japan is used. The polymerized monomers and mass fractions used in the fiber are: 92% acrylonitrile, 7% allyl chloride, and 1% α-chloropropene. In the low temperature synchronous modification stage (such as figure 1 shown in the device), through the real-time adjustment of the speed of the front and rear two groups of driving rollers, a tension of 5 MPa is applied to the fibers. In the air medium, the temperature in the furnace is 120 ° C, and the residence time of the fibers in the furnace is 4 minutes, and low temperature synchronization is obtained. Modified fibers; the fibers after synchronous modification at low temperature are subjected to thermo-oxidative stabilization treatment at 200°C, 230°C, 255°C and 280°C in air medium, and the residence time in each temperature zone is 15min, totaling 60min. The draft ratio is 9%, and the thermal oxygen stabilized fiber is obtained; under the pr...

Embodiment 2

[0014] The 48K polyacrylonitrile copolymer fiber produced by Japan Asahi Kasei Co., Ltd. is used to apply a tension of 11 MPa to the fiber at low temperature synchronous modification. In the air medium, the temperature in the furnace is 140 ° C, and the residence time of the fiber in the furnace is 4 minutes. Simultaneously modified fibers, other process parameters and operations are the same as in Example 1.

Embodiment 3

[0016] The 48K polyacrylonitrile copolymer fiber produced by Japan Asahi Kasei Co., Ltd. is used, and a tension of 17 MPa is applied to the fiber at low temperature synchronous modification. In the air medium, the temperature in the furnace is 150 ° C, and the residence time of the fiber in the furnace is 6 minutes. Simultaneously modify the fiber; other process parameters and operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com