Antibacterial positive ion polyester blended yarn and preparation process thereof

A technology of cationic polyester and blended yarn, which is applied in the direction of yarn, textile and paper making, and can solve the problems of high hairiness, poor antibacterial property of cationic polyester, poor spinnability of chitosan fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

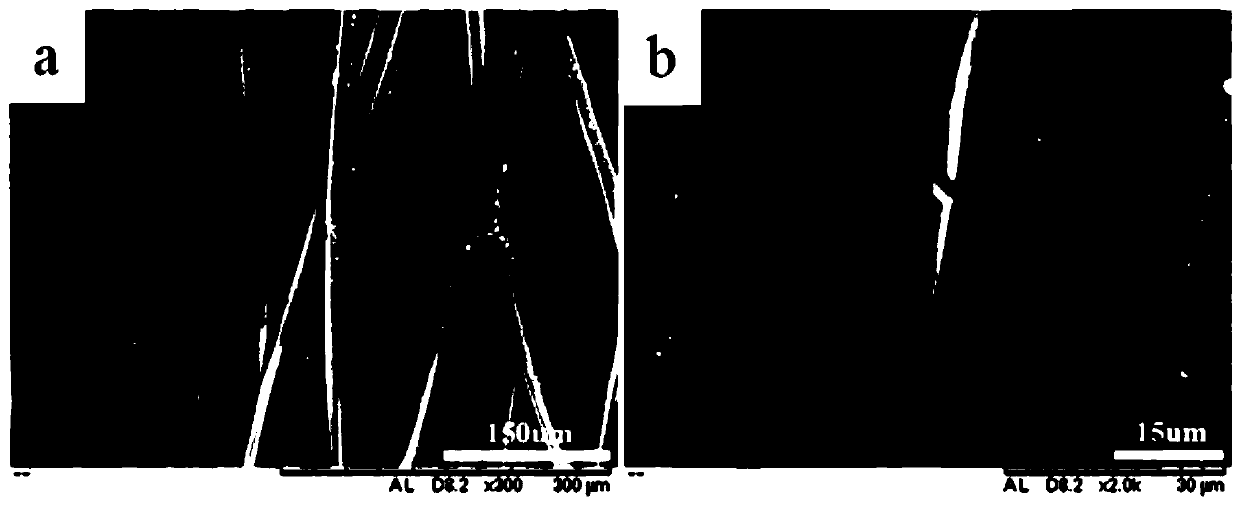

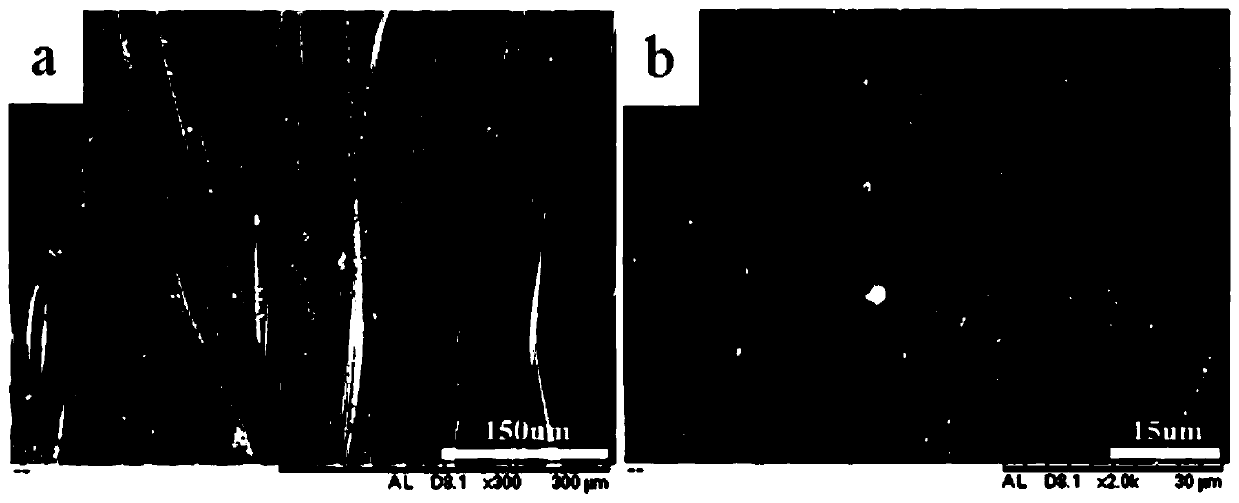

Image

Examples

Embodiment 1

[0050] A kind of preparation technology of antibacterial functional cationic polyester blended yarn, its specific steps are as follows:

[0051] (1) prepare chitosan fiber: under the condition of 40 ℃, chitosan is placed in the NaOH aqueous solution that mass fraction is 40%, and the chitosan powder of different deacetylation degree is obtained through deacetylation treatment at different times, and then A chitosan spinning stock solution with a mass fraction of 3% was prepared with 1% acetic acid aqueous solution as a solvent, and placed in a blast drying oven to keep the temperature constant at different temperatures. Finally, under the pressure of nitrogen, the spinning stock solution is extruded from the spinneret hole and enters the coagulation bath, and the coagulated fiber is stretched, washed and dried to obtain chitosan fiber;

[0052] (2) Prepare cationic polyester after plasma treatment:

[0053] (2.1) Add the third monomer dimethyl isophthalate-5-sodium sulfonate ...

Embodiment 2

[0081] A preparation process of antibacterial function cationic polyester blended yarn is basically the same as embodiment 1, the difference is the preparation method of chitosan fiber, the plasma treatment process of cationic polyester and the cationic polyester and cotton fiber after plasma treatment The mass ratio with chitosan fiber is 10:70:20;

[0082] The preparation method of chitosan fiber is as follows: under the condition of 40 ℃, chitosan is placed in the NaOH aqueous solution with mass fraction of 40%, and chitosan powder with different degrees of deacetylation is obtained through deacetylation treatment at different times, and then A chitosan spinning stock solution with a mass fraction of 3% was prepared with 1% acetic acid aqueous solution as a solvent, and placed in a blast drying oven to keep the temperature constant at different temperatures. Finally, under the pressure of nitrogen, the spinning stock solution is squeezed out of the spinneret hole and enters...

Embodiment 3

[0090] A kind of preparation technology of antibacterial functional cationic polyester blended yarn, its specific steps are as follows:

[0091] (1) prepare chitosan fiber: under the condition of 60 ℃, chitosan is placed in the NaOH aqueous solution that mass fraction is 55%, and the chitosan powder of different deacetylation degree is obtained through deacetylation treatment at different times, and then A chitosan spinning stock solution with a mass fraction of 5% was prepared with 3% acetic acid aqueous solution as a solvent, and placed in an air blast drying oven to keep the temperature constant at different temperatures. Finally, under the pressure of nitrogen, the spinning stock solution is squeezed out of the spinneret hole and enters the coagulation bath, and the coagulated fiber is stretched, washed and dried, and then processed to obtain chitosan fiber;

[0092] (2) Prepare cationic polyester after plasma treatment:

[0093] (2.1) Add the third monomer dimethyl isoph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Count | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com