Corrosion-resistant spinning machine ring traveler

A spinning machine and traveler technology, which is applied in the direction of textiles and papermaking, can solve the problems of reducing the service life of traveler, steel ring, spinning breakage or hairiness, and increasing storage costs, so as to reduce spinning breakage or Effects of hairiness, friction reduction, and storage cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

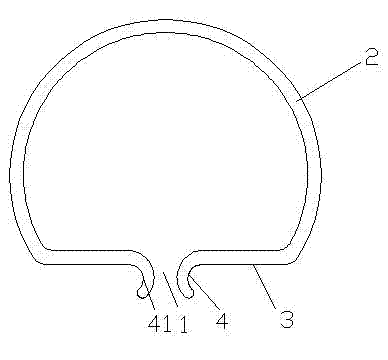

[0014] Such as figure 1 As shown, the anti-corrosion spinning machine traveler of the present invention is a steel ring containing openings 1 composed of multiple sections, and the surface of the steel ring is coated with a fluorine-coated layer. The overall structure is symmetrical, one of which is a circular arc segment 2 larger than a semicircle, and the two ends of the circular arc segment 2 are respectively connected to two straight line segments 3 in a smooth transition. . Preferably, the two straight line segments are located on a straight line. The ends of the two straight line segments 3 are respectively connected with an arc segment 4 in a smooth transition. An opening 1 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com