Nickel plating liquid and method for preparing nickel-based plating layer by using same

A technology of nickel plating solution and plating solution, which is applied in the field of metal surface treatment, can solve the problems of reducing the stability of chemical plating solution, environmental and human hazards, and high process cost, and achieve the simplification of the plating process, fewer processes, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1, a kind of nickel plating liquid, comprise each component of following weight: nickel sulfate 25g, potassium sodium tartrate 70g, sodium hydroxide 30g, water 1000g 。

[0033] 2, the nickel-plating solution described in the present embodiment prepares the method for nickel-based coating, it may further comprise the steps:

[0034] (1) Degreasing and cleaning the copper surface;

[0035] (2) Contact copper and pure aluminum, and immerse in the above-mentioned plating solution in time, and apply plating for 40 minutes at a temperature of 60°C;

[0036] (3) After the plating is completed, rinse and dry the copper surface.

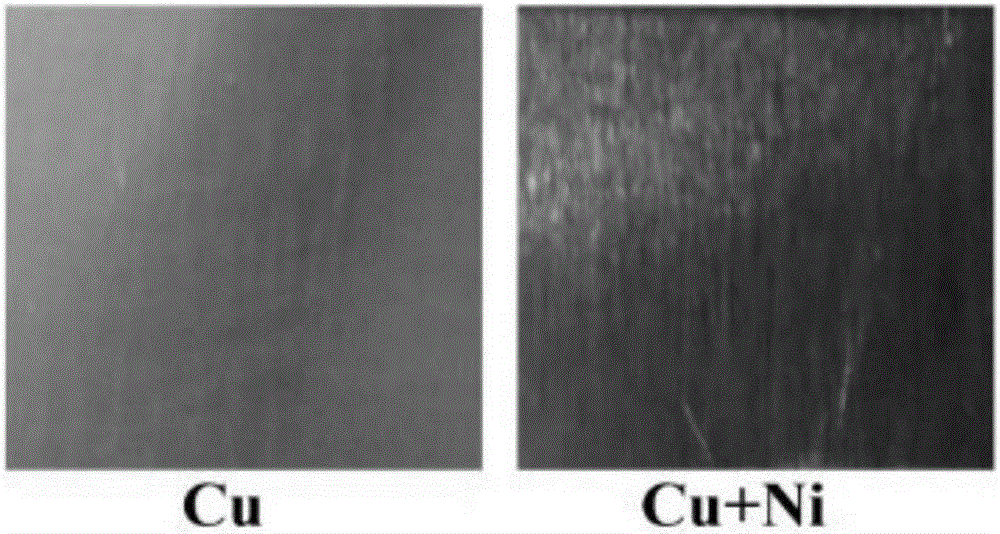

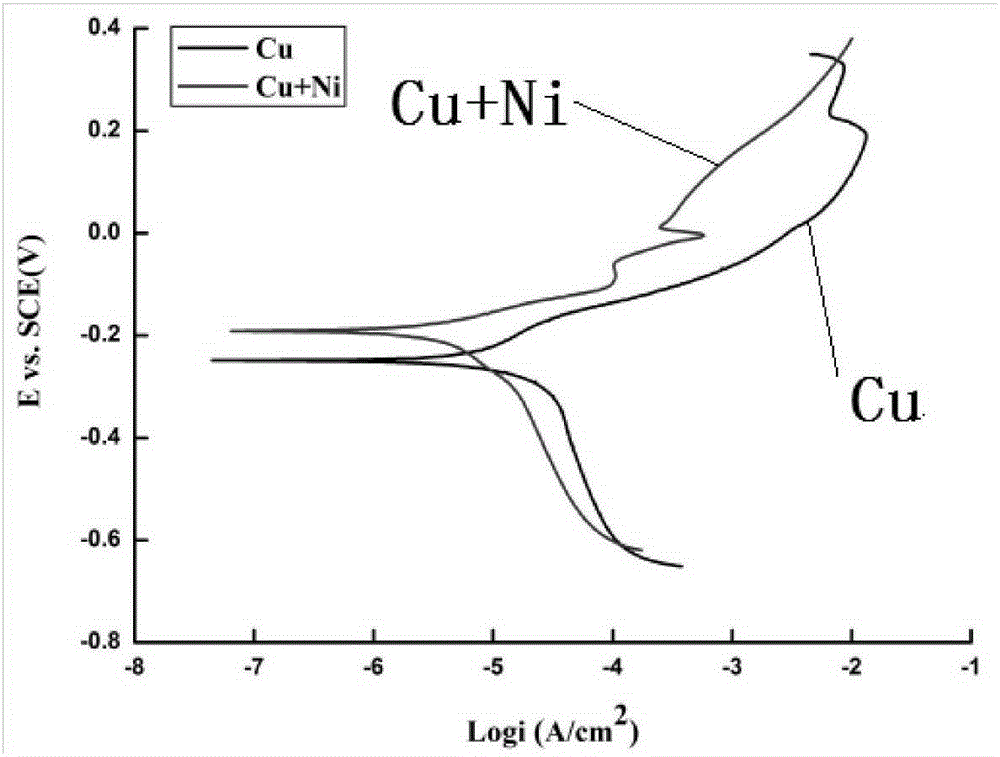

[0037] The nickel plating layer with good appearance is obtained through the above process technology, and the bonding force between the surface nickel plating layer and copper is good. Photos of copper before and after nickel plating are shown in figure 1 , the potentiodynamic polarization curves of copper in 3.5% NaCl solution before and after ni...

Embodiment 2

[0039] 1, a kind of nickel plating liquid, comprise each component of following weight: Plating liquid consists of: nickel sulfate 30g, ferrous sulfate 10g, potassium sodium tartrate 120g, water 1000g, 10% sodium hydroxide aqueous solution regulates the pH of plating liquid The value is 12.0.

[0040] 2, the nickel-plating solution described in the present embodiment prepares the method for nickel-based coating, it may further comprise the steps:

[0041] (1) Degreasing and cleaning the copper surface;

[0042] (2) Contact the copper and aluminum sheets, and immerse them in the above alkaline washing solution in time, and use them. Plating for 60 minutes at a temperature of 70°C;

[0043] (3) After the plating is completed, rinse and dry the copper surface.

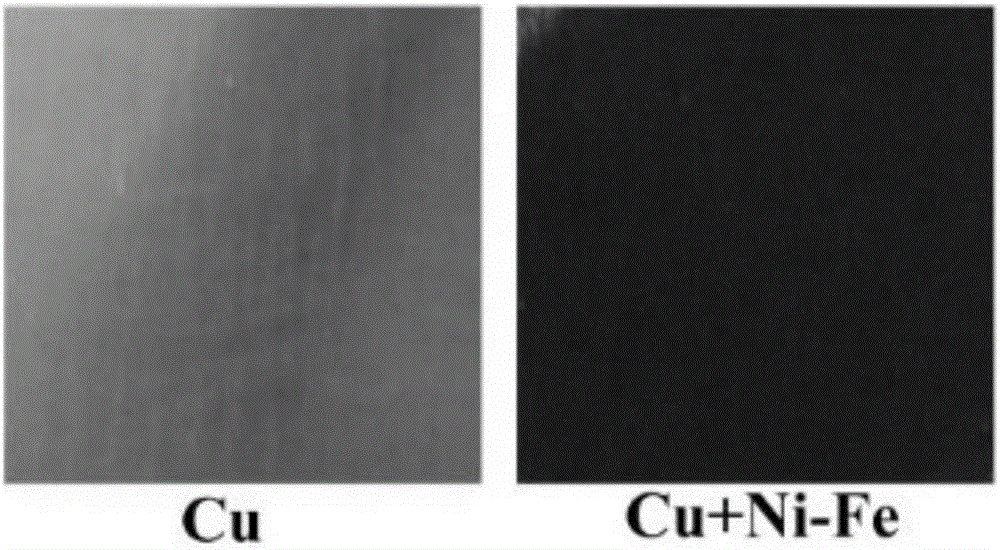

[0044] The nickel-iron coating with good appearance is obtained through the above process technology, and the surface nickel-iron coating has good bonding force with copper. See before and after photos of nickel-iron-...

Embodiment 3

[0046] 1, a kind of nickel plating liquid, comprise each component of following weight: Plating liquid consists of: nickel sulfate 20g / L, potassium sodium tartrate 100g / L, analytical pure ammoniacal liquor 200ml, water 1000g;

[0047] 2, the nickel-plating solution described in the present embodiment prepares the method for nickel-based coating, it may further comprise the steps:

[0048] (1) Degreasing and cleaning the copper surface;

[0049] (2) Contact the copper and aluminum sheets, and immerse them in the alkaline washing solution in time, and apply plating for 15 minutes at a temperature of 30°C;

[0050] (3) After the plating is completed, rinse and dry the copper surface.

[0051] The nickel plating layer with good appearance is obtained through the above process technology, and the bonding force between the surface nickel plating layer and copper is good. Compared with the copper substrate, the corrosion current density of copper after nickel plating decreased by 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com