Patents

Literature

32results about How to "Avoid the risk of disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

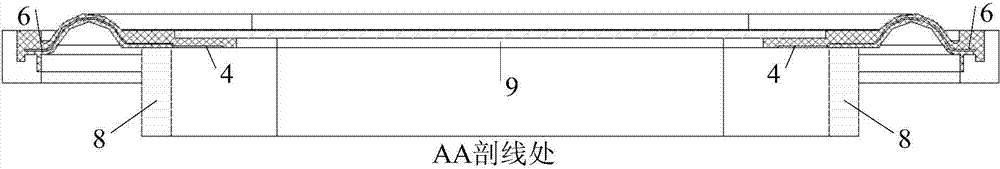

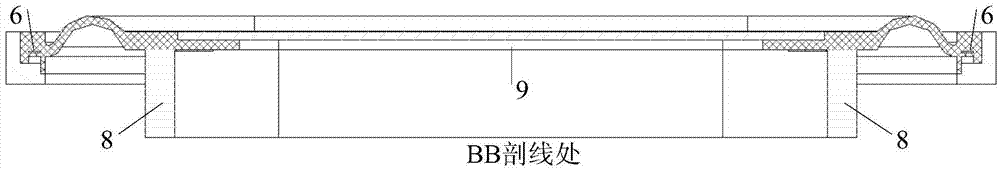

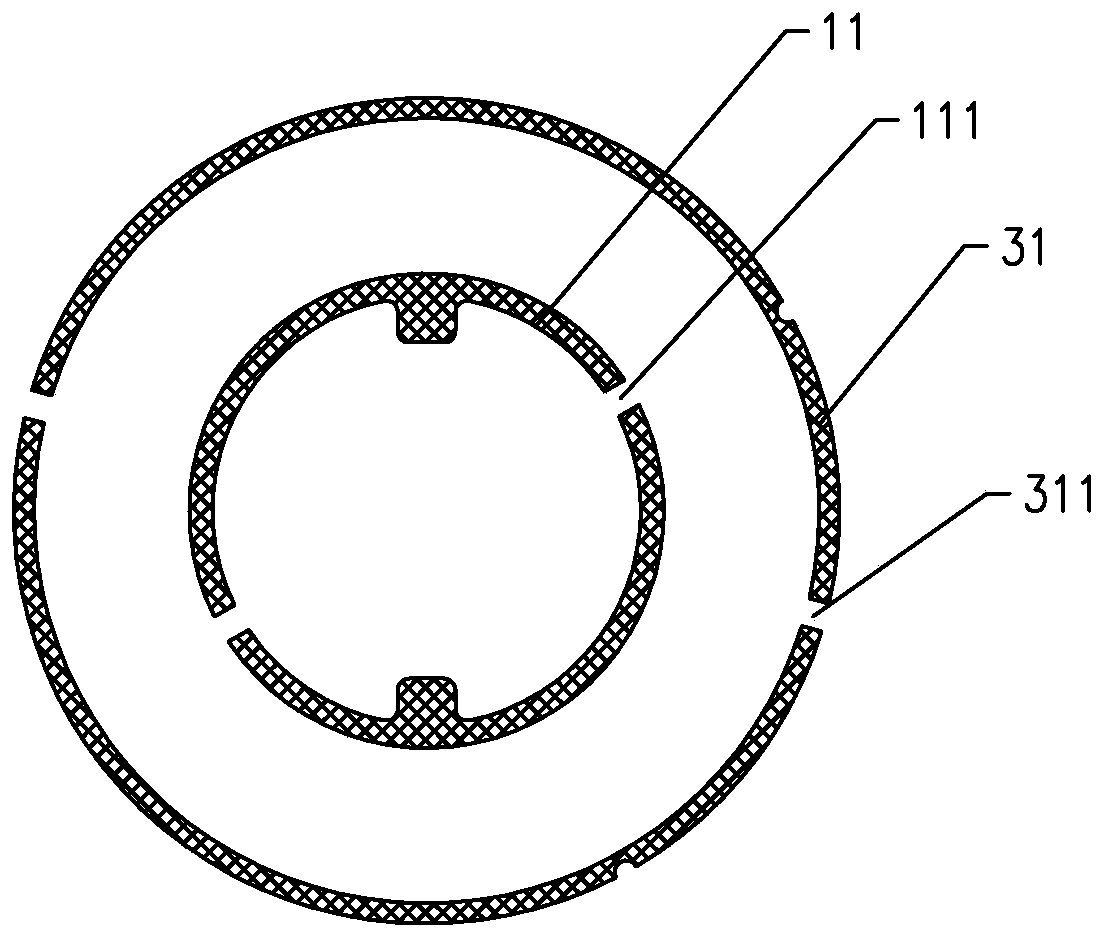

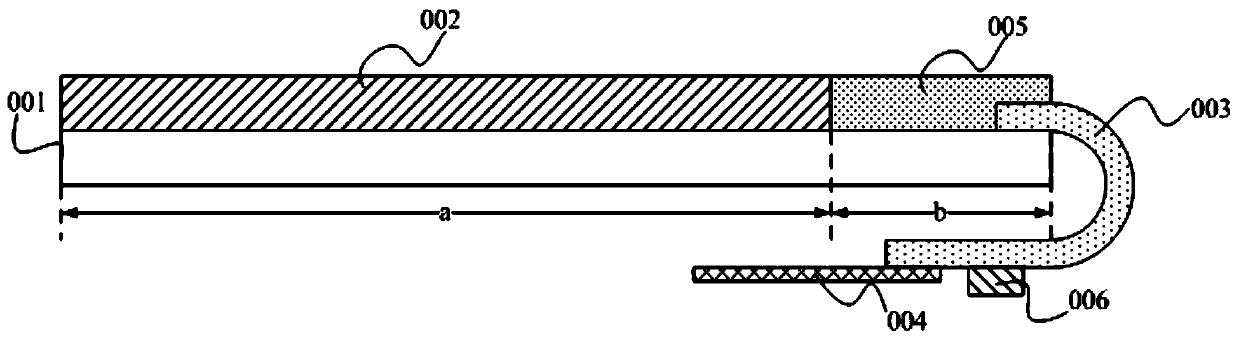

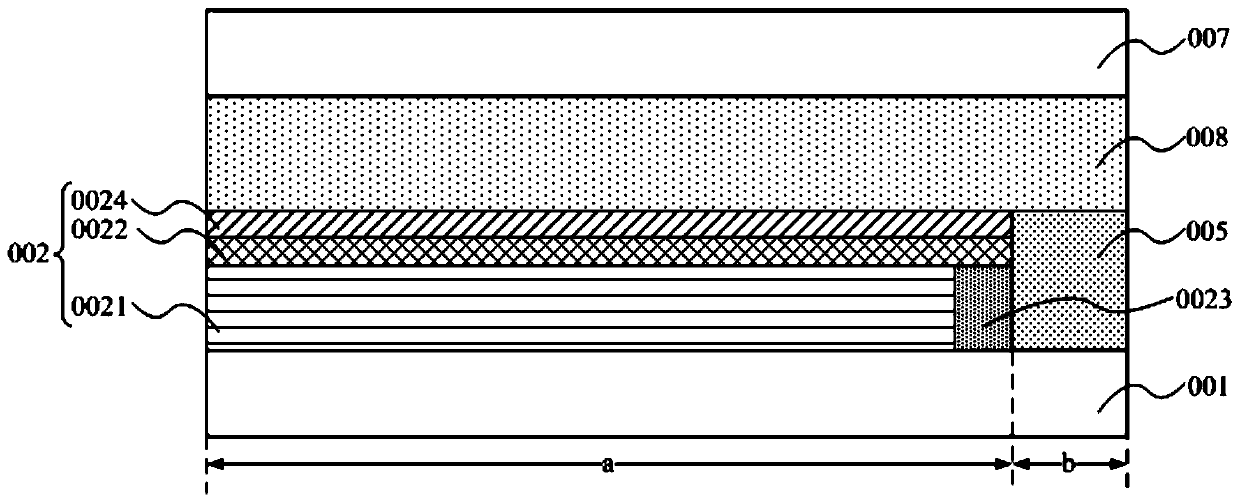

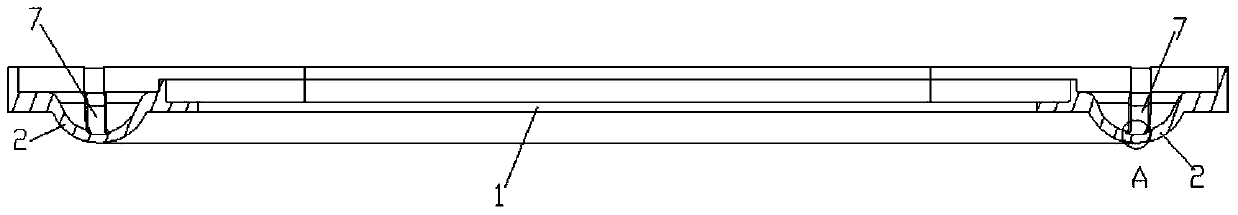

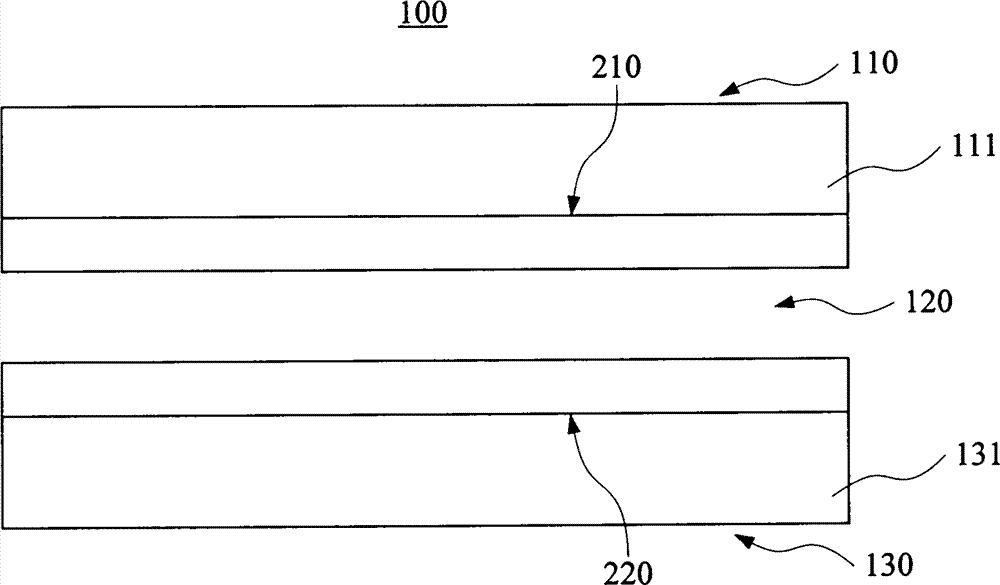

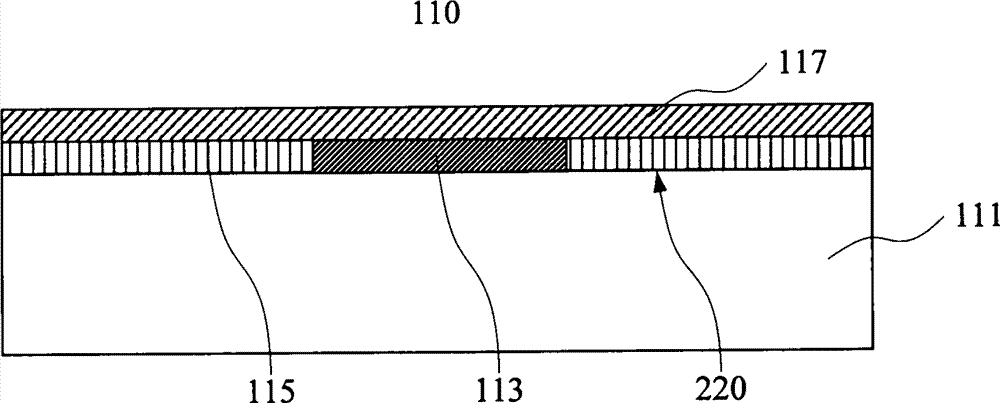

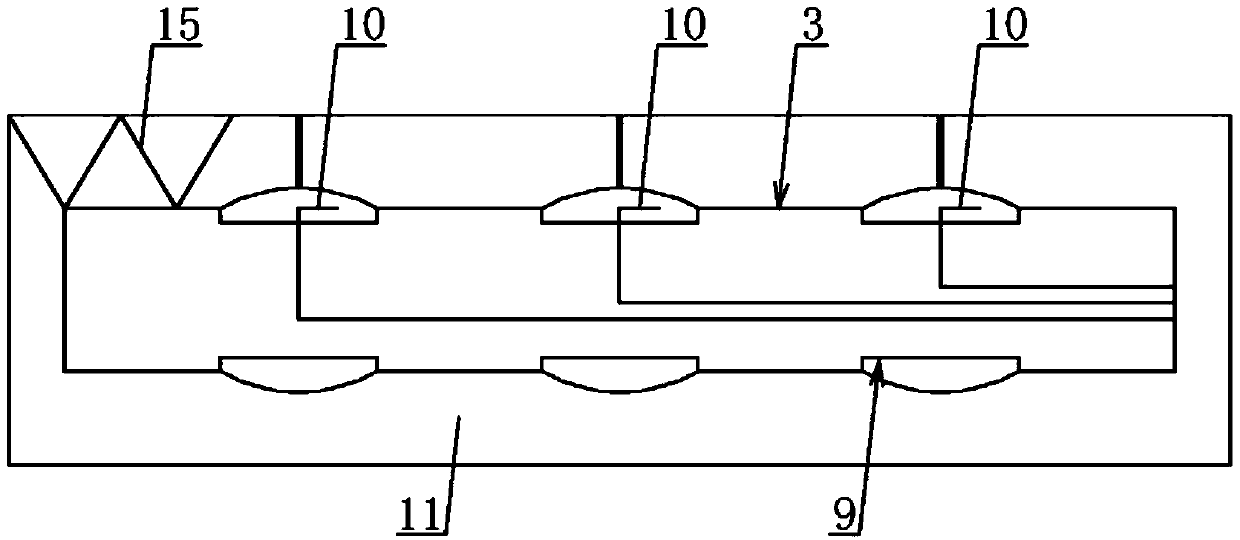

Flexible display panel and flexible display apparatus

ActiveCN107316881AGuaranteed bending performanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

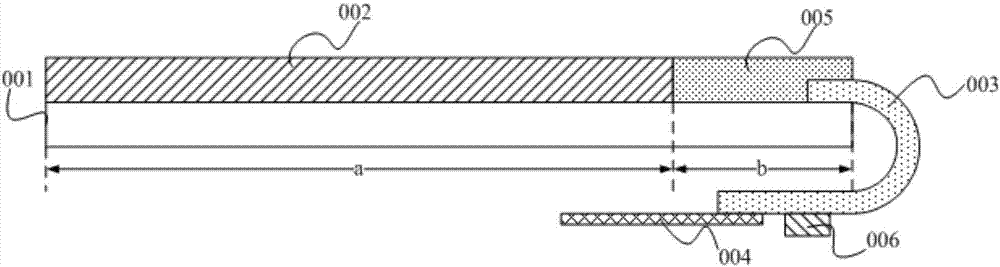

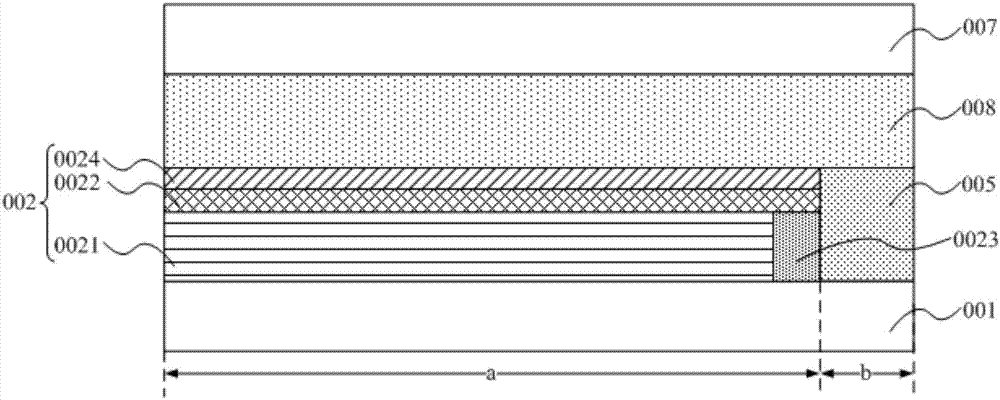

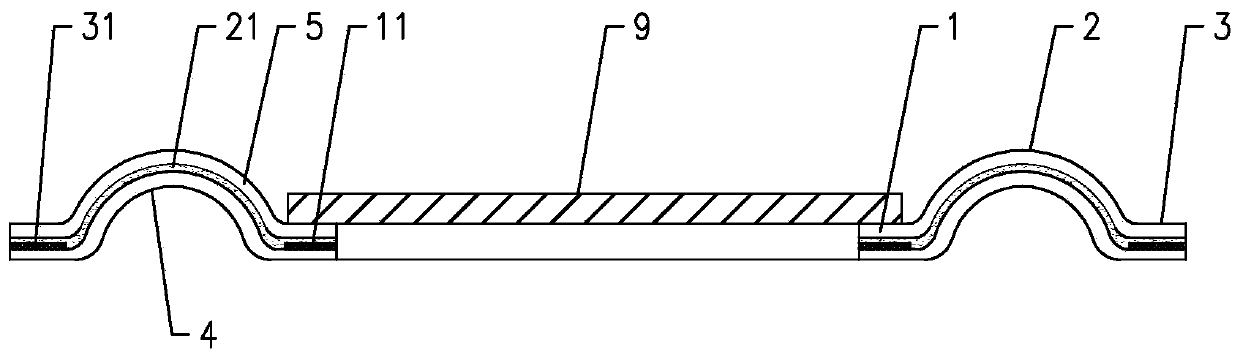

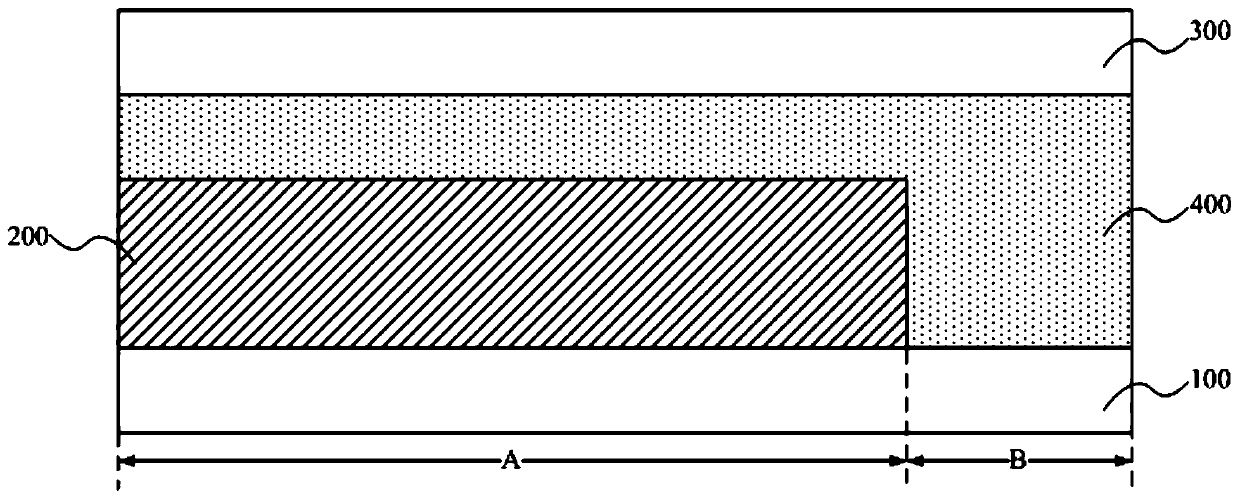

The invention discloses a flexible display panel and a flexible display apparatus. The flexible display panel comprises a flexible substrate with a display region and a bonding pad region, and multiple display elements arranged on the display region of the flexible substrate. The display region and the bonding pad region of the whole flexible substrate are covered with a protection film, and a bonding layer is directly arranged in the space between the protection film and the display elements and in the space between the binding region of the flexible substrate and the protection film separately, only single adhesive exists in the welding region between the flexible substrate and the protection film; when the flexible display panel is bent under stress, it is ensured that a strain neutral layer in the welding region of the flexible display panel can be positioned in the bonding layer, so that the risk of line breaking caused by cracks of a signal trace in the welding region due to overhigh stress can be avoided; and by virtue of the bonding layer, the elasticity modulus can be controlled within a range of 0.5-10MPa, so that the bonding layer has relatively high flexibility, thereby ensuring the buckling performance of the flexible display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

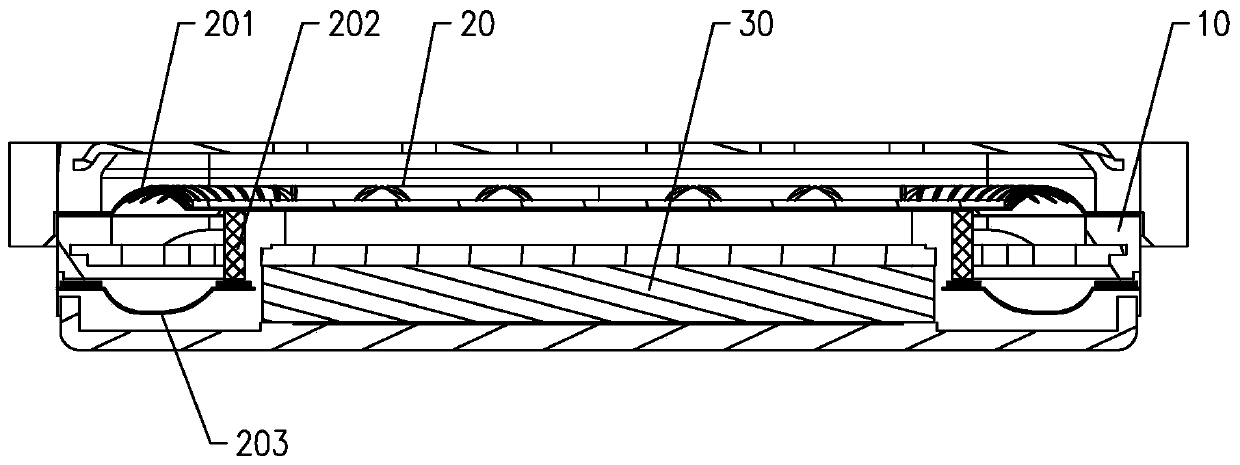

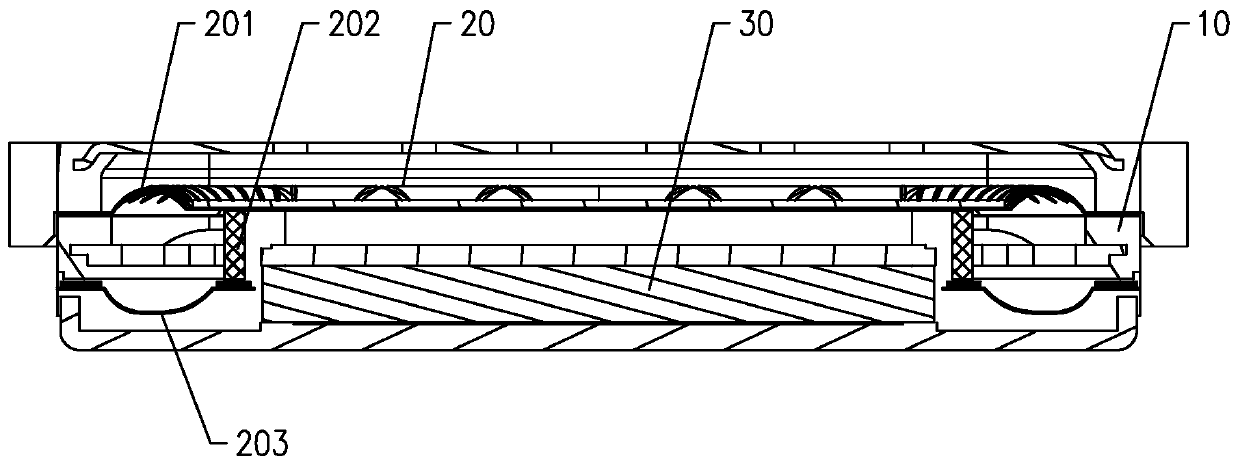

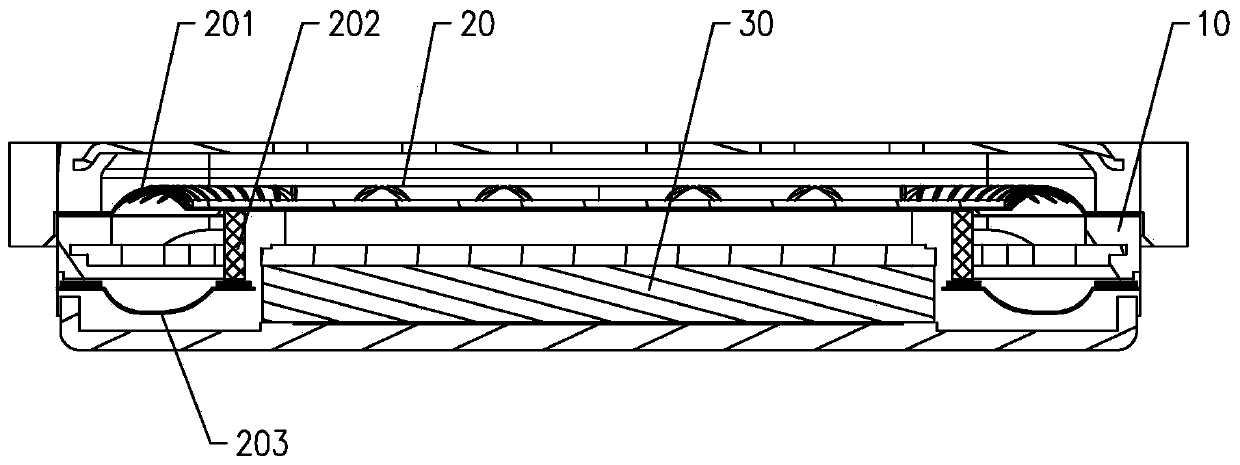

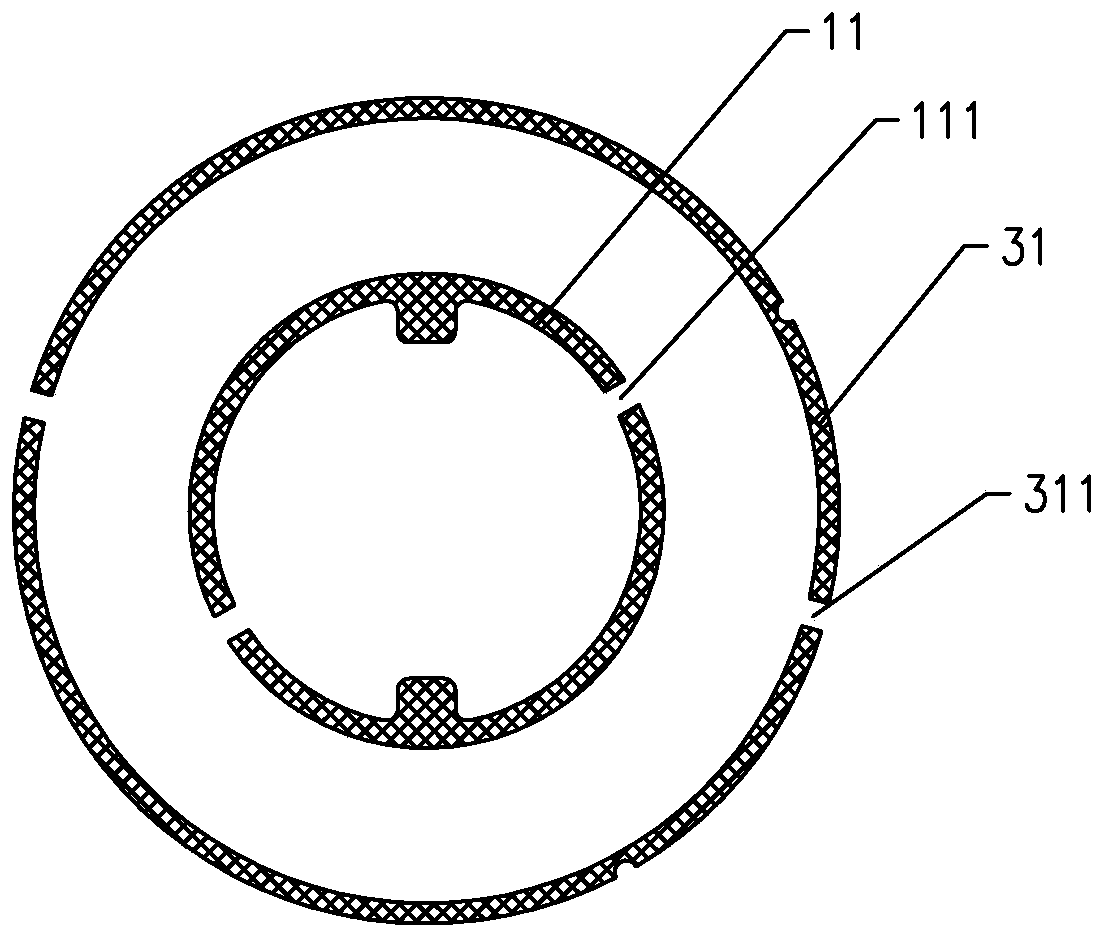

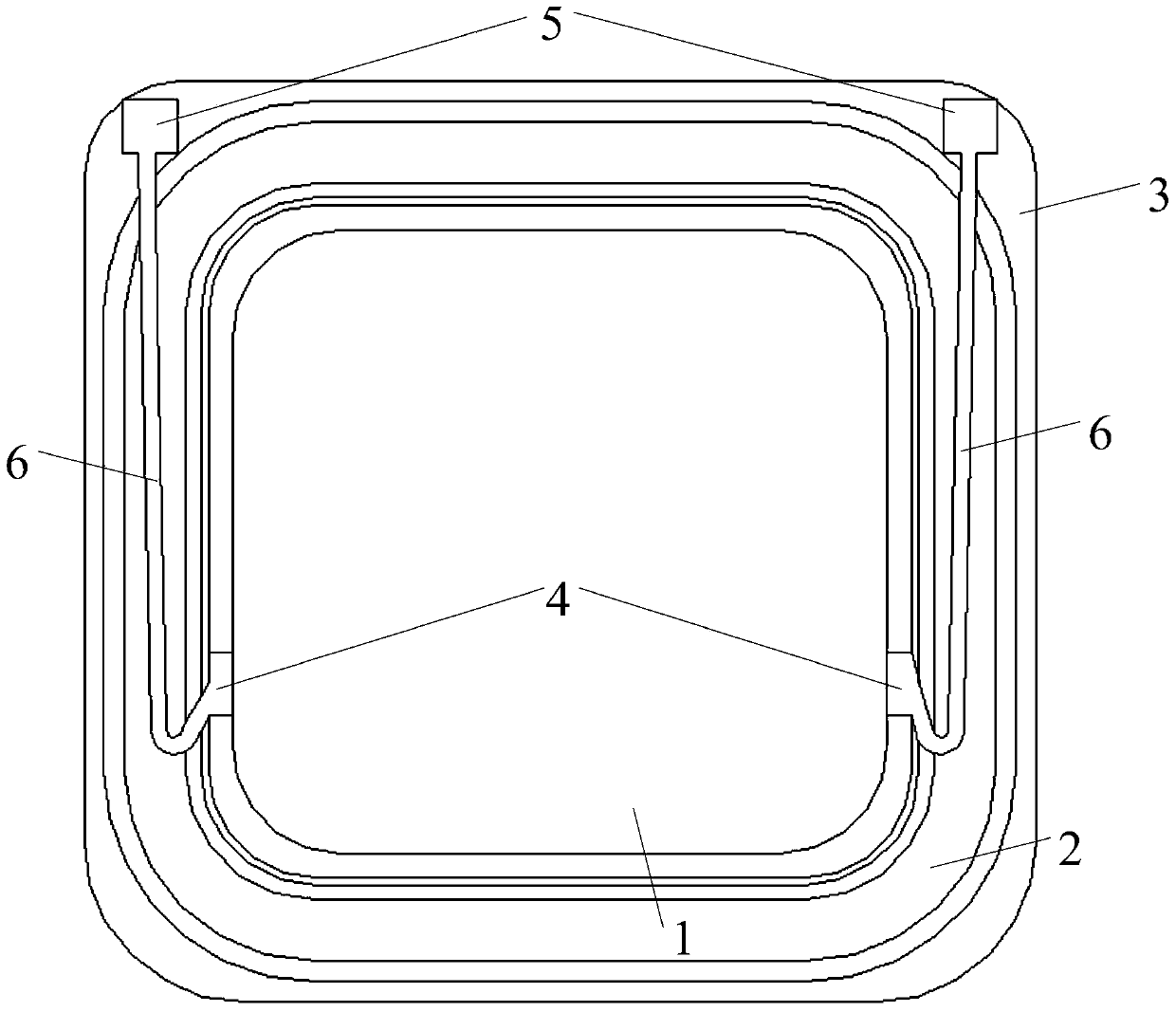

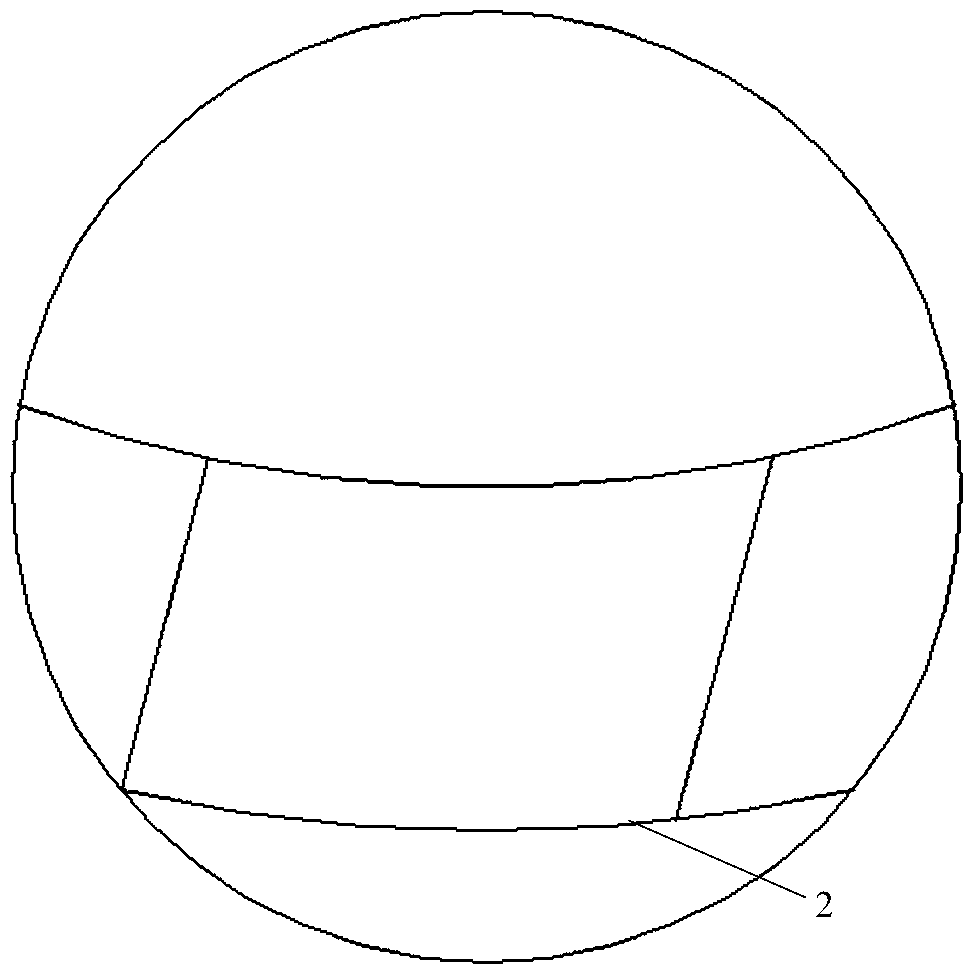

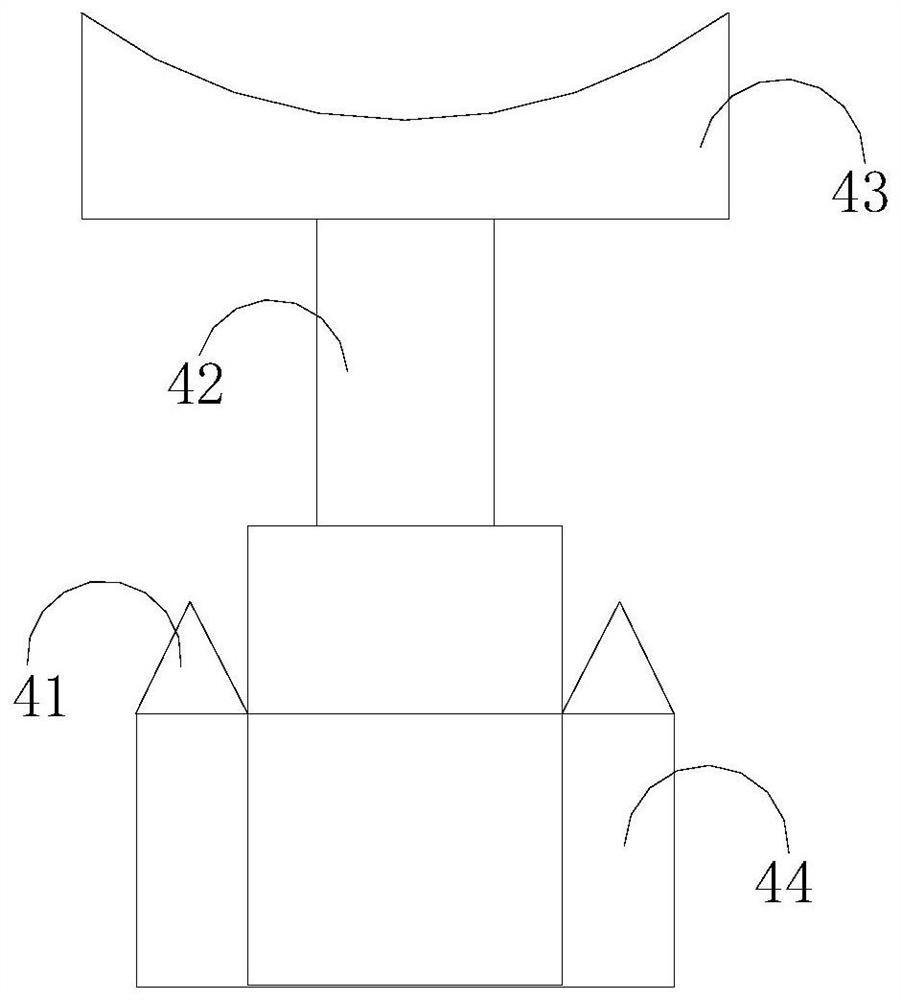

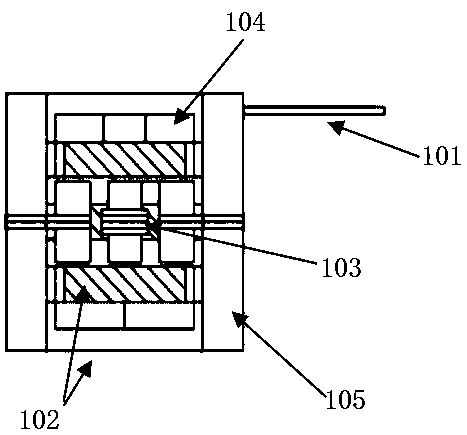

Silicone vibrating diaphragm, receiver module and method for processing silicone vibrating diaphragm

InactiveCN104853304AAchieve connectionTroubleshoot hearing problemsEarpiece/earphone attachmentsPlane diaphragmsSilica gelInjection moulding

The invention discloses a silicone vibrating diaphragm, a receiver module and a method for processing the silicone vibrating diaphragm. Two blocks of sheet metal are integrally formed on the silicone vibrating diaphragm through injection molding, the two blocks of sheet metal are embedded in the silicone vibrating diaphragm symmetrically, and both ends of each sheet metal are provided with a first welding part and a second welding part; each first welding part is embedded in a plane part, close to a folded ring part, of the silicone vibrating diaphragm, and is used for welding a coiling tap of a voice coil on the inner side of the voice coil; each second welding part extends out of or is embedded in a fixing part of the silicone vibrating diaphragm, and is used for welding a welding pad on an outer shell; and a connecting part connecting each first welding part and the corresponding second welding part is embedded in the silicone vibrating diaphragm to form a conductive path. By adopting the technical scheme of replacing lead wires of the voice coils with the two blocks of sheet metal of the silicone vibrating diaphragm, the problem of poor listening effect caused by collision of lead wires of the voice coils can be solved thoroughly, a wire-break risk of the lead wires of the voice coils can be avoided through the sheet metal embedded in the silicone vibrating diaphragm, and the product stability is improved.

Owner:GOERTEK INC

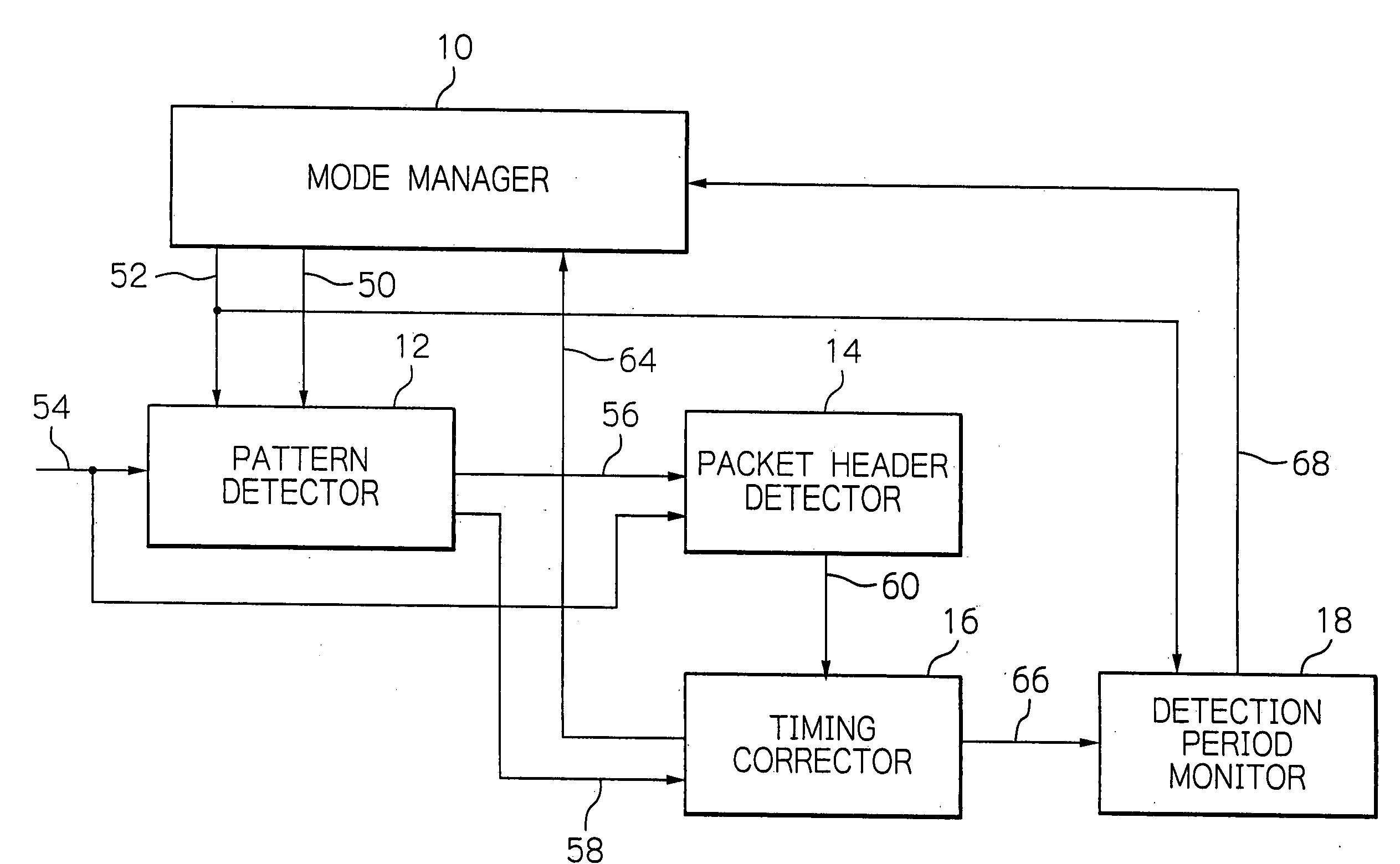

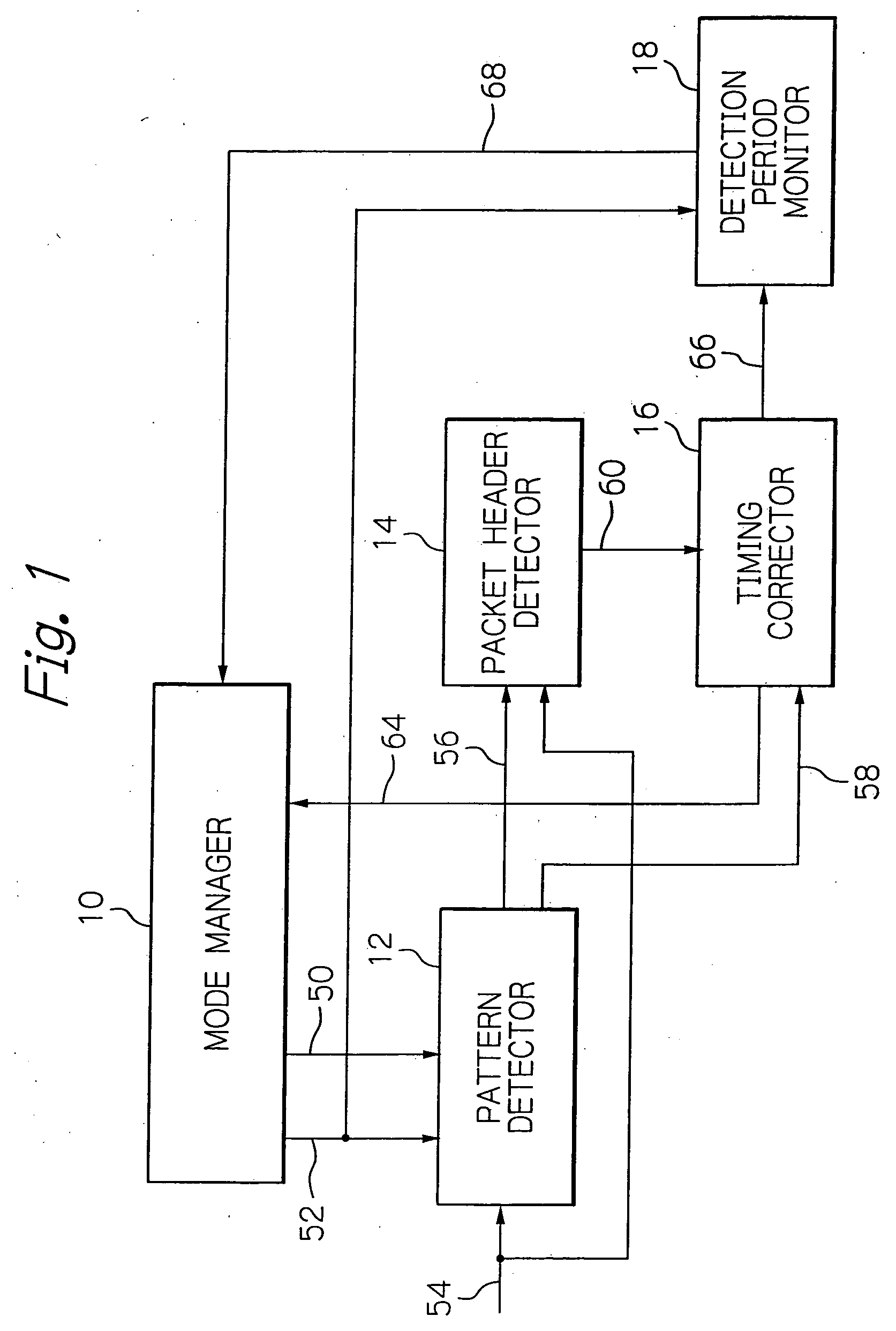

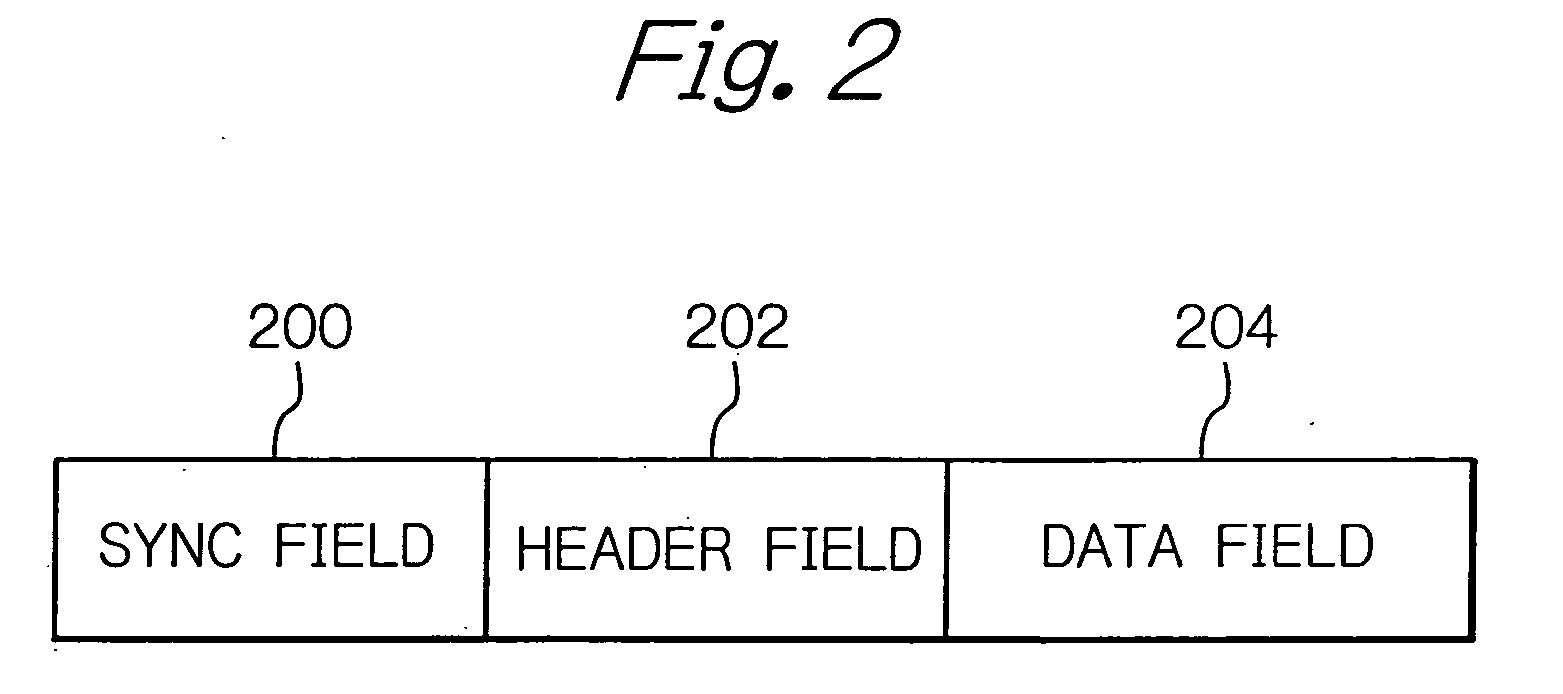

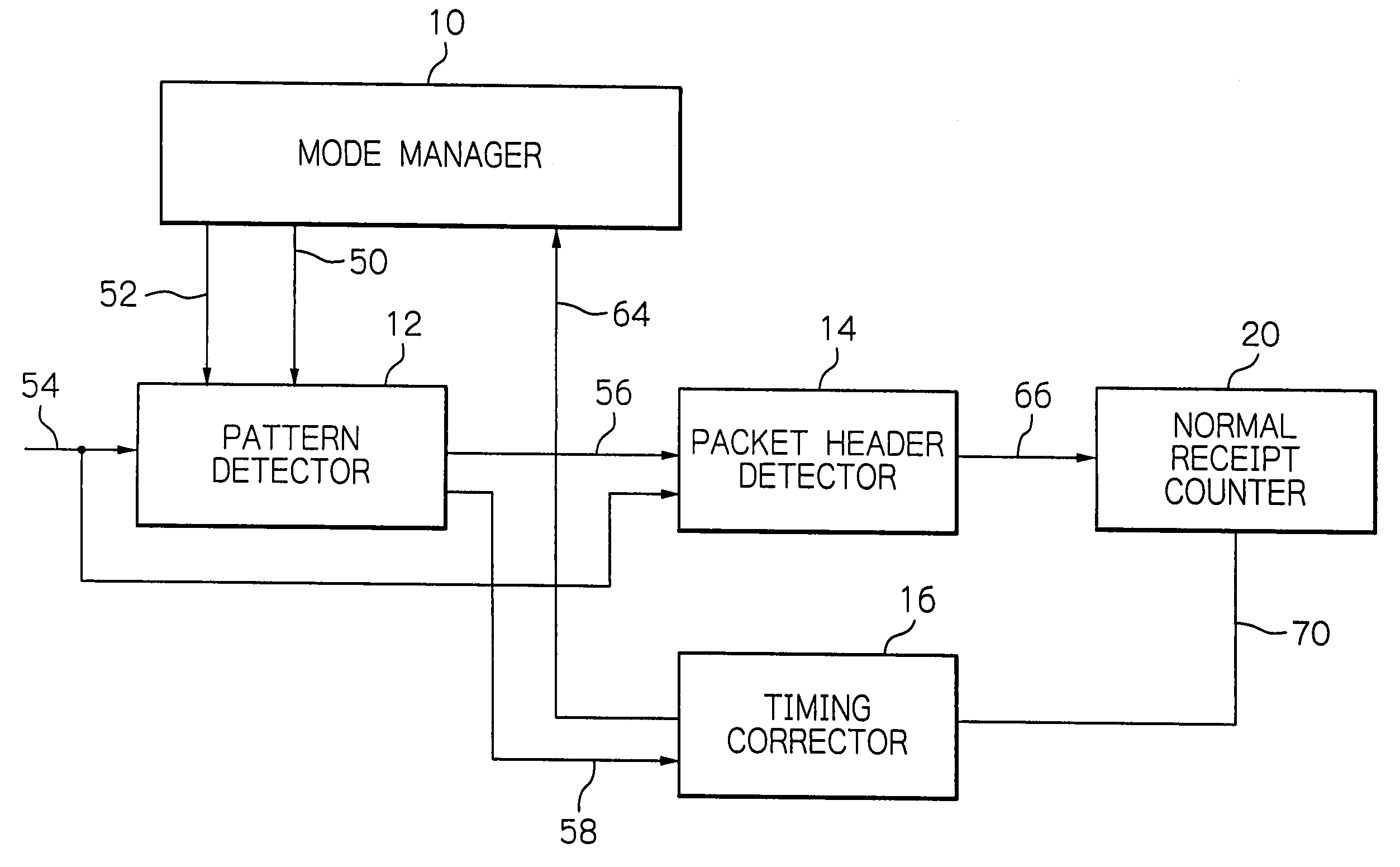

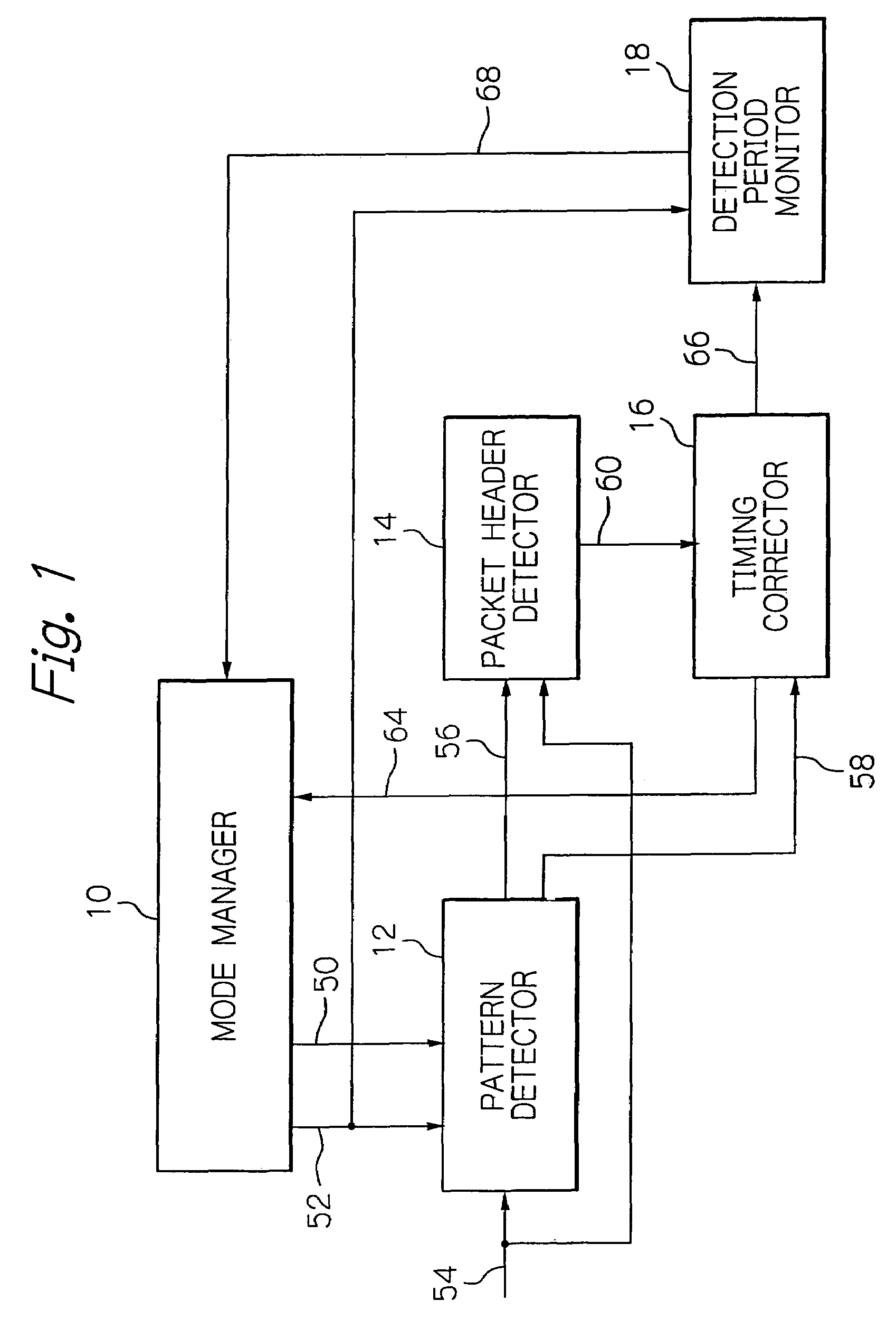

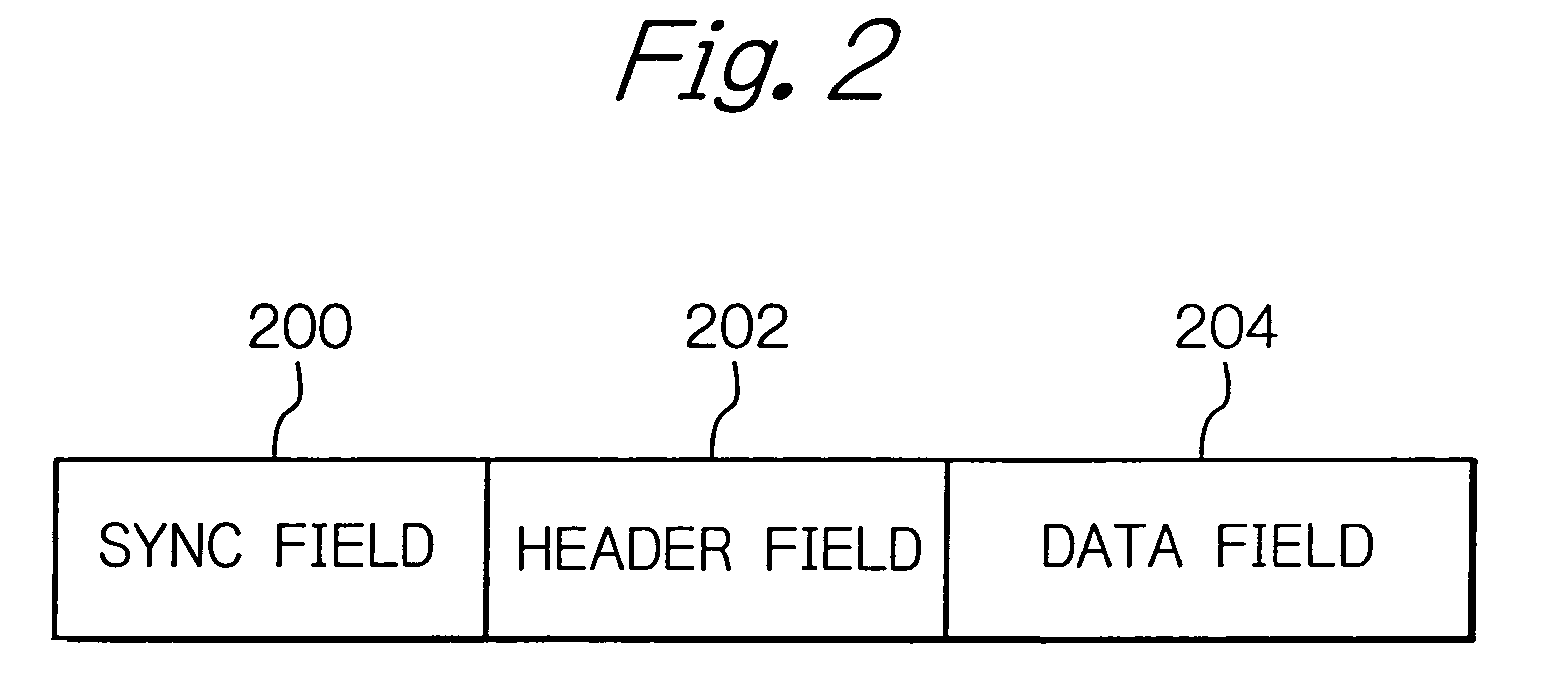

Device for preventing erroneous synchronization in wireless communication apparatus

ActiveUS20050135528A1Avoid disconnectionGood channel qualityElectronic circuit testingError detection/correctionComputer hardwareTelecommunications link

An erroneous synchronization preventing device includes a pattern detector detecting a sync pattern from received data with a broader sync window to output a sync detection notice and a sync timing. On receipt of the notice, a packet header detector checks an error in a header field of the received data, and, if detecting no error, outputs a header-normally-received notice, on receipt of which the timing corrector makes the inner timing synchronous with the sync timing to output a timing correction end notice. The mode manager in turn outputs a change notice. The pattern detector then detects the sync pattern with a narrower sync window. Unless the end notice is received within a predetermined period as from receipt of the change notice, a detection period monitor outputs an out-of-synchronism notice. The mode manager then outputs a restoration command for instructing detection of the sync pattern with the broader sync window. Disconnection of a communication link due to erroneous synchronization will be avoided.

Owner:LAPIS SEMICON CO LTD

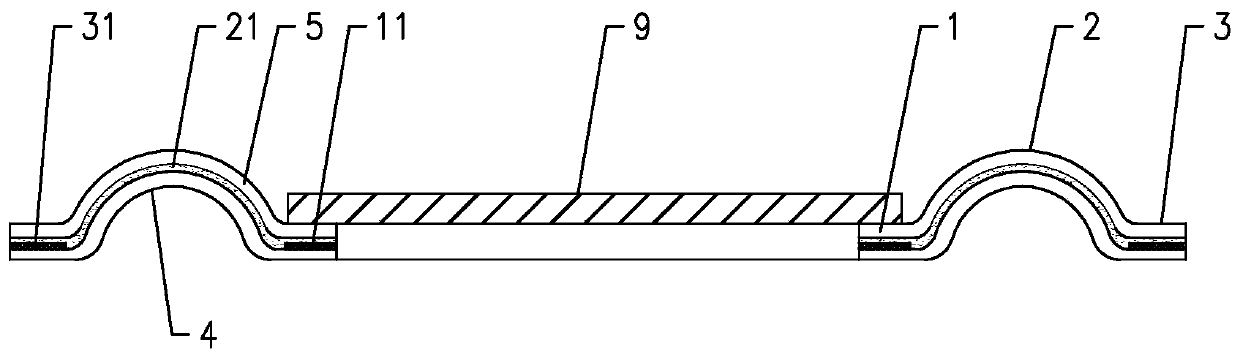

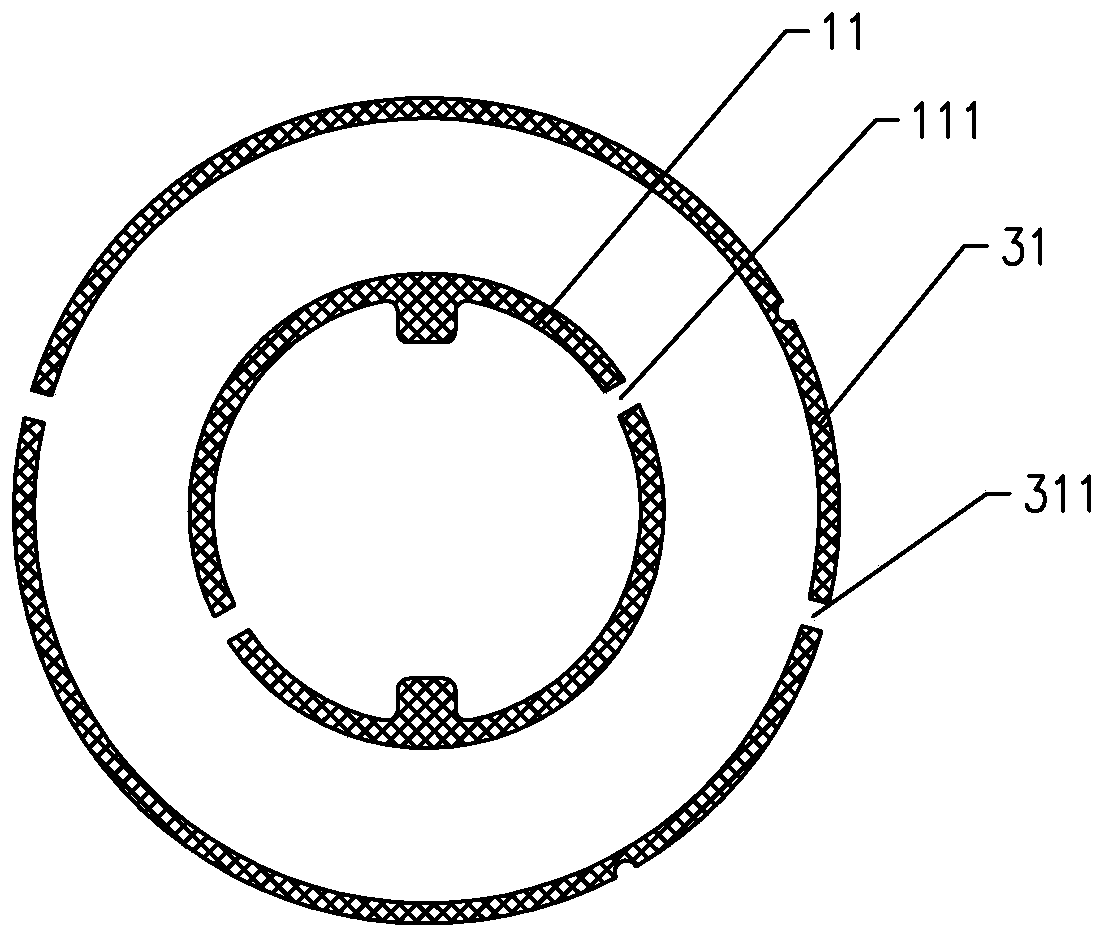

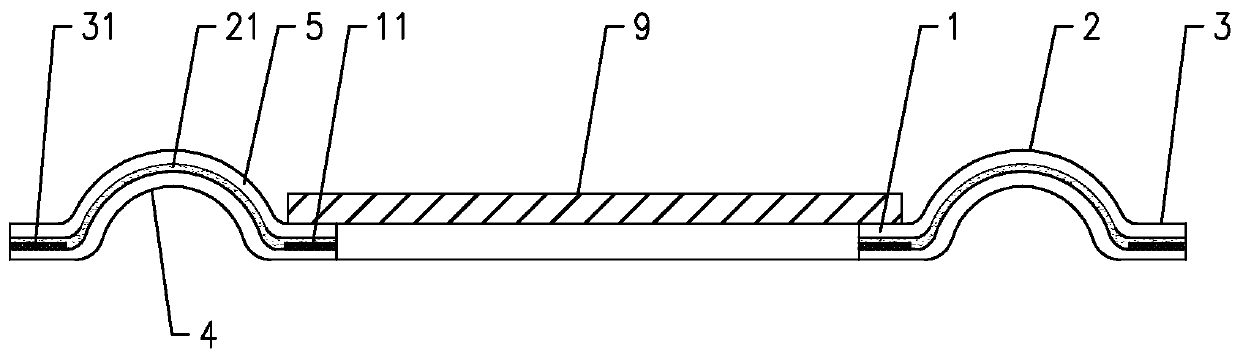

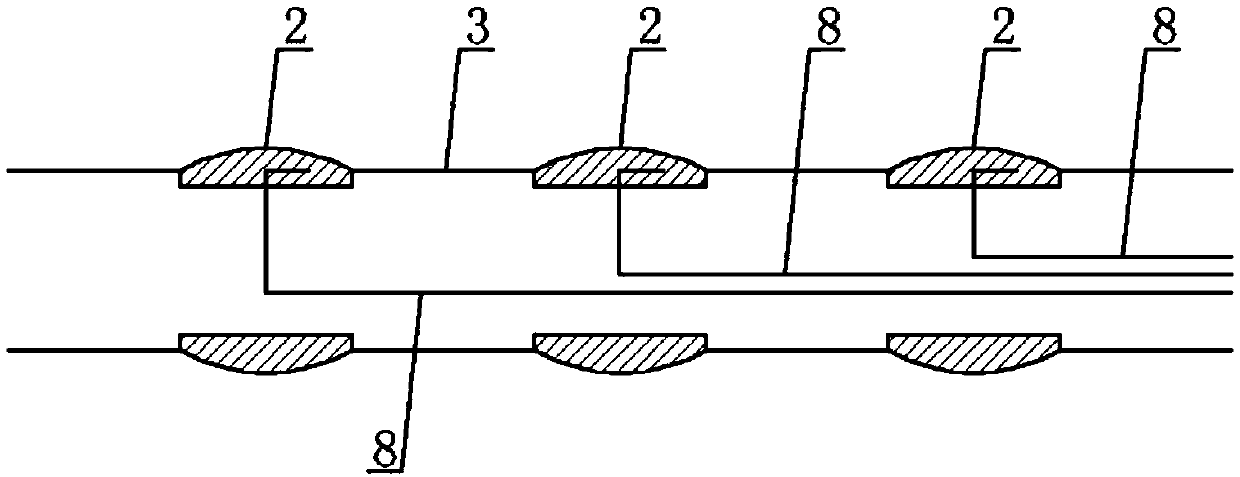

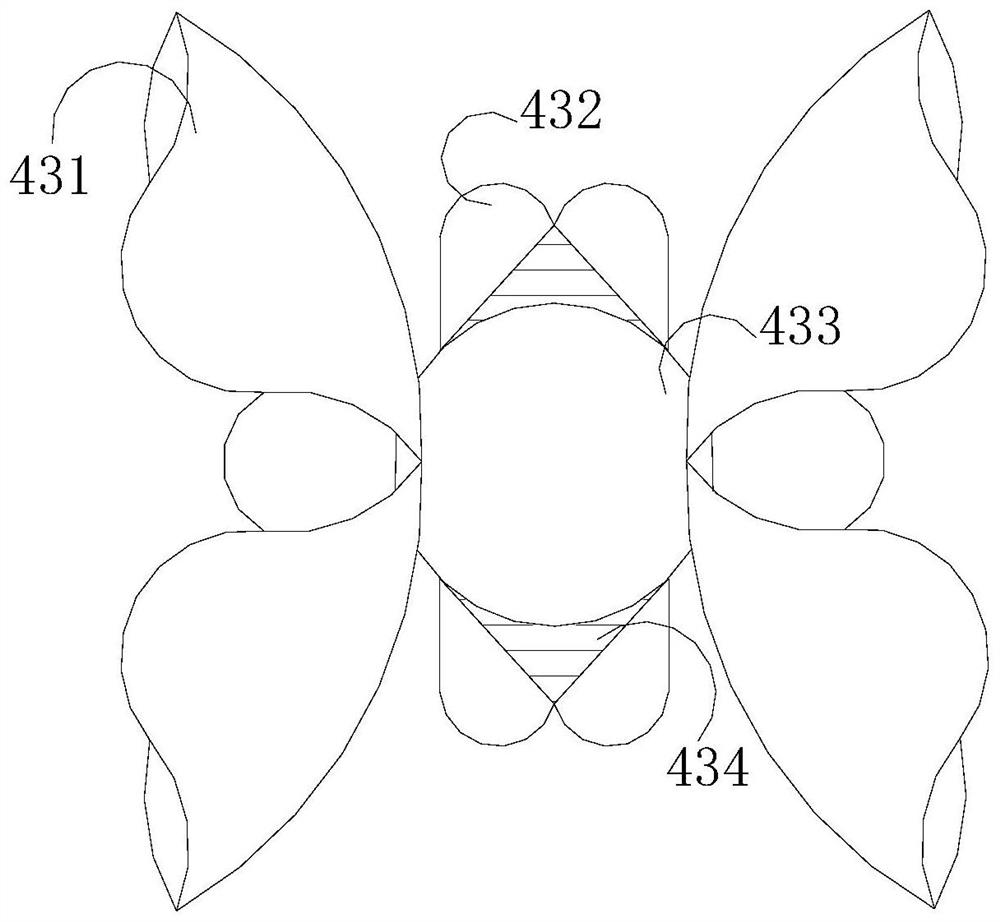

Conductive film for sound production device and sound production device

ActiveCN110784810ALarge amplitudeHigh sensitivityCircuit lead arrangements/reliefDiaphragm mounting/tensioningMetallic foilElectrical connection

The invention discloses a conductive film for a sound production device and the sound production device. The conductive film comprises a conductive layer and base material layers located at two sidesof the conductive layer, and the conductive film comprises an inner side part, a deformation part and an outer side part; the conducting layer comprises a first conducting layer arranged on the innerside part, a second conducting layer arranged on the deformation part and a third conducting layer arranged on the outer side part, and the two ends of the second conducting layer are electrically connected with the first conducting layer and the third conducting layer respectively; both the first conductive layer and the third conductive layer adopt metal foils, the second conductive layer is a conductive adhesive layer formed in a coating or printing mode, the thickness of the conductive adhesive layer is 6-15 [mu] m, and the sheet resistance of the conductive adhesive layer is 10-30 m [omega] / mm < 2 > / mil. One technical effect of the invention is that the conductive film has conductivity, can be used as a sound production diaphragm, and can also be used as a support diaphragm.

Owner:GEER TECH CO LTD

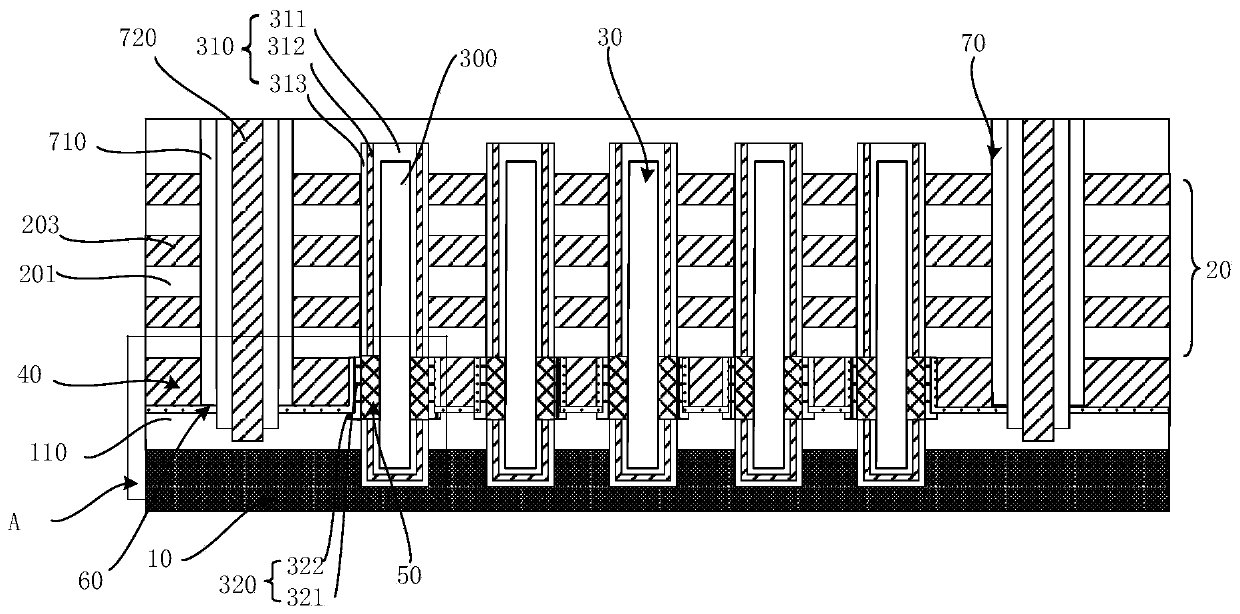

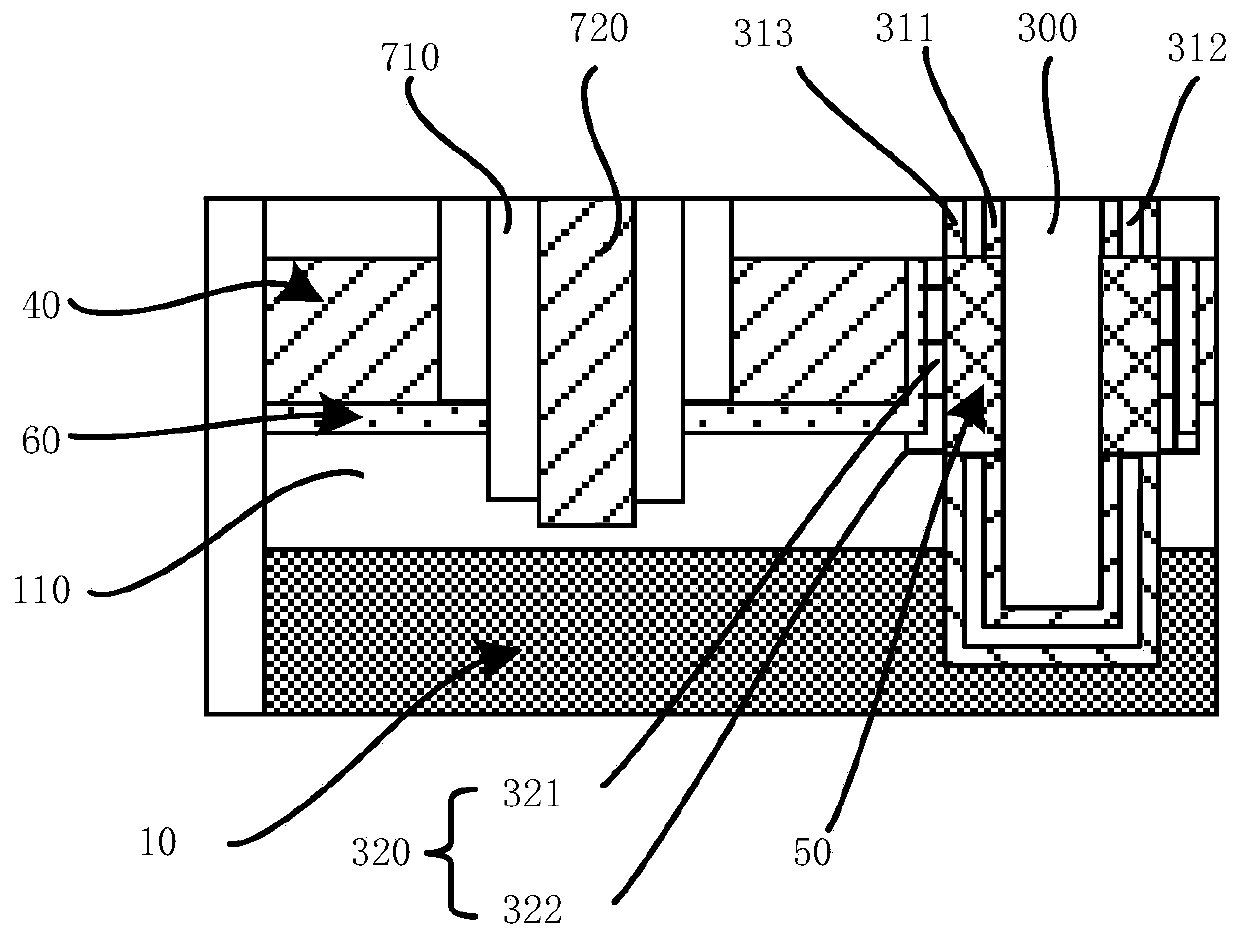

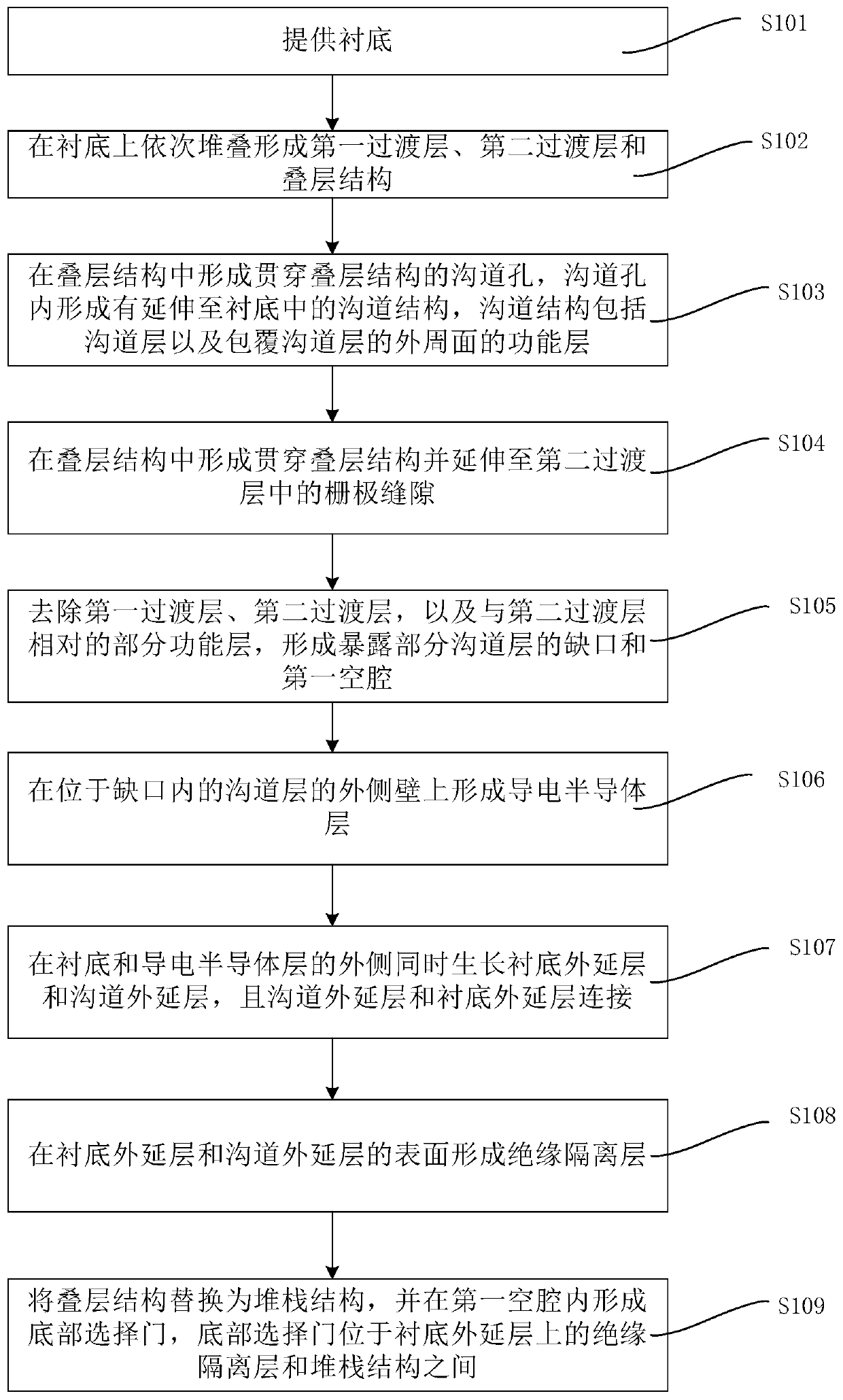

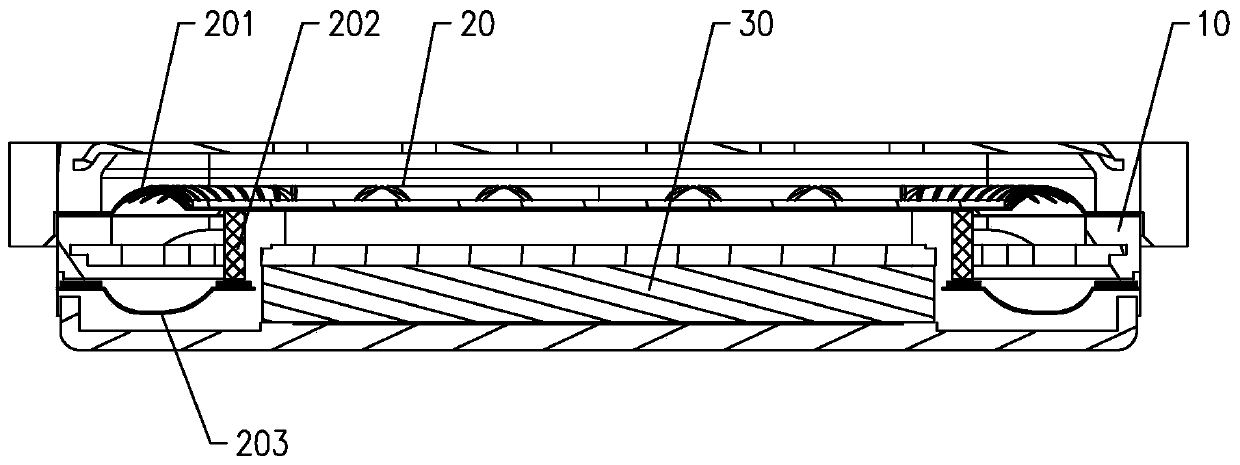

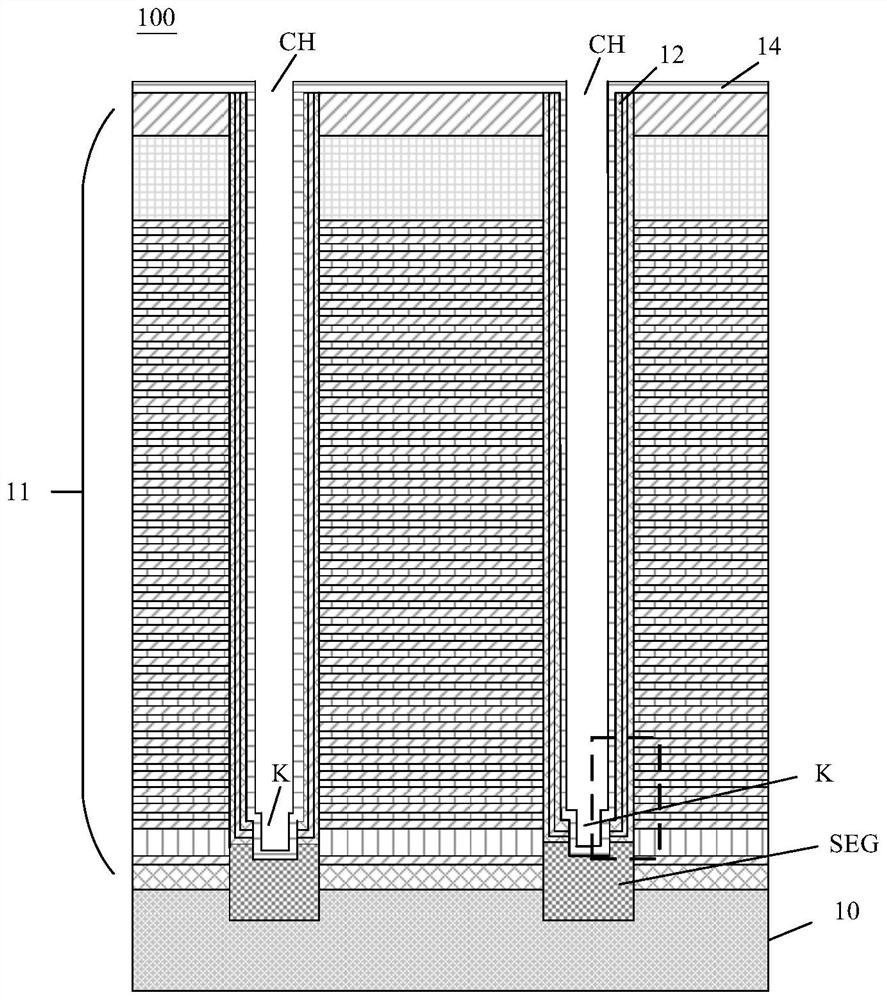

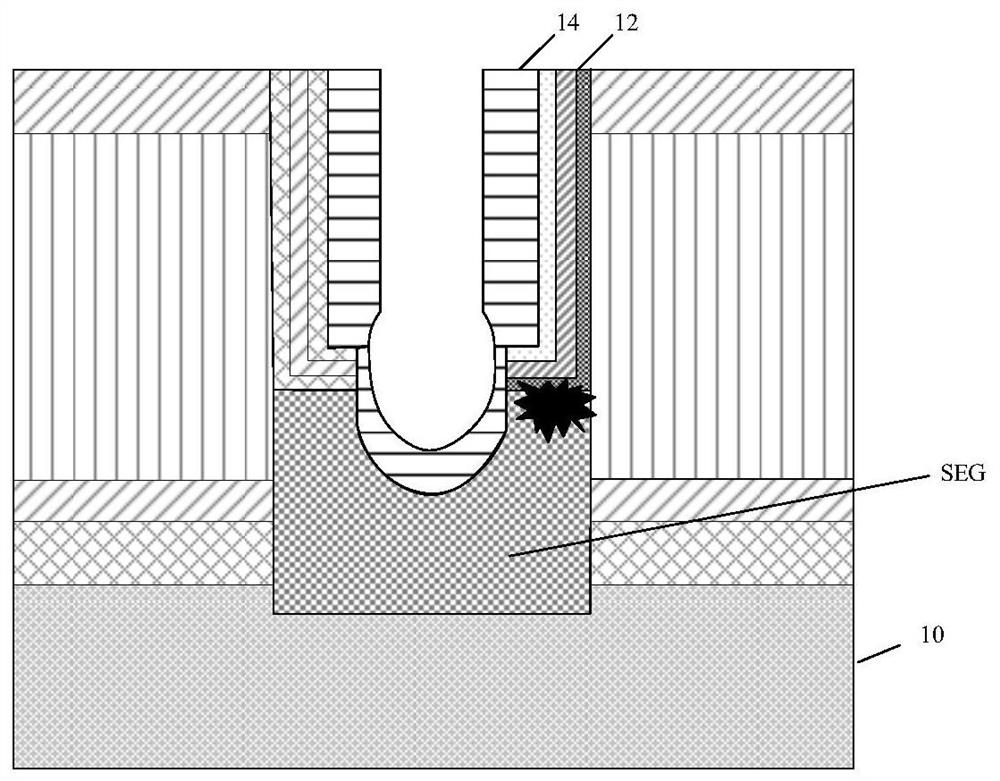

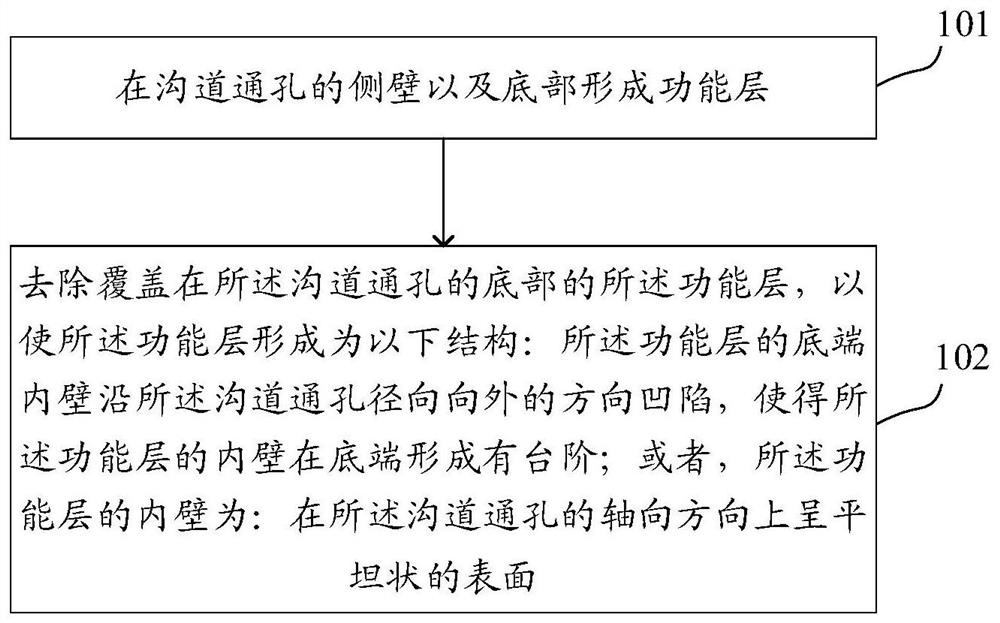

Three-dimensional memory and preparation method thereof

ActiveCN111430359AAvoid the risk of disconnectionHas conductive propertiesSolid-state devicesEnergy efficient computingCondensed matter physicsSemiconductor

The invention belongs to the technical field of memory equipment, and particularly relates to a three-dimensional memory and a preparation method of the three-dimensional memory. The three-dimensionalmemory comprises a substrate, a stack structure arranged on the substrate, and a channel structure penetrating through the stack structure and extending into the substrate. A substrate epitaxial layer is arranged between the substrate and the stack structure; the functional layer is provided with a gap, and the side wall of part of the channel layer exposed in the gap is provided with a conductive semiconductor layer; and a channel epitaxial layer is arranged on the conductive semiconductor layer and is connected with the substrate epitaxial layer. The risk of channel disconnection caused bythe fact that the channel layer is easily etched by hydrochloric acid when the channel layer is prepared by adopting a silicon epitaxial growth method in the prior art is overcome.

Owner:YANGTZE MEMORY TECH CO LTD

Conductive film for sound production device and sound production device

InactiveCN110691306ALarge amplitudeHigh sensitivityLoudspeakersDiaphragm extensionsElastomerMetal foil

The invention discloses a conductive film for a sound production device and the sound production device, the conductive film comprises a conductive layer and a first base material layer and a second base material layer which are located at two sides of the conductive layer, and the conductive film comprises an inner side part, a deformation part and an outer side part; the conducting layer comprises a first conducting layer arranged on the inner side part, a second conducting layer arranged on the deformation part and a third conducting layer arranged on the outer side part, and the first conducting layer, the second conducting layer and the third conducting layer are connected to form at least one conducting circuit; the first conducting layer and the third conducting layer are both madeof metal foils, the Young modulus of the second conducting layer is smaller than that of the metal foils, and the first base material layer is a thermoplastic elastomer layer. One technical effect ofthe invention is that the conductive film has conductivity, can be used as a sound production diaphragm, and can also be used as a support diaphragm.

Owner:GEER TECH CO LTD

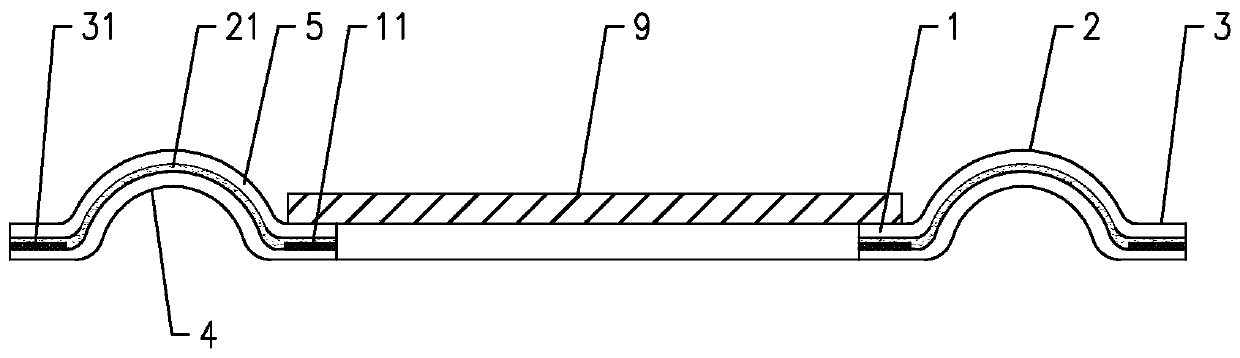

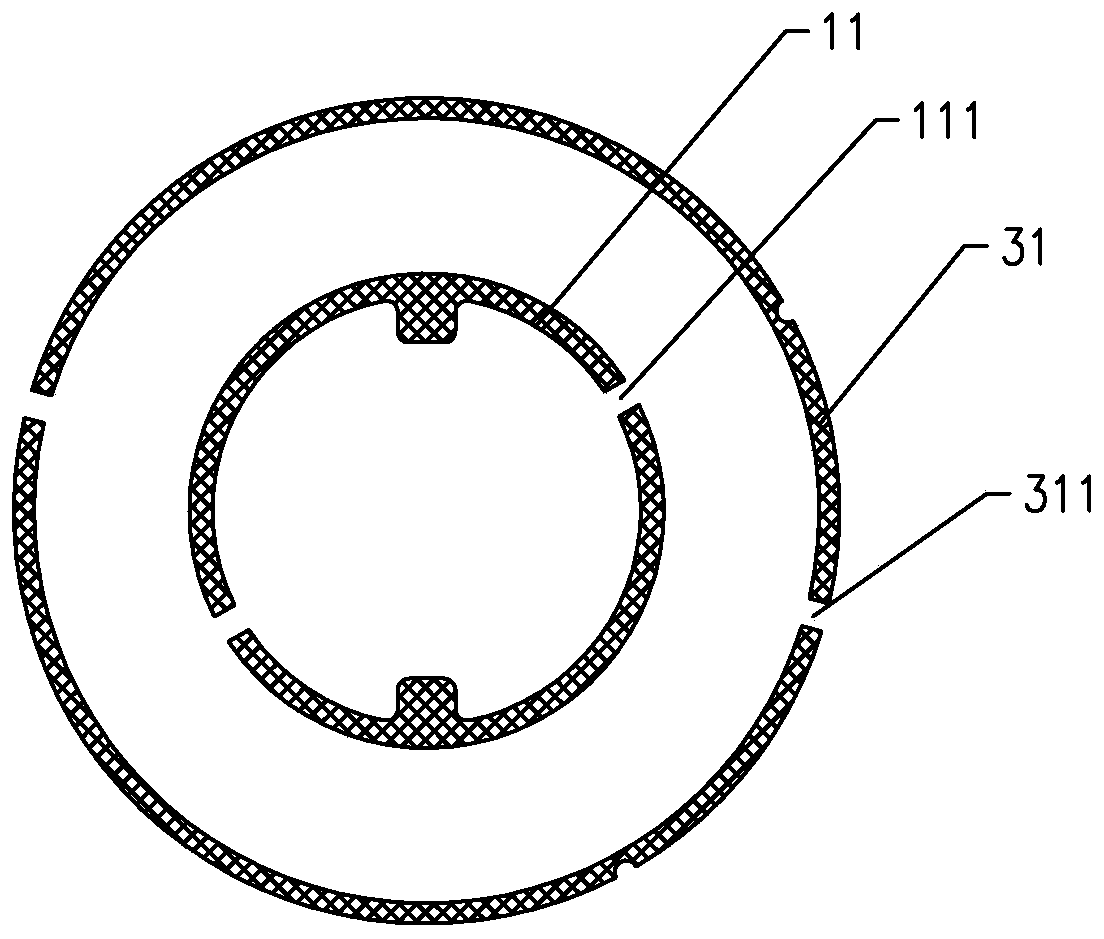

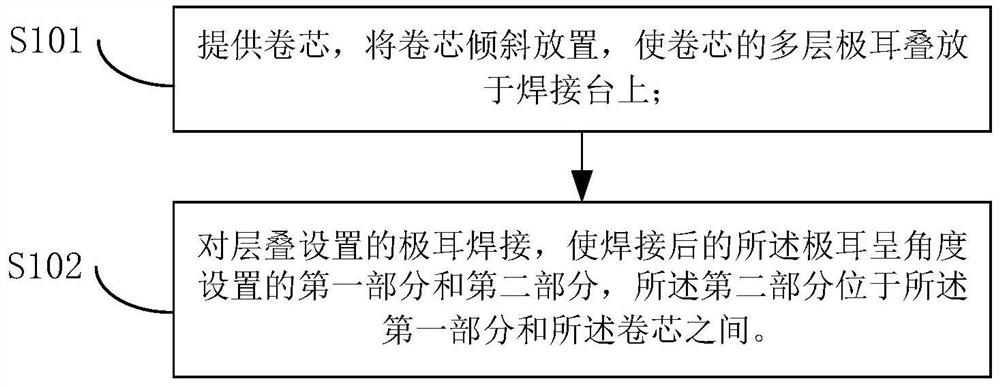

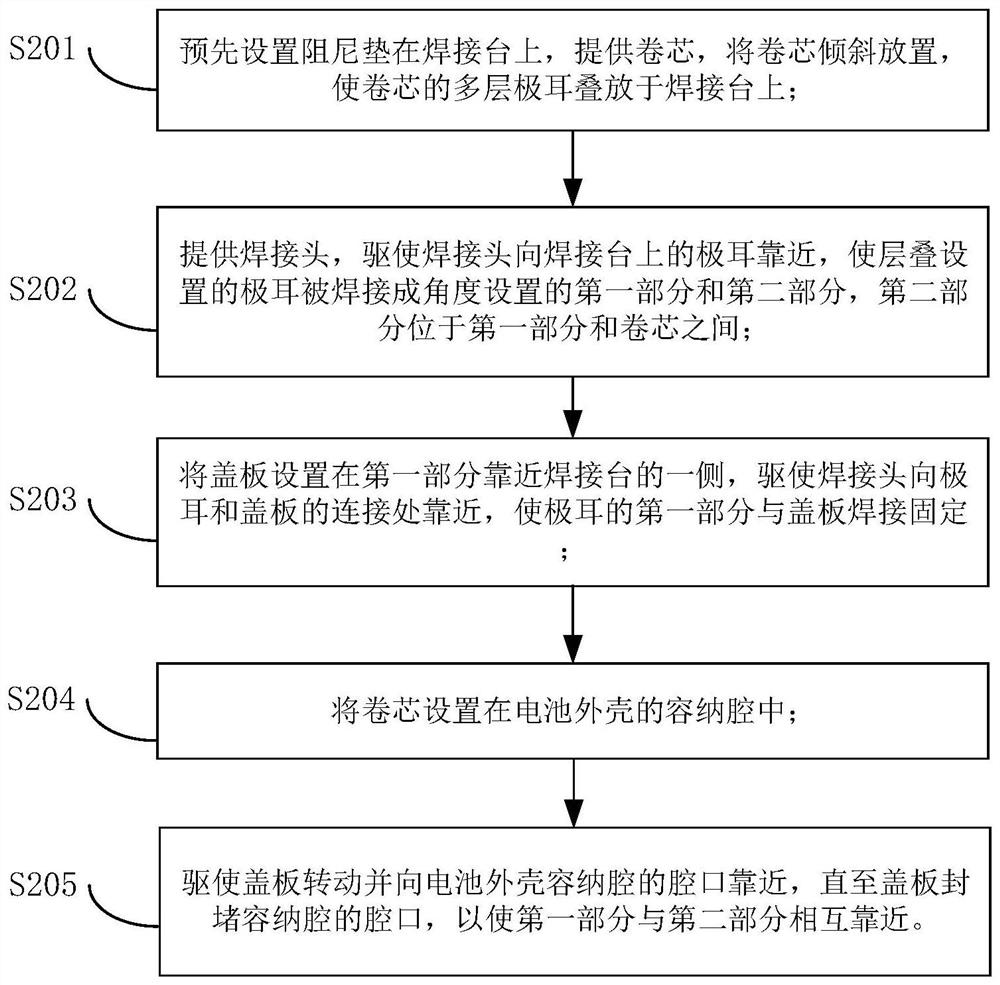

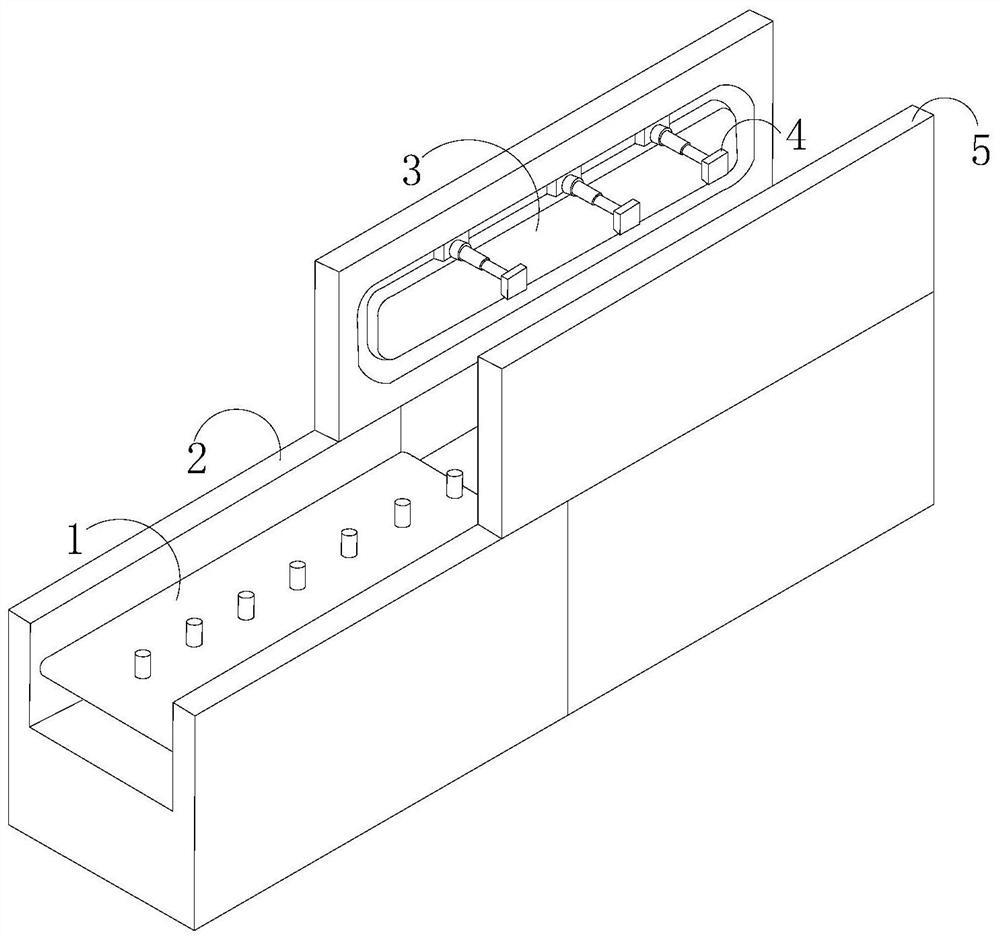

Tab welding method and tab welding device

ActiveCN112792490AReduced soldering areaReduce frictionFinal product manufactureWelding/cutting auxillary devicesElectrical batteryInternal resistance

The invention relates to the technical field of batteries, and particularly discloses a tab welding method and a tab welding device. The tab welding method comprises the following steps of providing a roll core, obliquely placing the roll core, and stacking a plurality of layers of tabs of the roll core on a welding table; and welding the stacked tabs to enable the welded tabs to form first parts and second parts at angles, wherein the second parts are located between the first parts and the roll core. According to the tab welding method, the friction force and the pressing movement distance when the tab on the upper layer is welded and pressed down can be reduced, the defect that the tab on the upper layer is torn due to excessive displacement can be overcome, the problems that the tabs and a cover plate are not firmly connected after welding, even insufficient welding and the like are solved, therefore, the risks that the internal resistance of a battery is abnormal or the tabs are disconnected from the cover plate is avoided, the fracture defect and the untight attachment defect of the tabs can be reduced, a connecting piece is not needed, an additional process and the weight of the battery are prevented form being increased, and the effective volume utilization rate and the energy density of the battery are improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Conductive film for sound production device and sound production device

PendingCN110691308ALarge amplitudeHigh sensitivityLoudspeakersDiaphragm extensionsMetal foilSound production

The invention discloses a conductive film for a sound production device and the sound production device. The conductive film comprises a conductive layer, and a first substrate layer and a second substrate layer at two sides; the conductive film comprises an inner side part, a deformation part and an outer side part; the conductive layer comprises a first conductive layer arranged on the inner side part, a second conductive layer arranged on the deformation part and a third conductive layer arranged on the outer side part; the first conductive layer and the third conductive layer both adopt metal foils, and the Young modulus of the second conductive layer is smaller than that of the metal foils; the first conducting layer and the third conducting layer are bonded with the first base material layer through an adhesive layer. The second conducting layer is connected with the first base material layer, the first conducting layer and the third conducting layer in a coating or printing mode. One technical effect of the invention is that the conductive film has conductivity, can be used as a sound production diaphragm, and can also be used as a support diaphragm.

Owner:GEER TECH CO LTD

Device for preventing erroneous synchronization in wireless communication apparatus

ActiveUS7359367B2Avoid synchronizationAvoid the risk of disconnectionElectronic circuit testingError detection/correctionTelecommunications linkCommunication link

An erroneous synchronization preventing device includes a pattern detector detecting a sync pattern from received data with a broader sync window to output a sync detection notice and a sync timing. On receipt of the notice, a packet header detector checks an error in a header field of the received data, and, if detecting no error, outputs a header-normally-received notice, on receipt of which the timing corrector makes the inner timing synchronous with the sync timing to output a timing correction end notice. The mode manager in turn outputs a change notice. The pattern detector then detects the sync pattern with a narrower sync window. Unless the end notice is received within a predetermined period as from receipt of the change notice, a detection period monitor outputs an out-of-synchronism notice. The mode manager then outputs a restoration command for instructing detection of the sync pattern with the broader sync window. Disconnection of a communication link due to erroneous synchronization will be avoided.

Owner:LAPIS SEMICON CO LTD

Conductive film for sound production device and sound production device

InactiveCN110691307ALarge amplitudeHigh sensitivityLoudspeakersDiaphragm extensionsMetallic foilElectrical connection

The invention discloses a conductive film for a sound production device and the sound production device, the conductive film comprises a conductive layer and base material layers located at two sidesof the conductive layer, and the conductive film comprises an inner side part, a deformation part and an outer side part; the conductive layer comprises a first conductive layer arranged on the innerside part, a second conductive layer arranged on the deformation part, and a third conductive layer is arranged on the outer side part; the two ends of the second conductive layer are electrically connected with the first conductive layer and the third conductive layer respectively, and the first conductive layer, the second conductive layer and the third conductive layer are connected to form atleast one conductive circuit; both the first conducting layer and the third conducting layer adopt metal foils, and the Young modulus of the second conducting layer is smaller than that of the metal foils. One technical effect of the invention is that the conductive film has conductivity, can be used as a sound production diaphragm, and can also be used as a support diaphragm.

Owner:GEER TECH CO LTD

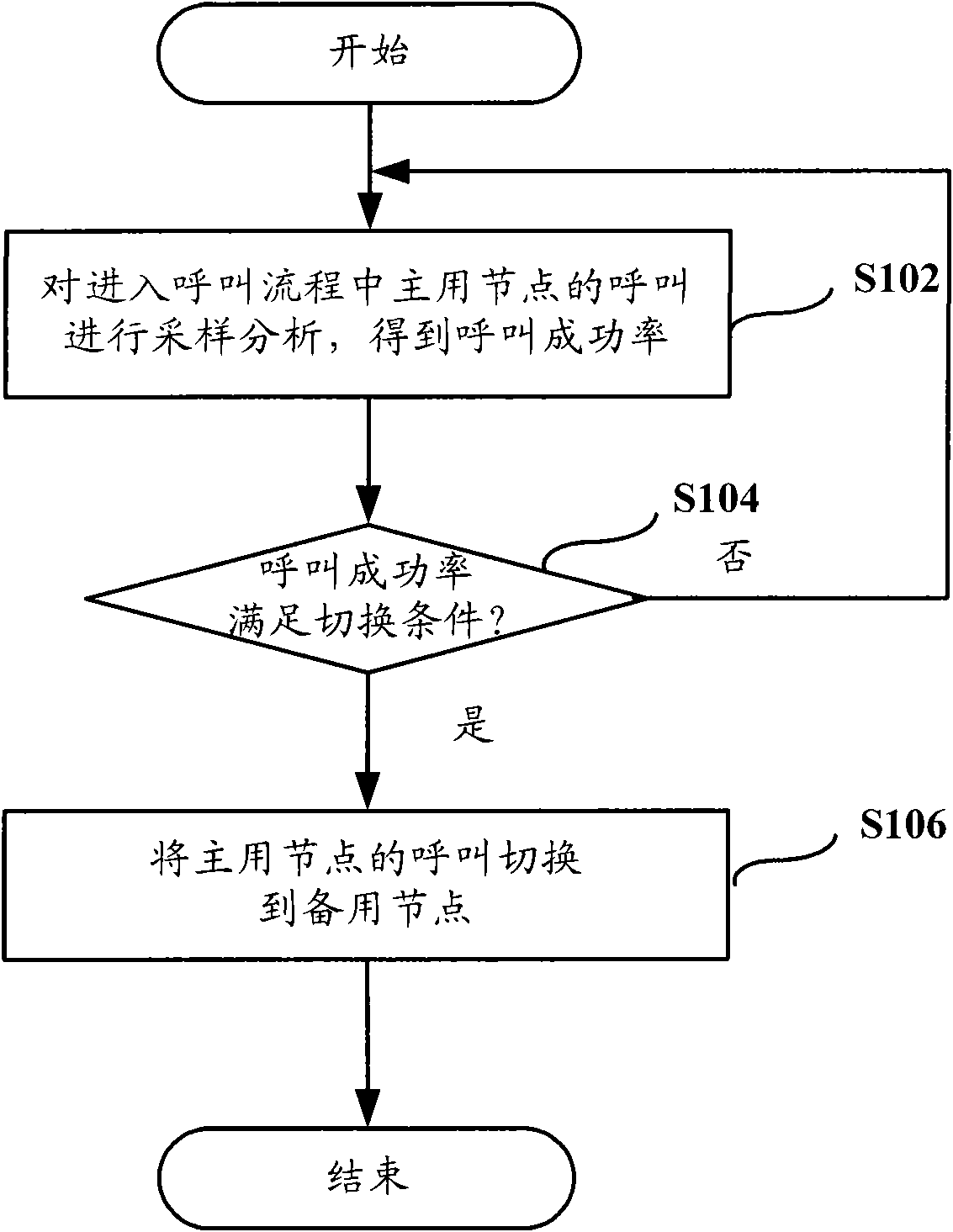

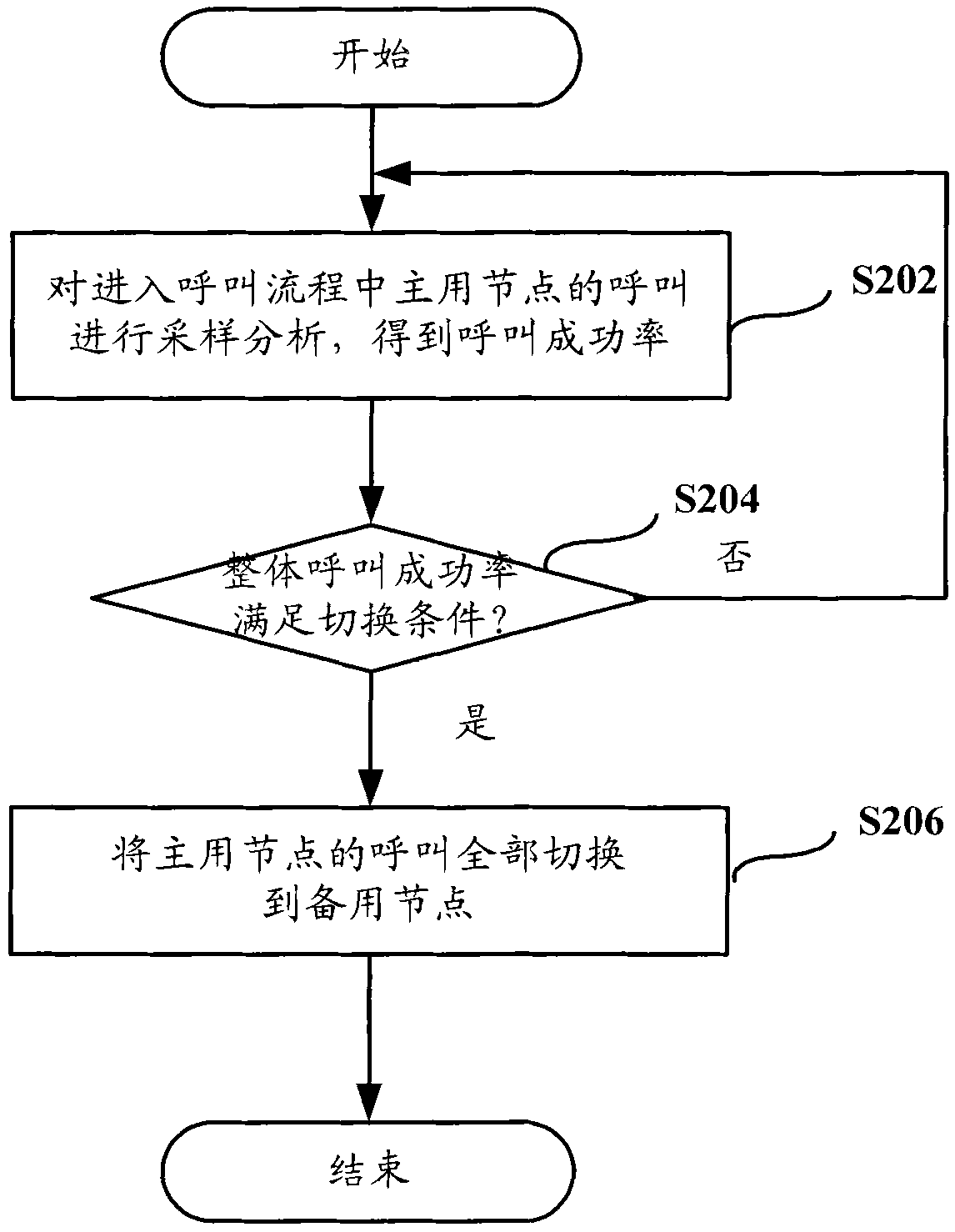

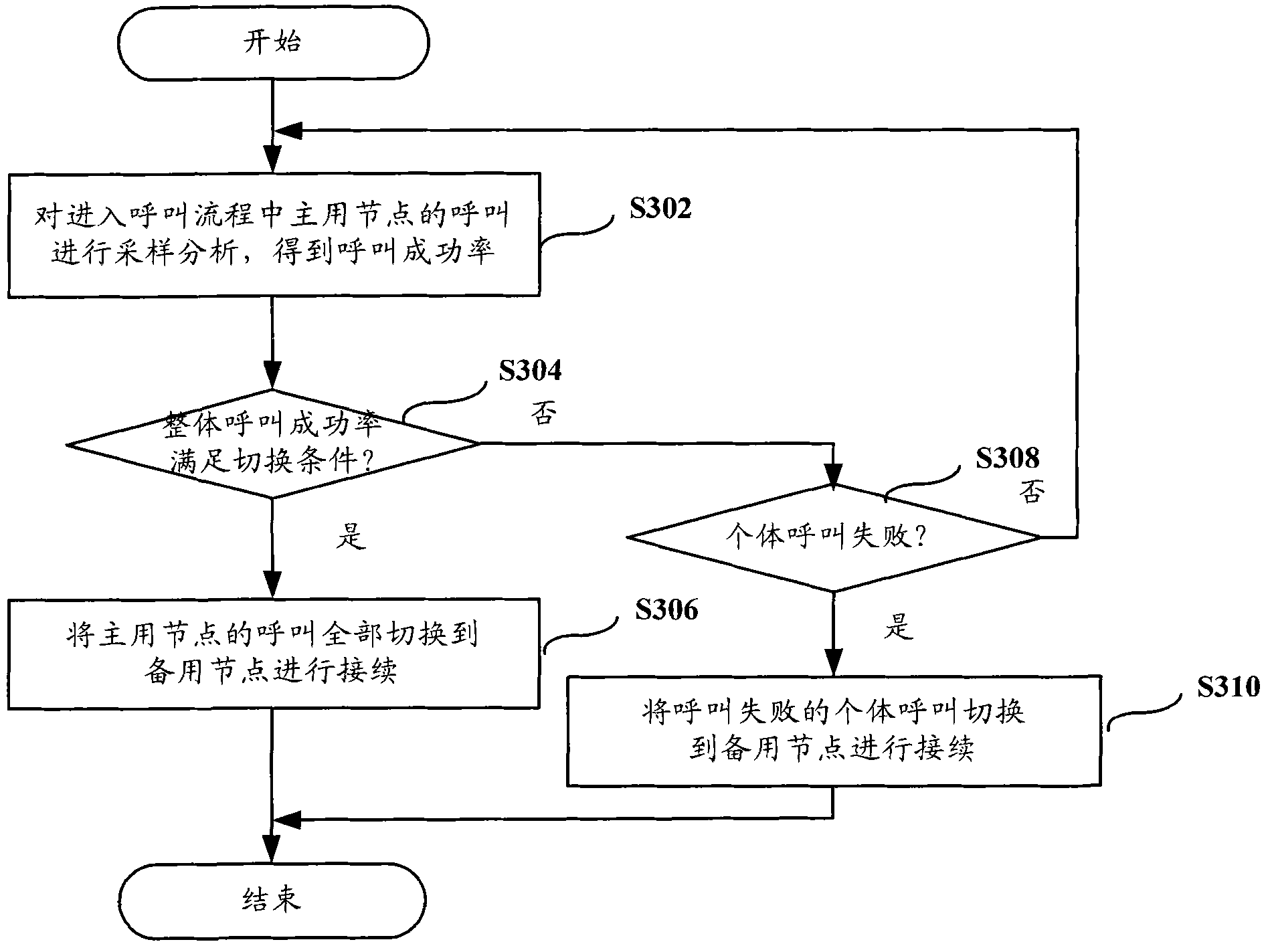

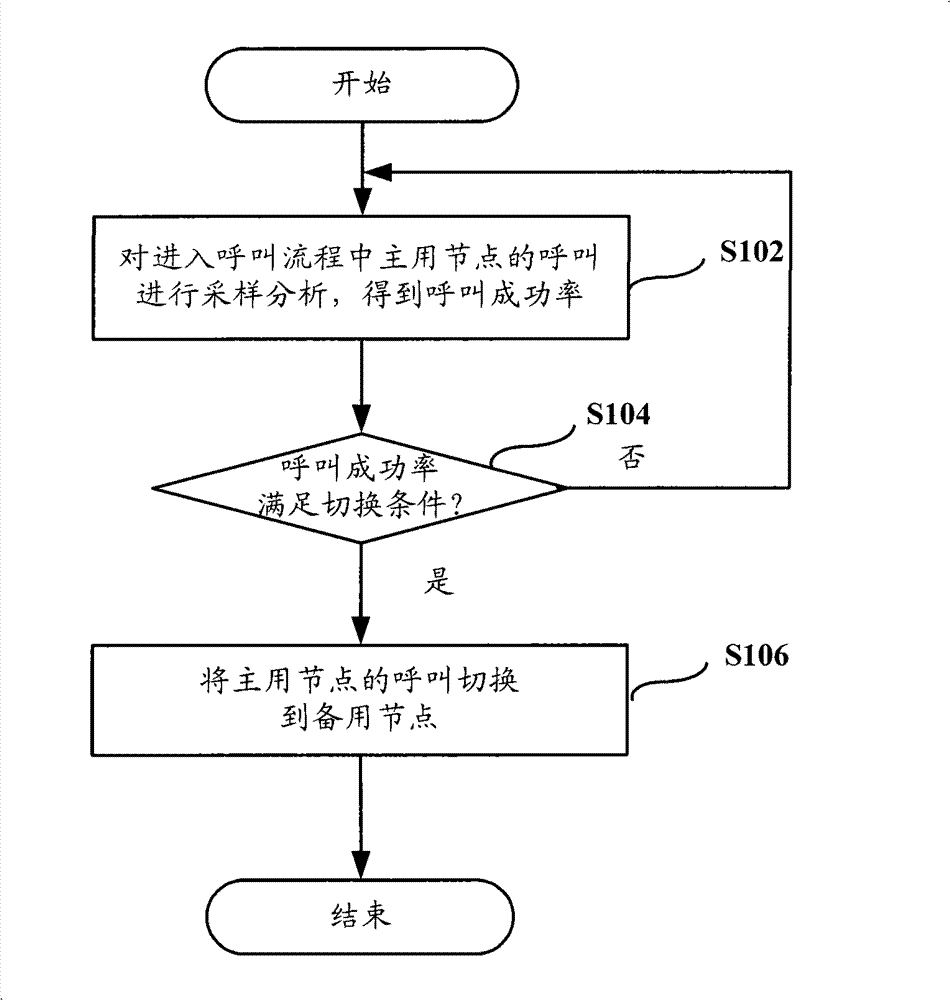

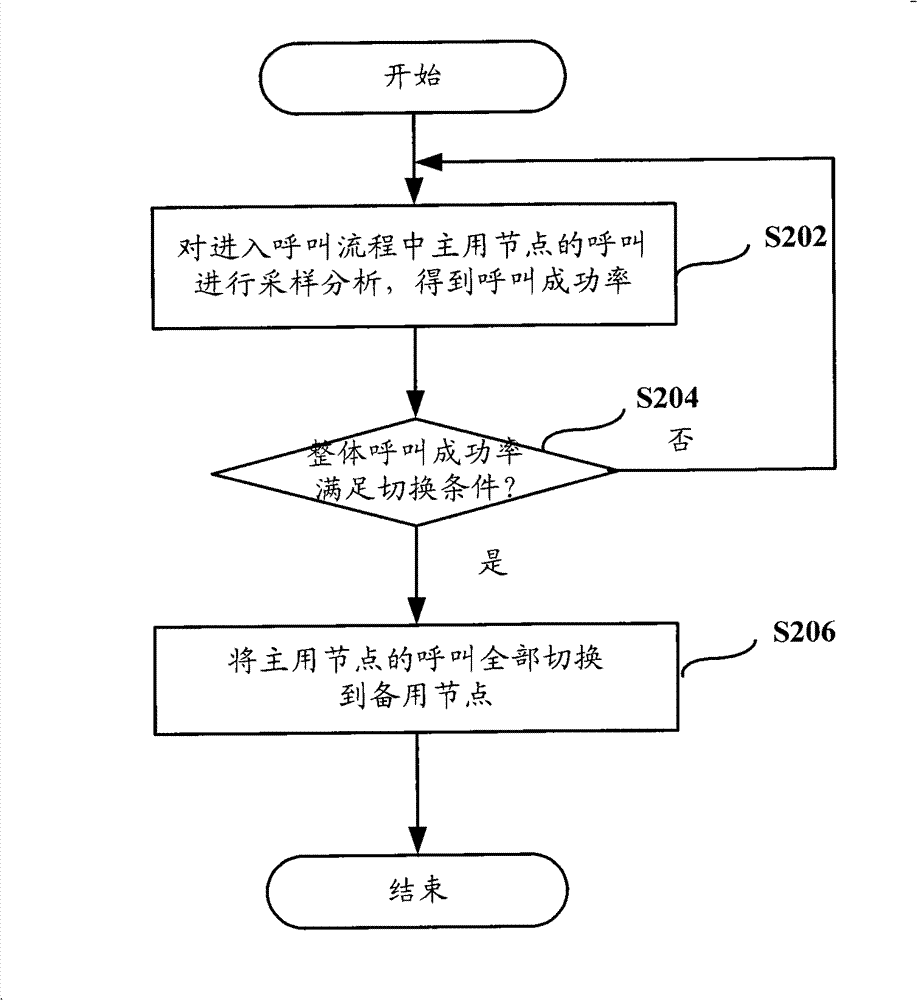

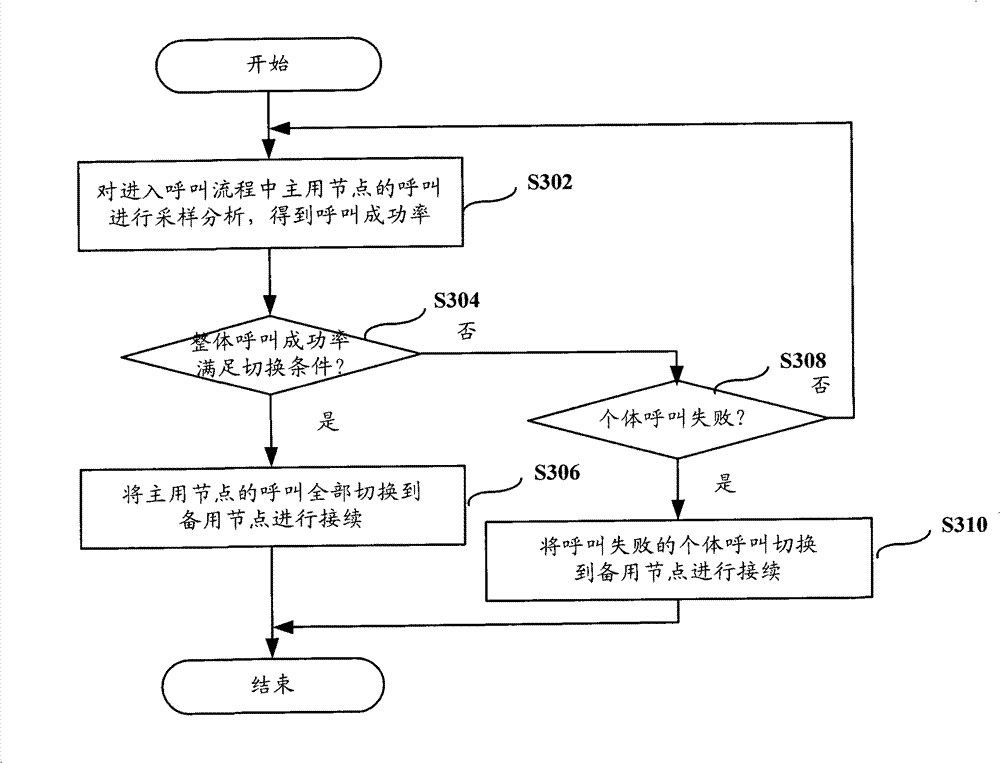

Call flow processing method, device and system

ActiveCN101841609AIncrease success rateGuaranteed connectionSpecial service for subscribersSelection arrangementsQuality of serviceOperating environment

The invention discloses a call flow processing method, a device and a system. The method comprises the following steps: respectively setting a host node and a standby node for each branch node in a call flow; and entering the call of the host node of each branch node in the call flow, switching the call of the host node to the standby node of the branch node after meeting the preset switching condition. The invention solves the problem that data is easy to congest when the call volume is large, reduces the dependence on the operating environment, further improves the success rate of call connection because of considering the failure of individual calls, ensures the normal connection of the individual calls and improves the quality of service.

Owner:CHINA MOBILE GROUP ANHUI

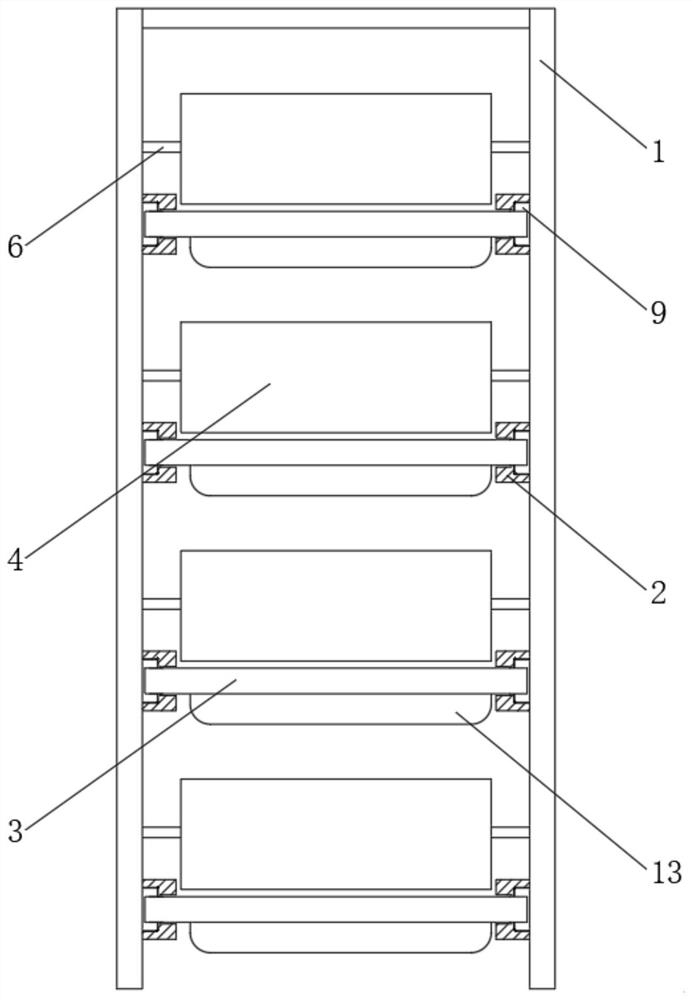

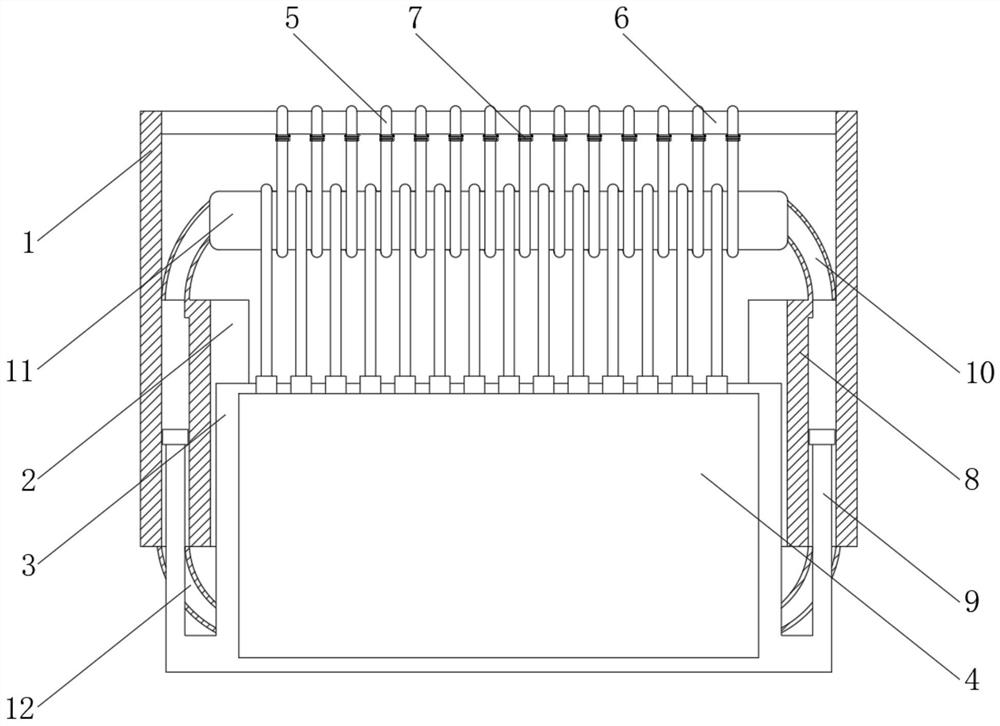

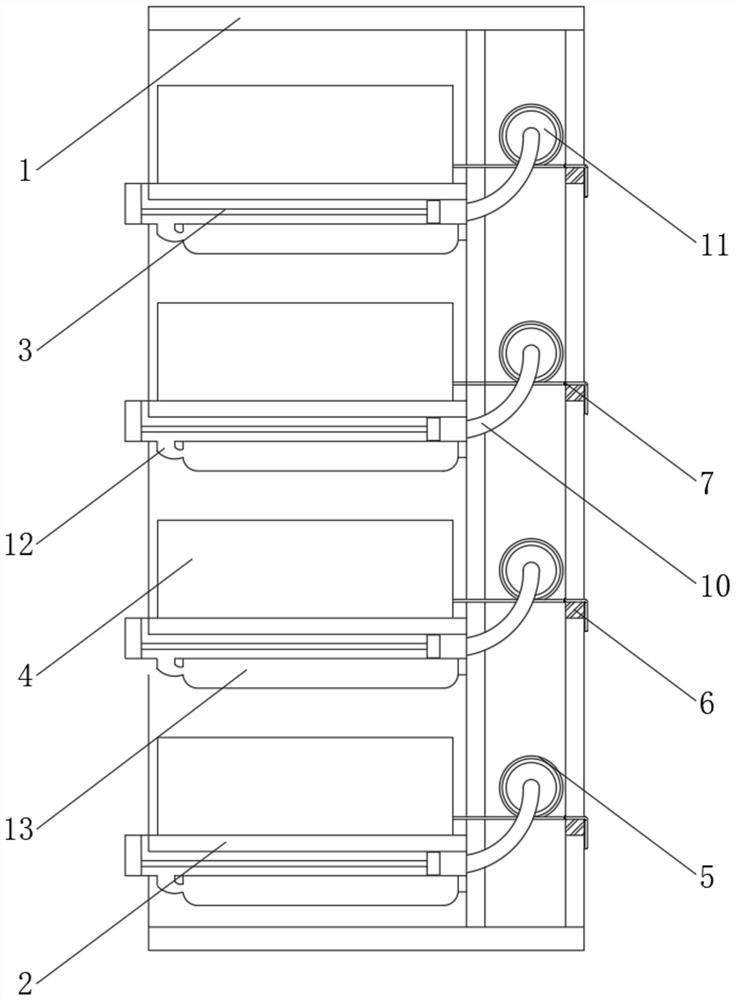

Cloud computing storage rack-mounted server

InactiveCN112105215AOrganize effectivelySection perimeter increasesServersCooling/ventilation/heating modificationsSlide plateCloud computing

The invention relates to the technical field of computers, and discloses a cloud computing storage rack type server which comprises a server rack, sliding rails are fixedly connected to the two sidesof the server rack, a sliding plate is movably connected to the top ends of the sliding rails, a server is placed at the top end of the sliding plate, and an electronic cable is movably connected to the back face of the server. A fixing rod is fixedly connected to the back face of the server rack, a fixing binding belt is fixedly connected to the middle of the electronic cable, the electronic cable is fixed to the fixing rod through the fixing binding belt, and a piston cylinder is fixedly connected to the outer side of the sliding rail. According to the invention, an air bag is additionally arranged to arrange electronic cables with excessive lengths, a piston is connected to the sliding plate, and the movement of the piston is realized by pushing and pulling the sliding plate, so that the perimeter of the section of the air bag filled with gas is increased when the sliding plate is pushed into the rack, and messy electronic cables on the back surface of the server are effectively arranged and stored.

Owner:肇庆悦能科技有限公司

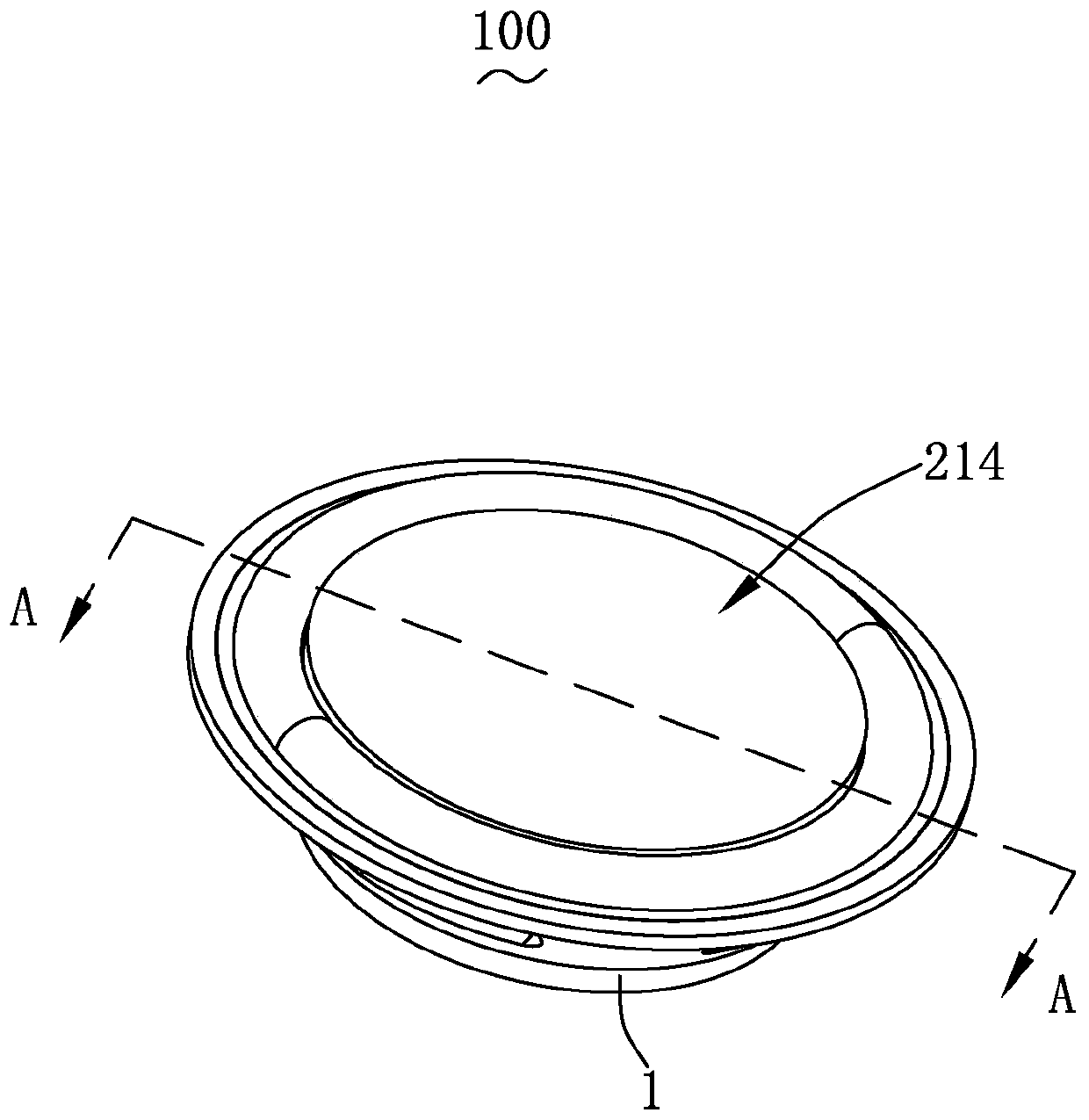

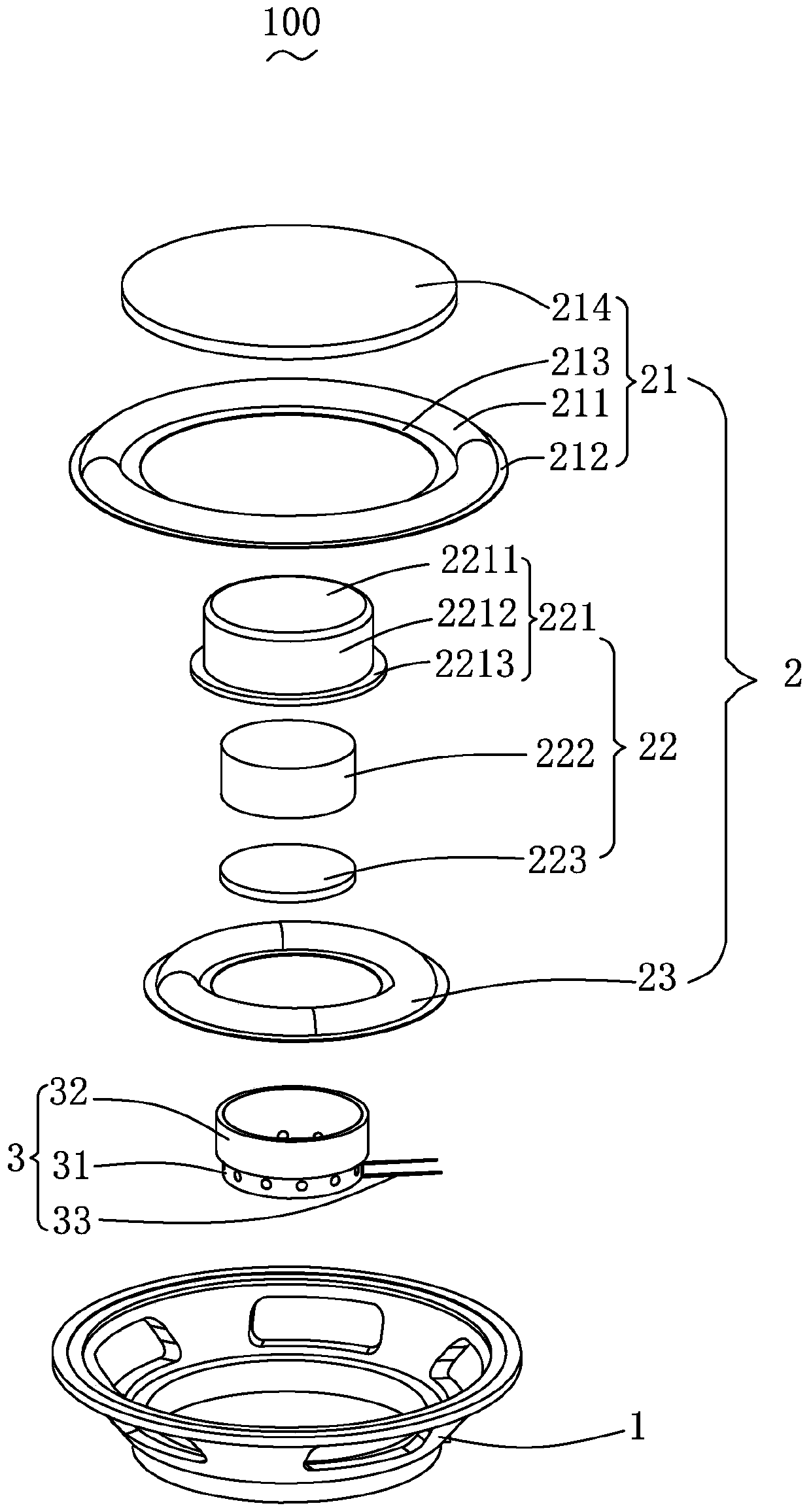

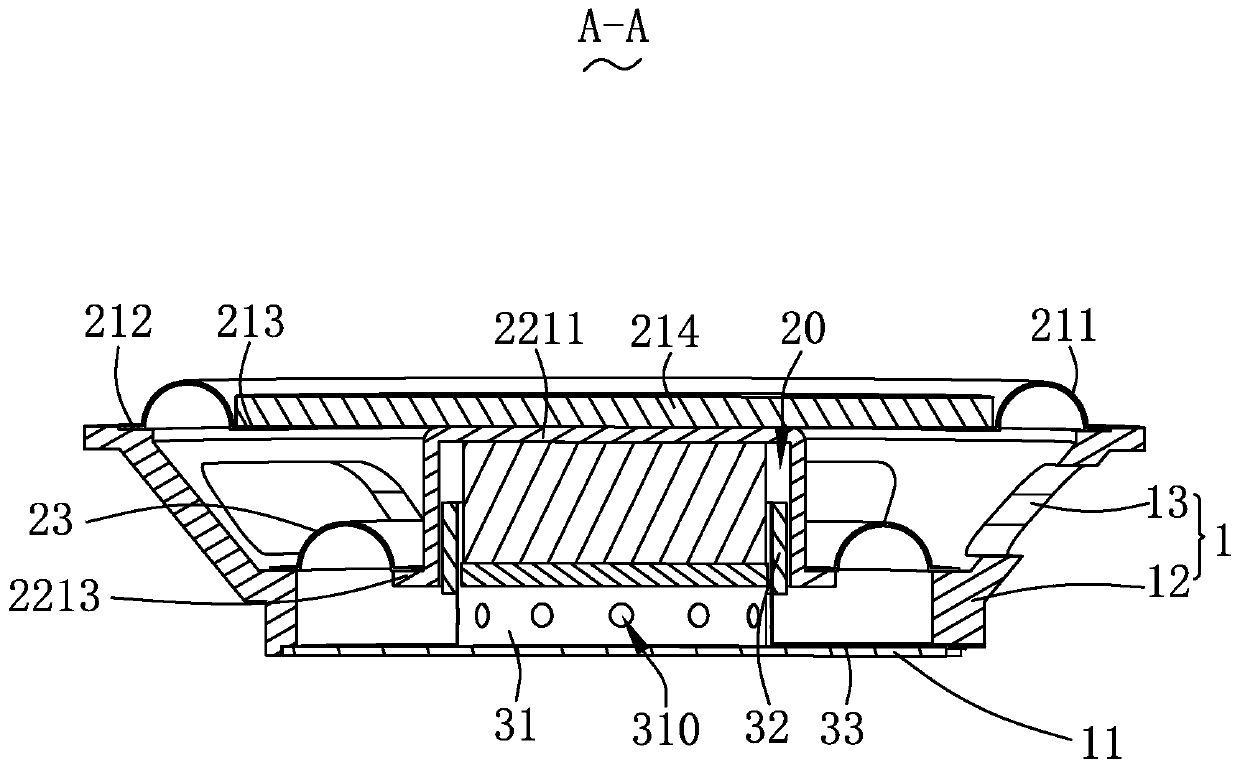

Sound production device

InactiveCN111263281ASimple structureEasy to assembleElectrical transducersEngineeringSound production

The invention provides a sound production device. The sound production device comprises a cone stand, and a vibration system and a voice coil assembly which are respectively fixed on the cone stand. The vibration system comprises a vibrating diaphragm fixed on the cone stand, a magnetic assembly which drives the vibrating diaphragm to vibrate and produce sound and is provided with a magnetic gap,and an auxiliary vibrating diaphragm which is arranged opposite to the vibrating diaphragm at an interval and elastically supports the magnetic assembly. The voice coil assembly is fixed at the side,far away from the vibrating diaphragm, of the cone stand, and at least part of the voice coil assembly is inserted into the magnetic gap. Compared with the prior art, the sound production device is simple in structure, good in reliability and excellent in acoustic performance.

Owner:AAC TECH PTE LTD

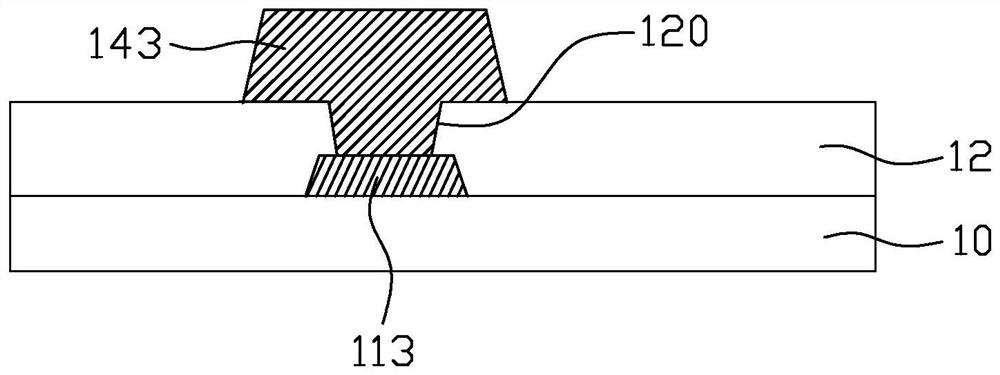

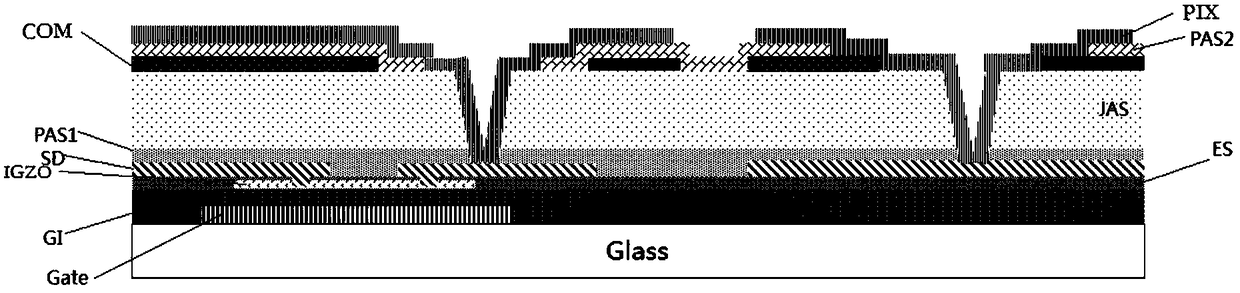

Manufacturing method of array substrate and array substrate

ActiveCN111952250AAvoid undercutAvoid the risk of disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

The invention provides a manufacturing method of an array substrate and the array substrate. A first insulating layer and an active layer film which cover a first metal layer are sequentially formed on a substrate, the etching rate of the active layer film is higher than that of the first insulating layer, and the active layer film and the first insulating layer are stacked up and down. The activelayer thin film is used as a guide layer of the first insulating layer during trepanning, and the active layer thin film and the first insulating layer are trepanned at the positions corresponding tothe first contact holes, so that the first contact holes penetrating through the active layer thin film and the first insulating layer from top to bottom can be formed. The etching rates of the active layer film and the first insulating layer are different, through the guidance of the active layer film during trepanning, the good taper angles can be obtained at the positions of the first contactholes while the undercut problem of the first insulating layer below is avoided, so that the risk of breakage of the second metal layers subsequently filled into the first contact holes is avoided, the product yield is effectively improved, a new photomask is not needed, and the cost is saved.

Owner:KUSN INFOVISION OPTOELECTRONICS

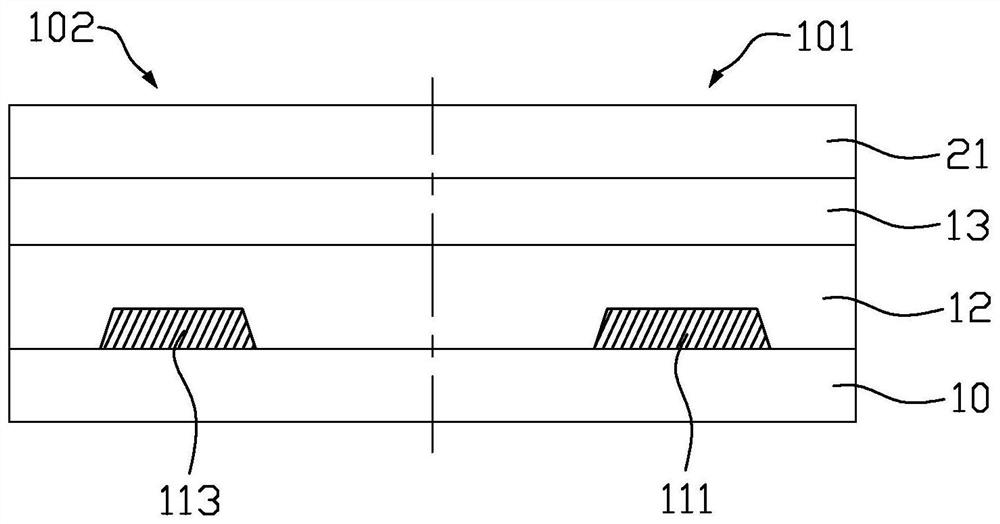

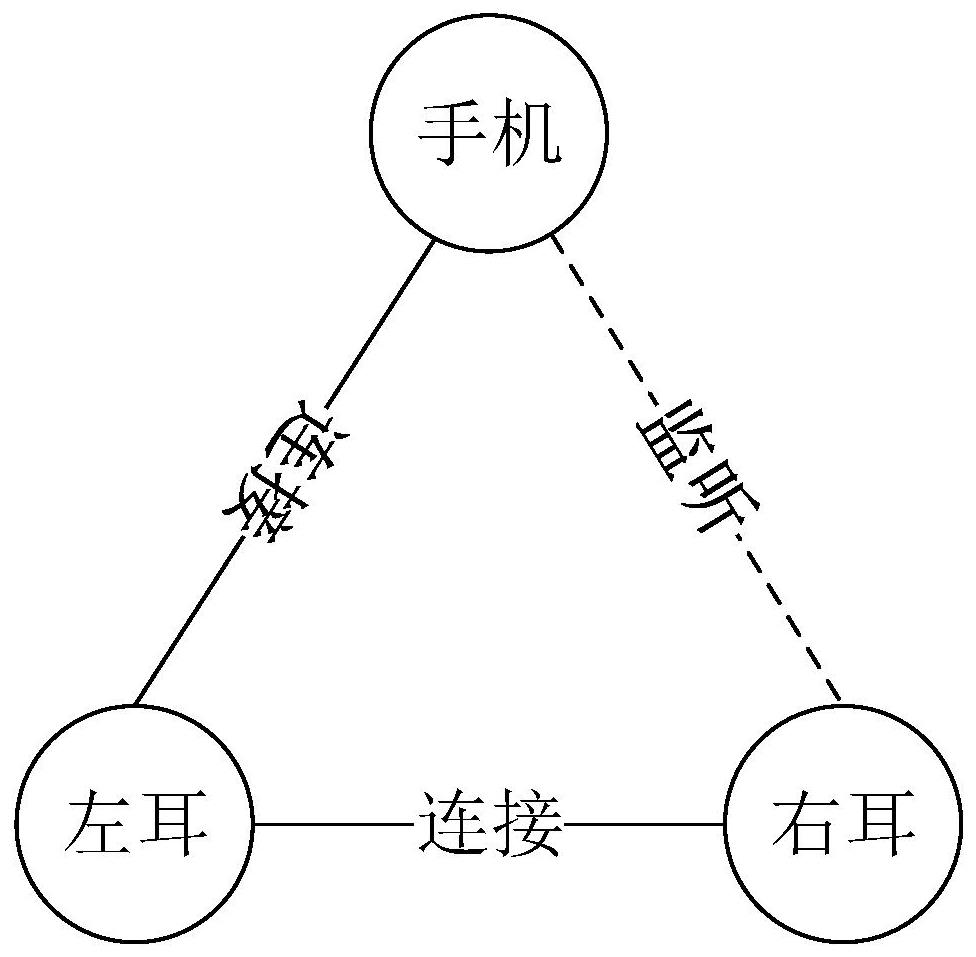

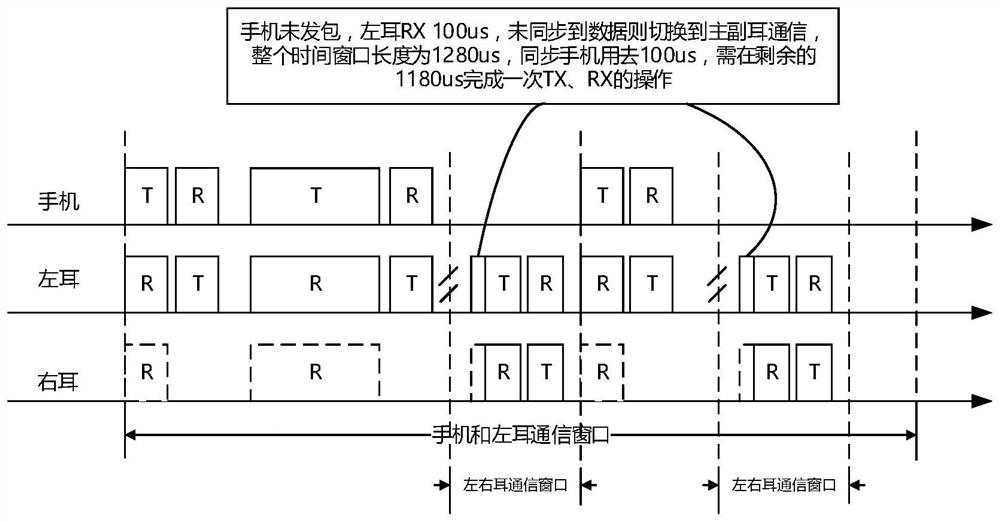

Main and auxiliary earphone communication method of TWS earphone and TWS earphone

PendingCN114449661AImprove communication performanceAvoid retransmissionHeadphones for stereophonic communicationEarpiece/earphone mechanical/electrical switchesHeadphonesComputer science

The invention discloses a main and auxiliary earphone communication method of a TWS earphone and the TWS earphone, and the method comprises the following steps: a main earphone establishes a Bluetooth connection with an intelligent device, the main earphone establishes a main and auxiliary connection with an auxiliary earphone, and the auxiliary earphone monitors communication data of the main earphone and the intelligent device by receiving an air signal; switching to main and auxiliary earphone communication in an idle time slot of communication between the main earphone and the intelligent equipment; and after the main earphone and the auxiliary earphone are switched to communicate, the main earphone and the auxiliary earphone send and receive data, and after a first preset time interval, the main earphone is switched to communicate with the intelligent equipment. According to the embodiment of the invention, communication between the left ear and the right ear is carried out by effectively utilizing the idle time slot of communication between the mobile phone and the left ear, communication between the left ear and the right ear can be completed under the condition that the performance of communication between the mobile phone and the left ear is not influenced, and a TWS earphone function is realized.

Owner:珠海慧联科技有限公司

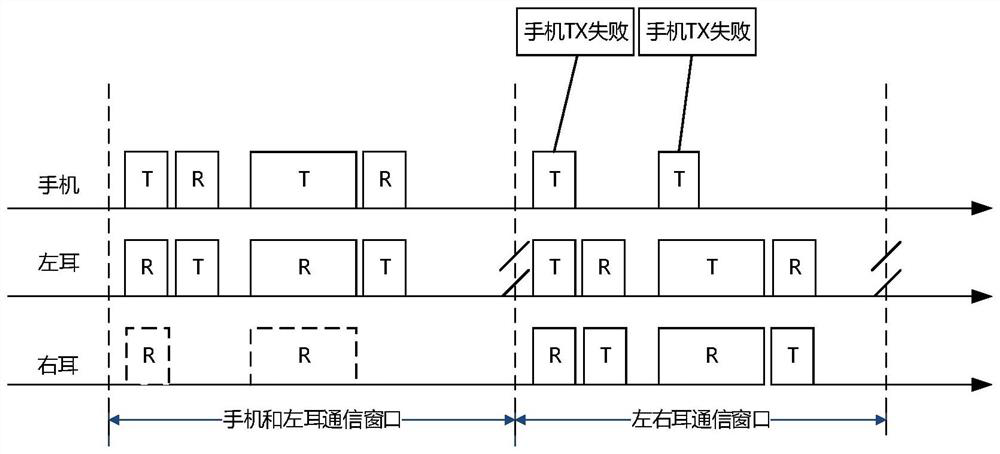

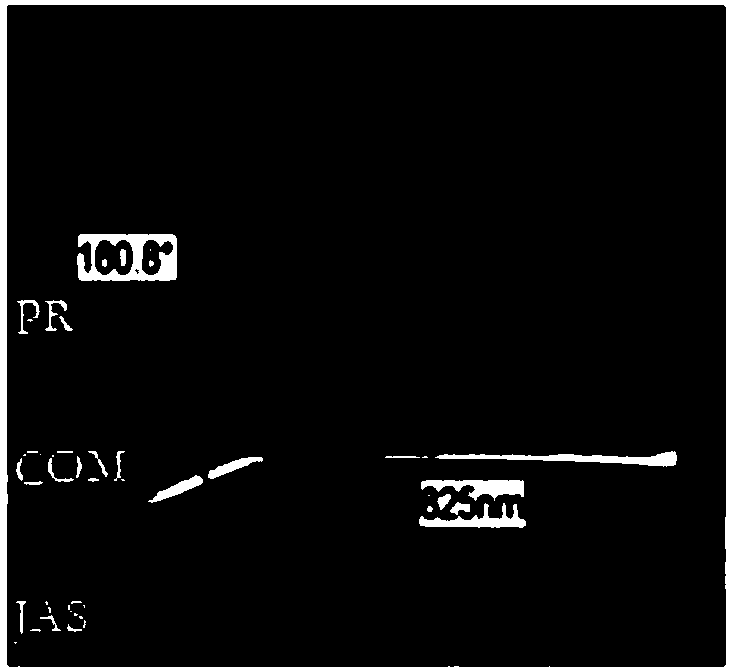

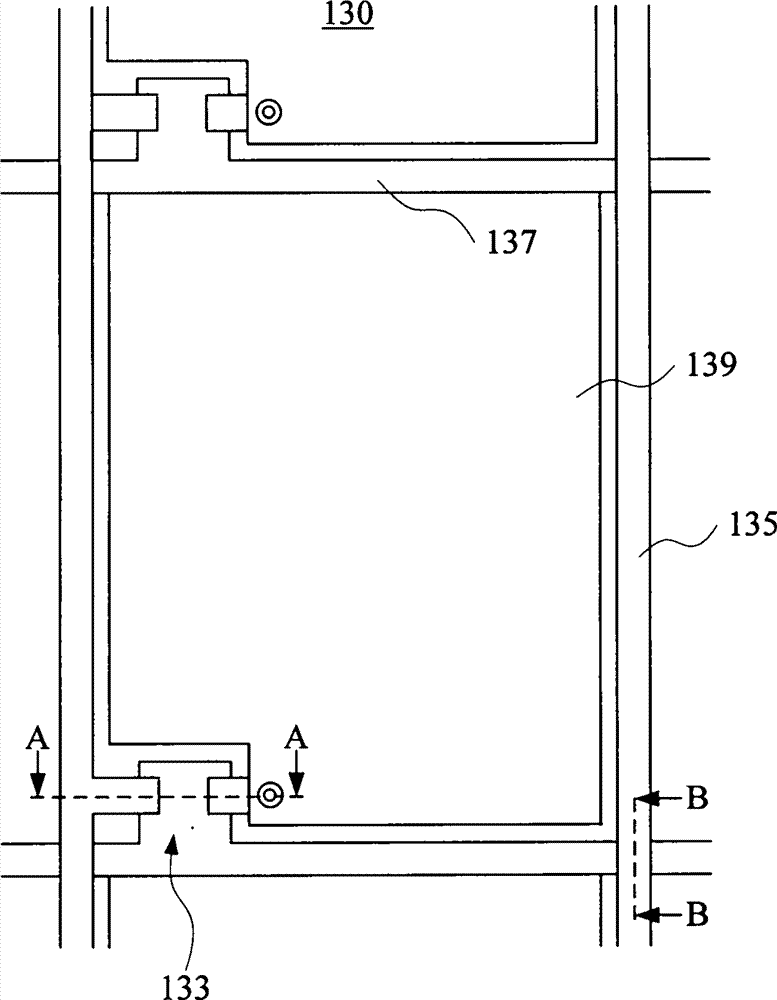

Embedded touch control panel and manufacturing method thereof

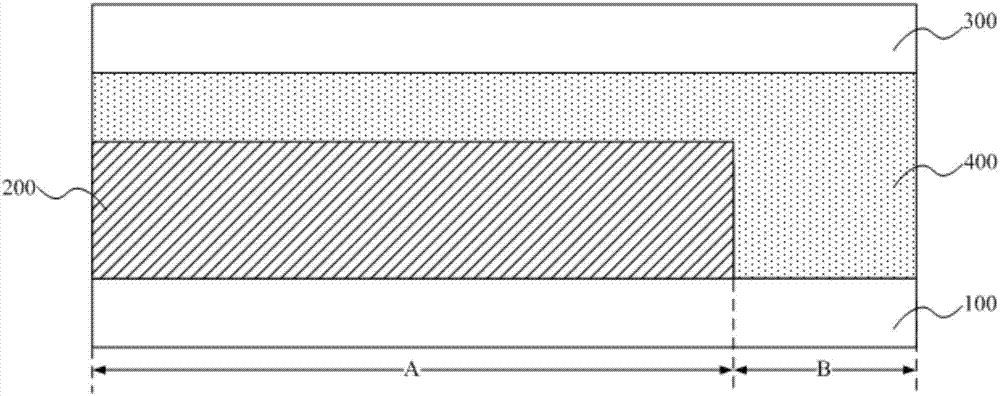

InactiveCN108493193ASolution to the risk of disconnectionAvoid the risk of disconnectionSolid-state devicesNon-linear opticsElectricityEngineering

The invention discloses an embedded touch control panel and a manufacturing method thereof. The method comprises the steps that a first metal layer, a semiconductor layer, a second metal layer, a first insulating layer, a flat layer, a first conductive layer, a second insulating layer and a second conductive layer are formed successively; the apertures of first and second holes in the second insulating layer are lower than the aperture of a common electrode hole in the first conductive layer, the second insulating layer covers the first conductive layer completely, a third hole is formed in the second insulating hole, and the first conductive layer is electrically connected with the second conductive layer via the third hole. Thus, the problem that the second conductive layer PIX tends tobreakage is solved effectively.

Owner:NANJING CEC PANDA FPD TECH CO LTD

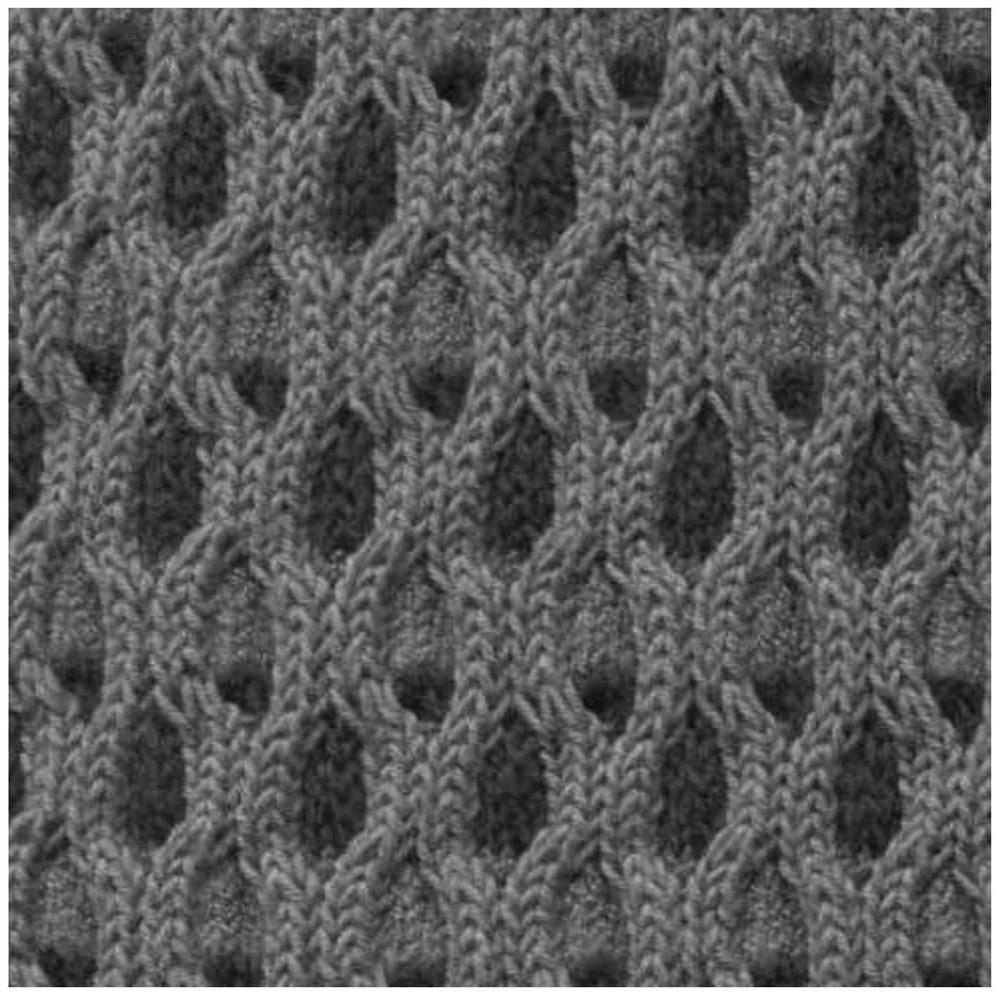

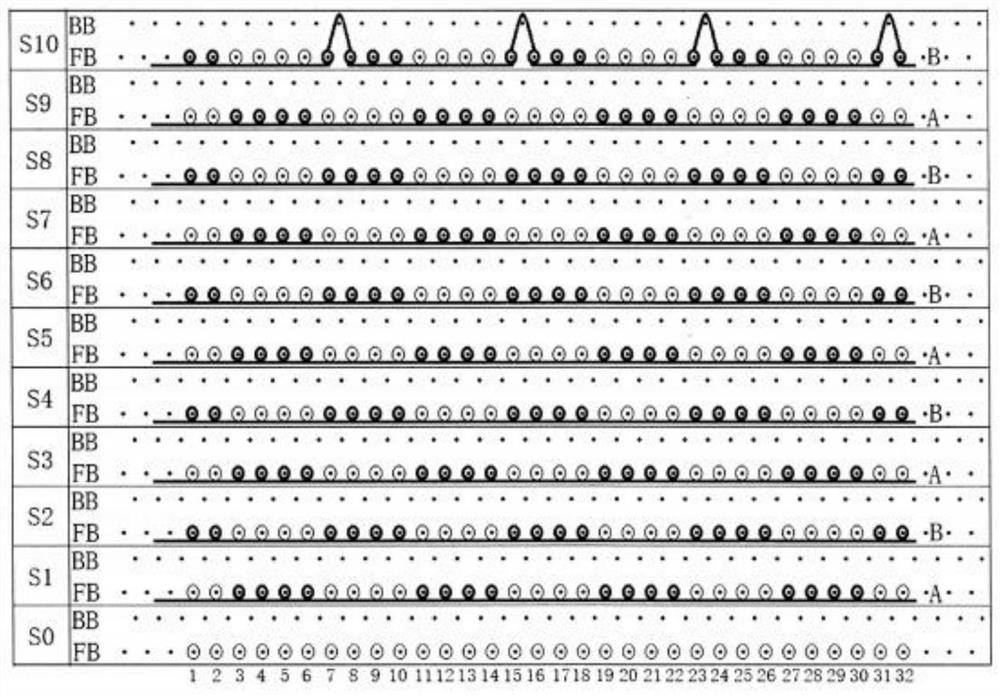

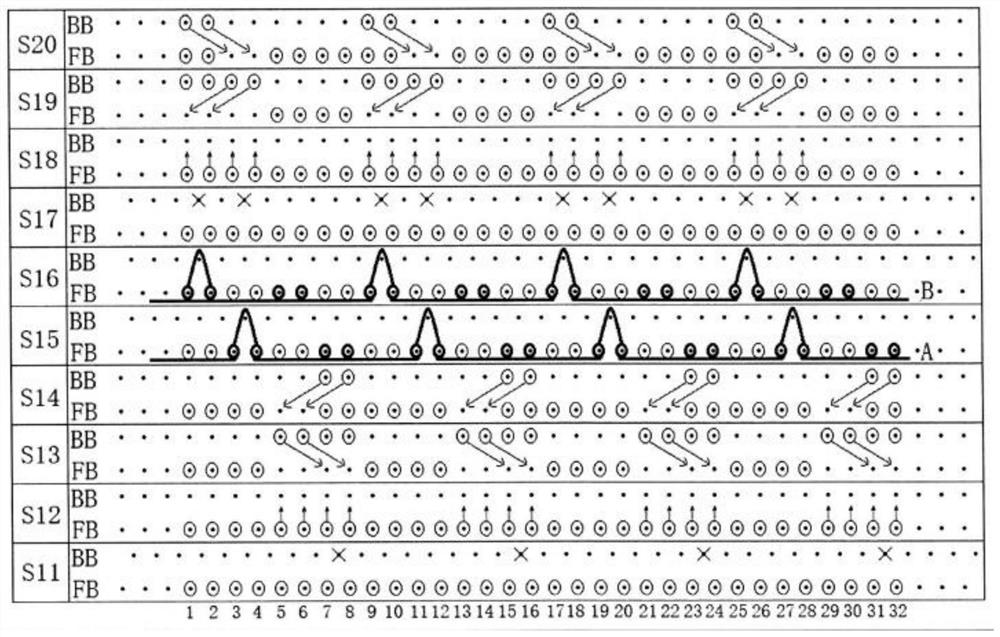

Method for knitting grid knitted fabric composed of bent stripes

PendingCN112831900ASmooth appearanceIncrease the lengthWeft knittingEngineeringStructural engineering

The invention discloses a method for knitting a grid knitted fabric composed of bent stripes. According to the invention, on the basis of knitting two-color longitudinal stripe weaves which are staggered with each other, by multiple times of twisted pattern knitting, an A-color loop is inclined on part of a knitting transverse row and is always positioned on the front surface of the knitted fabric, and a B-color loop or other-color loop is always located on the reverse side of the knitted fabric; meanwhile, in the process of twisted pattern knitting, in order to avoid the risk of thread breakage caused by the falling arc of the excessively-stretched loops, the same-color loops which are originally located on the same knitting transverse row and move leftwards and rightwards are changed into loops located on different knitting transverse rows; and in addition, for the loop with the relatively large loop transfer stitch length, loop hanging and knocking-over treatment is performed on part of knitting needles, so that the length of the loop can be increased, the knitting process is smooth, and the appearance of the knitted fabric is smooth.

Owner:HUIZHOU UNIV

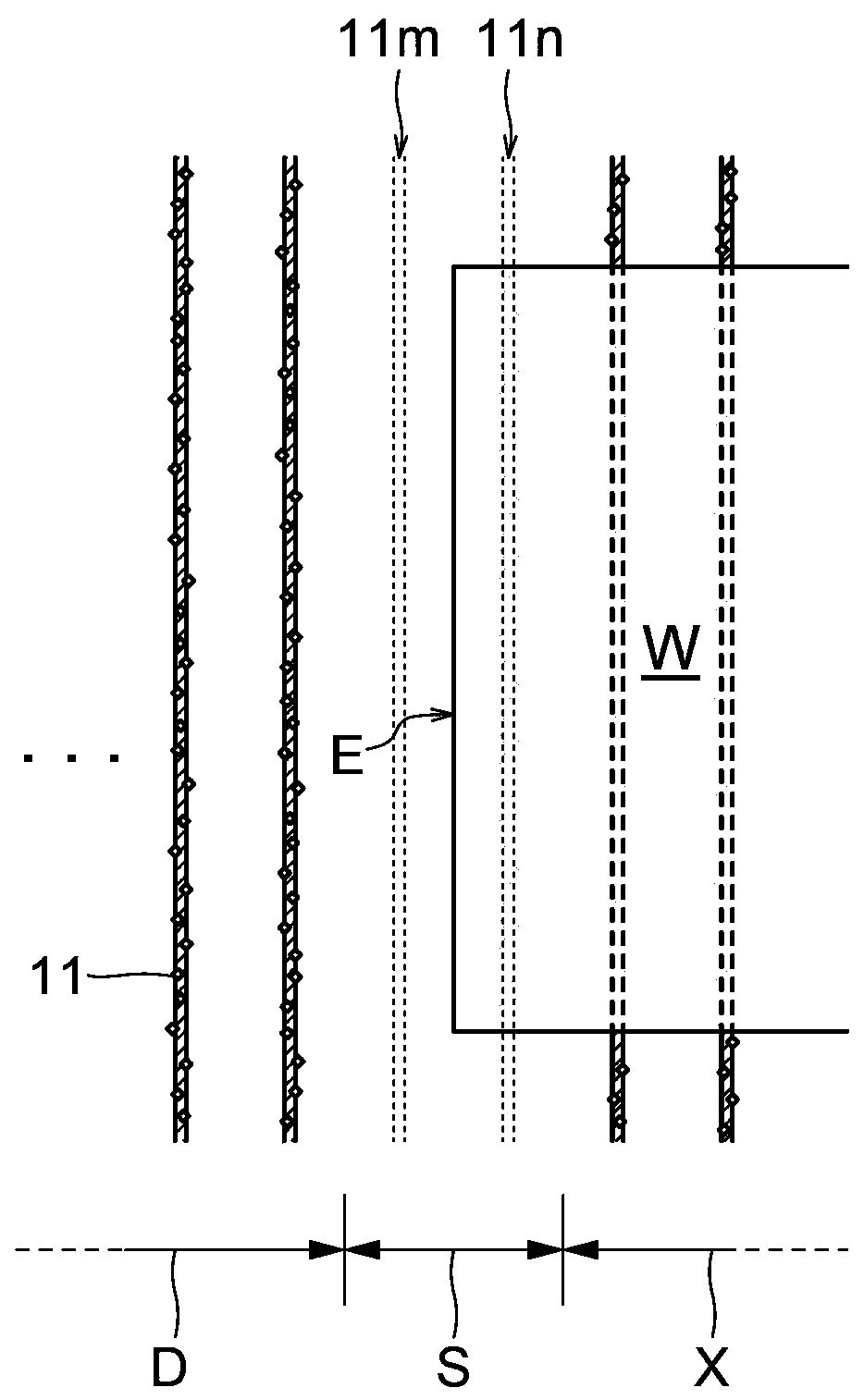

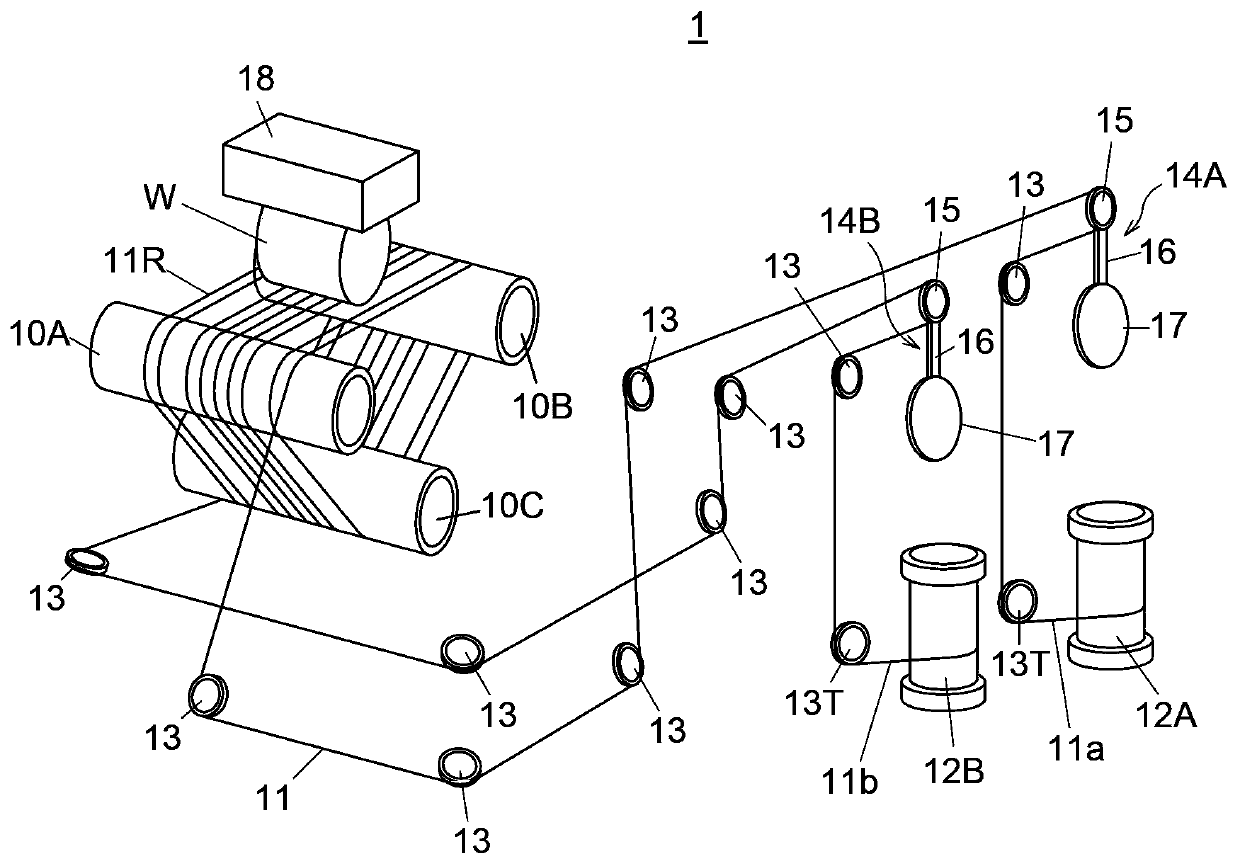

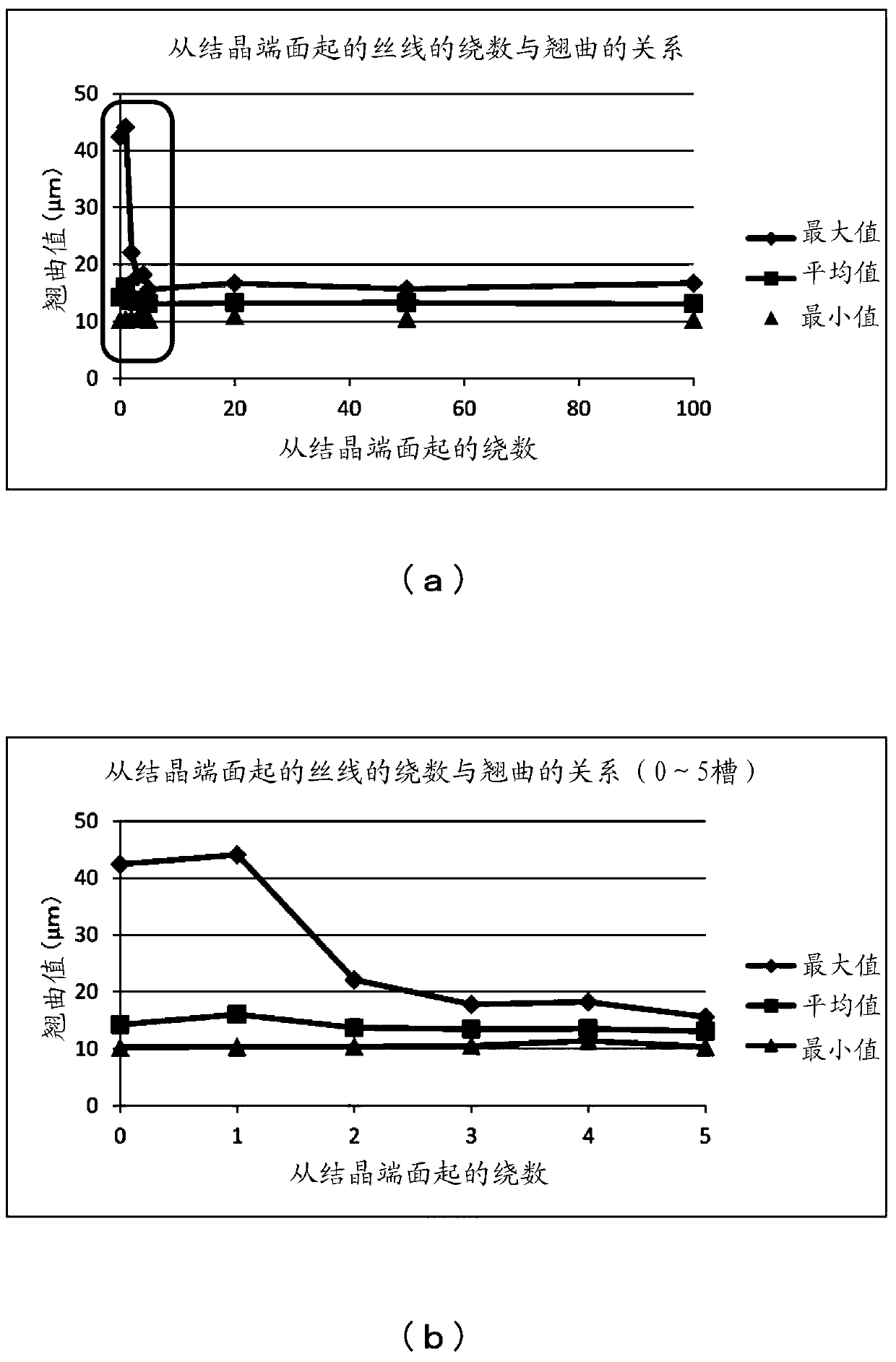

Cutting method of workpiece

ActiveCN107443599BAvoid the risk of disconnectionImprove qualityWorking accessoriesFine working devicesWire rodEngineering

The invention realizes prevention of wire materia cutting-off risk and quality improvement of wafers at two ends of a workpiece. The workpiece cutting-off method is characterized in that wire material row (11R) is formed through hanging a wire (11) between a plurality of parallel main rollers (10A,10B) by multiple times; the workpiece is machined to a wafer-shaped member through abutting against a wire row (11R) in an advancing state by the workpiece (W); and a wire saw is utilized. The wire row (11R) comprises the components of a real wire arranging area (X), wherein in a workpiece cutting-off area which is closer to inside than two ends of the workpiece, the wires (11) are arranged in a certain distance and contact with the workpiece in performing cutting-off processing on the workpiece; a wire jumping area (S) which is next to two ends of the workpiece, and the wires (11) are not arranged in a certain distance; and a first pseudo wire arranging area (D) which is outside the wire jumping area (S), wherein after more than two wires (11) are arranged in the certain distance, the wires are leaded to outside the hanging ring of the plurality of main rollers, and the wires do not contact with any workpiece in cutting-off the workpiece.

Owner:SUMCO CORP

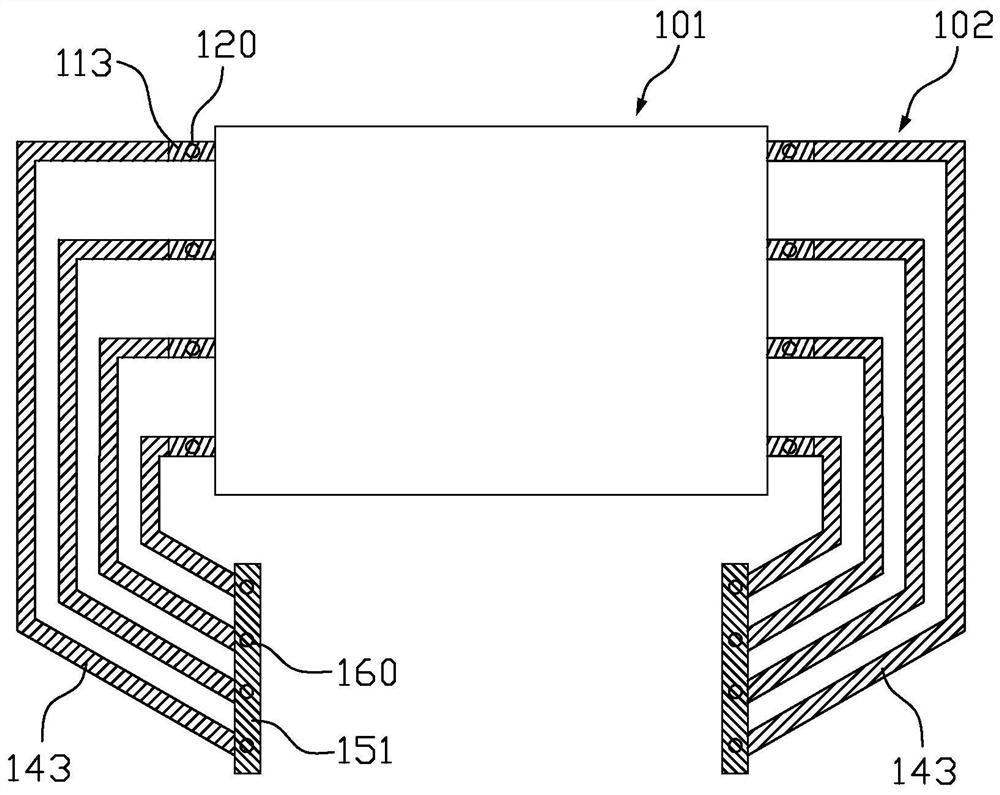

A kind of flexible display panel and flexible display device

ActiveCN107316881BGuaranteed bending performanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention discloses a flexible display panel and a flexible display device, comprising: a flexible base substrate having a display area and a pad area, and a plurality of display elements arranged on the display area of the flexible base substrate. By covering the display area and pad area of the entire flexible substrate substrate with the protective film, and directly setting the adhesive layer in the space between the protective film and the display element and the space between the pad area of the flexible substrate substrate and the protective film In such a way that there is only a single adhesive in the soldering area between the flexible substrate substrate and the protective film. When the flexible display panel is bent under force, it can ensure that the strain neutral layer in the welding area of the flexible display panel is located at the adhesive layer, avoiding cracks and disconnection of the signal lines located in the welding area due to excessive stress risk; and by controlling the elastic modulus of the adhesive layer in the range between 0.5MPa-10MPa, the adhesive layer has better flexibility to ensure the bending performance of the flexible display panel.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

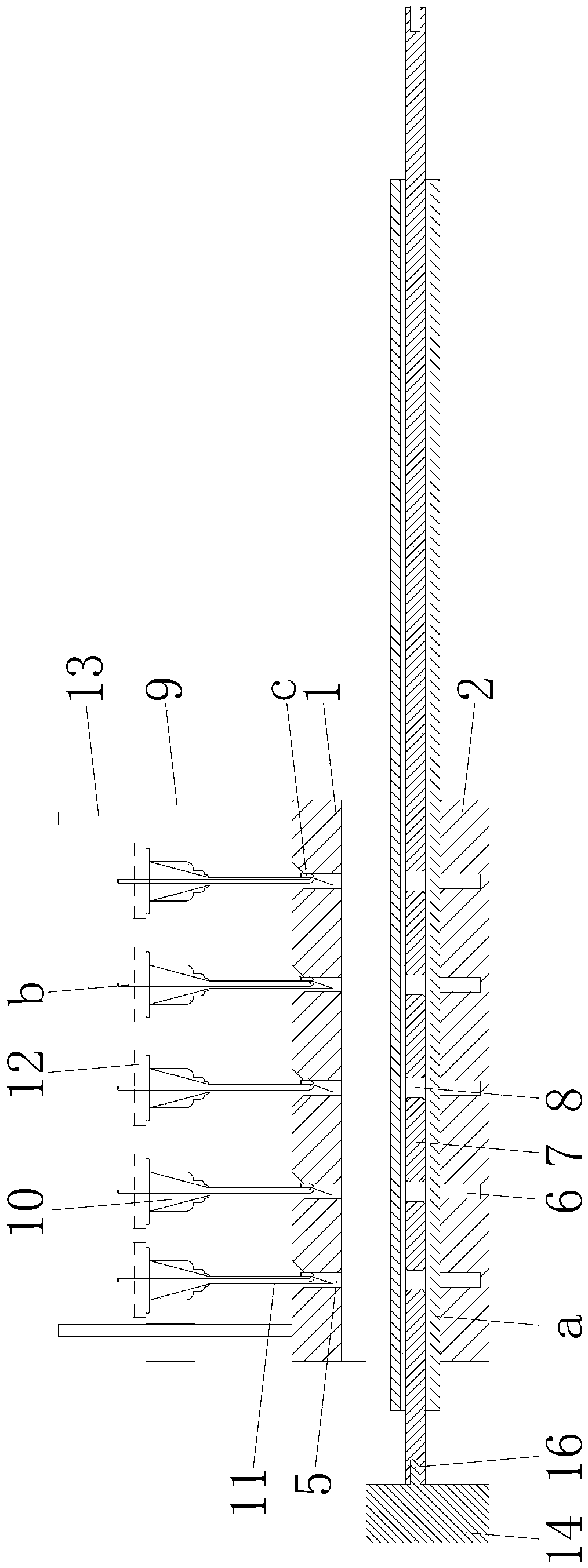

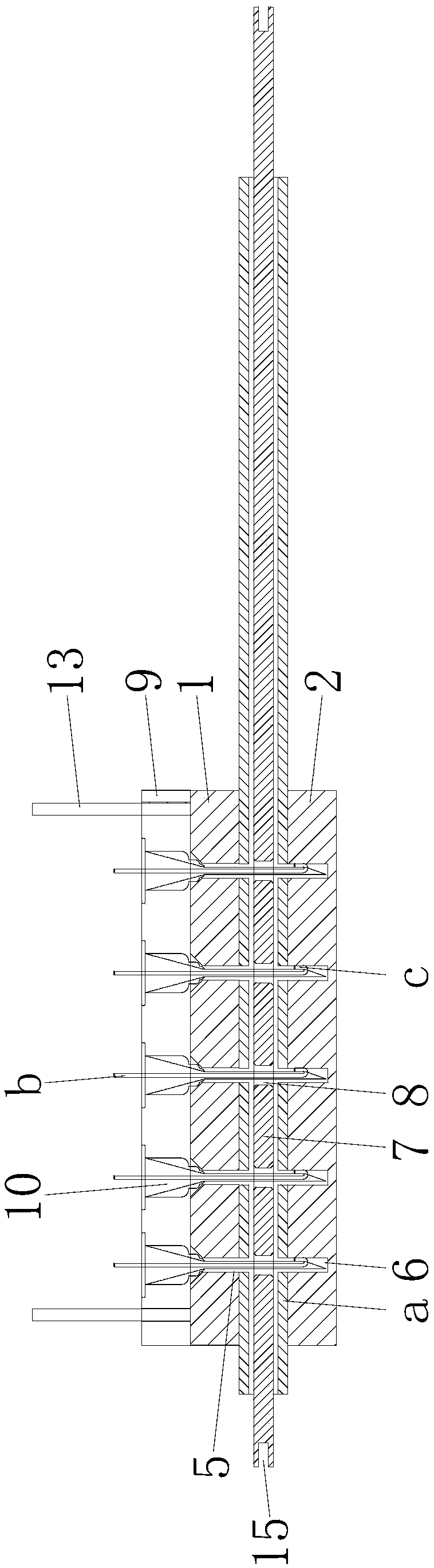

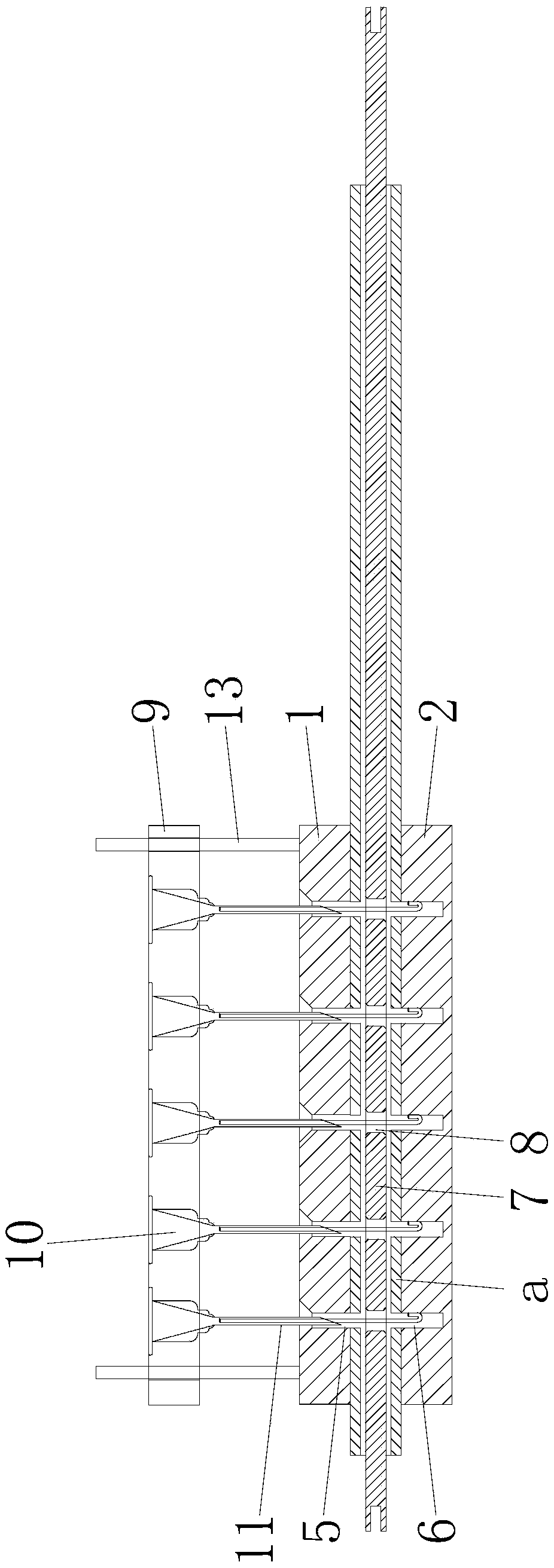

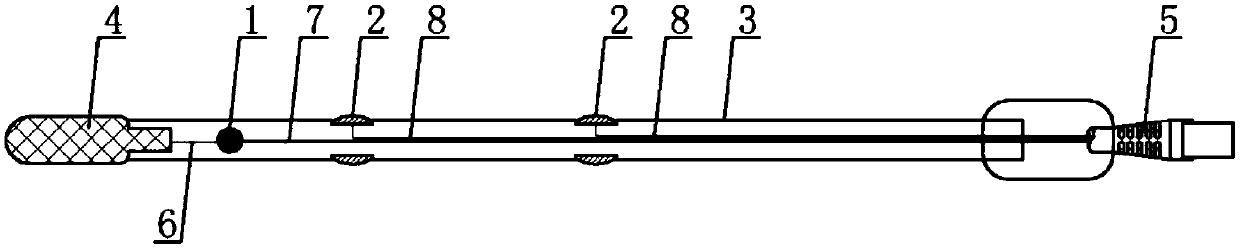

A device and a method for laying a lead by an electrode cathete

The invention provides a device and a method for laying a lead by an electrode catheter, and belongs to the technical field of medical device processing. The invention solves the problems of low threading efficiency and low reliability of the existing electrode catheters in multi-section sequential threading. the device comprises an upper mold and a lower mold, A low mold has a mounting groove, the upper mold is provided with a mounting groove 2 arranged opposite to the mounting groove 1, the mounting groove 1 and the mounting groove 2 form a mounting hole for mounting a conduit when the uppermold and the lower mold are buckled, the upper die is provided with a plurality of guide holes 1 distributed along the length direction of the mounting holes, A guide hole 1 is vertically arranged and the lower end is communicated with the mounting groove 2, The upper mold is provided with a punching and threading structure for piercing the catheter and threading the conductor into the catheter,and the mounting hole is provided with a pulling wire structure for pulling the conductor into the catheter out from one end of the catheter; and the laying method comprises fixing the catheter, threading the pulling shaft, punching and threading, withdrawing the hollow needle, pulling the wire and winding the wire, and the like. The invention has the advantages of wide application range, high working efficiency and high reliability.

Owner:重庆金山医疗技术研究院有限公司

A kind of three-dimensional storage device and its preparation method

ActiveCN109326600BUniform or increased thicknessLower the resistance valueSolid-state devicesSemiconductor devicesStructural engineeringMechanical engineering

Owner:YANGTZE MEMORY TECH CO LTD

Silicone diaphragm, speaker module and method for reprocessing the silica gel diaphragm

ActiveCN104853294BNot easy to fall offImprove conductivityPlane diaphragmsCircuit lead arrangements/reliefLaser etchingEngineering

The invention discloses a silica gel diaphragm, a loudspeaker module and a method for reprocessing the silica gel diaphragm. The silica gel diaphragm adopts laser etching technology to etch two symmetrical line grooves on its surface; each line groove is A conductive metal layer is deposited, and the two ends of each conductive metal layer are provided with a first welding part and a second welding part. The first welding part is deposited on the plane part of the silicone diaphragm near the ring part, which is used for the voice coil The winding tap of the voice coil is welded on the inner side; the second welding part is deposited on the fixed part of the silicone diaphragm for welding the pad on the shell; the middle part connecting the first welding part and the second welding part is deposited in the silicone diaphragm Form a conductive path. The technical solution of the present invention can solve the problem of poor acoustics caused by the collision of the voice coil lead wires in the traditional solution, avoid the risk of voice coil lead wire breakage, and improve the acoustic performance and stability of the product; and the conductive metal layer deposited in the wire slot has a relatively high Good compactness, high uniformity, superior electrical conductivity.

Owner:GOERTEK INC

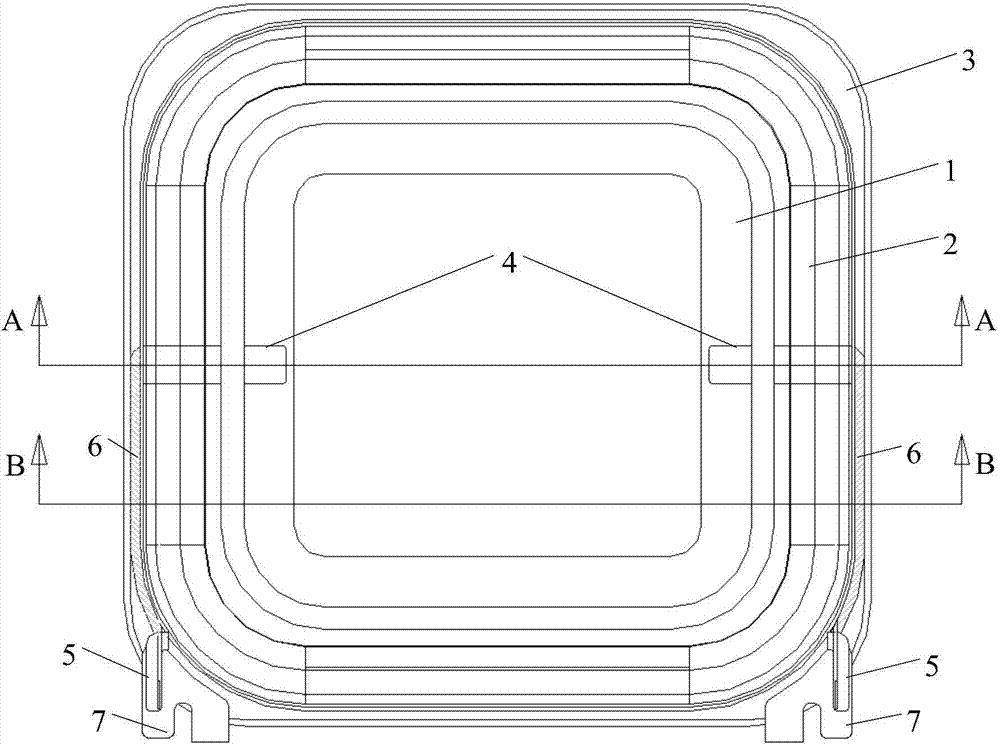

An array substrate and its manufacturing method, and a display panel using the array substrate

ActiveCN102306652BAvoid the risk of disconnectionDefects to prevent disconnectionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

The invention relates to the panel display technology field, especially relating to an array substrate which comprises a second transparent substrate which has a plurality of third surfaces forming a plurality of accommodation space, and a plurality of film transistors and grid lines which are formed on the second transparent substrate. The film transistors comprise grids. The grids on a same line connect with the grid lines, and both of them are accommodated in the accommodation space. In addition, the invention provides an array substrate manufacturing method and a display panel using the array substrate.

Owner:SHENZHEN LAIBAO HI TECH

Impedance-pH electrode catheter and processing method thereof

The invention provides an impedance-pH electrode catheter and a processing method thereof, which belong to the technical field of medical instruments. The problems that an existing impedance-pH electrode catheter is unreliable in quality and complex in machining procedure are solved. The impedance-pH electrode catheter comprises a catheter body provided with an antimony electrode and an impedancecomponent arranged at the side part; a reference electrode is arranged at the front end of the catheter body; a connecting module is arranged at the rear end of the catheter body; an insulated wire I,an insulated wire II and an insulated wire III are arranged in the catheter body in a penetrating manner; an annular positioning groove is formed in the side portion of the catheter body, the impedance component is annular and positioned in the positioning groove, a through hole communicated with an inner cavity of the catheter body is formed in the bottom of the positioning groove, the front endof the insulated wire III penetrates out of the through hole and then is connected with the impedance component, raw materials are poured into the positioning groove in the machining process, and theimpedance component is formed in a heating curing mode. The electrode catheter has the advantages of reliable quality, high processing efficiency and the like.

Owner:重庆金山医疗技术研究院有限公司

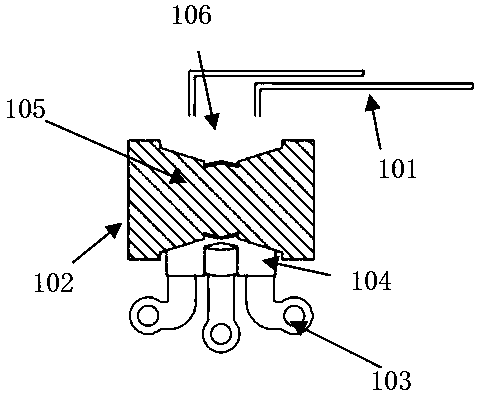

Automatic one-way valve element assembling machine

InactiveCN112959038AAvoid the risk of disconnectionGuaranteed to coverMetal working apparatusEngineeringMachine

The invention discloses an automatic one-way valve element assembling machine. The automatic one-way valve element assembling machine structurally comprises a conveying belt, a base, a fixing plate, a clamping jaw and side plates, the conveying belt is connected to one end of the base, the two side plates are connected to the other end of the base, the fixing plate is connected to the side plates, the clamping jaw is installed on the fixing plate, and a clamping mechanism is provided with a pipe hoop and an auxiliary device. The pipe hoop and the auxiliary device are matched on a progressive body, when the outer circumference of a spring is welded to a valve element, the bottom of the spring can be bent in the auxiliary device due to pressing and rotate and hook in the auxiliary device, the auxiliary device is driven to run in and drive the pipe hoop to rotate upwards to be attached to the outer circumference of the spring, and the risk that the spring is disjointed during welding is avoided.

Owner:李德水

Call flow processing method, device and system

ActiveCN101841609BIncrease success rateGuaranteed connectionError preventionQuality of serviceOperating environment

The invention discloses a call flow processing method, a device and a system. The method comprises the following steps: respectively setting a host node and a standby node for each branch node in a call flow; and entering the call of the host node of each branch node in the call flow, switching the call of the host node to the standby node of the branch node after meeting the preset switching condition. The invention solves the problem that data is easy to congest when the call volume is large, reduces the dependence on the operating environment, further improves the success rate of call connection because of considering the failure of individual calls, ensures the normal connection of the individual calls and improves the quality of service.

Owner:CHINA MOBILE GROUP ANHUI

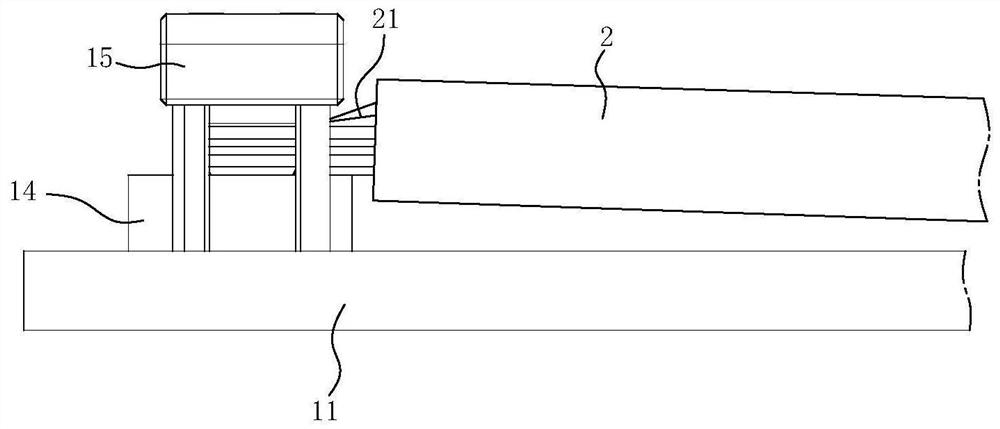

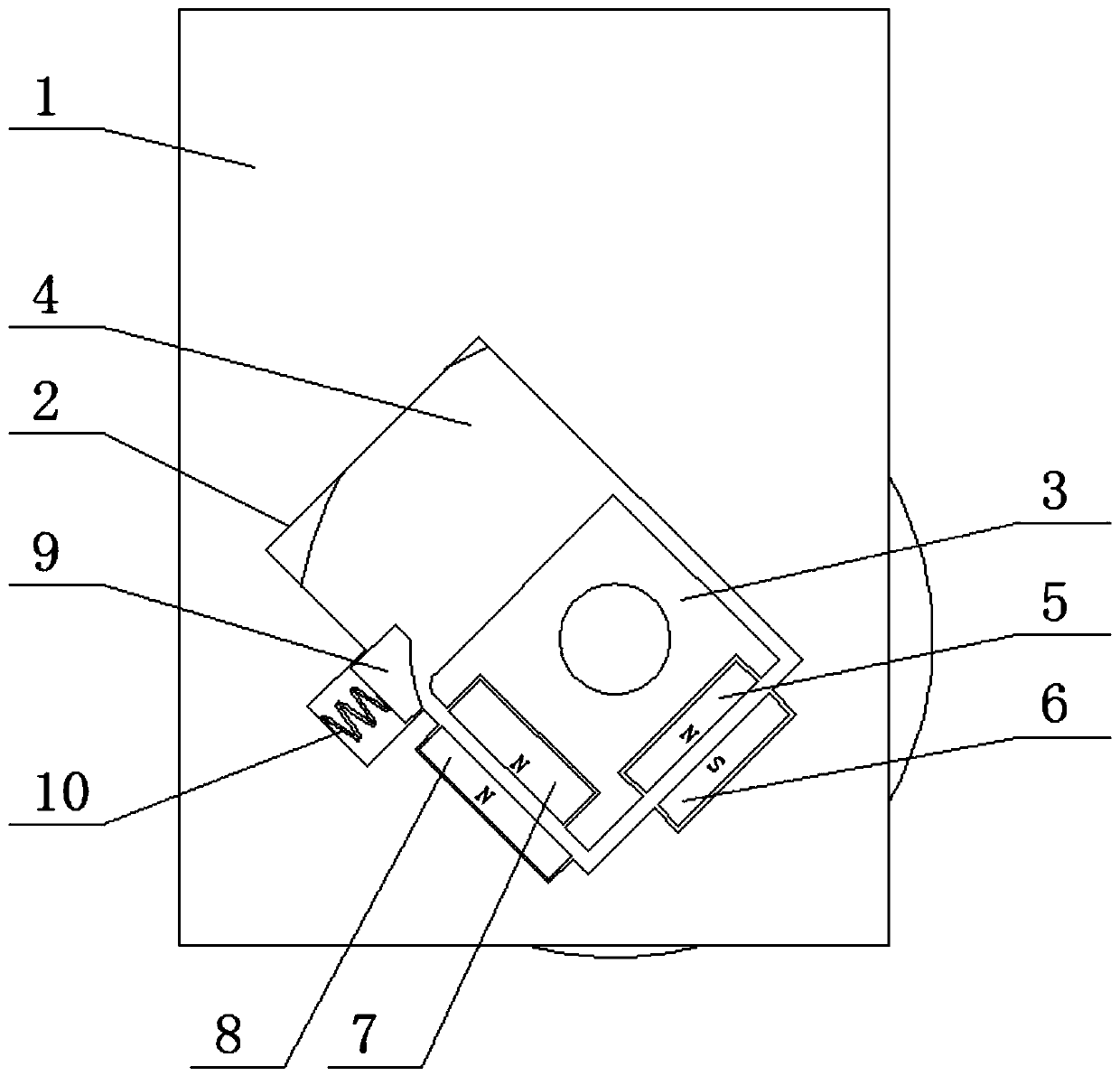

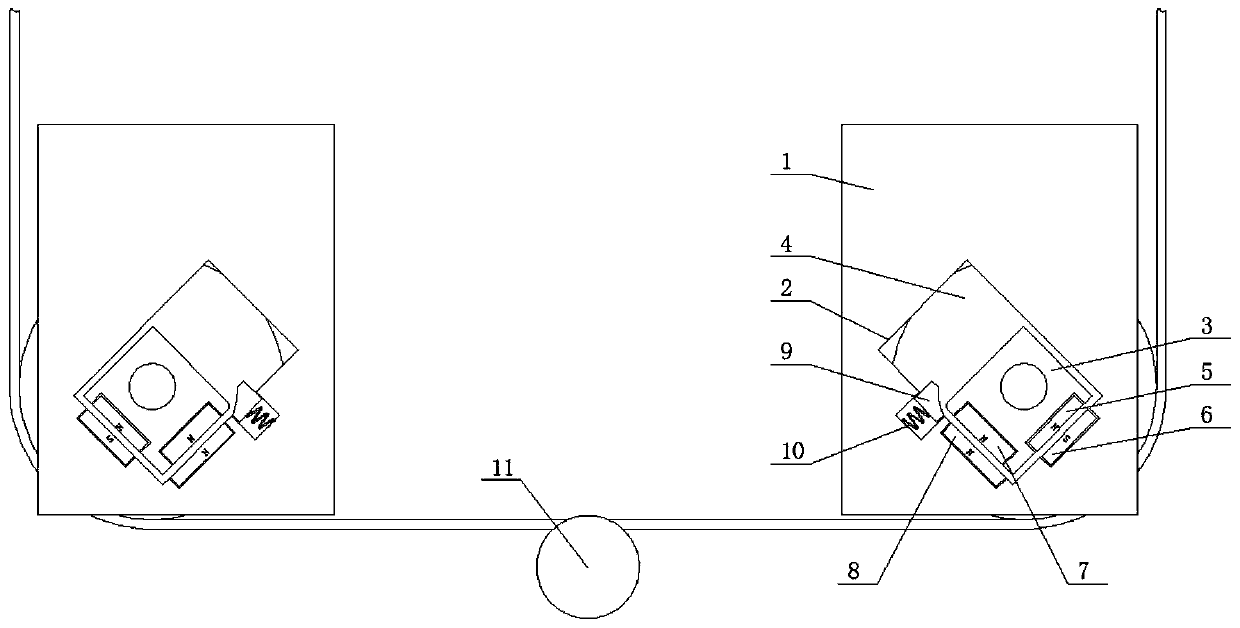

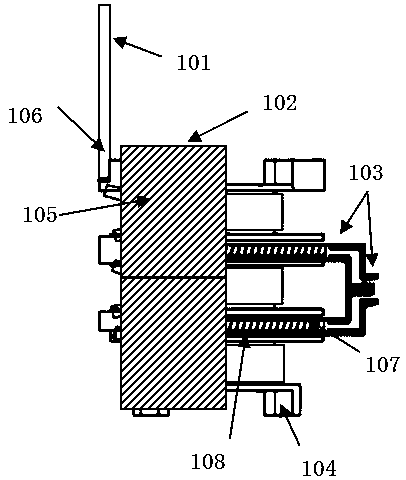

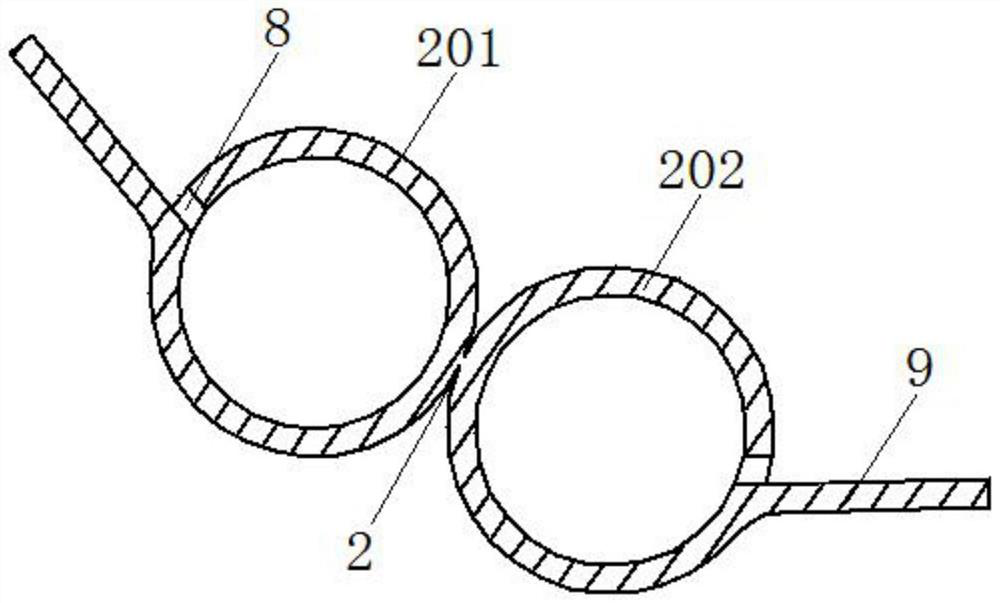

Mounting structure of wire wheels of diamond wire cutting machine

ActiveCN109773988AAvoid the risk of disconnectionReduce frictional resistanceFine working devicesWire cuttingEngineering

The invention relates to the technical field of photovoltaic equipment, and discloses a mounting structure of wire wheels of a diamond wire cutting machine. The mounting structure comprises a mountingplate; a guiding slot is formed in the obverse side of the mounting plate; the guiding slot is of a rectangular aslant-arranged hole; a guiding sliding block is connected with the inner part of the guiding slot in a clamping manner and can be slid in an inner cavity of the guiding slot; and the back of the guiding sliding block is fixedly connected with a central rotating shaft of the wire wheel.According to the mounting structure of the wire wheels of the diamond linear cutting machine disclosed by the invention, the wire wheels are fixedly mounted on the mounting plate through magnetic force, the wire wheels can slide and climb up in the guiding slot along with the guiding sliding block; the guiding slot is aslant arranged, and the guiding sliding block can be pulled and climbed up because of the designed tension force when a diamond wire is tightened because a hard point of a crystal is cut by the diamond wire, so that a space between the two wire wheels is reduced to ensure thatthe diamond wire positioned between the two wire wheels reaches a loosening state, and meanwhile, the two wire wheels are climbed up, so that the diamond wire positioned between the two wire wheels isupwards away from the hard point of the crystal; and therefore, a comprehensive effect ensures that avoidance of the risk of wire breakage of the diamond wire.

Owner:义乌市鼎莎针织有限公司

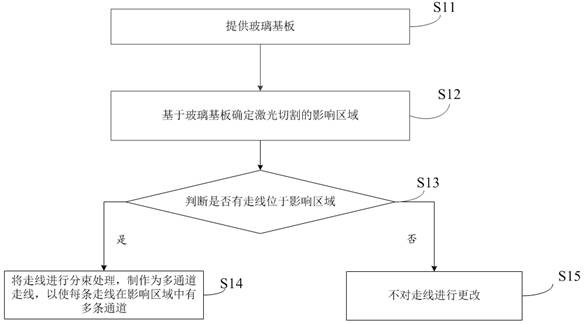

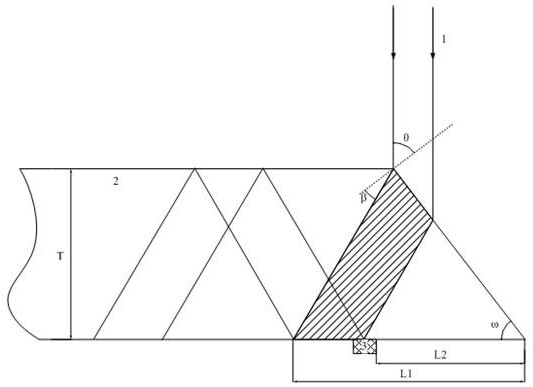

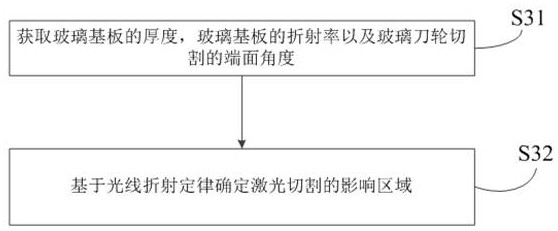

Special-shaped panel and manufacturing method thereof

ActiveCN113620587BFirmly connectedGuaranteed connectivityGlass severing apparatusGlass productionLaser cuttingMaterials science

The present application discloses a special-shaped panel and a manufacturing method thereof. The manufacturing method of the special-shaped panel includes: providing a glass substrate; determining an affected area of laser cutting based on the glass substrate; judging whether a wiring is located in the affected area; Beam-split to make multi-channel traces so that each trace has multiple lanes in the area of influence; if not, make no changes to the trace. Through the above method, the risk of laser ablation of the traces of the glass substrate is reduced.

Owner:HKC CORP LTD

Combined transformer

PendingCN111210978ASimple structureGuaranteed stabilityTransformers/inductances coils/windings/connectionsFixed transformersMagnetic coreCopper wire

The invention relates to a combined transformer, and belongs to the field of transformers. A framework is arranged, and a winding groove is machined in an outer side wall of the framework. A frameworkhole is arranged in the middle of the framework; annular limiting holes parallel to the winding groove are further machined in the framework; and at least two annular copper sheets are inserted intothe annular limiting holes, breaking seams are machined in the annular copper sheets, an annular insulating spacer is inserted between every two adjacent annular copper sheets, the two adjacent annular copper sheets are connected in series, and two cylindrical magnetic cores are inserted into the framework hole and penetrate through copper sheet holes in the middle of the copper sheets and an insulating sheet hole in the middle of the insulating spacer. A copper wire is replaced with the copper sheet, a risk of wire breakage is eradicated, a technological process of winding is simplified, quality stability of the transformer is guaranteed, and cost of an enterprise is correspondingly reduced. Limiting grooves of the framework and the copper sheets which are used as limiting plates are cooperated to achieve assembling, disassembling and integration are more convenient, and conversion between one output end and two output ends of the transformer can be achieved.

Owner:WEIHAI DONGXING ELECTRONICS

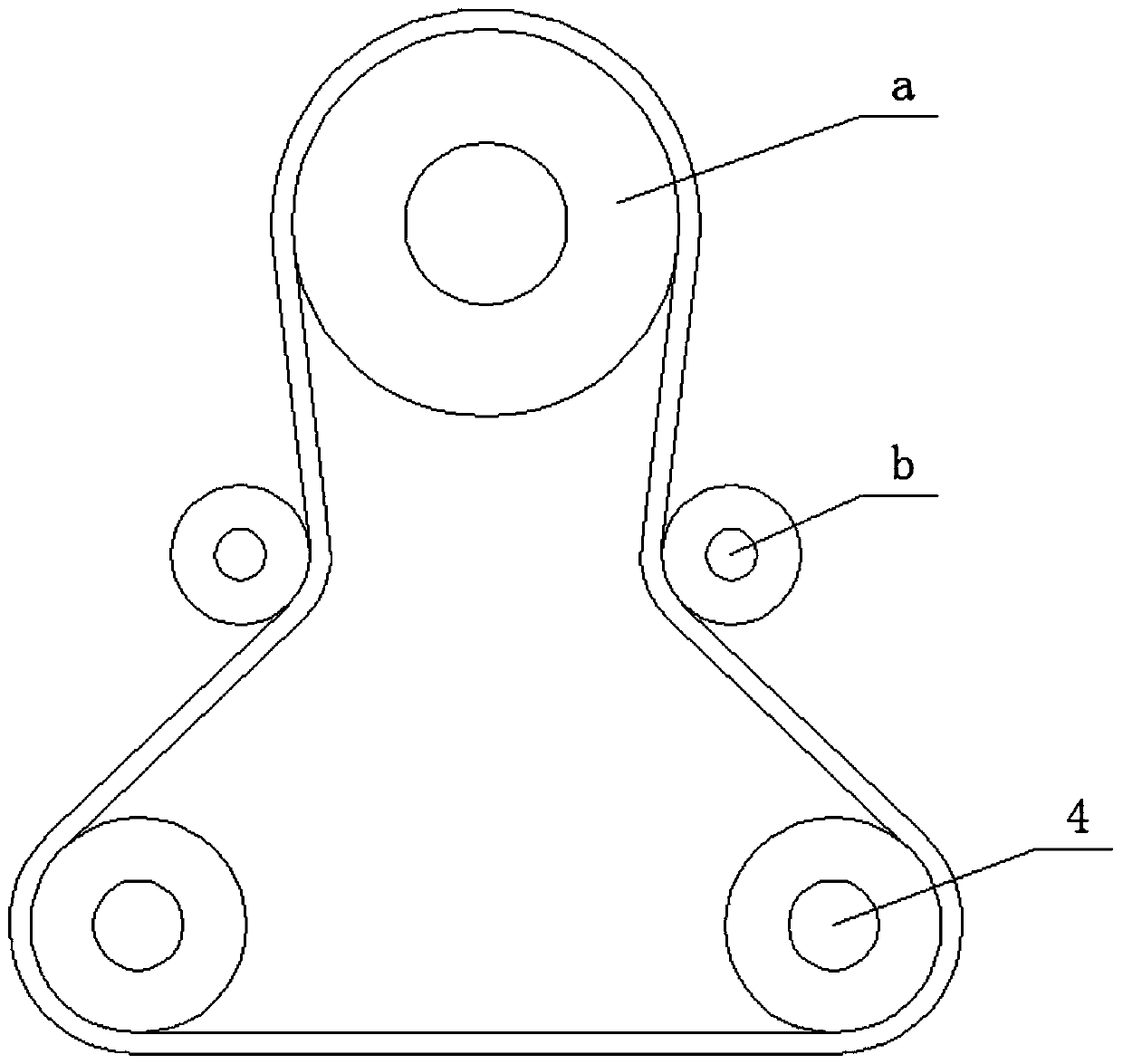

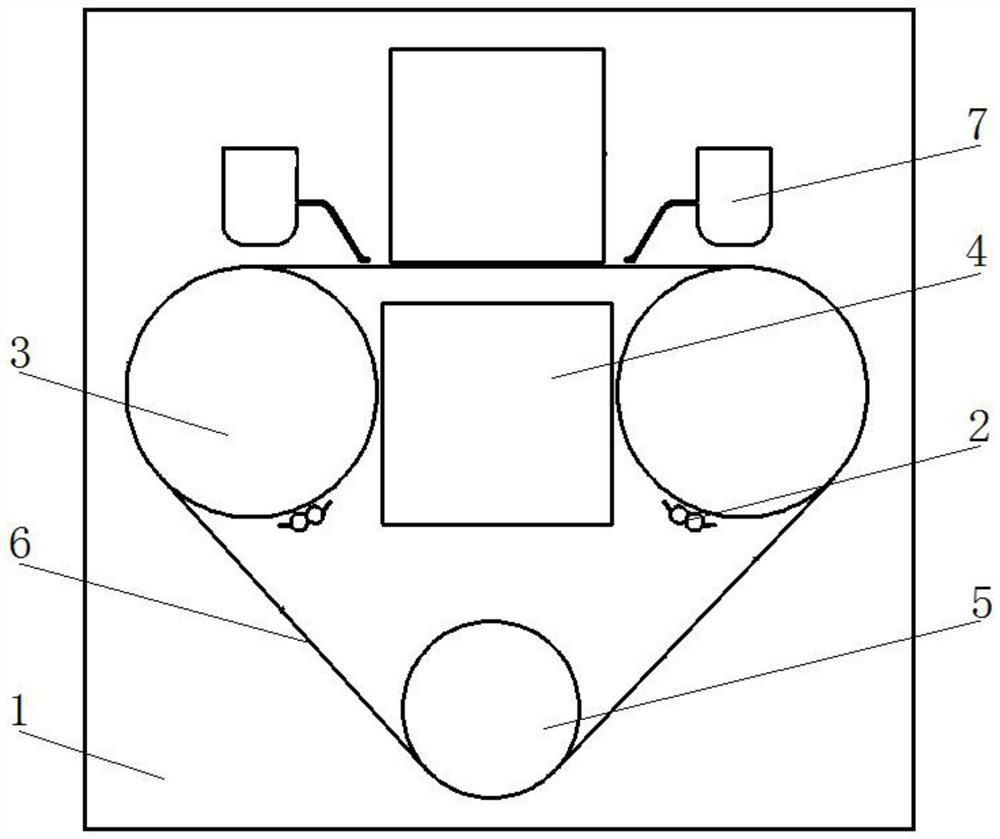

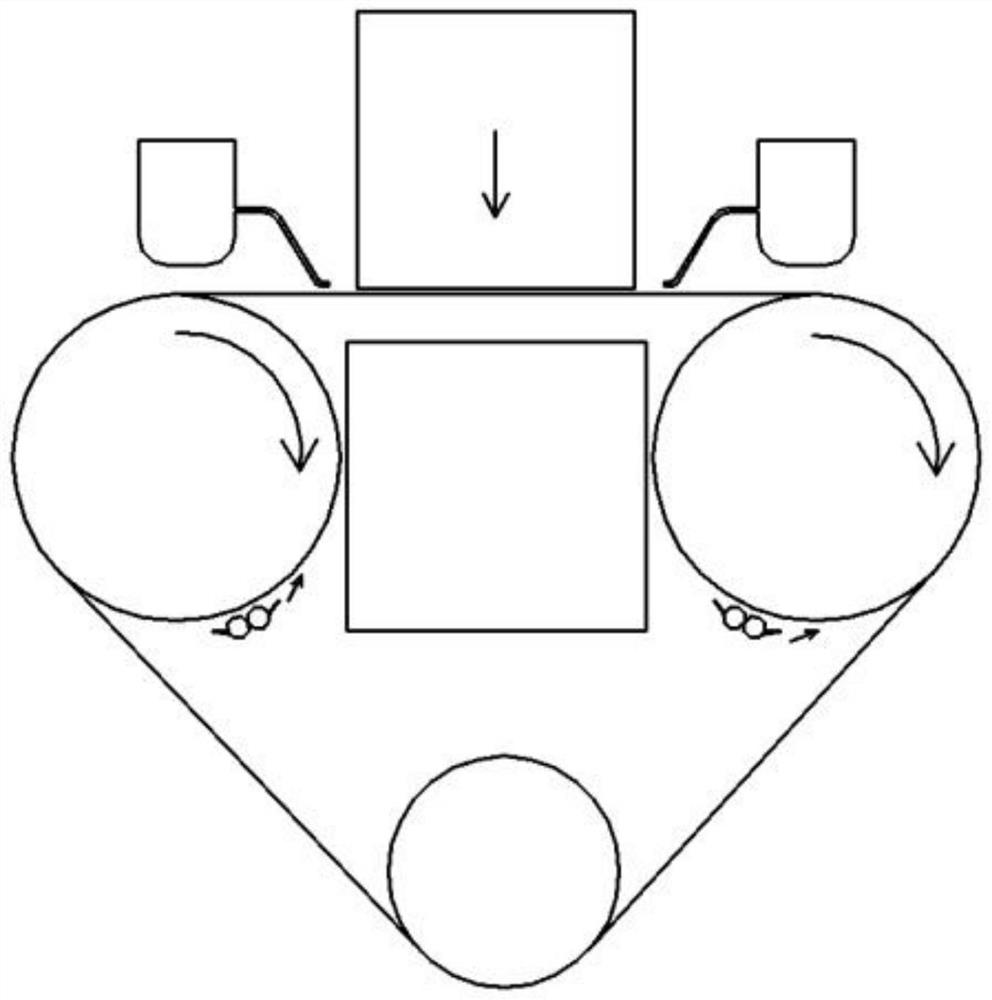

Device for reducing wire jumping rate in silicon rod cutting and cutting method

PendingCN114434664AAvoid accumulationPrevent jumperWorking accessoriesGrinding machinesForeign matterWire cutting

The invention discloses a device for reducing the wire jumping rate of silicon rod cutting and a cutting method. The device comprises a slicing machine body and an air pipe assembly, main rollers are symmetrically arranged on the slicing machine body, a fragment groove is formed between the two main rollers, a small roller is arranged below the fragment groove, and diamond wires are distributed on the main rollers and the small roller; the air pipe assembly is arranged below the main roller, the air outlets are formed in the two sides of the air pipe assembly, when the branch air pipes supply air, the symmetrical air knife-like design is formed, air flow periodically cleans the wire groove of the main roller in the rotating direction of the main roller in the cutting process, silicon powder and other foreign matter are prevented from being accumulated in the wire groove, and the service life of the wire groove is prolonged. According to the diamond wire cutting method, the risks of wire jumping and even wire breaking caused by the fact that the diamond wire is extruded out of a wire groove by foreign matter during high-speed cutting are avoided, the hidden danger of wire breaking caused by groove body defects is effectively made up when the diamond wire becomes thinner and thinner, and in the cutting method, points where impurities are likely to accumulate and become the hidden danger are cleaned in a targeted mode; and the influence on the diamond wire in the cutting process is avoided.

Owner:GUANGDONG GOKIN SOLAR ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com