Embedded touch control panel and manufacturing method thereof

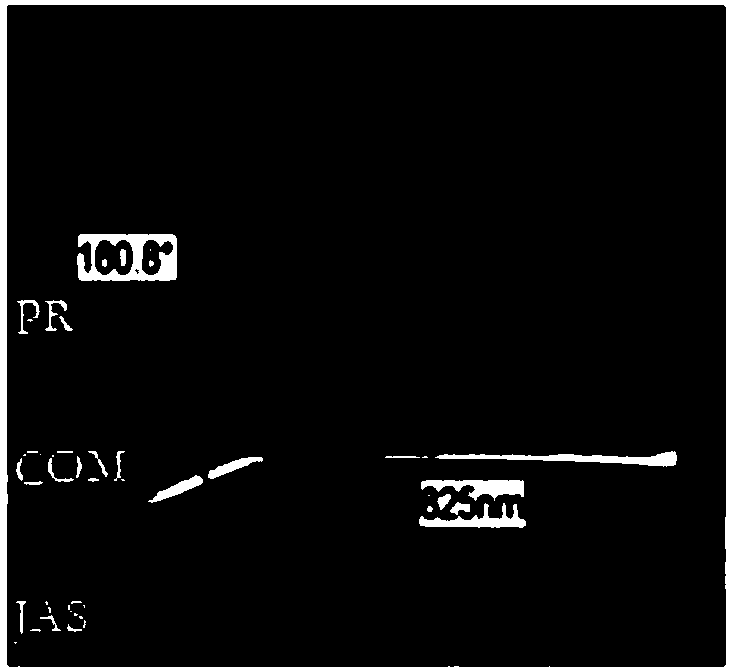

A technology of touch panel and manufacturing method, applied in the directions of optics, instruments, electrical components, etc., can solve the problems of large step difference between the edge of the first conductive layer COM and the flat layer JAS, broken wires, broken wires of bridge wires, etc., to achieve easy solution The effect of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

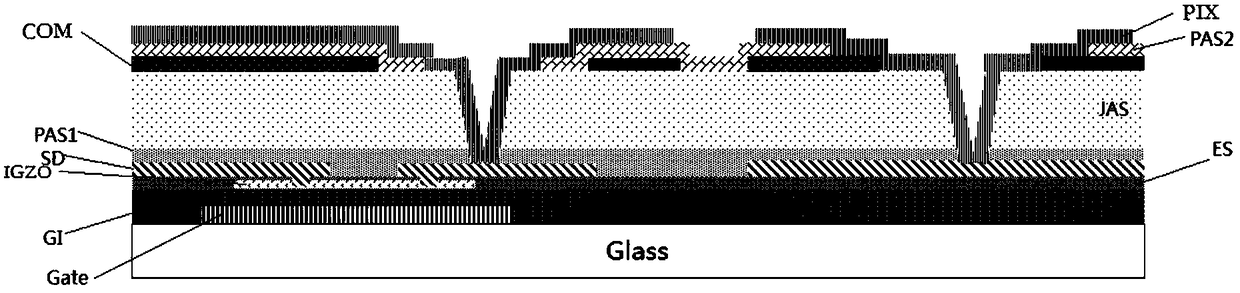

[0040] Figure 4-Figure 11 It is a schematic diagram of all steps of a manufacturing method of an in-cell touch panel of the present invention, as shown in the figure, the manufacturing method includes the following:

[0041] Step 1, forming a first metal layer on a substrate (Glass), the first metal layer is etched to form a scan line (not shown) and a gate (Gate), and the gate (Gate) is connected to the scan line, such as Figure 4 shown.

[0042] Step 2, firstly form a gate insulating layer GI covering the first metal layer, and then form a semiconductor layer (IGZO) on the gate insulating layer GI and set it opposite to the gate (Gate), such as Figure 5 shown.

[0043] Specifically, such as Image 6 As shown, wherein step 2 further includes the steps of: forming an etch barrier layer (ES) above the semiconductor layer (IGZO), and forming a first contact hole and a second contact hole on the etch barrier layer (ES); The first contact hole and the second contact hole ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com