Silicone vibrating diaphragm, receiver module and method for processing silicone vibrating diaphragm

A silicone diaphragm and liquid silica gel technology, applied in the direction of fixing/tightening the diaphragm, planar diaphragm, sensor, etc., can solve problems such as diaphragm or shell noise, voice coil lead collision, etc., to avoid disconnection and improve Yield rate, the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Considering the forming method of the traditional diaphragm, it is only possible to connect the voice coil and the pad with the lead wire in a straight line, so the problem of the collision of the voice coil lead wire cannot be completely solved. The invention creatively injects the metal sheet into the silicone diaphragm, and replaces the lead wire of the traditional voice coil with the metal sheet to connect the welding pad along the line.

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

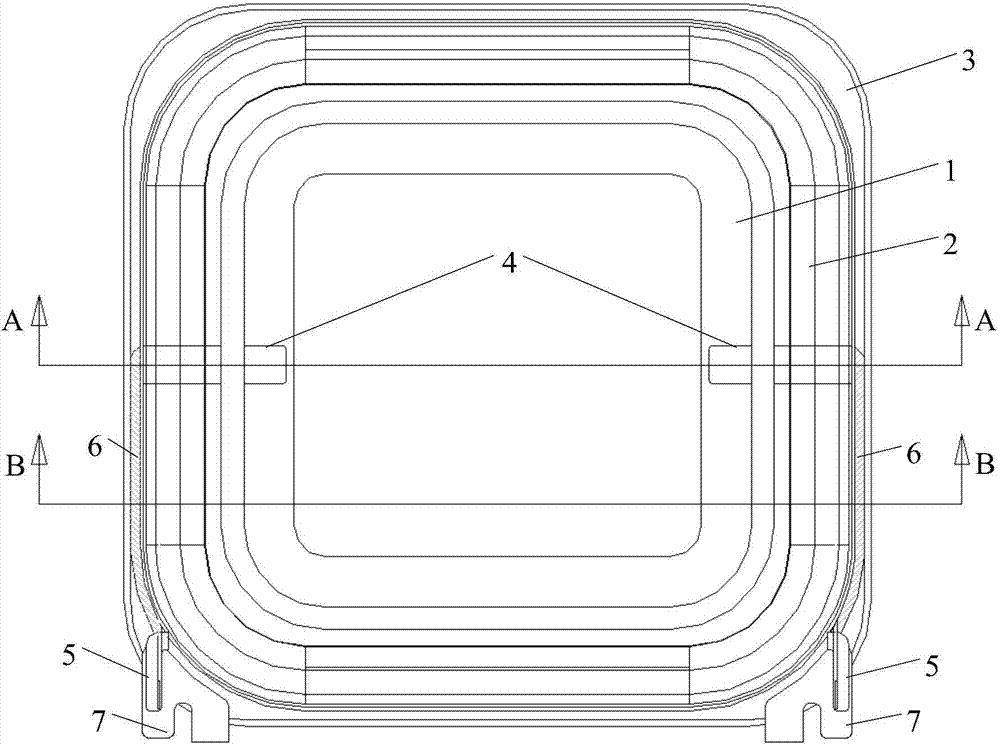

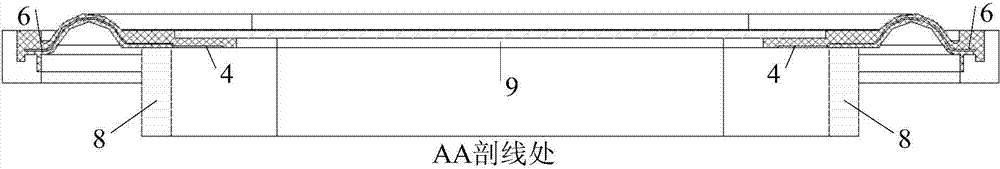

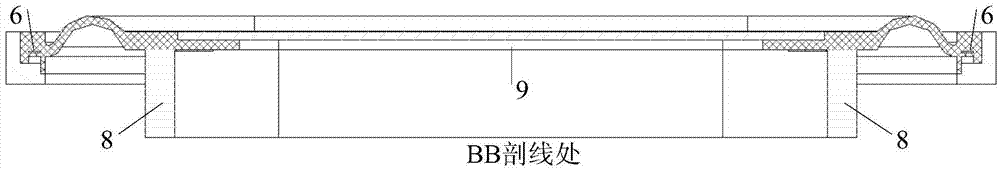

[0038] figure 1 It is the front view of the silicone diaphragm provided by the embodiment of the present invention. The silicone diaphragm includes a planar part 1 in the center, a ring part 2 arranged on the edge of the planar part 1, and a ring part connected to the periphery of the ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com