Patents

Literature

63results about How to "Prevent jumper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

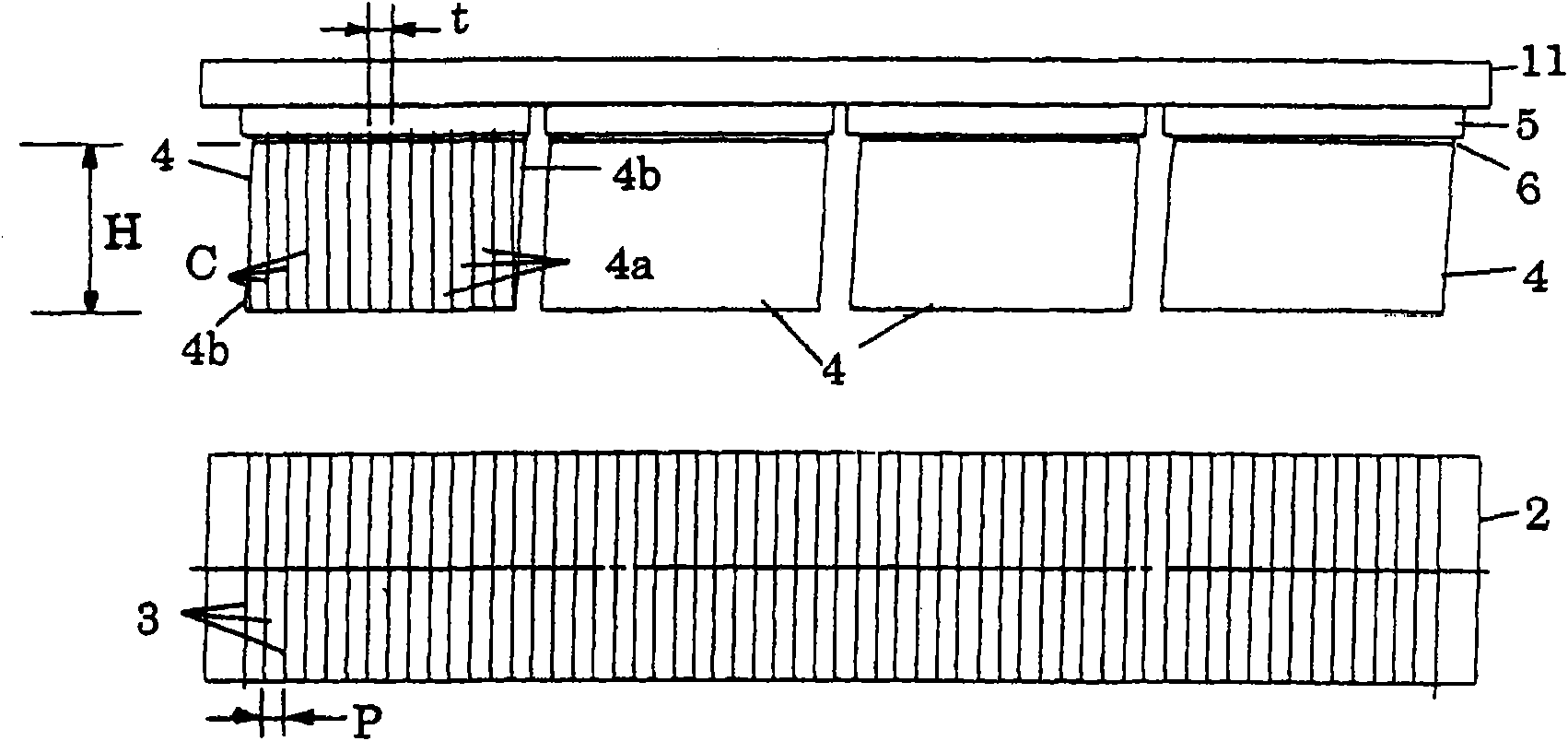

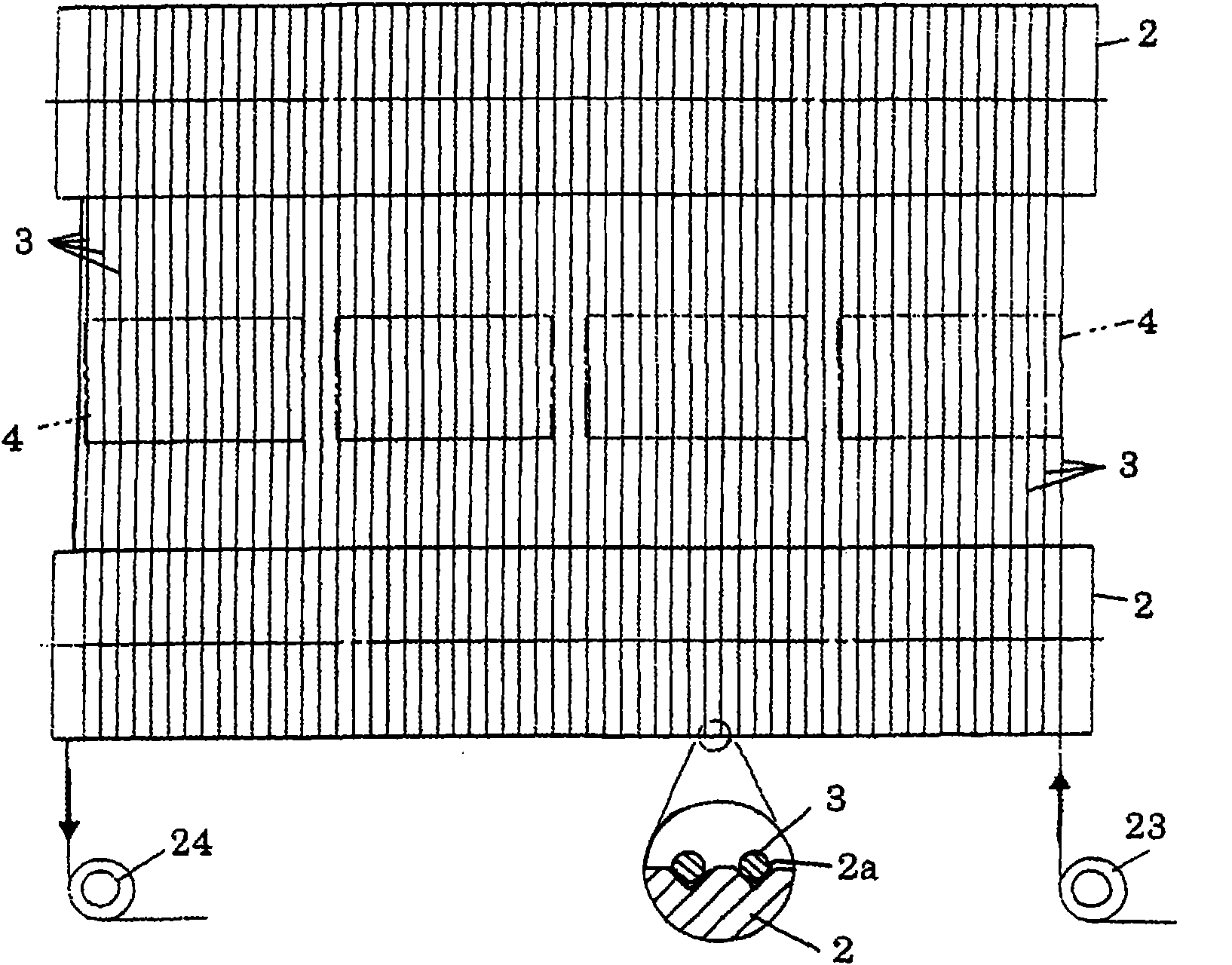

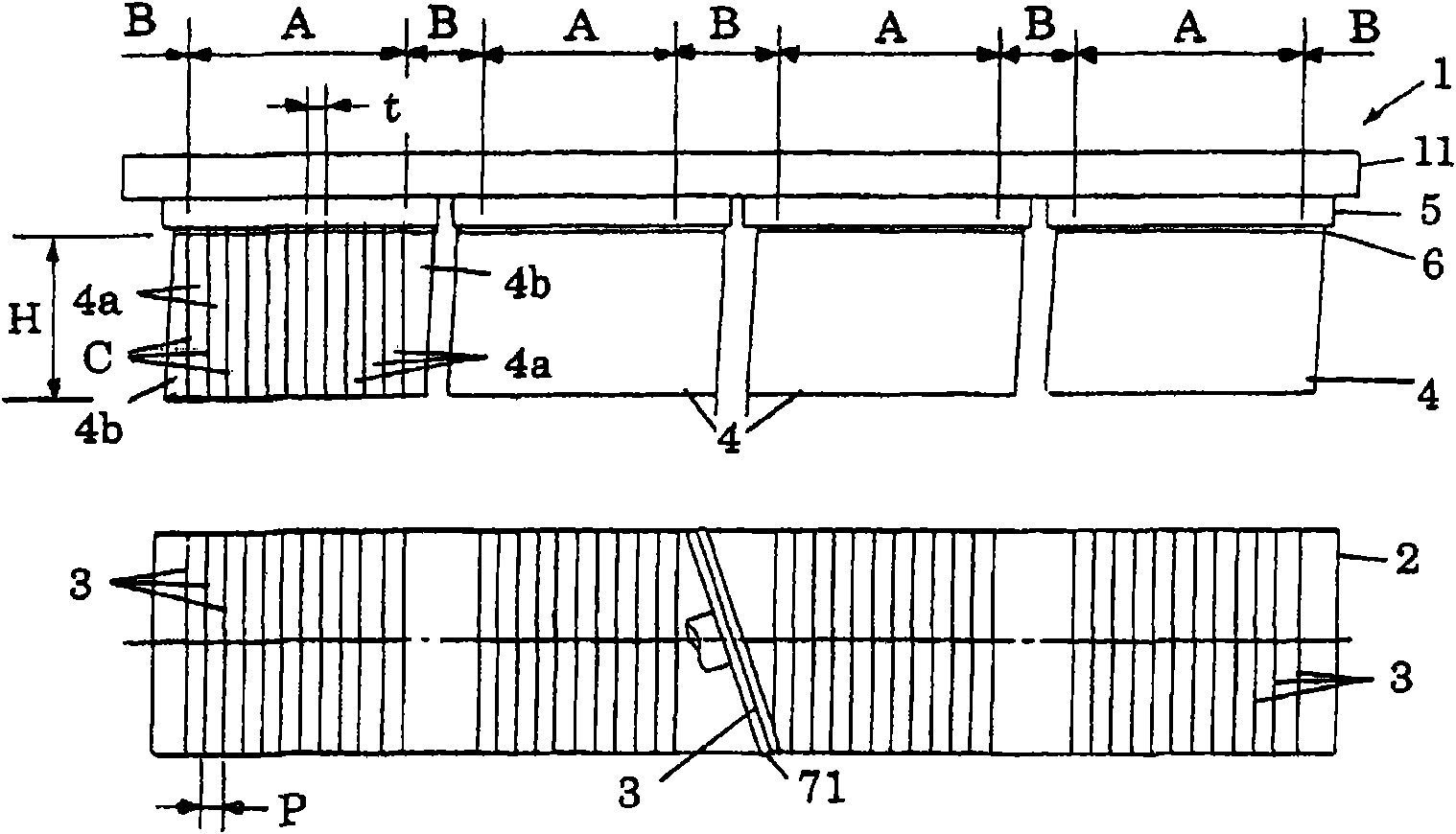

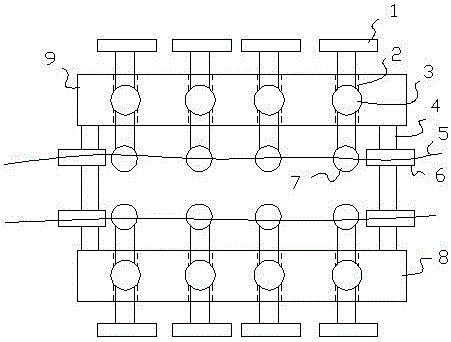

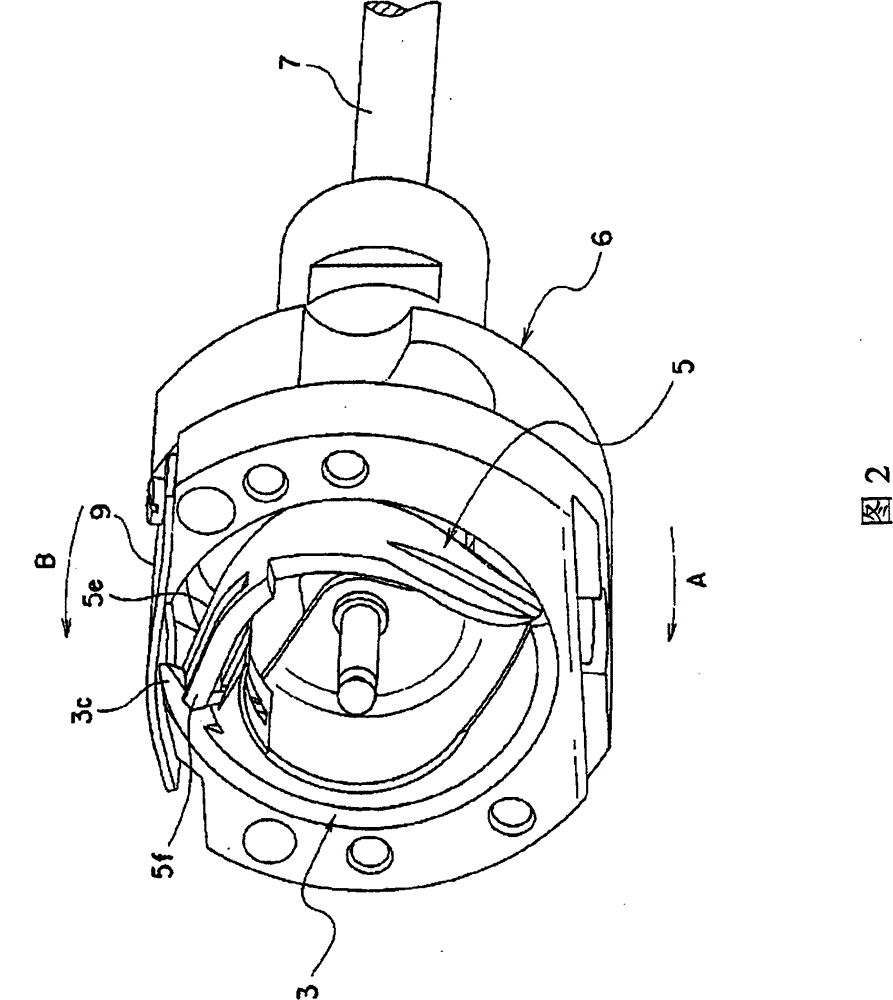

Method for cutting workpiece and device for changing rolling width of wire cutting workpiece

InactiveCN101850579APrevent jumperAvoid disconnectionMeasurement/indication equipmentsMetal sawing toolsWire rodWire cutting

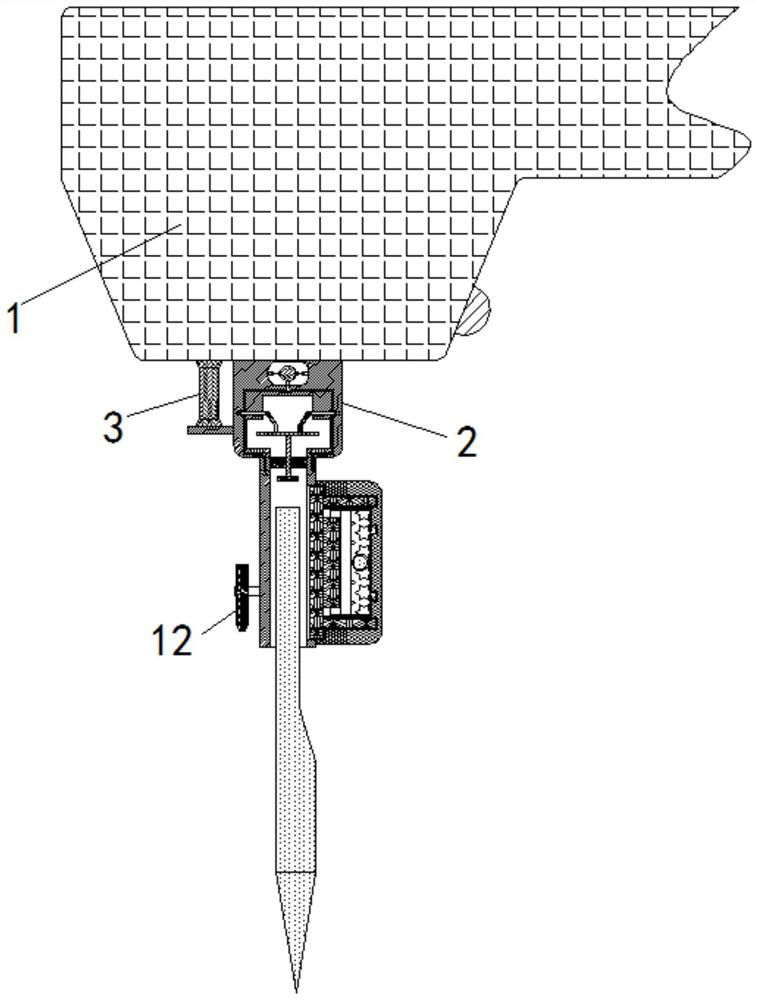

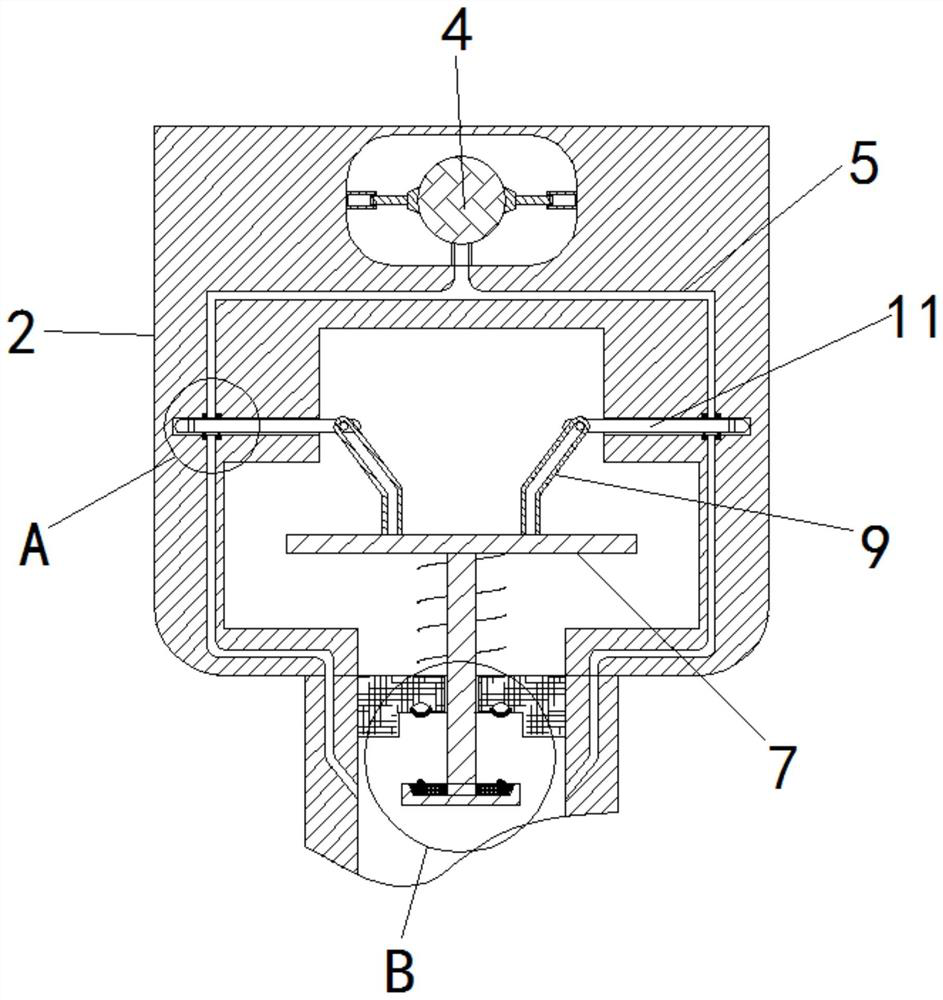

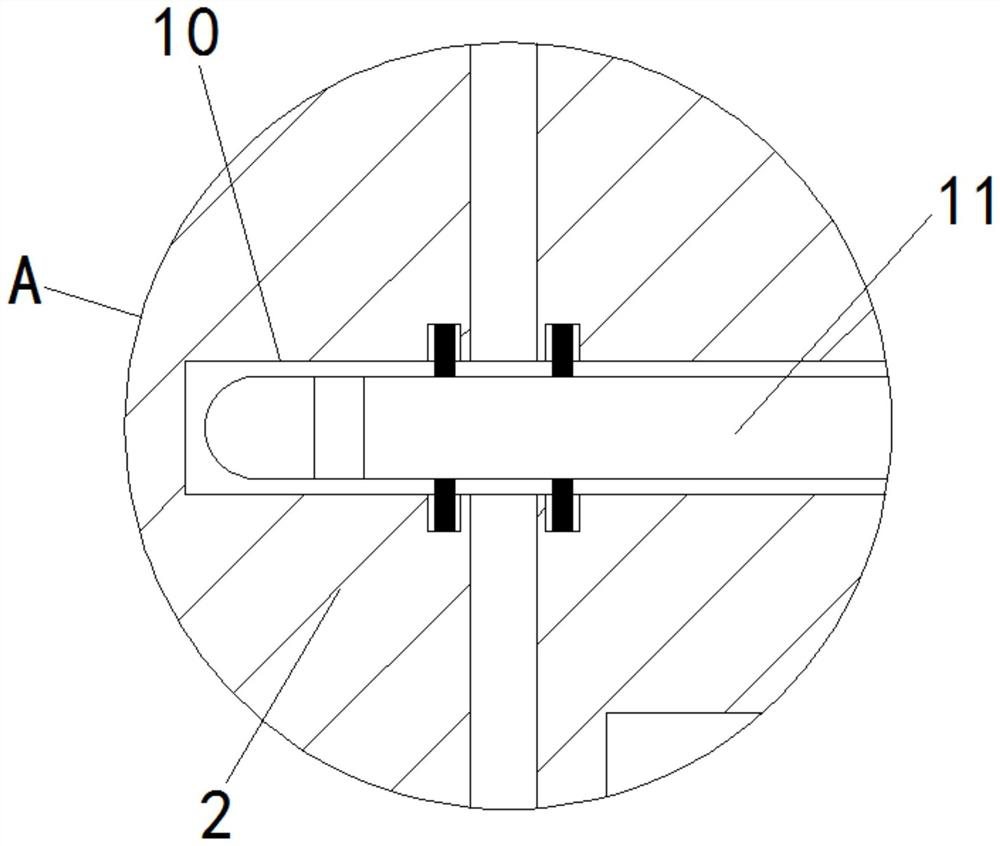

The invention provides a wire saw. Even the workpiece is cut off, the workpiece is constrained by an adhesive layer, the end material and the wire material are not interfered and the end material is prevented from entering into a groove of a main roller. Coiled wire materials travel between a plurality of parallel main rollers. The workpiece which is constrained on a rack by the adhesive layer is pressed on the wire material in a traveling state, the thickness of the workpiece cut to the target is t, and in the direction of target thickness t of the workpiece, two end portions of the workpiece have partially residual adhesive layer; and a workpiece cut-off area A is set in a range capable of ensuring necessary sizes (cut-off height H, cut-off length L and cut-off width W) of the workpiece; in the workpiece cut-off area A, the distance P between wire materials is set to a value corresponding to the target thickness t; and a wire material jump area B is set out of the workpiece cut-off area A; and there is no wire material in the range of the wire material jump area B, where the wire material is in interference with the workpiece.

Owner:KOMATSU NTC LTD

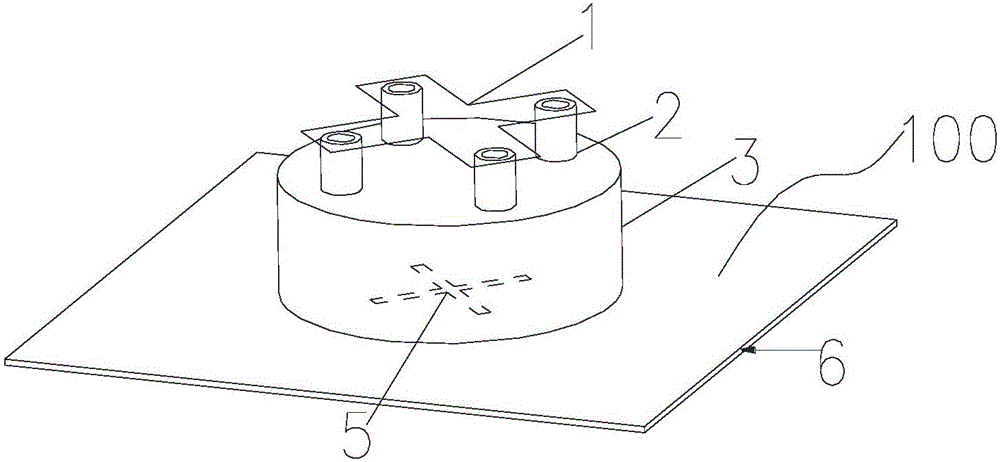

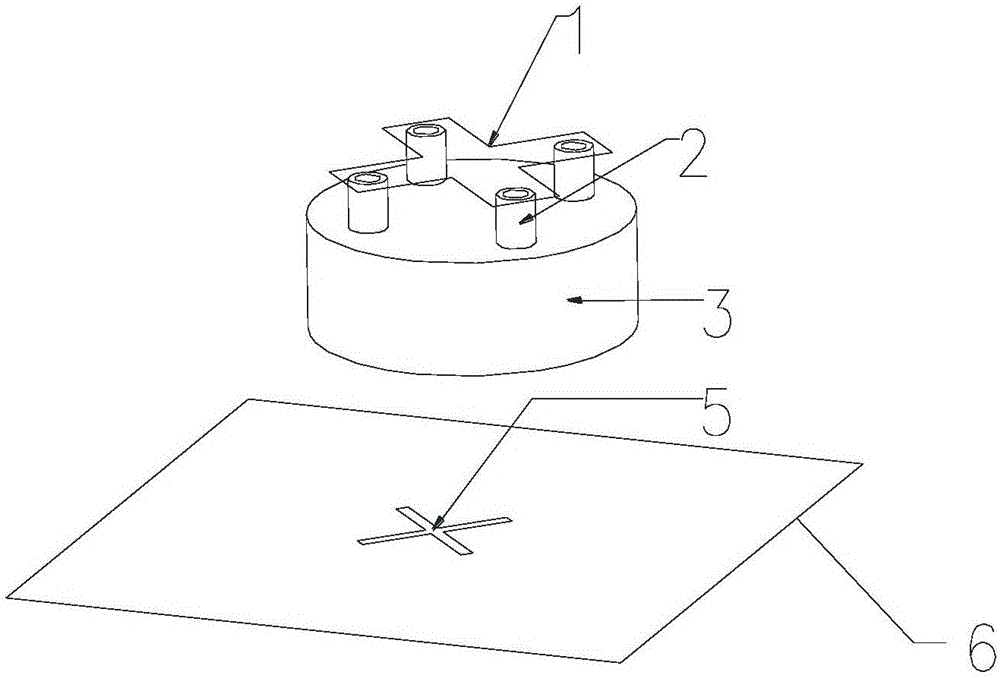

Dual-polarization dielectric resonator antenna unit and base station antenna

ActiveCN106099333AHigh gainLow profileRadiating elements structural formsAntenna earthingsDielectric resonator antennaDielectric resonator

The invention provides a dual-polarization dielectric resonator antenna unit, and the dielectric resonator antenna unit comprises a substrate, a dielectric resonator and a director, wherein the substrate, the dielectric resonator and the director are sequentially connected from the bottom to the top. The upper surface of the substrate is provided with a grounding surface, and a gap is disposed in the grounding surface in an etching manner. The lower surface of the substrate is provided with a microstrip feed line which is matched with the gap and is used for feed. The projections of the dielectric resonator and the director on the substrate cover the gap. According to the embodiment of the invention, the dielectric resonator antenna unit meets the requirements of low profile and high gain of a dual-polarization dielectric resonator antenna unit. Moreover, a feed structure of the dielectric resonator antenna unit is symmetric, and is liable to assemble. In addition, the invention also discloses a base station antenna comprising the dielectric resonator antenna unit.

Owner:SOUTH CHINA UNIV OF TECH +1

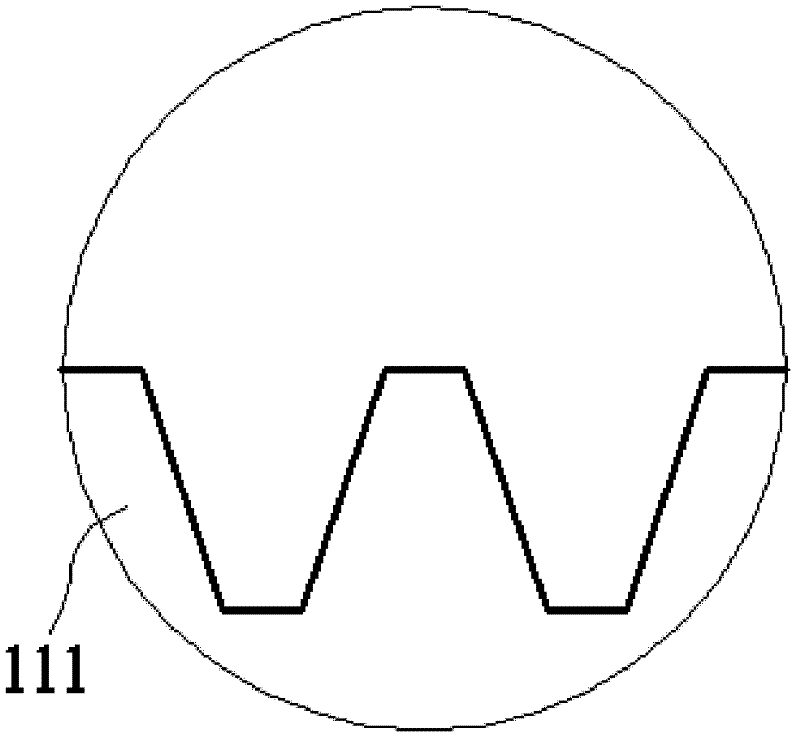

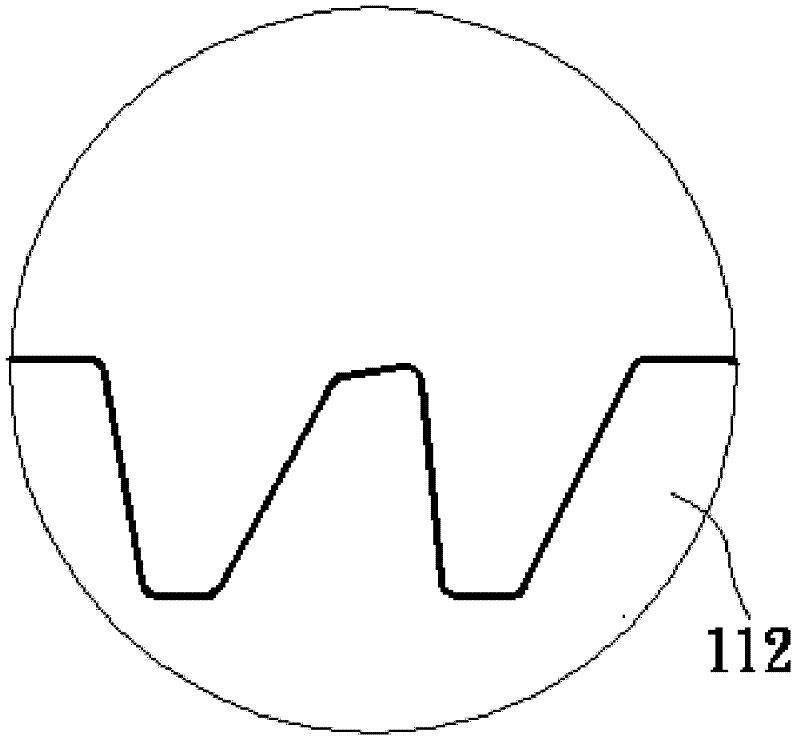

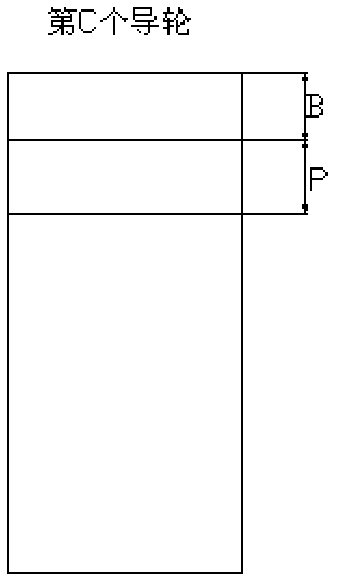

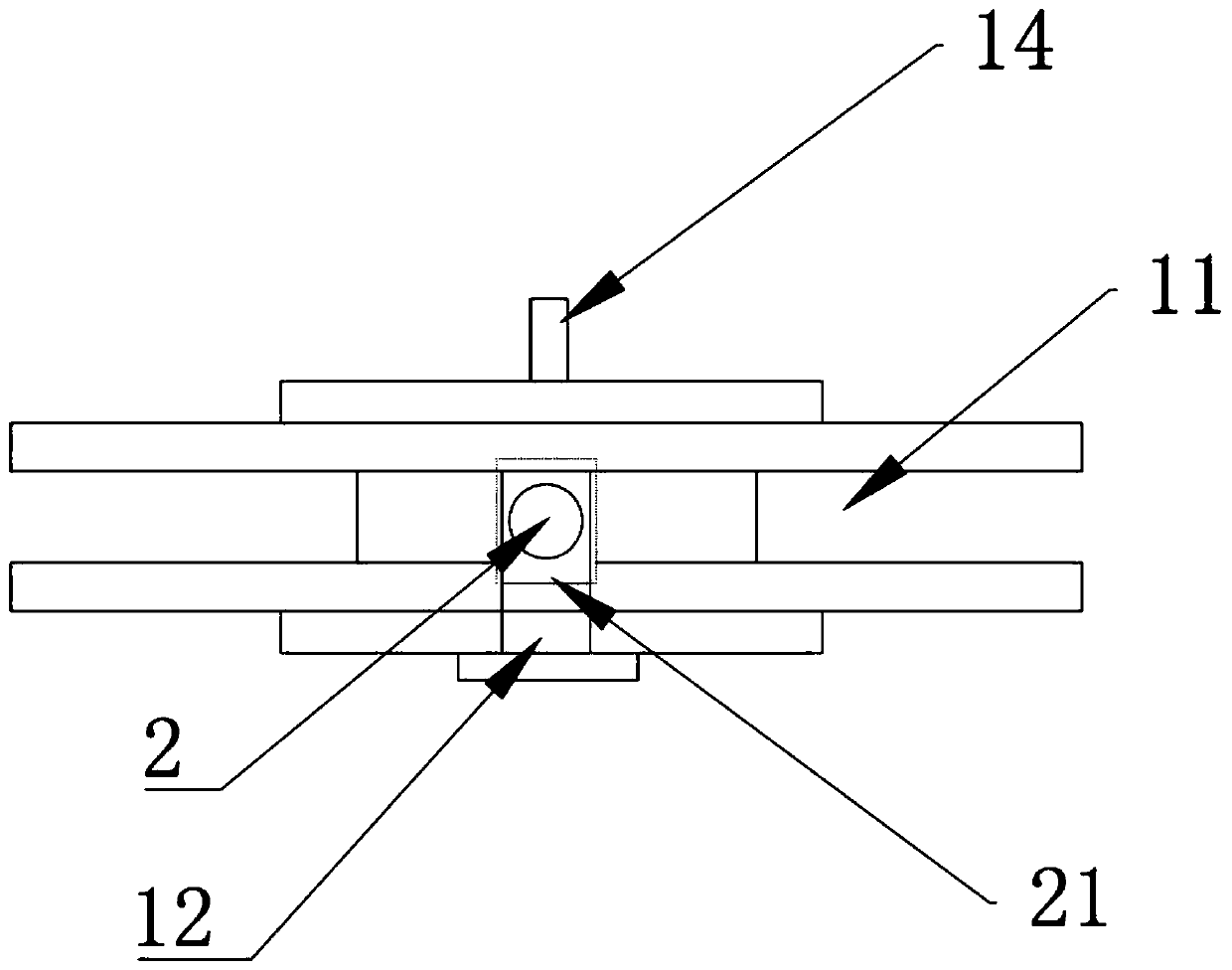

Slot structure of guide wheel of linear cutting machine

The invention discloses a slot structure of a guide wheel of a linear cutting machine. The slot structure is formed by integrally connecting a first slot and an arc-shaped groove through a U-shaped groove, wherein the first slot is close to a wire outlet end; the arc-shaped groove is internally molded at the upper end of the U-shaped groove; the width of an opening at the upper end of the arc-shaped groove is the same as the initial diameter of a wire rod; and the wire rod enters into the U-shaped groove through the opening at the upper end of the arc-shaped groove. Compared with the traditional large-opening U-shaped groove and V-shaped groove, the opening of the first slot provided by the invention is smaller, so as to avoid jumping the wire rod and the like; and the arc-shaped groove can be used for effectively slowing the wire rod to shake and the like; and therefore, according to the slot structure, the wire rod with a small wire diameter, which is formed at the wire outlet end due to wire loss, can be effectively compensated, so that the yield of wafer slices is improved, the service life of the guide wheel is prolonged and the aim of saving the cost is further achieved.

Owner:KUNSHAN HANHUI ELECTRONICS TECH CO LTD

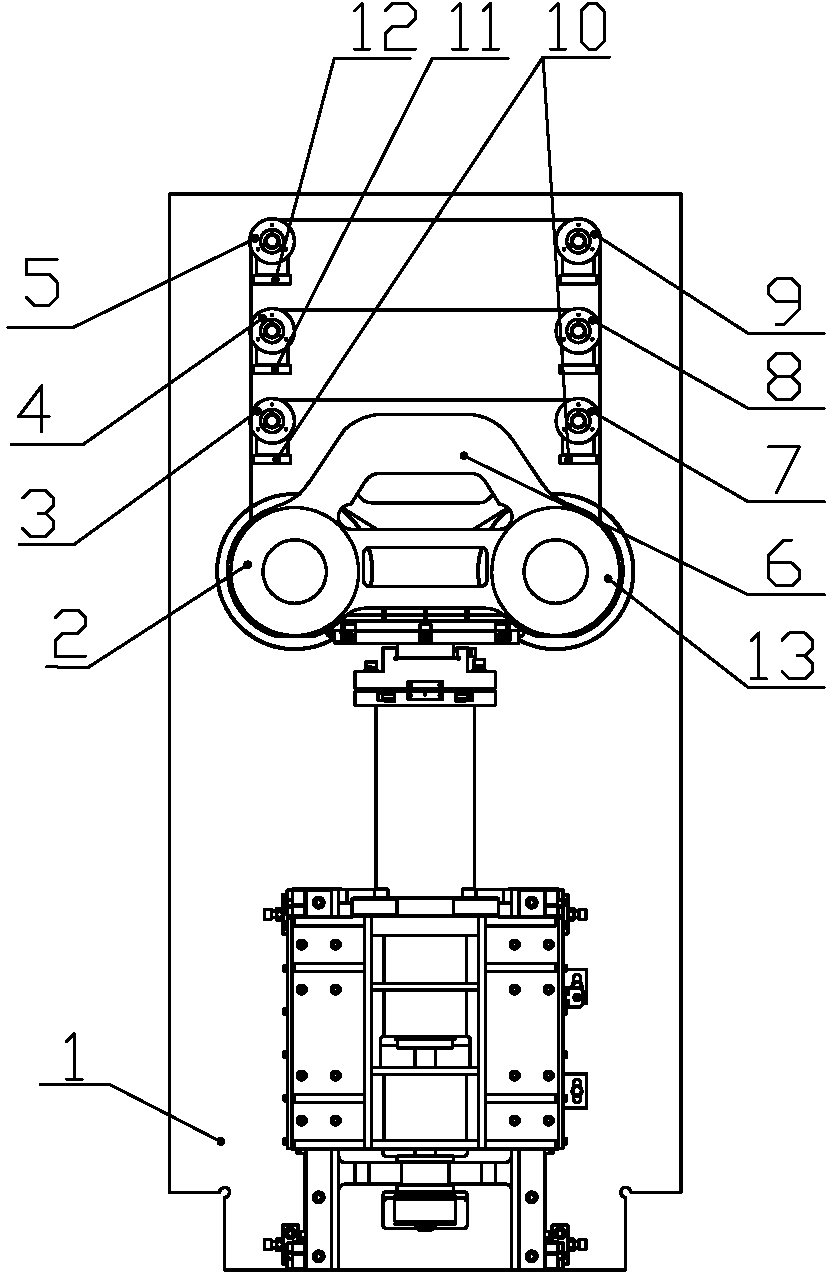

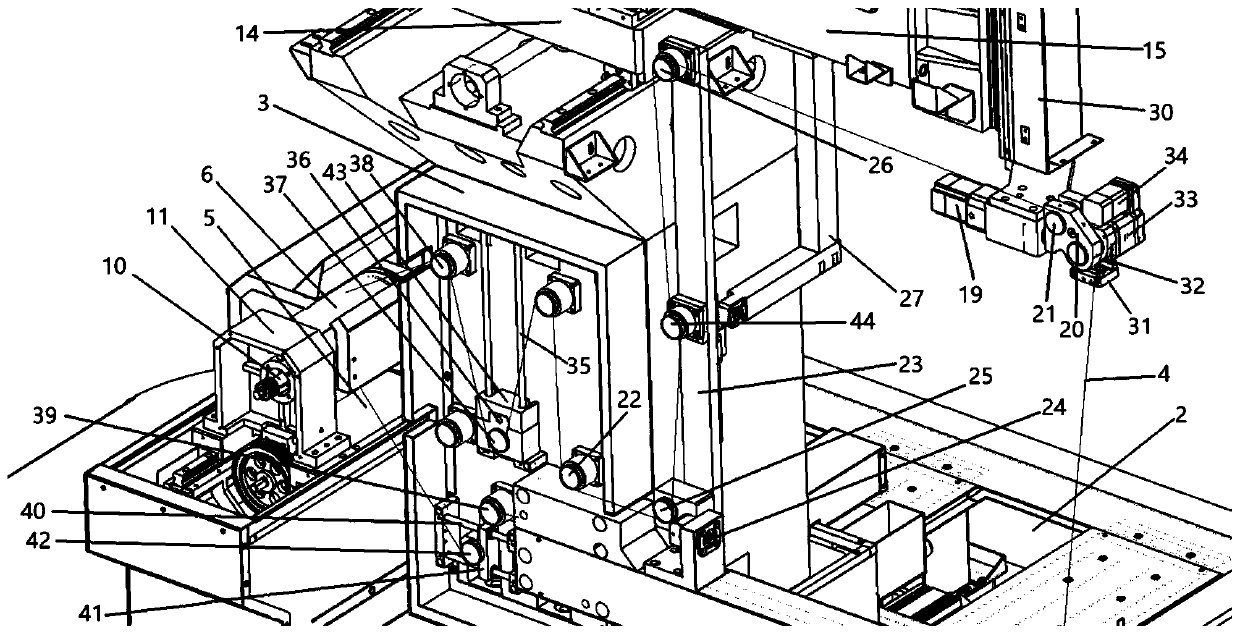

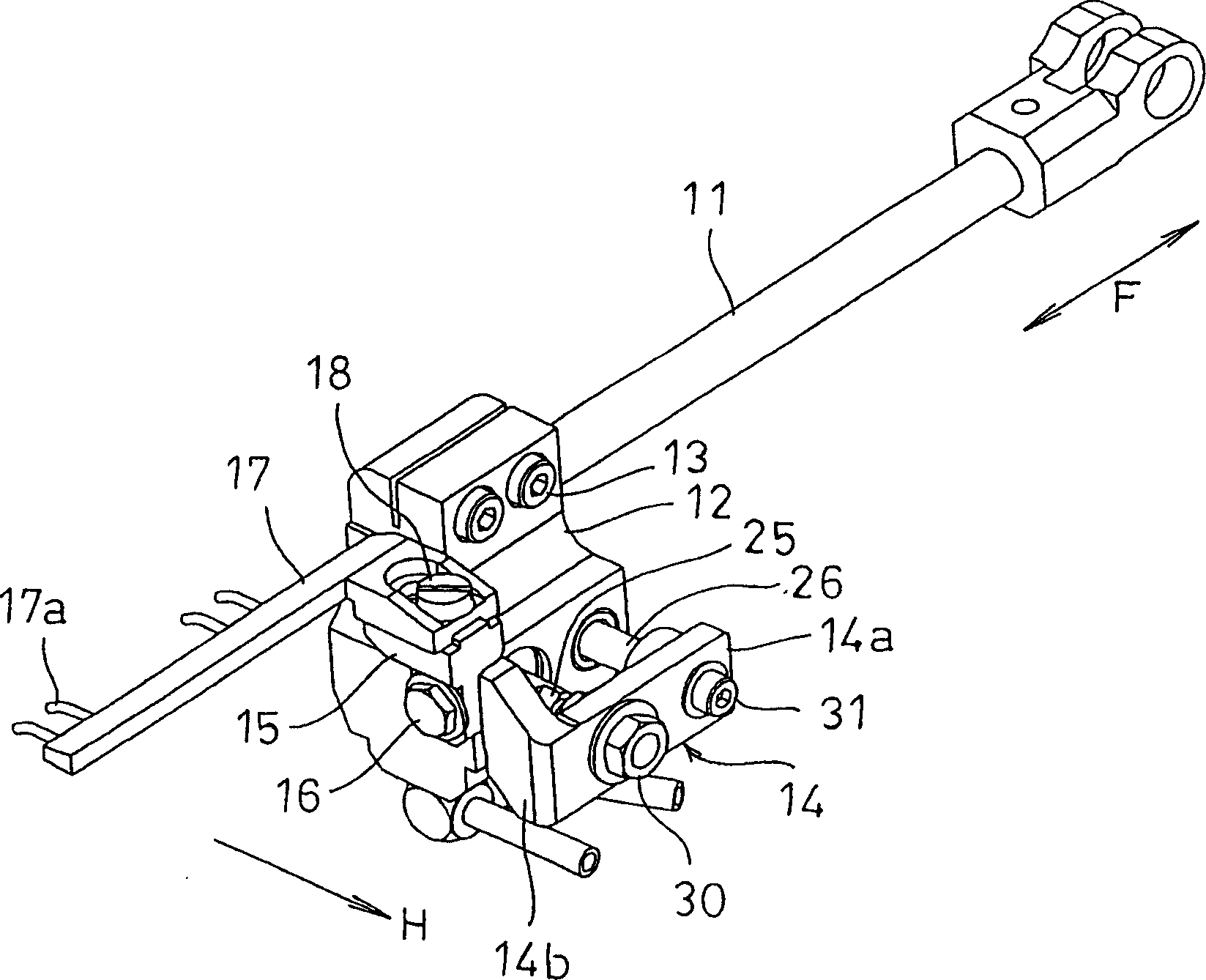

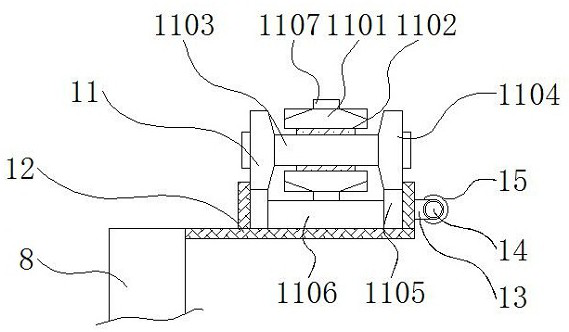

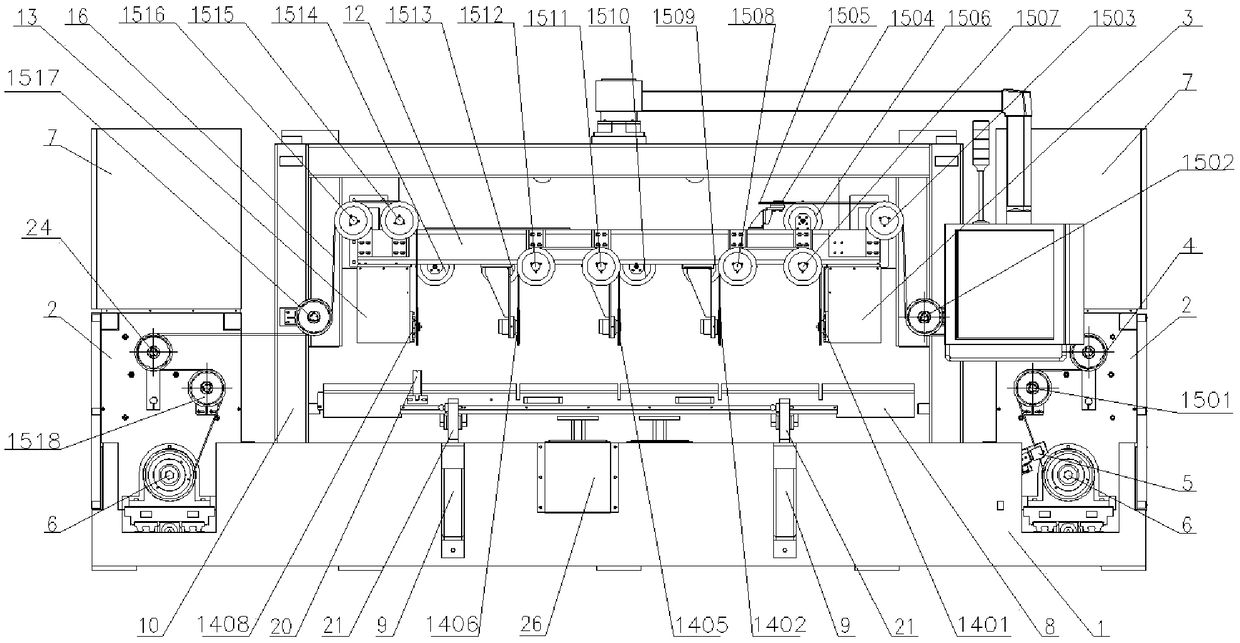

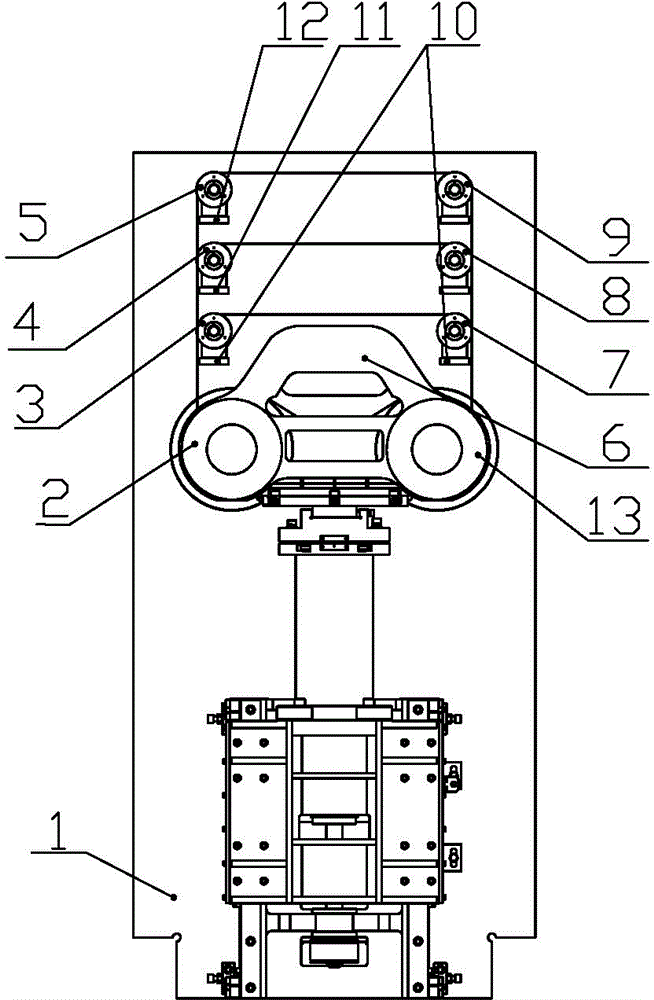

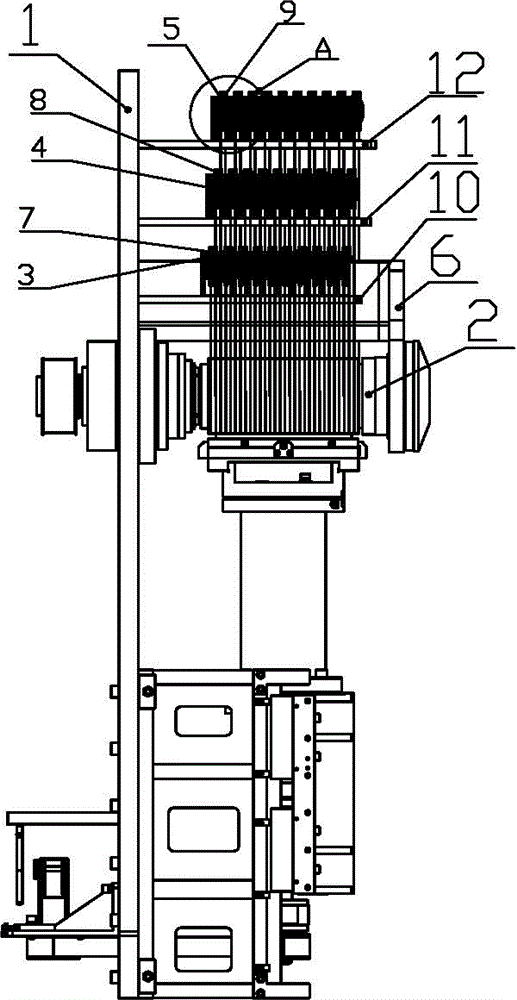

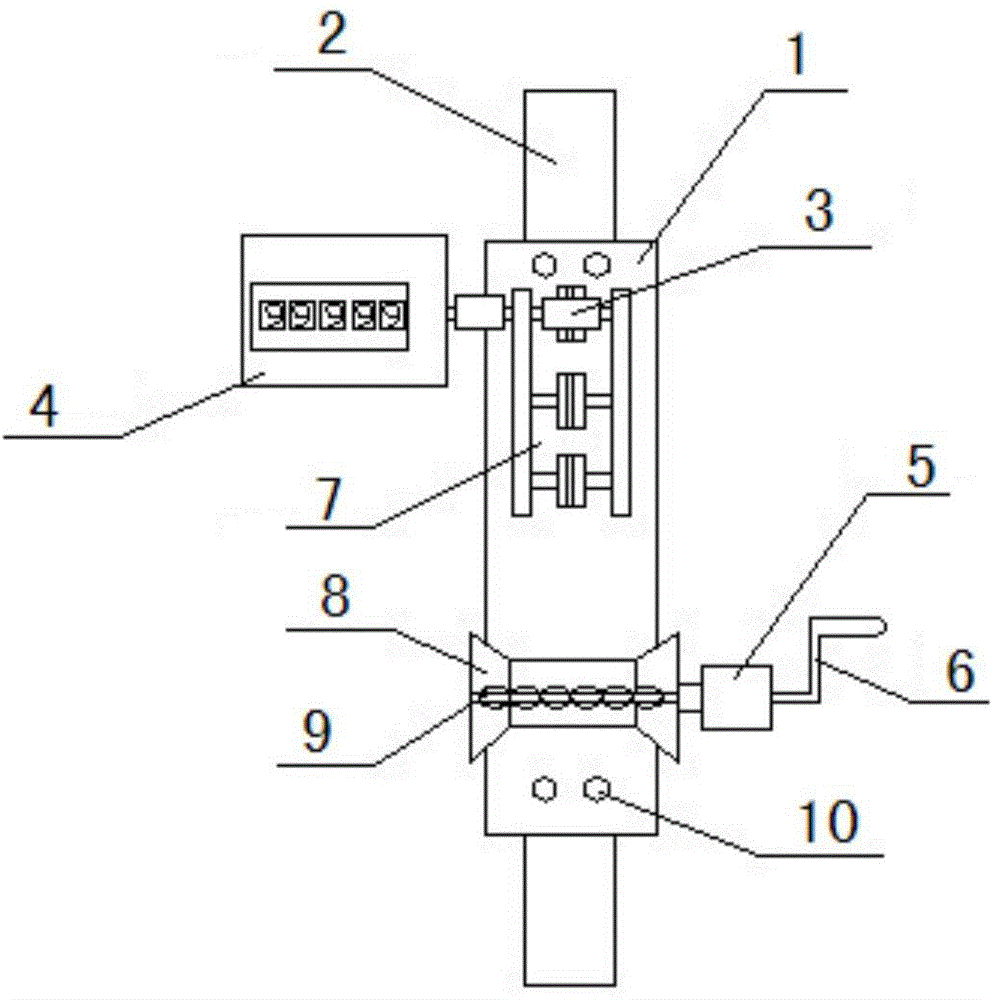

Wire regulating device of multi-wire cutting machine steel wire

InactiveCN103009490ASimple structurePrevent jumperFine working devicesWire cuttingProduct processing

The invention discloses a wire regulating device of a multi-wire cutting machine steel wire, which is used for increasing a cutting thickness range of a multi-wire cutting machine. The wire regulating device comprises a left cutting roller and a right cutting roller which are arranged on a front fixing board and a rear main board, wherein the size, the wire groove number and the groove distance of the left cutting roller are the same as those of the right cutting roller. The wire regulating device is characterized in that the rear main board is provided with a guide wheel installation board, the guide wheel installation board is respectively provided with a wire inlet guide wheel set and a wire outlet guide wheel set, a steel wire is vertically led out from a first wire groove of the left cutting roller, the steel wire is then pitched in a first guide wheel on the wire inlet guide wheel set, the steel wire is then pitched in a first guide wheel on the wire outlet guide wheel set, the first guide wheel on the wire outlet guide wheel set is coplanar with the first guide wheel on the wire inlet guide wheel set, the steel wire is then vertically pitched in a second wire groove of the right cutting roller, and thus the groove replacement of the steel wire is completed. According to the wire regulating device disclosed by the invention, bad phenomena of wire jumper and eccentric wear of the cutting rollers, which are caused by an overlarge span angle between the grooves of the cutting rollers due to overlarge distance between the V-shaped circular grooves on the cutting rollers, are prevented from happening, the product processing accuracy is ensured, and the processing cost is saved.

Owner:HUNAN YUJING MACHINE

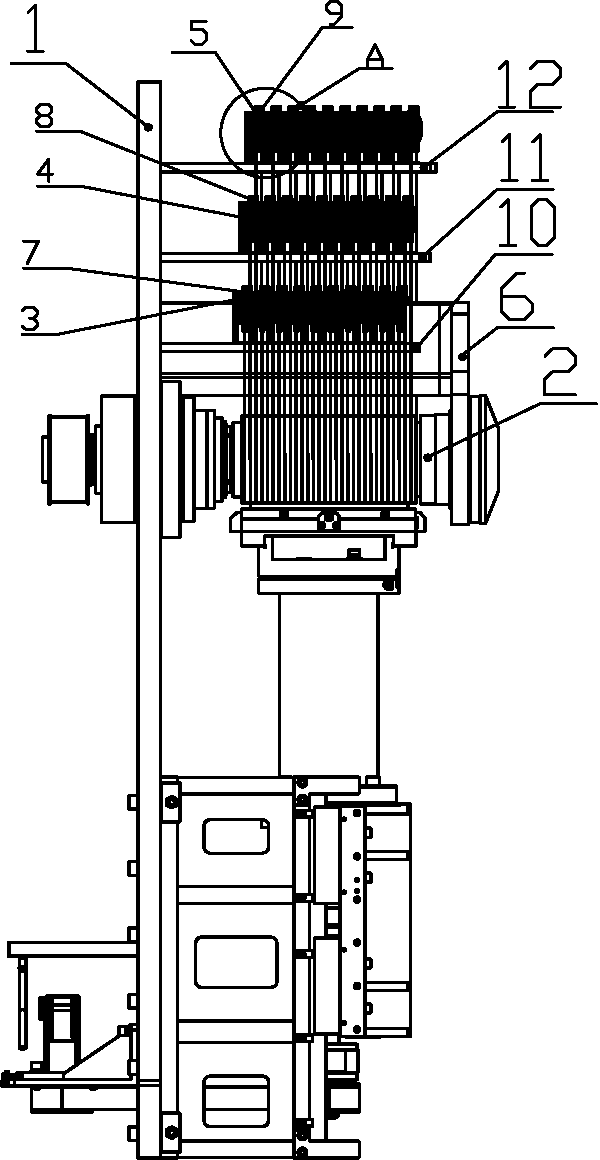

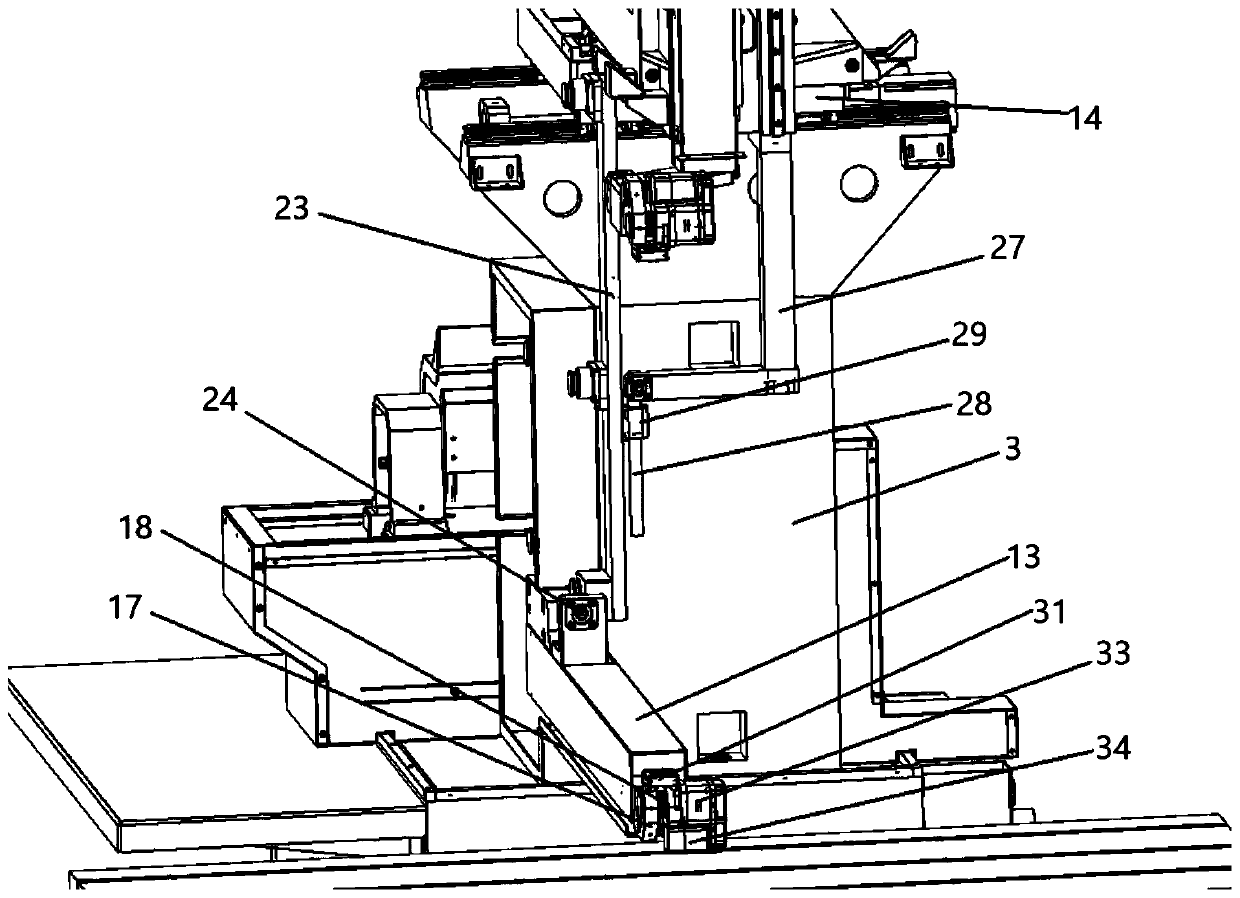

Electric spark wire cutting machine

PendingCN111347111AImprove cooling effectReduce frictionElectrical-based machining electrodesWire cuttingEngineering

The invention discloses an electric spark wire cutting machine. According to the technical scheme, the electric spark wire cutting machine is characterized by comprising a workpiece installing base for installing a workpiece, a base, a sliding base which is in horizontal sliding connection with the base, and a cutting wire arranged on the sliding base and used for cutting the workpiece. The sliding base is provided with a drive mechanism for driving a cutting wire to move and achieving cutting of the workpiece, and a bevel cutting mechanism for enabling the cutting wire to be in the inclined state and achieving bevel cutting. The purpose that the cutting wire is inclined within the space range and the workpeice is cut obliquely is achieved. Meanwhile, the problem that equipment is abradeddue to the fact that the cutting wire is pulled hard is effectively avoided.

Owner:浙江霸器智能装备股份有限公司

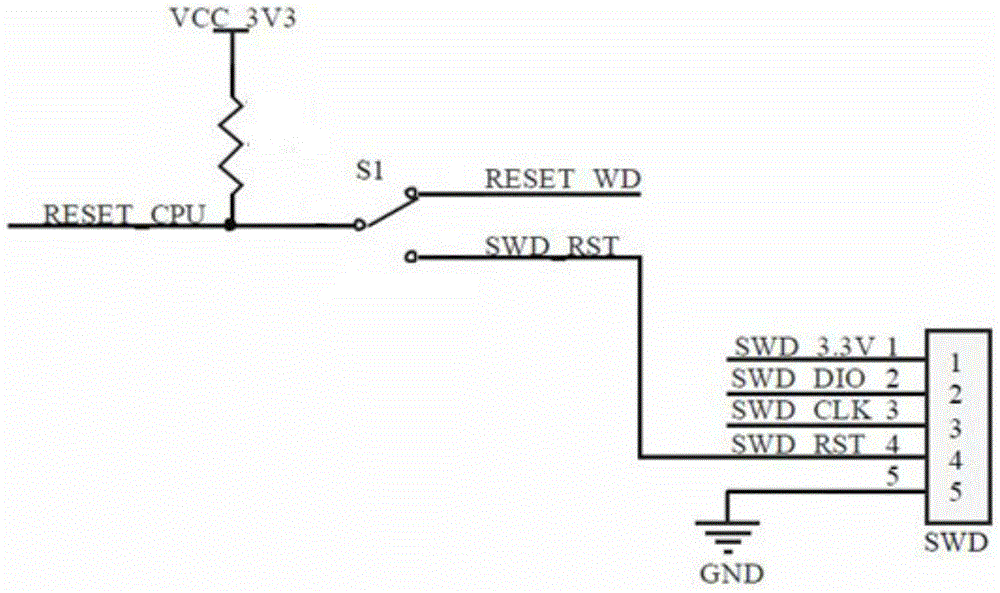

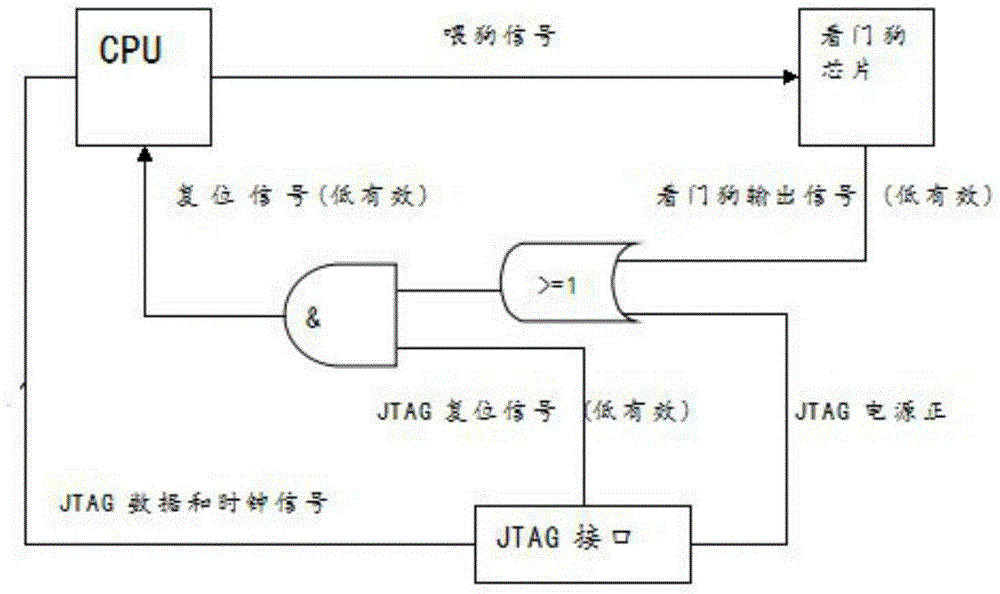

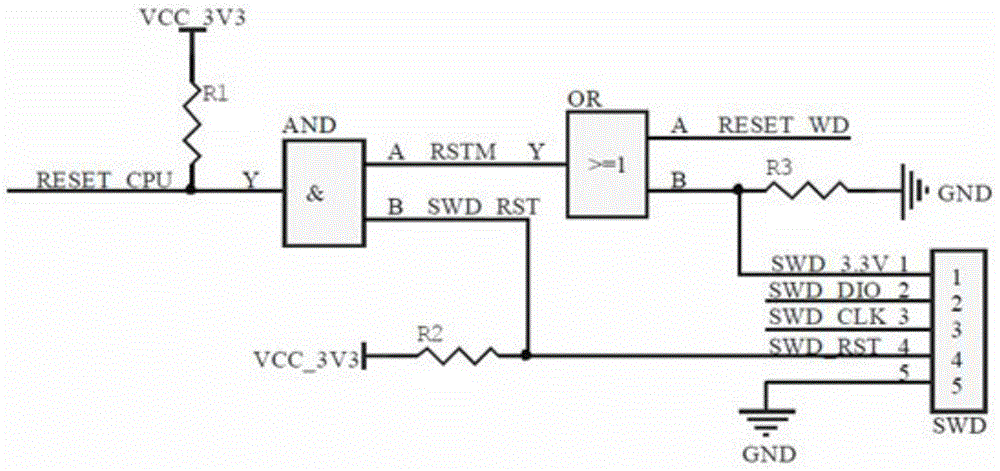

Jumper-free circuit for program running and JTAG program downloading

ActiveCN105224372ASave download timeSave debugging timeFault responseProgram loading/initiatingEngineeringJoint Test Action Group

The invention provides a jumper-free circuit for program running and JTAG program downloading. The jumper-free circuit comprises a CPU, a watchdog chip and a JTAG writer, wherein the CPU outputs a feeding-dog signal to the watchdog chip; a first signal RSTM is output by a watchdog reset signal RESET-WD output by the watchdog chip and a power supply signal SWD-3.3V of the JTAG writer through a 'or' logic; a second signal RESET-CPU is output by the first signal RSTM and a JTAG reset signal SWD-RST output by the JTAG writer through an 'and' logic; the signal is input into the CPU as a CPU reset signal; and the JTAG writer interacts with the CPU through data, clock and reset signals. The jumper-free circuit has the advantage that circuit switching devices such as a change-over switch and a dial switch are avoided, and is free of a jumper, high in reliability and low in cost; the JTAG program downloading and debugging time is greatly shortened; the area of a printed circuit board (PCB) is reduced; the production efficiency is improved; and meanwhile, the product running reliability is also increased.

Owner:INTEGRATED ELECTRONICS SYST LAB

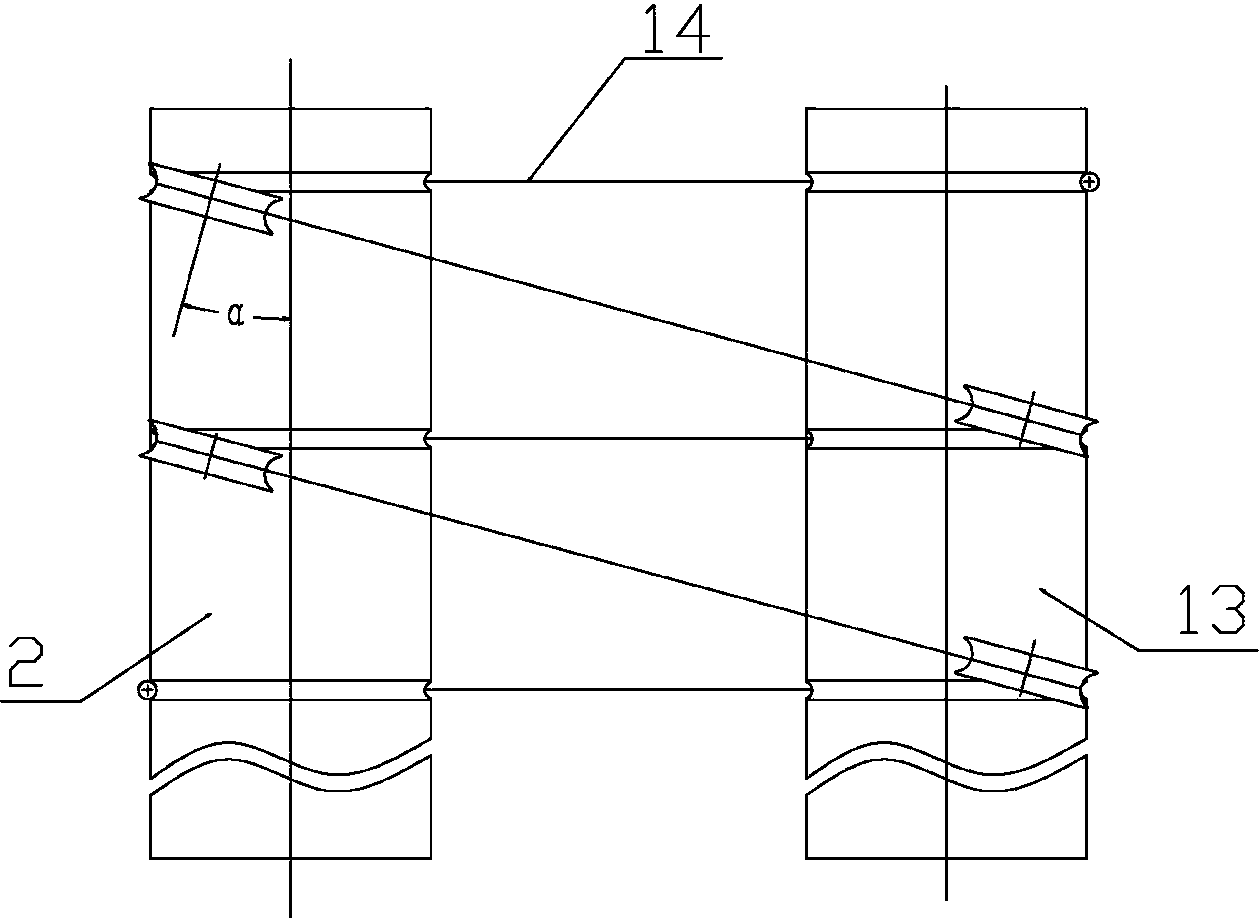

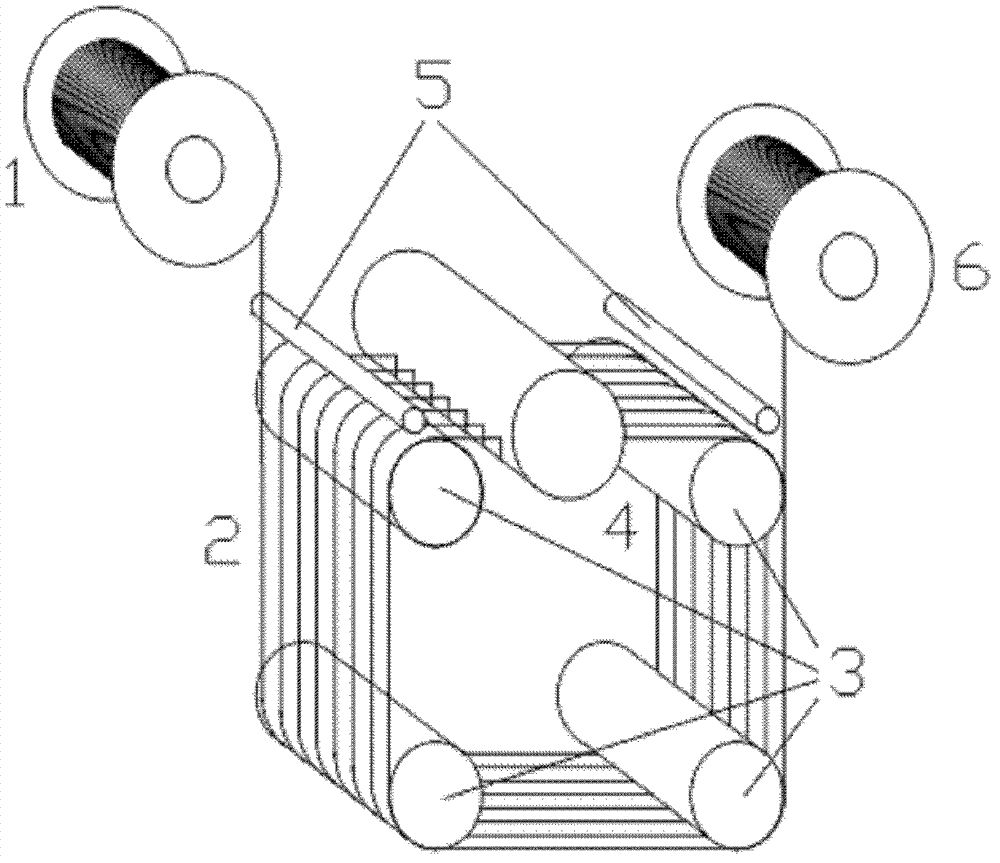

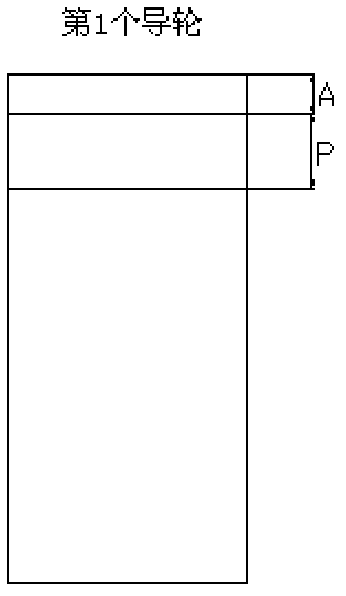

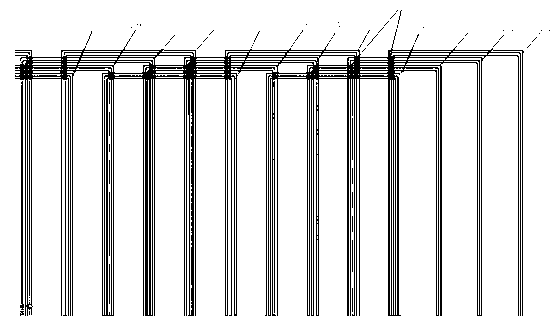

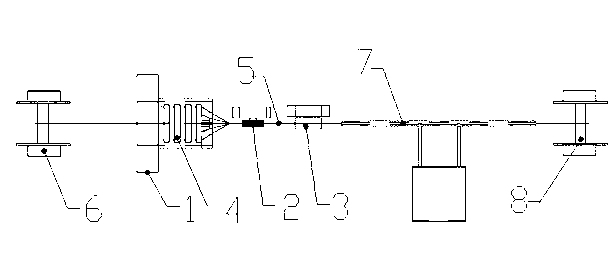

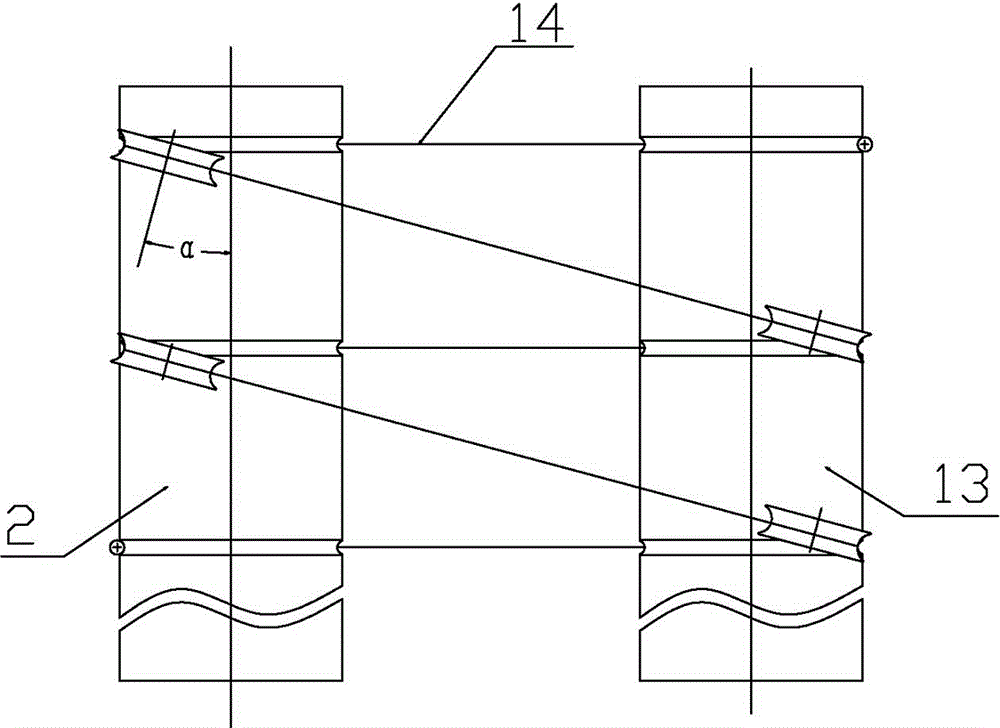

Grooving method for multi-wire cutting of super-thick products by aid of guide wheels

ActiveCN102814875AExpand product capabilitiesPrevent jumperFine working devicesWire cuttingMachine tool

A grooving method for multi-wire cutting of super-thick products by the aid of guide wheels includes determining the position of a first groove of each guide wheel in a guide wheel set consisting of the multiple guide wheels; and determining sequence numbers of mounting positions of the guide wheels in a machine tool according to the sequence that steel wires contact with the guide wheel. The grooving method has the advantages that a groove gap of a super-thick silicon wafer is divided, so that an included angle between each steel wire and the corresponding guide wheel is reduced, wire skipping is prevented, and capability of the products is expanded. Besides, the method can be applied to slicing various materials with the sizes of 4 inches, 5 inches, 6 inches, 8 inches and 12 inches or with non-standard sizes.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

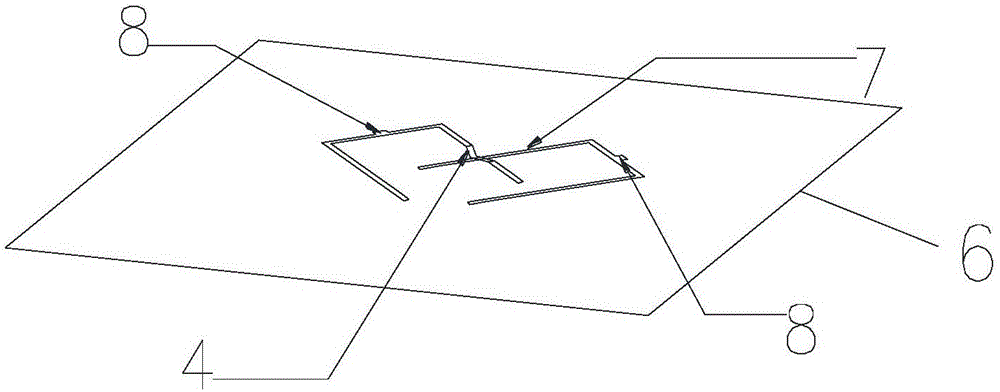

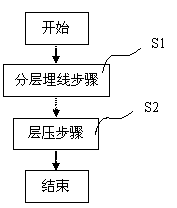

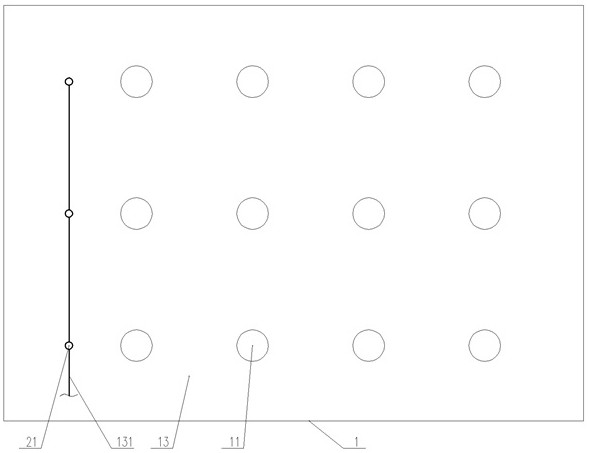

Antenna plate, touchpad, electronic device and manufacturing method of antenna plate for touchpad

InactiveCN102760939APrevent jumperAvoid disconnectionRadiating elements structural formsInput/output processes for data processingTouchpadEngineering

The invention discloses an antenna plate, a touchpad, an electronic device and a manufacturing method of the antenna plate for the touchpad, and belongs to the field of electromagnetic touch. The manufacturing method of the touchpad for the antenna plate comprises: a layered wire embedment step: producing a plurality of coils respectively in each of a plurality of sheets of base material in an ultrasonic wire embedding manner, so that each sheet of base material is formed into a coil layer, and multiple coils in each coil layer do not cross each other; and a lamination step: laminating the coil layers produced in the layered wire embedment step. According to the invention, excessive wire jumping in the ultrasonic wire embedment process is avoided, the velocity of wire embedment is increased, and thus the production efficiency is improved. Moreover, wire breaking due to excessive wire jumping is avoided, and thus the rate of finished products is increased. Thus, the invention can be widely applied in the field of electromagnetic touch.

Owner:HANVON CORP

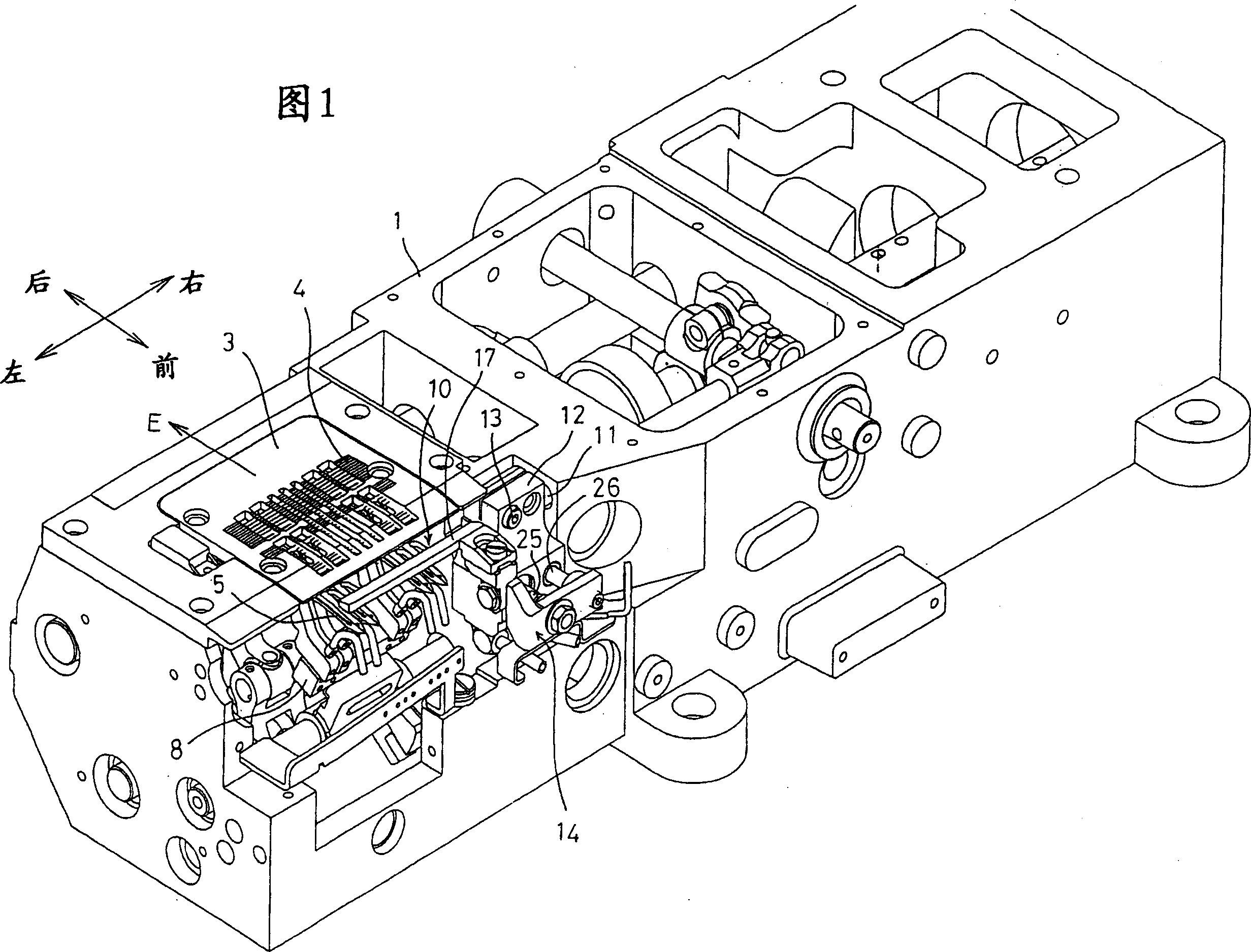

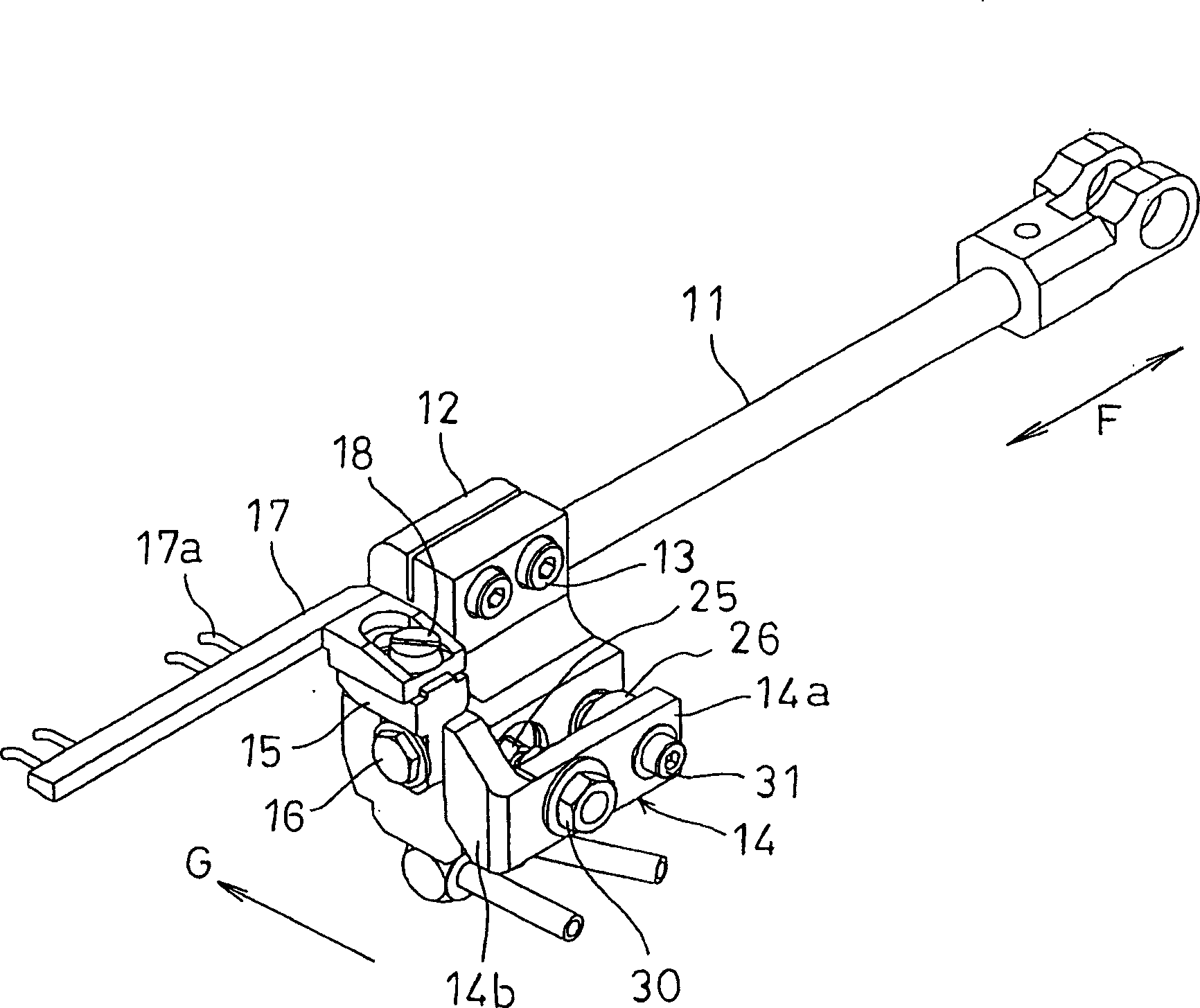

Voile dispersing mechanism for sartorius

The present invention provides a yarn divider mechanism of a sewing machine. The yarn divider of the yarn divider mechanism does not interfere with the looper, and can surely perform conscious thread skipping, and at the same time, can prevent unintentional thread skipping, and can perform proper thread skipping. sewing. It has a looper (5) and a yarn divider (17), the looper (5) is synchronized with the up and down motion of the sewing needle (2), by surrounding the looper bar (7) ) swings and engages with the upper thread to perform an elliptical motion to form stitches; the yarn divider (17) reciprocates in a left and right direction approximately perpendicular to the cloth feeding direction to pick up the bottom thread of the above-mentioned looper Lead the above-mentioned upper thread. The above-mentioned yarn divider (17) is arranged to be able to move forward and backward between the following two positions, that is, to advance in the direction G that is substantially the same as the cloth feeding direction, to carry out the wire position of the wire, and to move from the wire position. This is the retracted position for retracting in the direction opposite to the feed direction.

Owner:MORIMOTO MFG

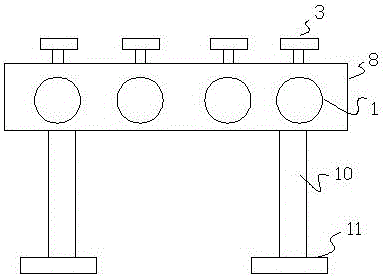

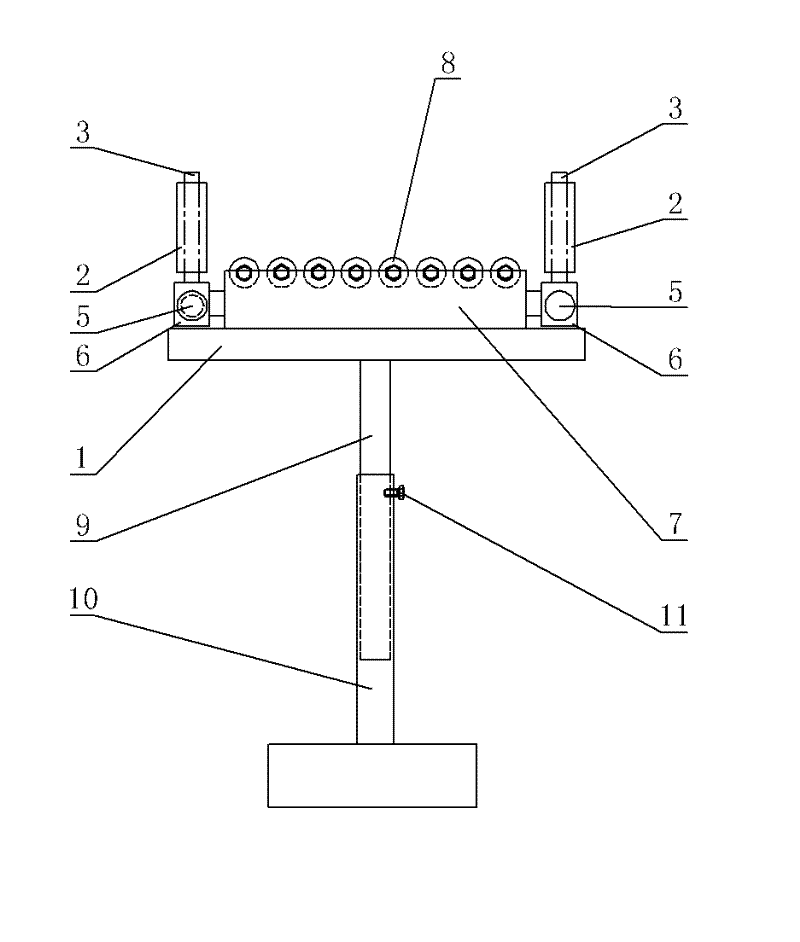

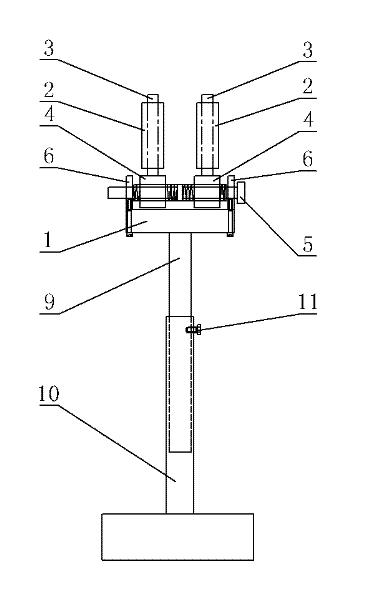

Yarn-jumping-prevention device for spinning

The invention relates to the field of spinning, in particular to a yarn-jumping-prevention device for spinning. The device can effectively prevent spinning yarn from jumping in the process of being guided into a spinning machine and structurally comprises a first fixing plate and a second fixing plate which are arranged in parallel; the two ends of the first fixing plate and the two ends of the second fixing plate are connected through supporting rods; the first fixing plate and the second fixing plate are each provided with a plurality of through holes; screw rods are inserted in the through holes, and threading rings are arranged inside the screw rods; fastening bolts for fixing the screw rods are vertically arranged on each of the first fixing plate and the second fixing plate; and rubber cylinders used for yarn leading are arranged on the supporting rods; and supporting legs are arranged at the bottom of the first fixing plate and the bottom of the second fixing plate. The yarn-jumping-prevention device is simple in structure, convenient to use and suitable for guiding of multiple kinds of spinning yarn.

Owner:WUJIANG XINJIN TEXTILE

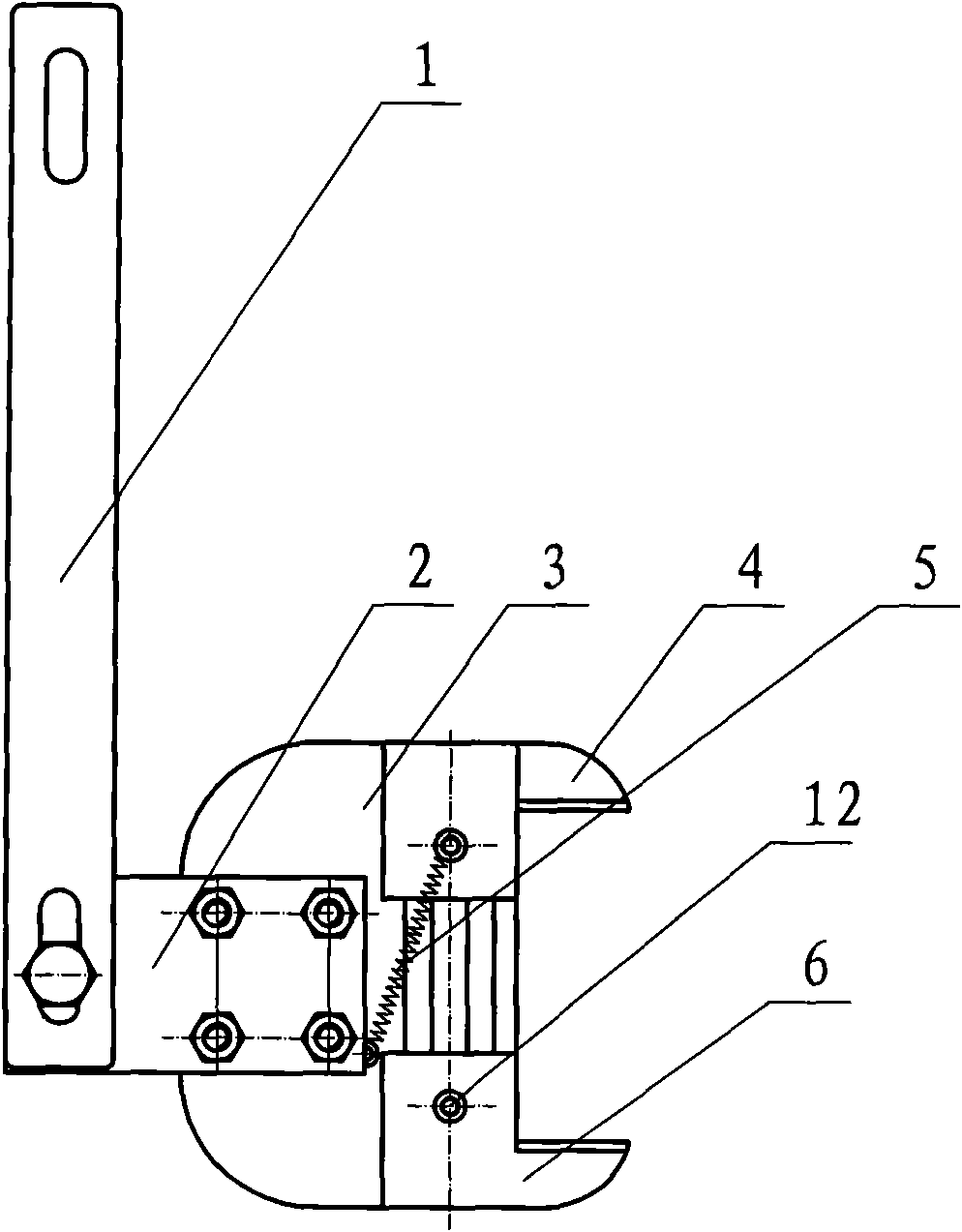

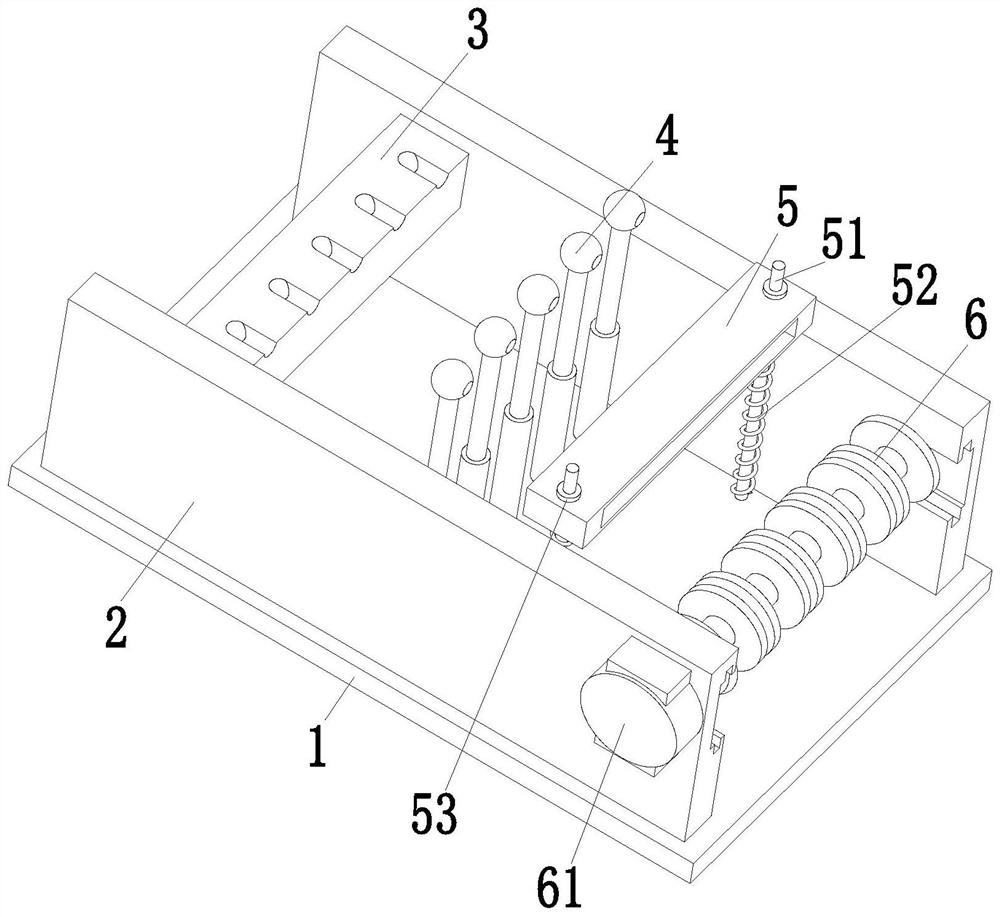

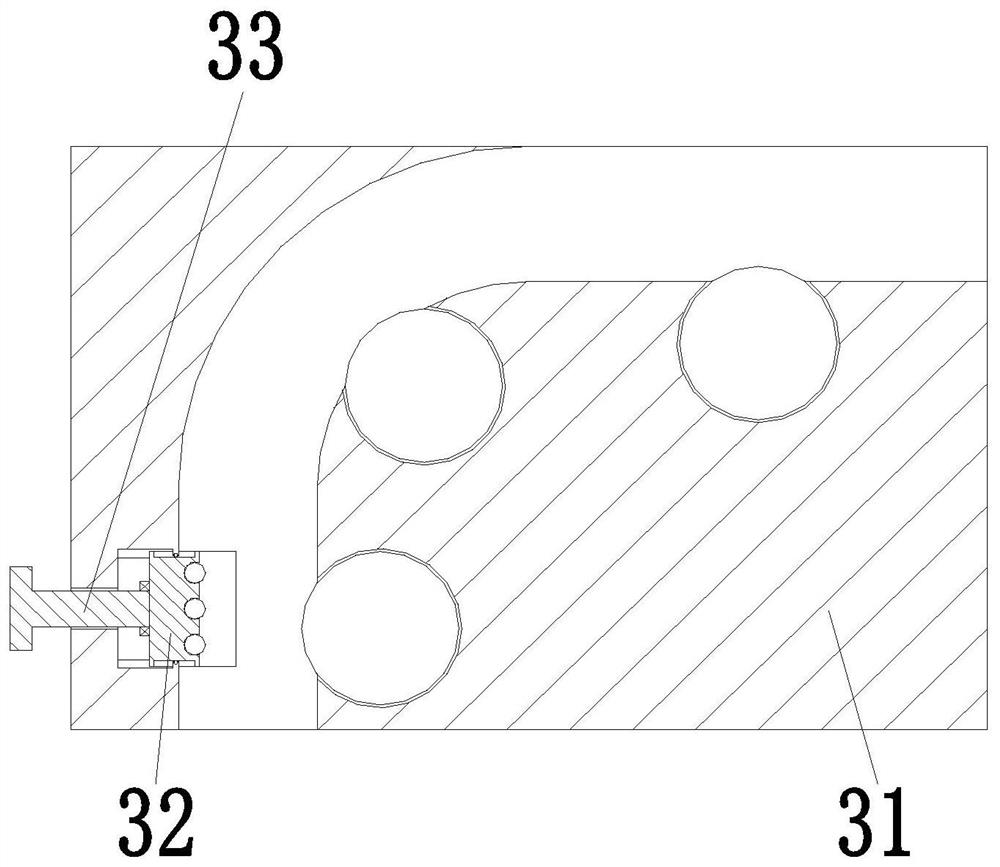

Wire arranging location mechanism of ring-shaped winding machine

ActiveCN101599362AGuarantee the quality of windingSmooth slidingCoils manufactureWinding machineEngineering

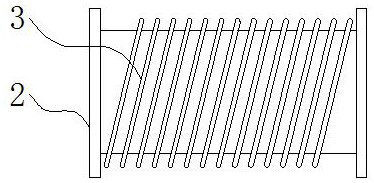

The invention discloses a wire arranging location mechanism of a ring-shaped winding machine, comprising a mounting rod (1), a main baffle body (3), a connecting plate (2), an upper locating head (4) and a lower locating head (6), wherein the main baffle body (3) is connected with the mounting rod (1) by the connecting plate (2). The wire arranging location mechanism is characterized in that the upper locating head (4) is installed on the main baffle body (3) in a sliding way. When in the winding process of the ring-shaped winding machine, the wire arranging location mechanism can be used for locating enamelled wires, and the upper locating head is matched with a tension spring to move up and down; no matter how the height of winding iron cores is, the wire arranging location mechanism can lead the upper locating head to cling to the surface of a bakelite disc for accurately locating the enamelled wires, thus avoiding the phenomenon of wire jumping, overlapping or crossing when in the winding process of the enamelled wires, and ensuring the winding quality.

Owner:温州市南方机械制造有限公司

Anti-falling-off type wire passing wheel of cutting machine

The invention discloses an anti-off type cutting machine thread wheel, which includes an aluminum alloy frame and a rubber ring, the rubber ring is placed outside the aluminum alloy frame, and the cut surface of the aluminum alloy frame becomes larger from the inside to the outside , the rubber ring includes an inner groove and an outer groove, the cut surface of the inner groove becomes smaller successively from the inside to the outside, and the outer end of the aluminum alloy skeleton is correspondingly embedded in the inner groove, so The two opposite side walls of the outer groove are respectively provided with baffles, and the baffles are provided in multiples and arranged at equal intervals on the two side walls of the outer groove. The invention has simple structure and convenient use, can effectively avoid wire jumping, increase use stability, and improve work efficiency.

Owner:SUZHOU RUNDE NEW MATERIAL

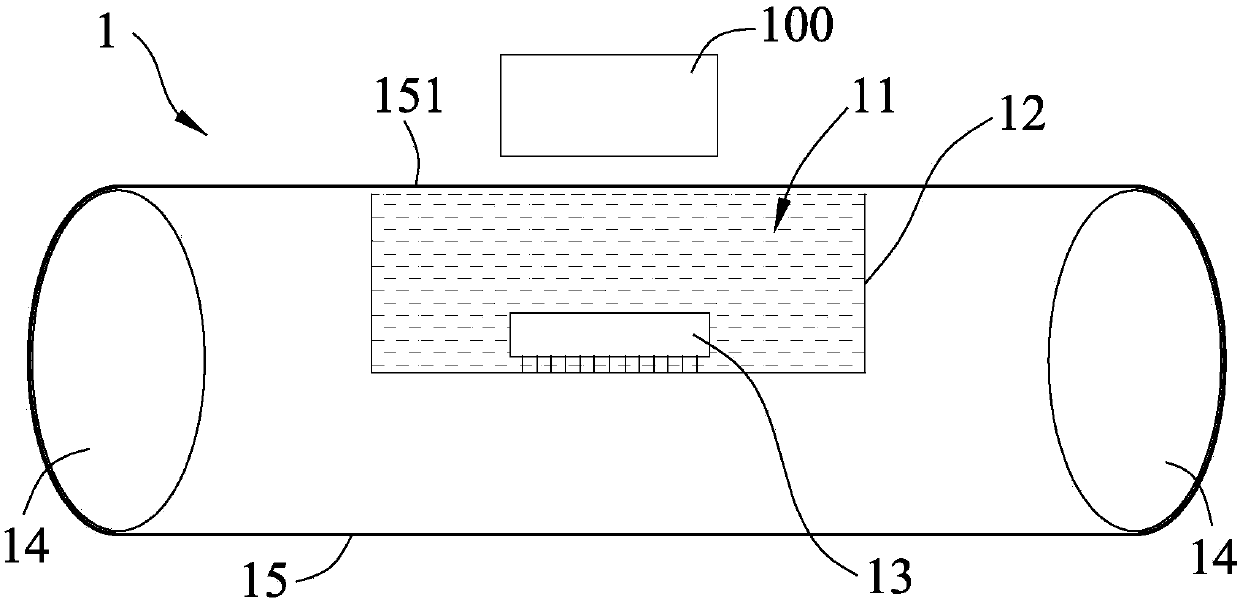

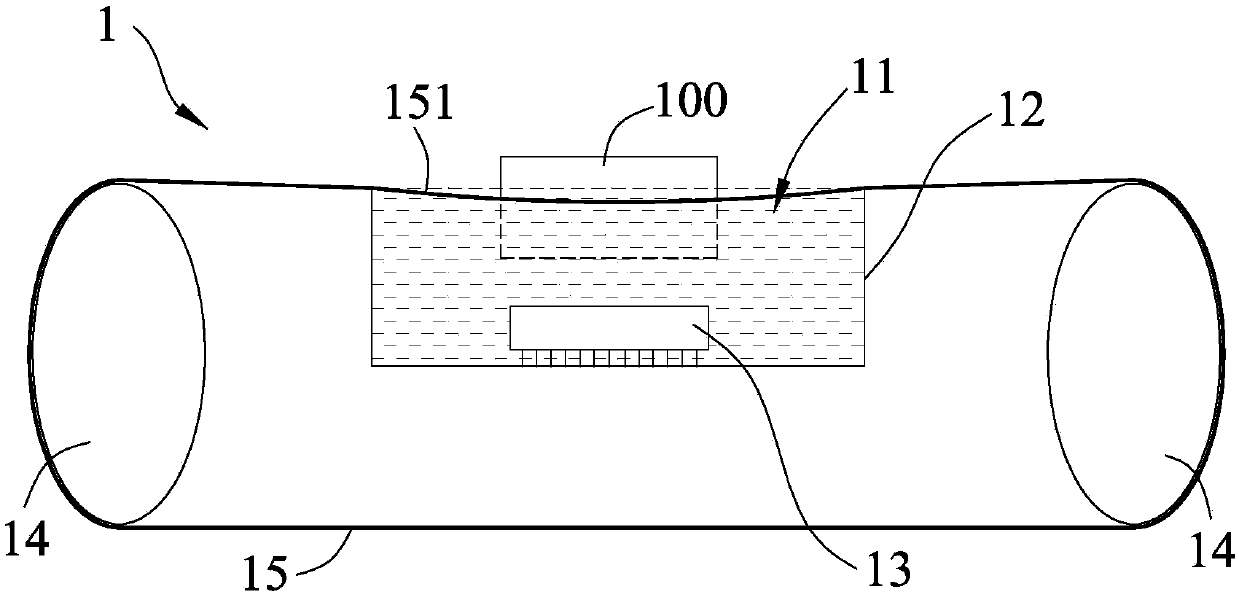

Cutting method of cutting ultrasonic auxiliary lines and apparatus thereof, and a method of producing wafers

InactiveCN107813434APrevent jumperAvoid disconnectionFine working devicesCapillary actionPatch cable

A sawing method of cutting ultrasonic auxiliary lines includes a preparation step and a cutting step. The preparation step includes: providing an ultrasonic auxiliary line cutting apparatus and a to-be-cut object, wherein the ultrasonic auxiliary line cutting apparatus includes a tank defining a receiving space having an opening, an ultrasonic vibrator disposed in the tank, a cutting liquid arranged in the receiving space, and multiple cutting lines located above the opening and spaced apart from the cutting liquid. The cutting step includes moving the to-be-cut object towards the direction ofthe cutting lines so that the to-be-cut object is cut by the cutting lines to form multiple cut grooves and is immerged into the cutting liquid, each of the cut grooves having a radial width generating capillary action and allowing the cutting liquid to enter the cut grooves by the capillary action. Therefore, ultrasonic energy can be simultaneously conducted to the to-be-cut object and the cutting lines to avoid line jumping or breaking of the cutting lines and reduce the energy loss. The invention also provides an ultrasonic auxiliary line cutting apparatus for executing the method and a method of producing wafers.

Owner:AUO CRYSTAL

Needle fixing device for sewing machine

The invention relates to the technical field of sewing machines, and discloses a needle fixing device for a sewing machine. The needle fixing device for the sewing machine comprises an equipment mainbody, the lower end of the equipment main body is movably connected with a connecting pipe, the left end of the connecting pipe is fixedly connected with an air bag column extending to the equipment main body, an air storage bag is arranged in an inner cavity of the upper part of the connecting pipe, air guide grooves are formed in the left wall and the right wall of the connecting pipe, a partition plate is fixedly installed in an inner cavity in the middle of the connecting pipe, and an elastic I-shaped rod is movably connected to the middle of the partition plate. According to the needle fixing device for the sewing machine, an elastic I-shaped rod is extruded through the needle, so that a metal bead makes contact with a metal sheet for reminding, an adjusting screw rod is rotated in amatching mode to enable a wedge block to extrude a securing plate to fix the needle, when the elastic I-shaped rod moves upwards in a matching mode, the air storage bag is deflated, therefore, the problem of needle wire jumping in the later period is avoided, the stability of needle installation is improved, and the accuracy of needle installation is improved.

Owner:金亚东

Wire drawing equipment with protection structure for steel wire production

PendingCN113385545AReduce tensionReduce deliveryMetal working apparatusStructural engineeringMachine

The invention discloses wire drawing equipment with a protection structure for steel wire production, and relates to the technical field of steel wire production. The wire drawing equipment comprises a machine frame, a lubricating mechanism and a display screen, wherein an unwinding drum is arranged on the lower left side of the exterior of the machine frame, a steel wire main body is arranged on the outer side of the unwinding drum, a water cooling box is fixed to the lower portion of the left side of the interior of the machine frame, the steel wire main body penetrates through a hollow groove inside the water cooling box, a first transition wheel, a guide wheel and a wire drawing die are sequentially arranged outside the steel wire main body from left to right, an electric push rod is arranged on the lower portion inside the machine frame, a support is fixed to the upper portion of the electric push rod, a tensioning wheel is arranged inside the support, and the tensioning wheel is located outside the steel wire main body. The wire drawing equipment has the beneficial effects that the first transition wheel, the guide wheel, the wire drawing die and the tensioning wheel inside the equipment is a one-time drawing process, and four-time drawing processes are arranged on the upper side and the lower side inside the machine frame in total so that the drawing precision can be effectively improved while the occupied area is saved.

Owner:成都蒙德艾特自动化设备有限公司

Processing apparatus and processing method for flocking flexible shaft

InactiveCN102913535AAvoid glue residueAvoid sticking inFlexible shaftsEngineeringUltimate tensile strength

The invention discloses a processing apparatus for a flocking flexible shaft. The processing apparatus comprises a material stack bin, a heating device and a traction wheel, wherein a wool spool coiled with wool is arranged in the material stack bin; the to-be-flocked flexible shaft used as a core wire is coiled on the flexible shaft wool spool; one end of the flexible shaft penetrates the material stack bin and the heating device to be connected to the traction wheel; and the wool is coiled on the flexible shaft. The processing apparatus adopts a hot melting method to realize mechanical automatic production, thereby reducing work intensity of operation staff and dependence on the manual technology, allowing processing technology to realize reel production of the flocking flexible shafts, and improving the processing efficiency. The produced flocking flexible shaft has universality.

Owner:SUHNER SUZHOU IND TECH

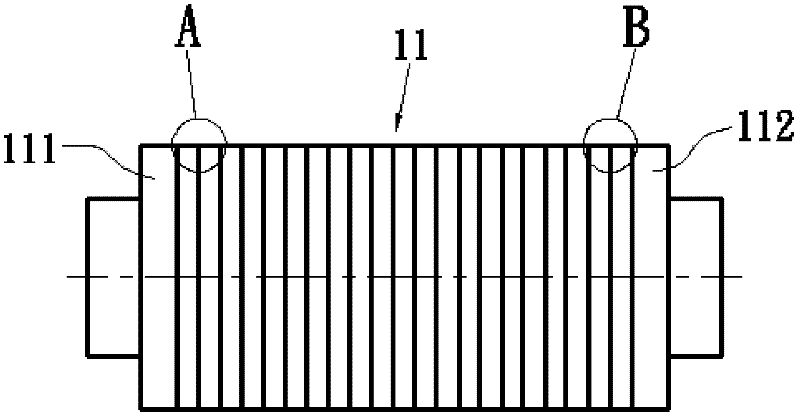

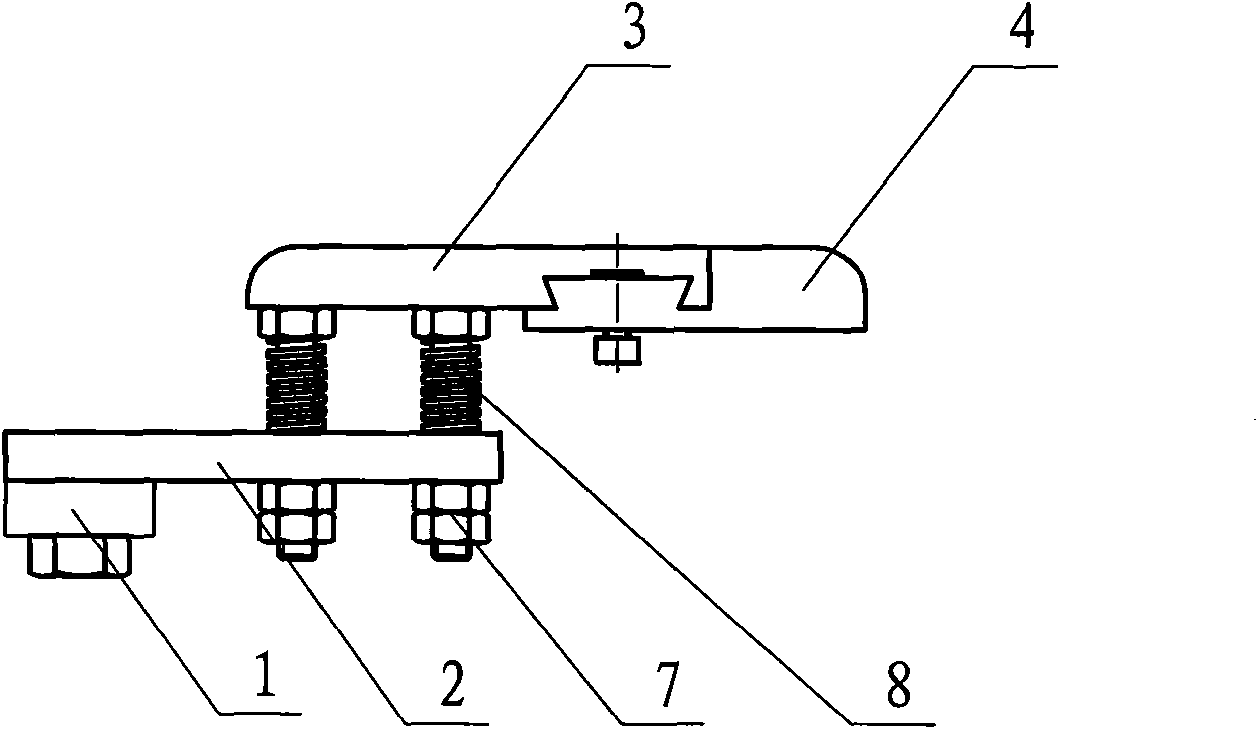

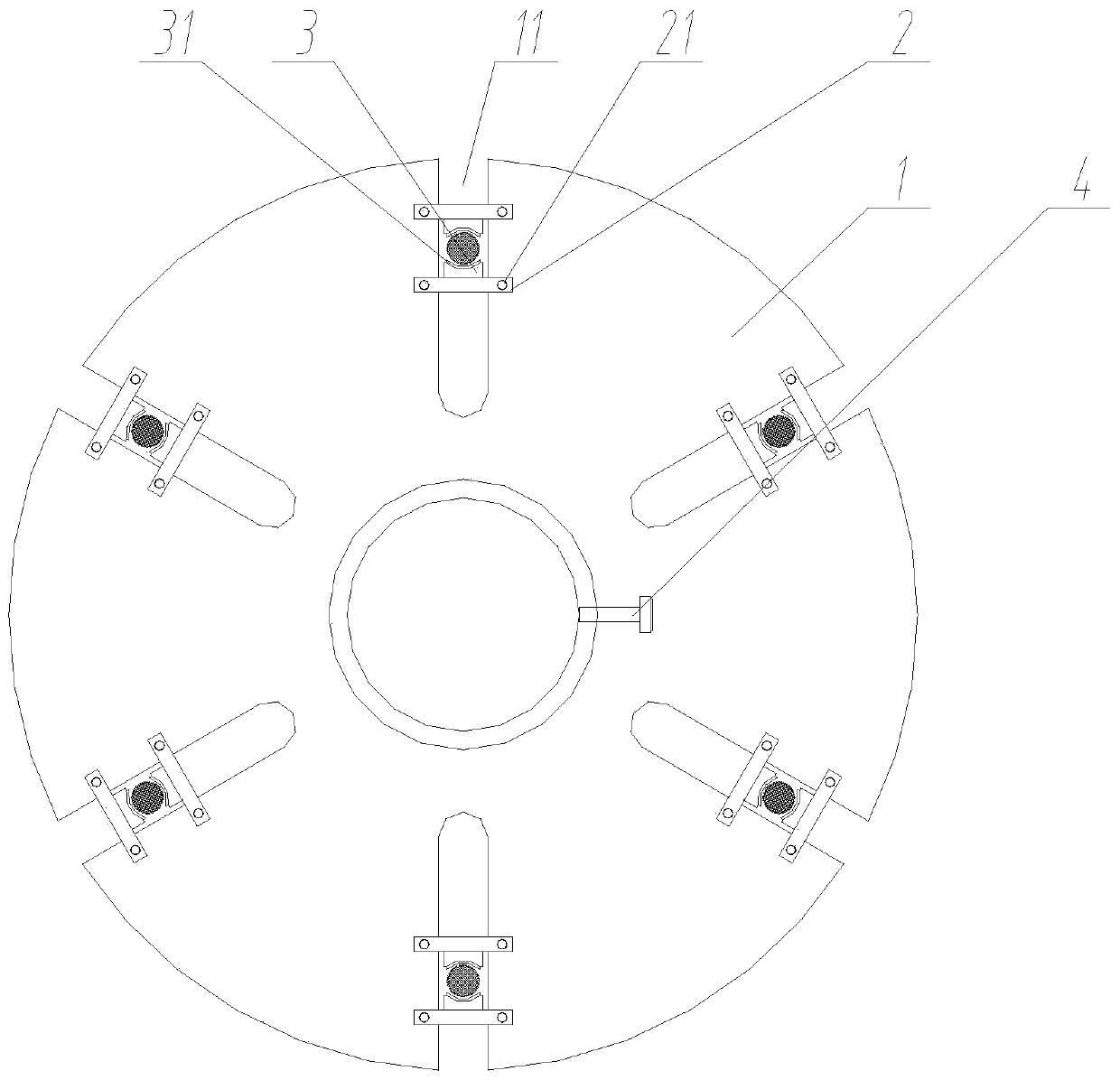

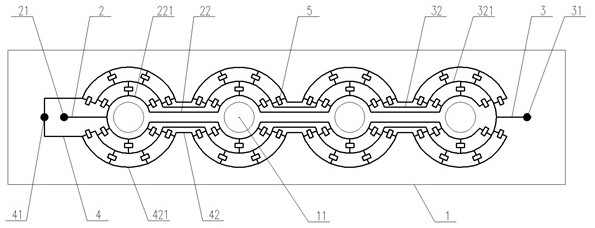

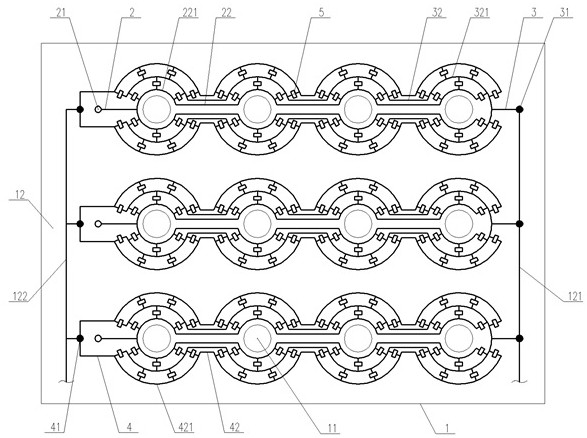

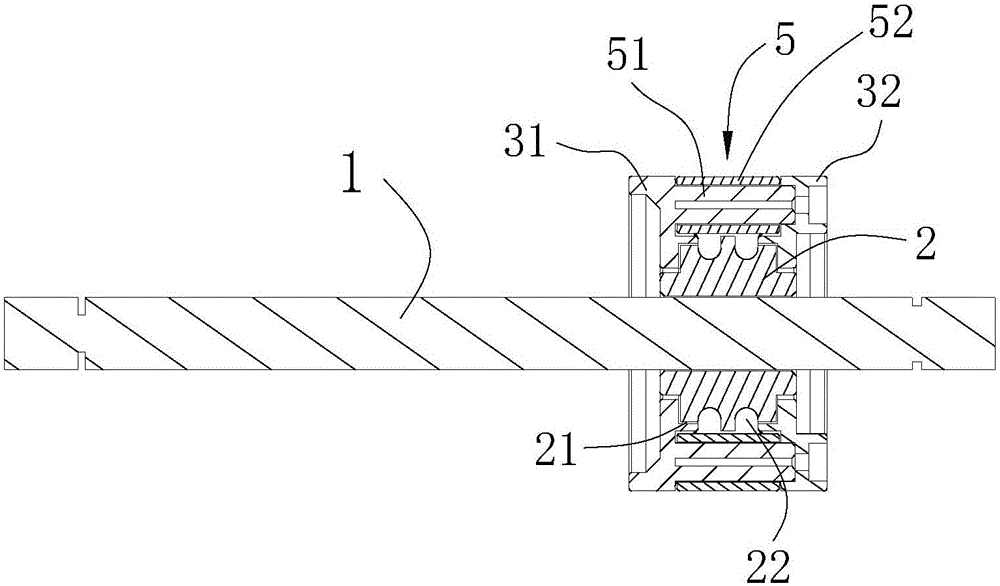

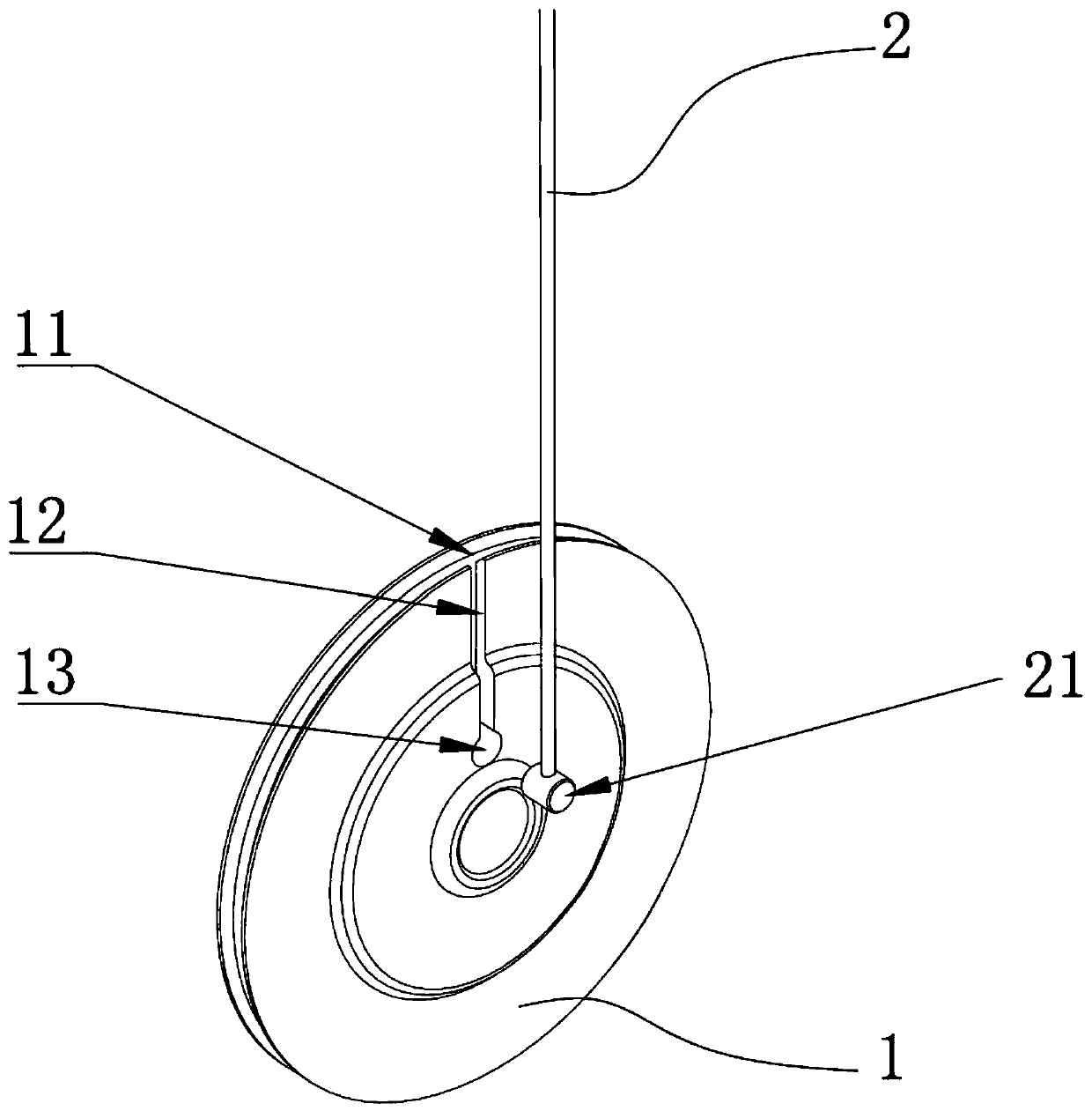

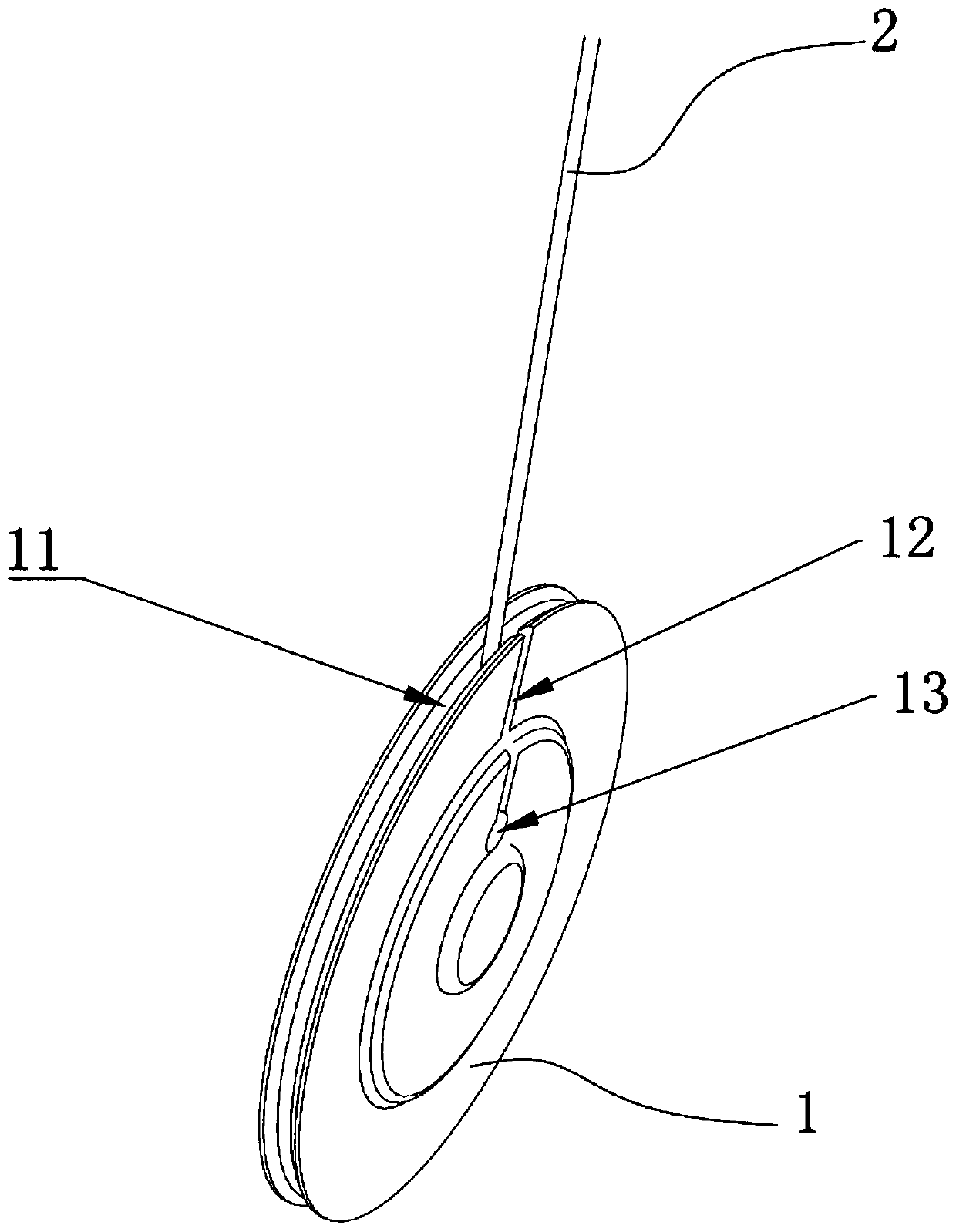

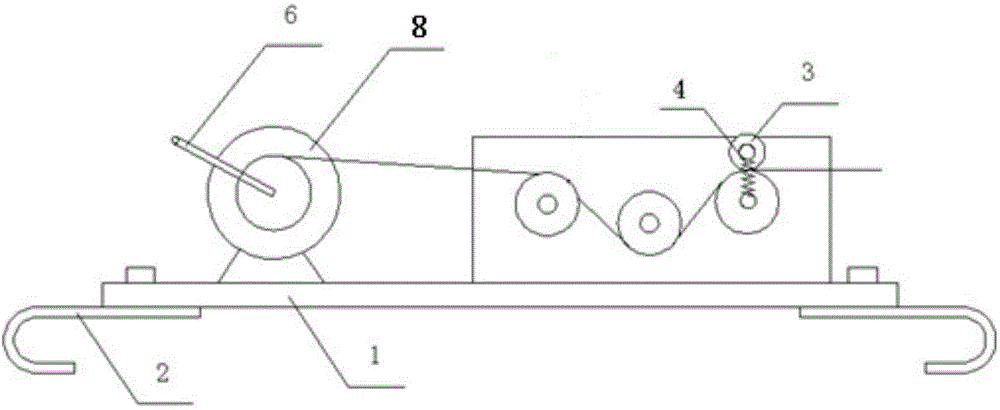

Threading disc for stranded wire

ActiveCN110600203APrevent jumperPrevent vibration and other phenomenaCable/conductor manufactureEngineeringSlide plate

The invention discloses a threading disc for a stranded wire. The threading disc includes a threading plate and stopping devices, wherein the threading plate is provided with multiple through slots with openings on the edge; the through slots are evenly distributed in the circumferential direction; the stopping devices are correspondingly arranged at the through slots; each stopping device includes an outer stopping device and an inner stopping device; the inner stopping device is arranged close to the center of the threading plate; the outer stopping device is arranged outside the inner stopping device; the inner stopping device includes a slide plate, a stopping plate, and a locking rod; the slide plate is slidably disposed in the through slot and is locked and fixed by the locking rod;and the stopping plate is disposed outside the slide plate. The threading disc for a stranded wire has a simple structure, stops the wire before the wire is stranded, and prevents a jump phenomenon caused by vibration and the like from affecting the stranded wire processing.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

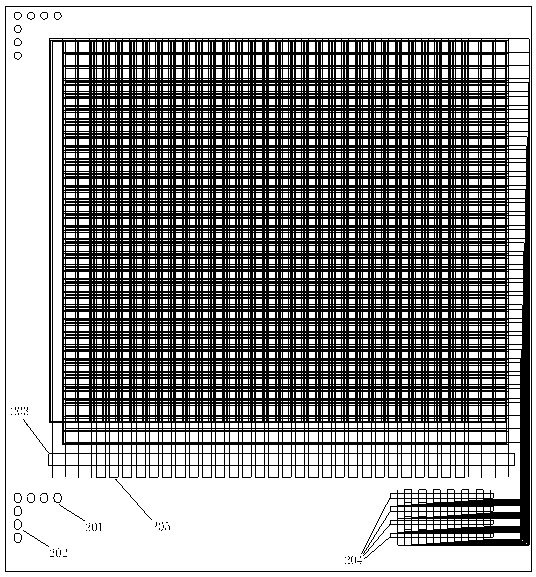

Plant leaf back light supply lamp panel

InactiveCN111853717AImprove photosynthesis efficiencySolve the problem of insufficient light intensityElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringPlantlet

The invention provides a plant leaf back light supply lamp panel, and relates to the technical field of plant planting. According to the technical scheme, the plant leaf back light supply lamp panel comprises a substrate, wherein a plurality of planting holes arranged in an array mode are formed in the substrate; each row of planting holes is provided with a set of power lines; the power lines comprise first wires, second wires and third wires. Each planting hole corresponds to one plant, a plurality of LED elements are evenly distributed around the planting holes, each plant can obtain uniform bottom light supply, the photosynthesis capacity of the bottom faces of leaves is developed, the overall photosynthesis efficiency of the plants is improved, and the purpose of increasing the yieldis achieved. The planting holes are distributed in the substrate in an array mode, the circuit structure and the circuit width of the first wires, the second wires, the third wires and the like on thesubstrate for supplying power to the LED elements are optimized, crossing, winding and wire jumping are avoided, the length of a power supply circuit is reduced as much as possible, enough width is guaranteed so as to reduce resistance, and the current carrying capacity is guaranteed.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

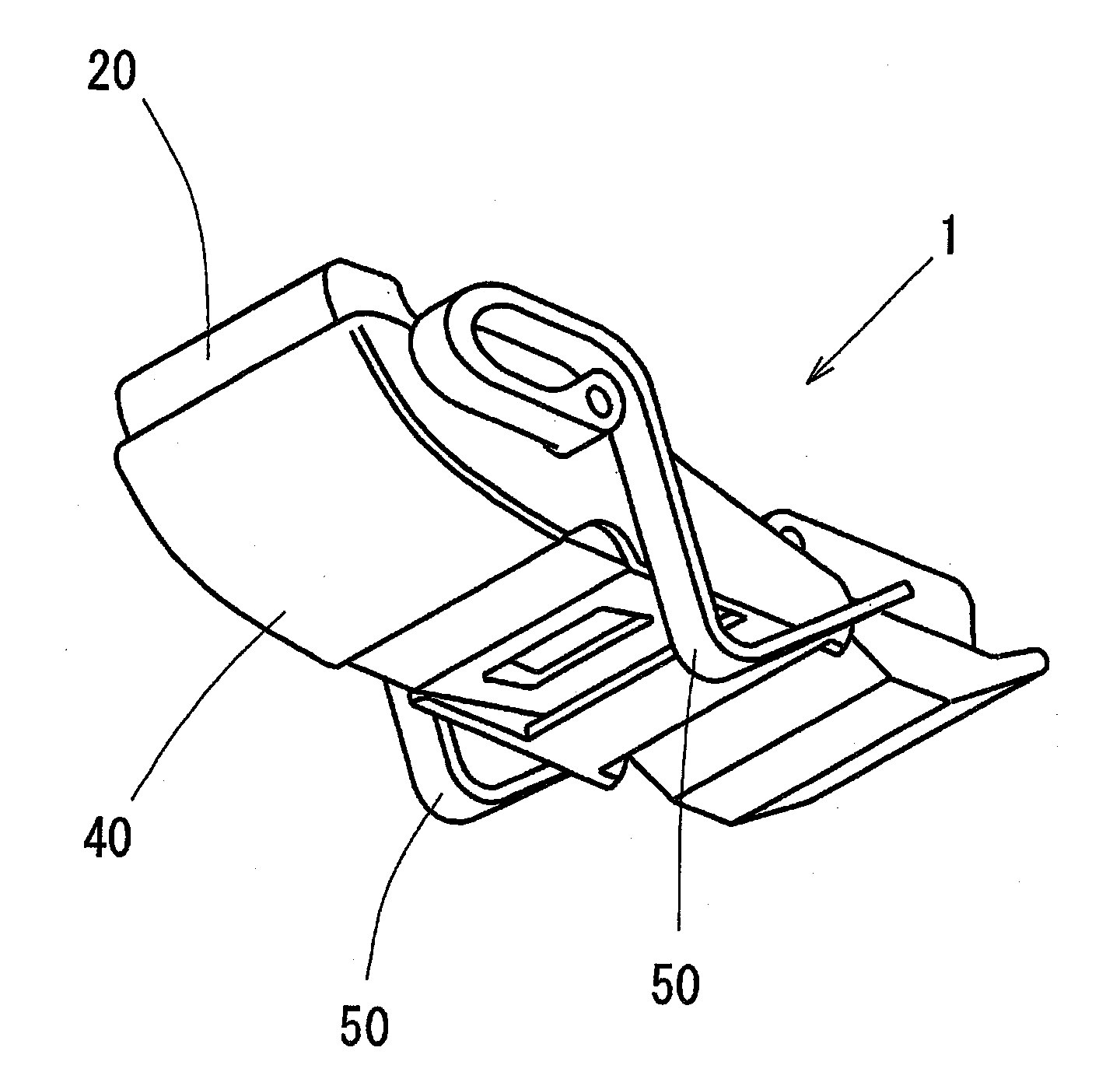

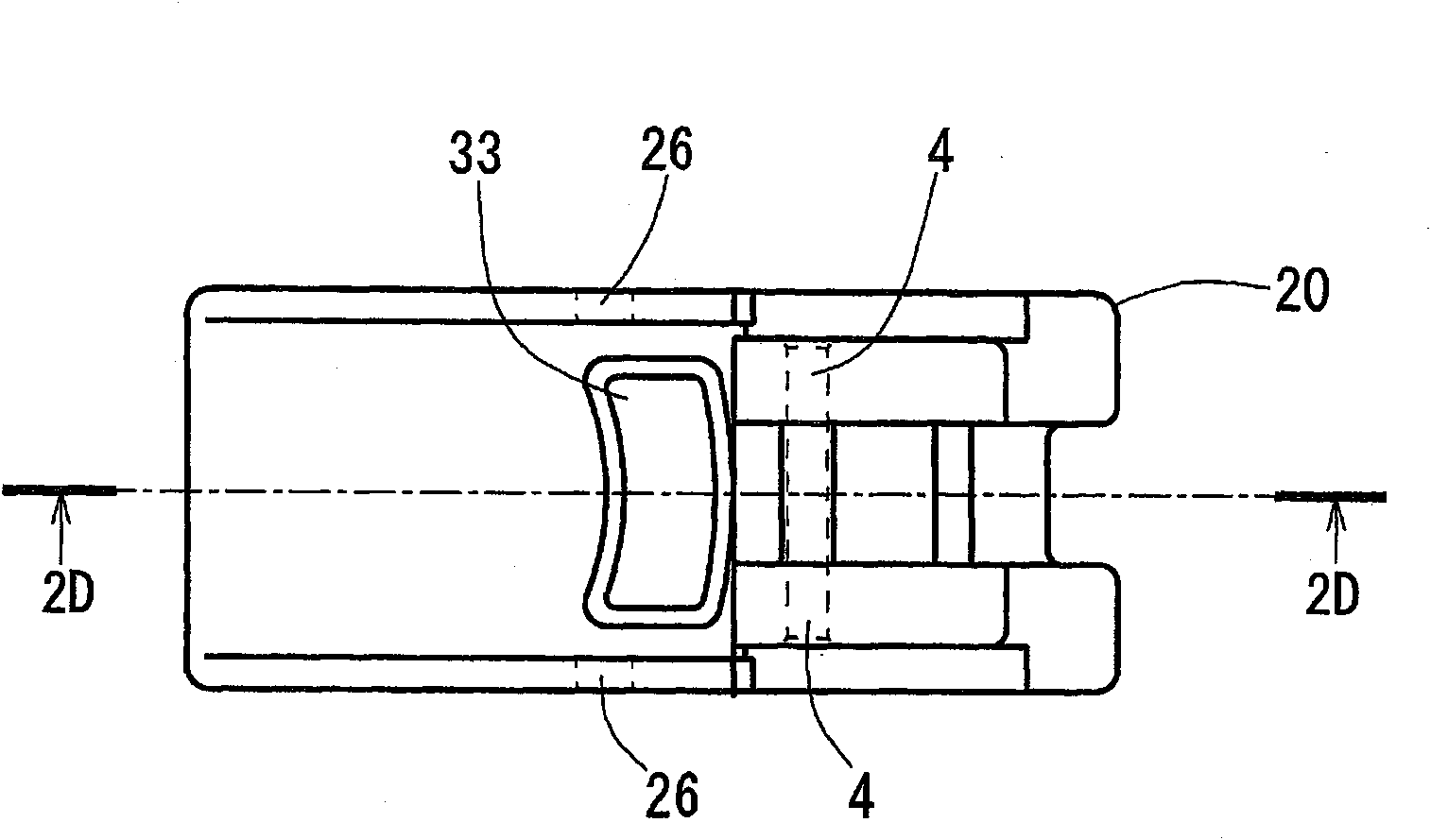

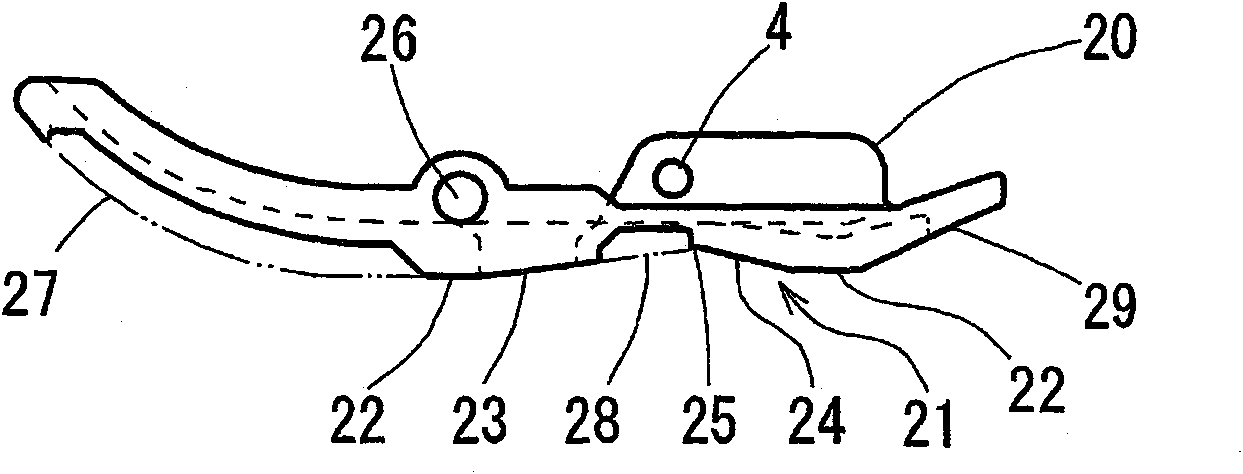

Presser foot for sewing machine

A presser foot (1) for a sewing machine includes a main body (20) rotatably attached to a presser holder (2) via a pivot shaft (4) and having a needle receiving hole (33), and a restriction member (40) rotatbly attached to the main body (20), wherein the restriction member (40) includes a restriction portion (50), which protrudes downward from a bottom face (21) of the main body (20) to press a work material to thereby restrict a movement of the work material when a stepped portion (10) of the work material comes in contact with the presser foot (1).

Owner:积家国际株式会社

Rod splicing glue and preparation method thereof, rod splicing glue film and preparation method and application thereof

ActiveCN112708383AStickySticky noNon-macromolecular adhesive additivesFinal product manufacturePtru catalystAdhesive

The invention discloses a rod splicing glue, a preparation method thereof, a rod splicing glue film, a preparation method thereof and application. The rod splicing glue comprises, by mass, 5-10 parts by mass of acrylate pressure-sensitive adhesive; 50-60 parts by mass of modified epoxy resin; 15-30 parts by mass of a high-hardness filler; 2.5-5 parts by mass of a dicyandiamide curing agent; 0.5-1 part by mass of an imidazole catalyst; and 5-10 parts by mass of a solvent. As a novel glue for special purposes, the rod splicing glue disclosed by the invention has certain viscosity at normal temperature, has no viscosity after being cured at high temperature, and is high in hardness and relatively strong in tear resistance. According to the rod splicing glue film, the silicon blocks are spliced into the combined silicon block, the combined silicon block is cut after being heated and cured, thick pieces are prevented from being generated at the splicing position during cutting, and the silicon wafer output rate is increased; and moreover, the problems of wire jumping and wire breaking of the cutting wire at the splicing position are avoided, and the working efficiency is improved. The preparation process of the rod splicing glue and the rod splicing glue film is simple and easy to implement.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

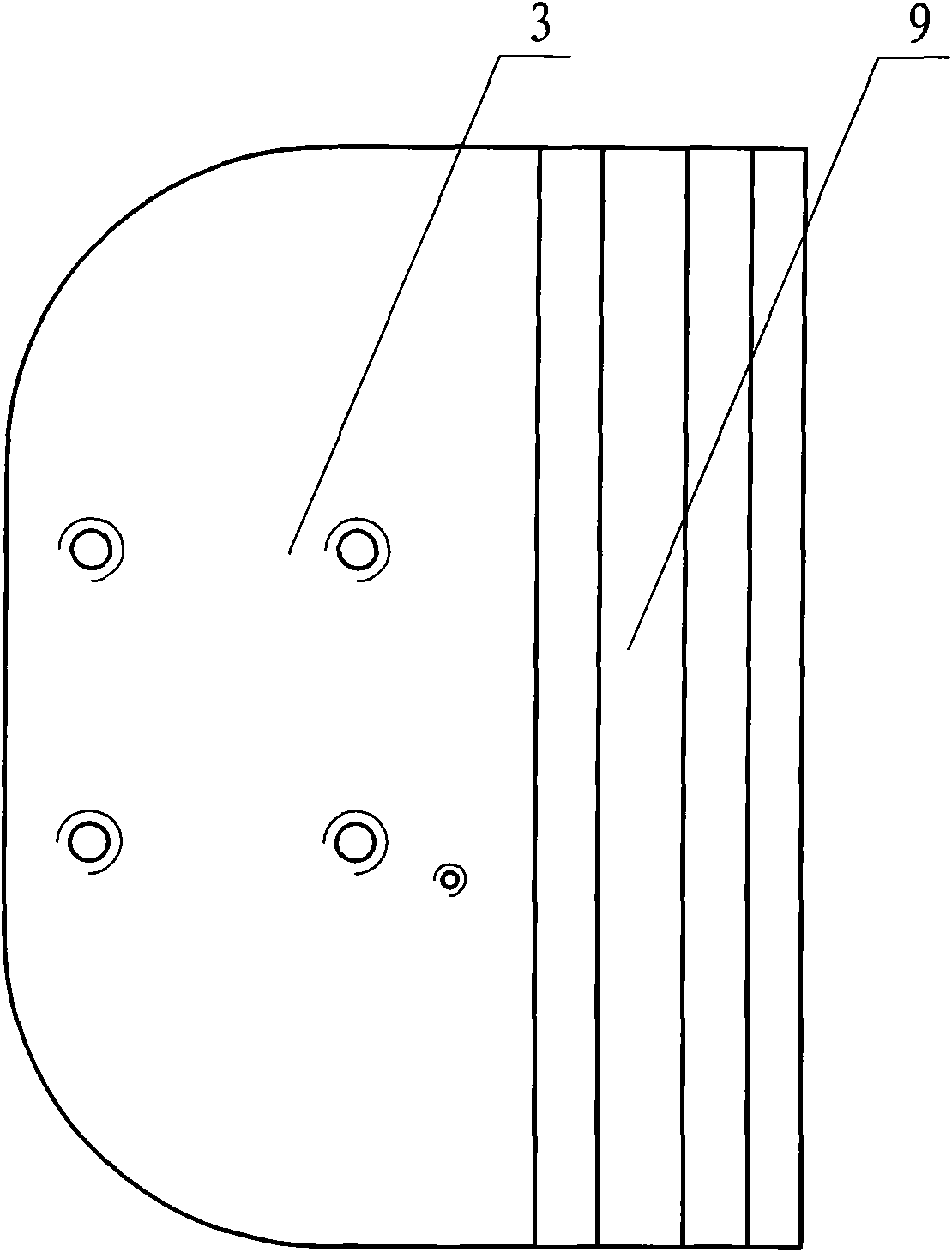

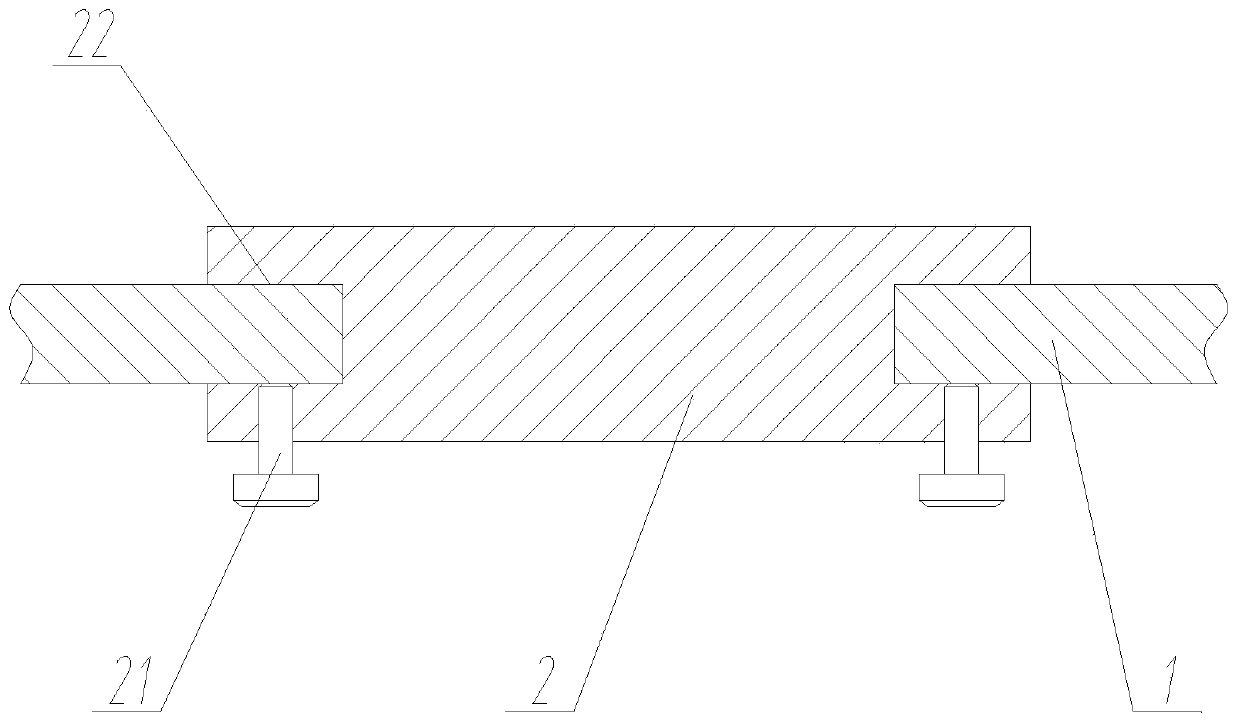

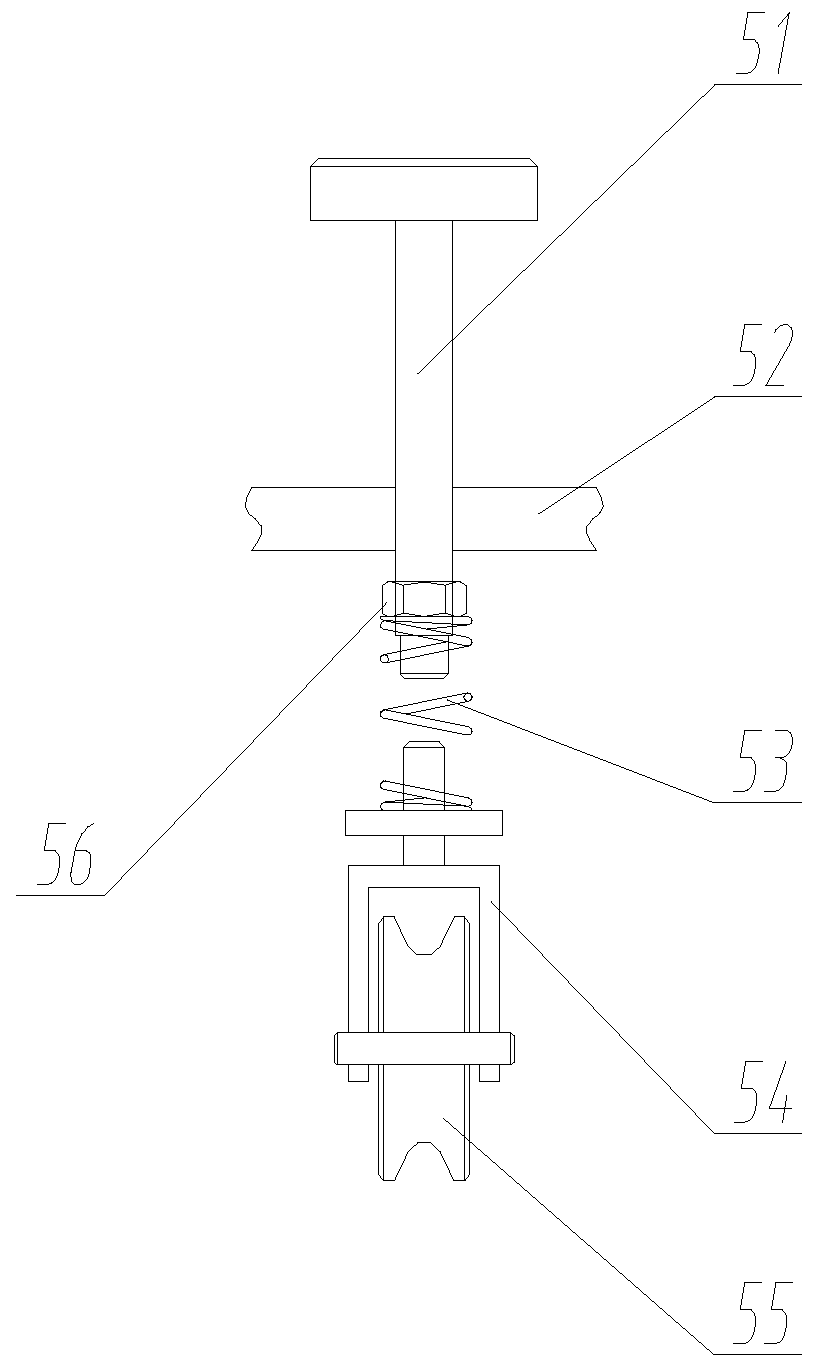

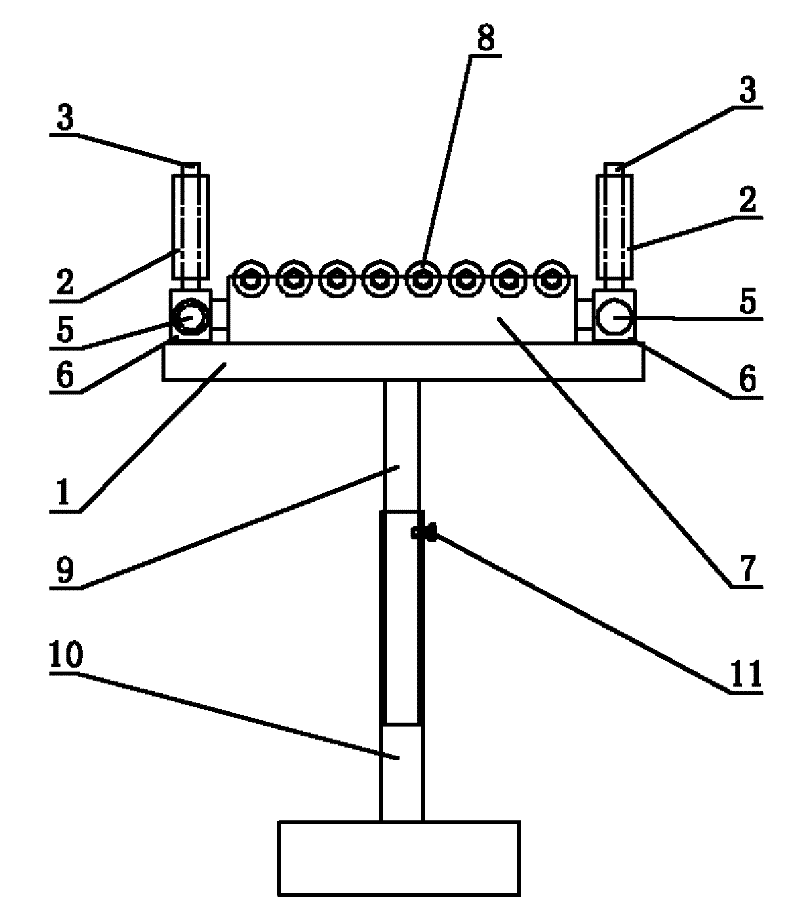

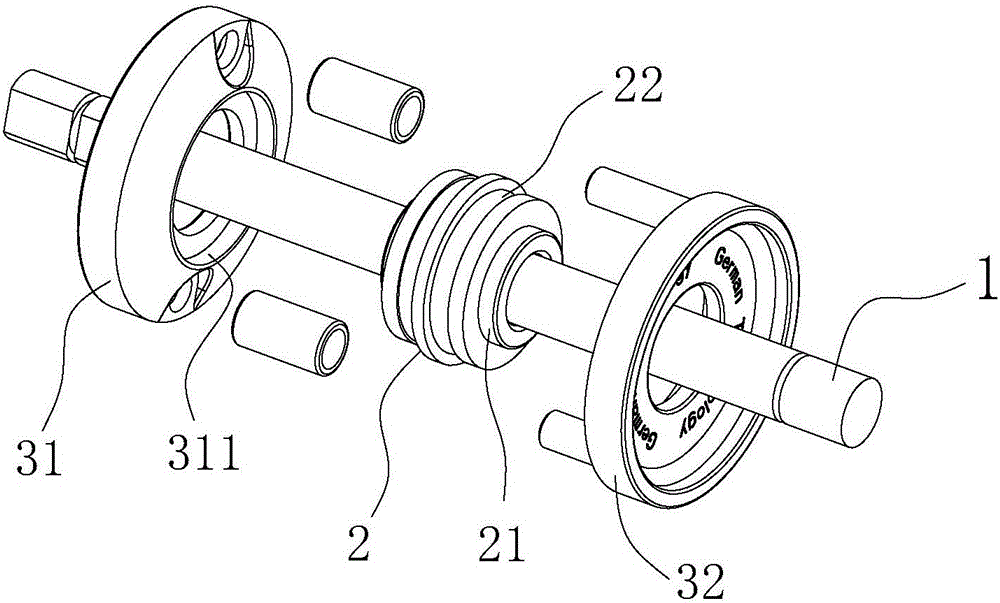

Wire binding device of transposed conductor

ActiveCN102005268BGuarantee processing qualityPrevent jumperManufacturing wire harnessesEngineeringPatch cable

The invention provides a wire binding device of a transposed conductor, which can ensure consistent length of a bundle conductor in the process of conveying the bundle conductor between a transposed head and a winding cage, thus preventing the phenomenon that jumper generates due to bending which is caused by self-gravity action of the bundle conductor when the bundle conductor winds, and ensuring the processing quality of the transposed conductor. The wire binding device comprises a base and is characterized in that the two ends of the base are provided with two groups of bundle roller devices symmetrically, a transposed conductor carriage device is arranged horizontally along the base, and the lower part of the base is provided with a vertical regulating mechanism.

Owner:WUXI XIZHOU MAGNET WIRES

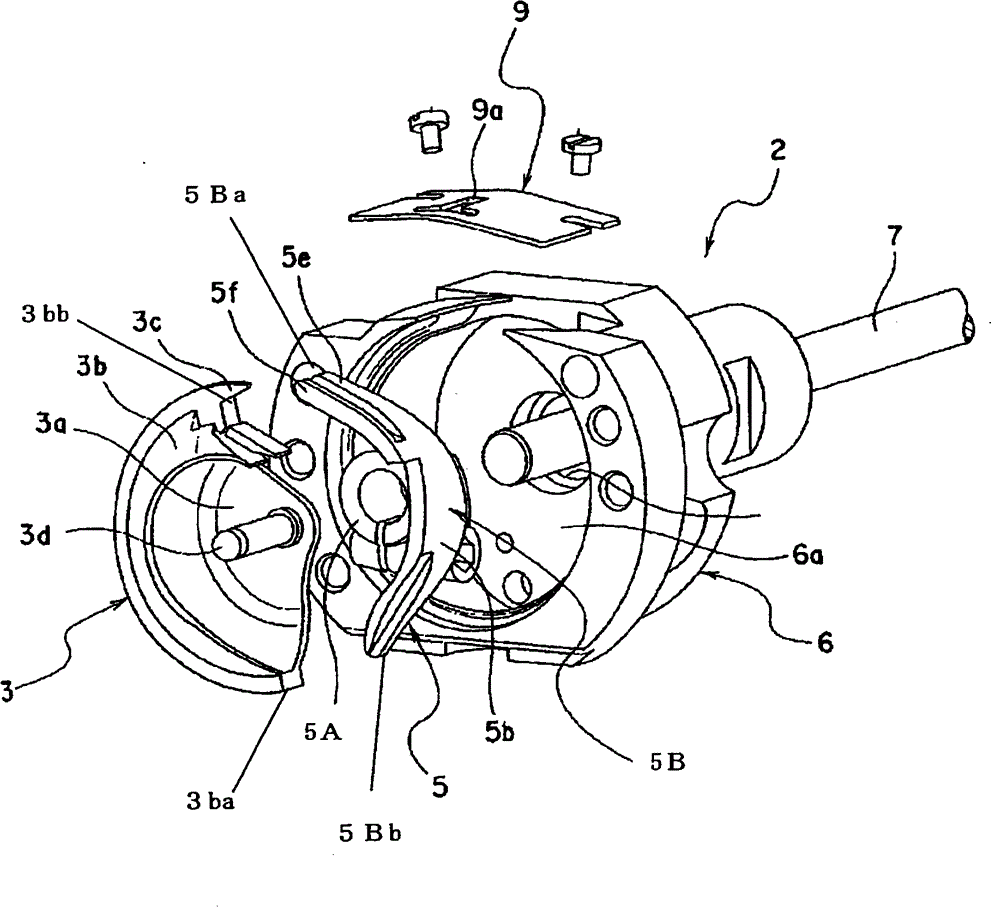

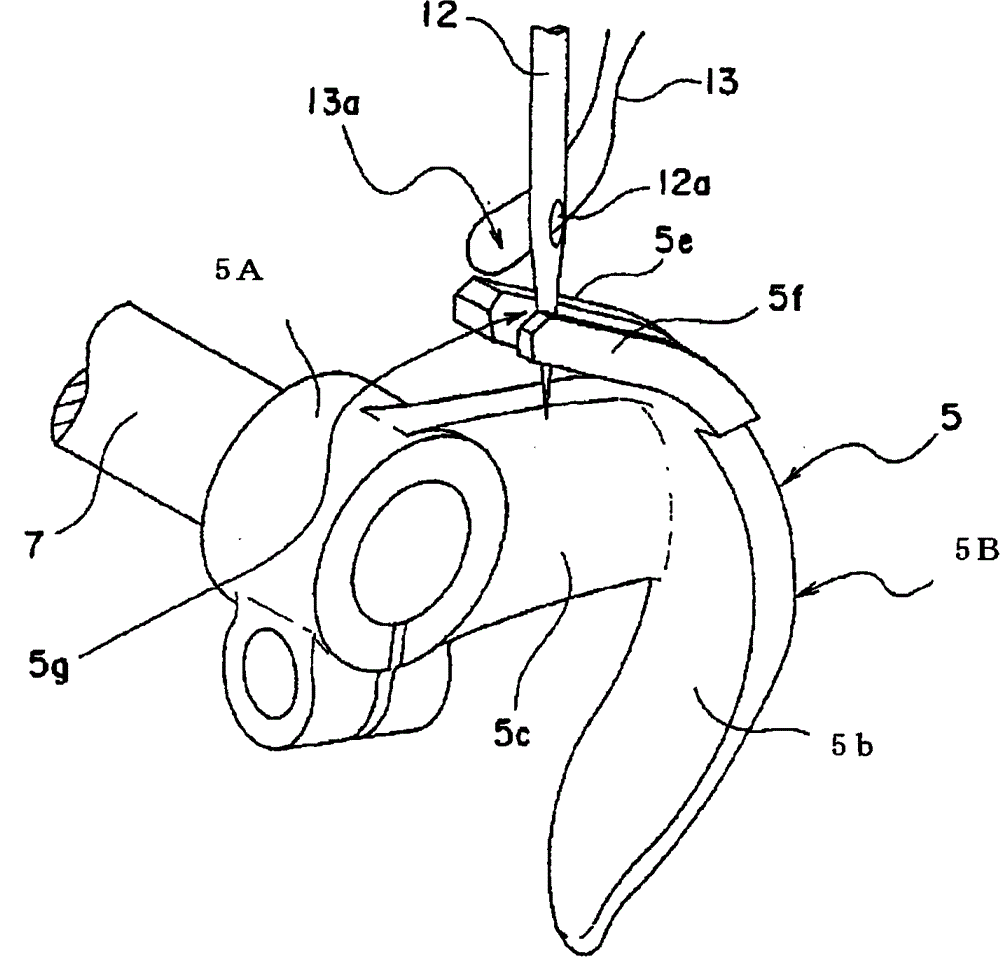

Semi-rotating kettle device of sewing machine

The invention provides a caracol kettle apparatus of sewing machine capable of reliably prevent generating wire jumper or yarn break or fluff of an upper wire loop by preventing separation of sewing needle and point. The caracol kettle apparatus has: a sewing needle (12) forming the upper wire loop (13a) with sewing string (13); a middle kettle (3) for capturing point 3c of the upper wire loop (13a) through rotating action; and a driver (5) of activating the middle kettle to rotate to-and-fro, the driver (5) has a rear-side support section (5e) of the needle, which supports a back surface of the sewing needle (12) opposite to the point (3c); and a front-side support section (5f) of the needle, which supports a front surface of the sewing needle (12).

Owner:JUKI CORP

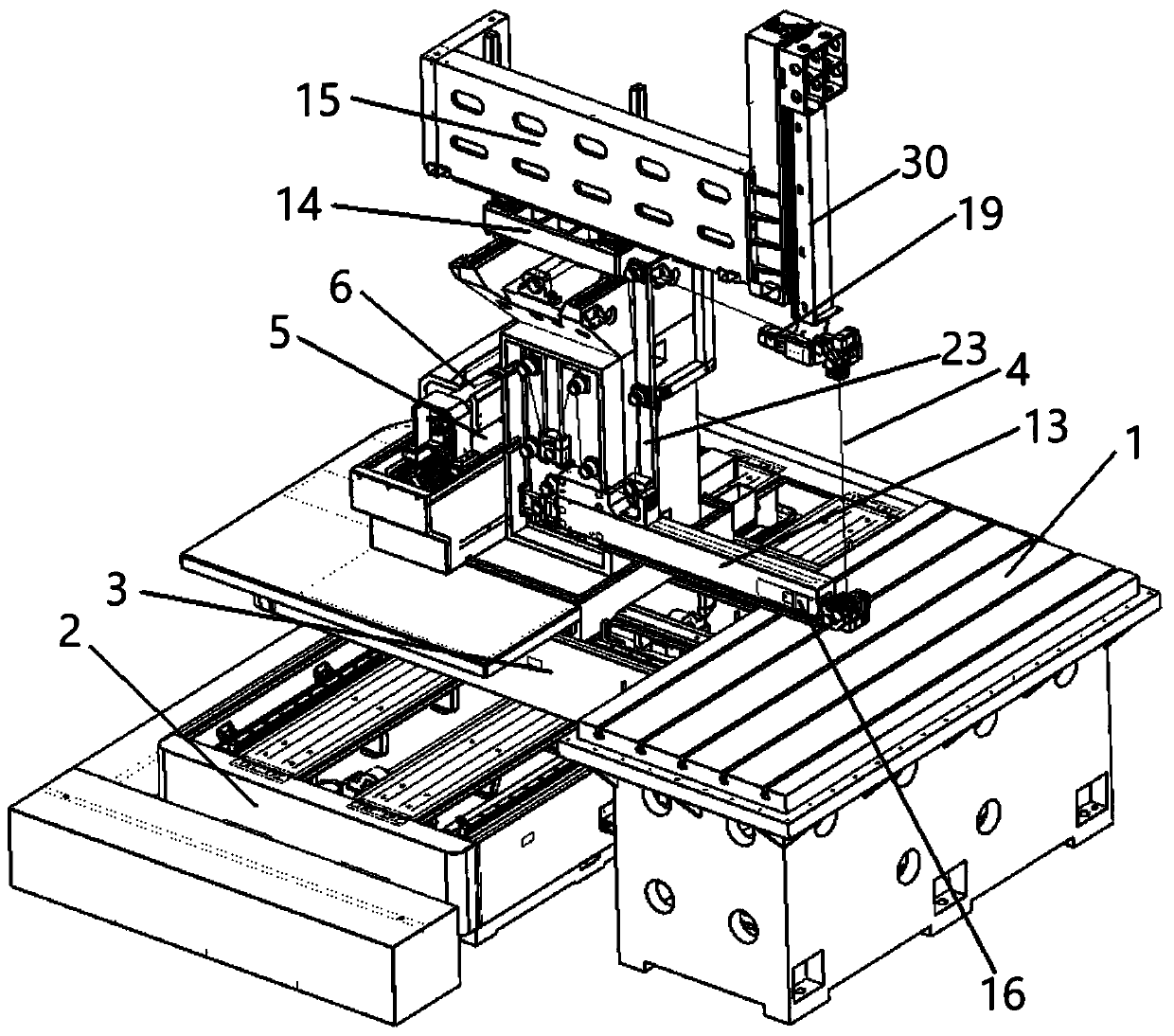

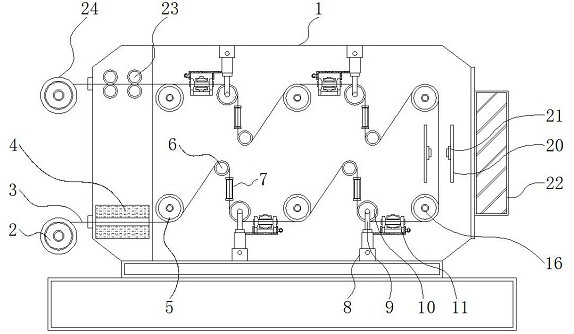

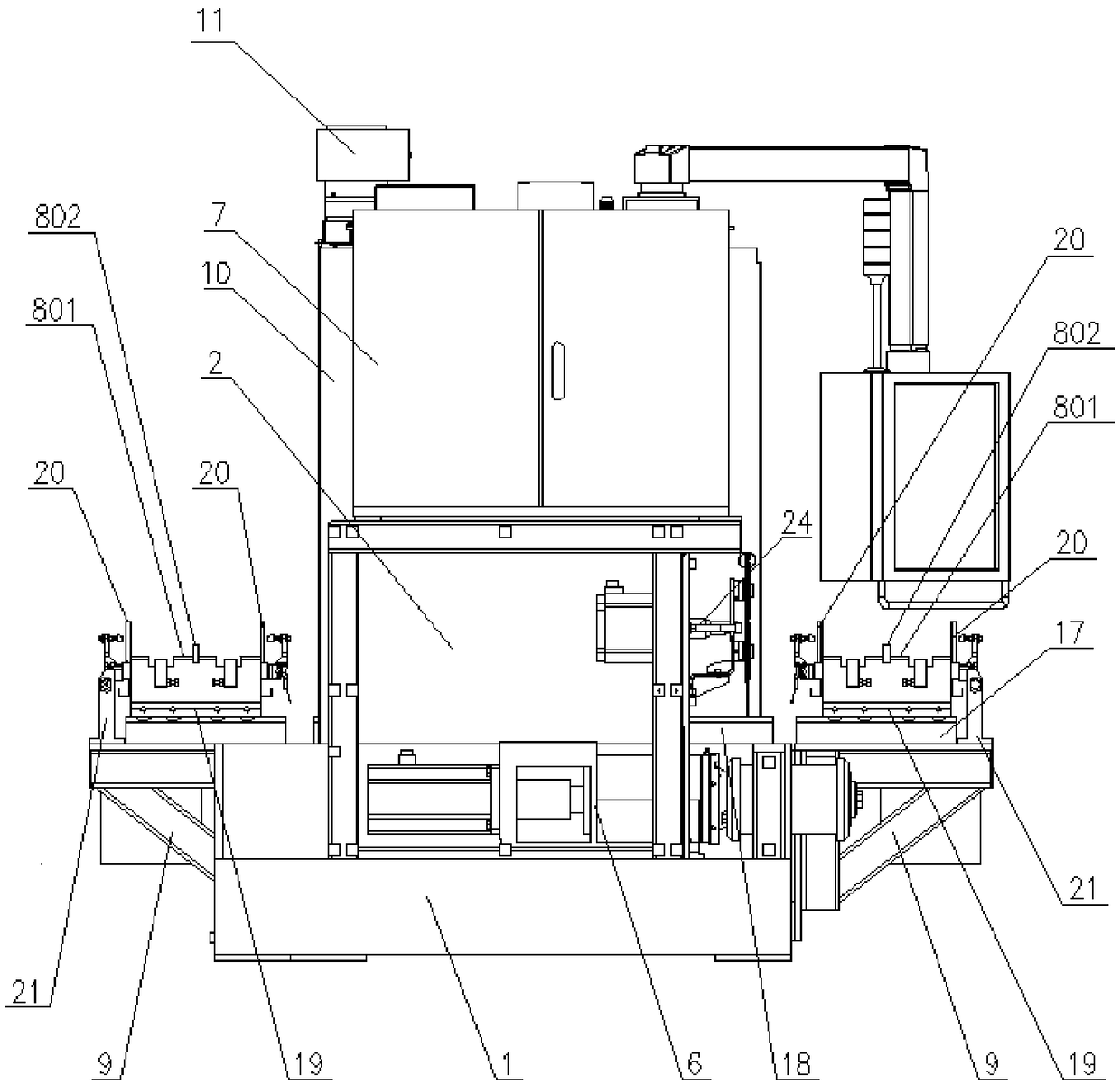

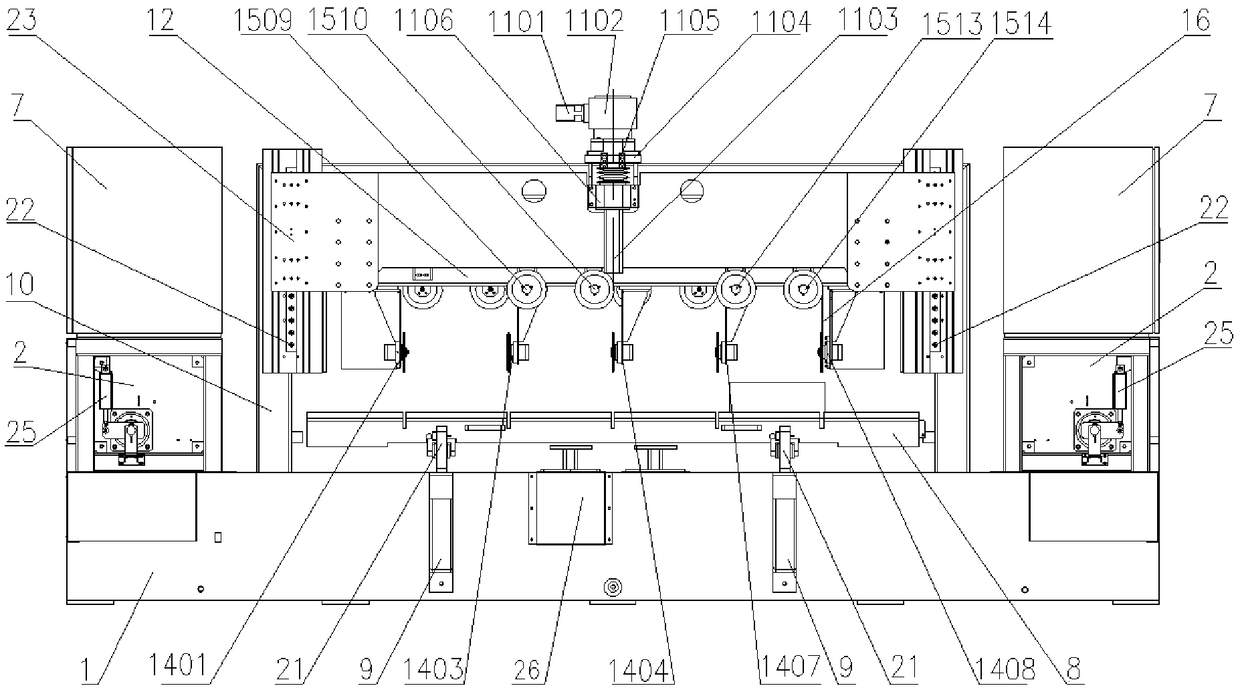

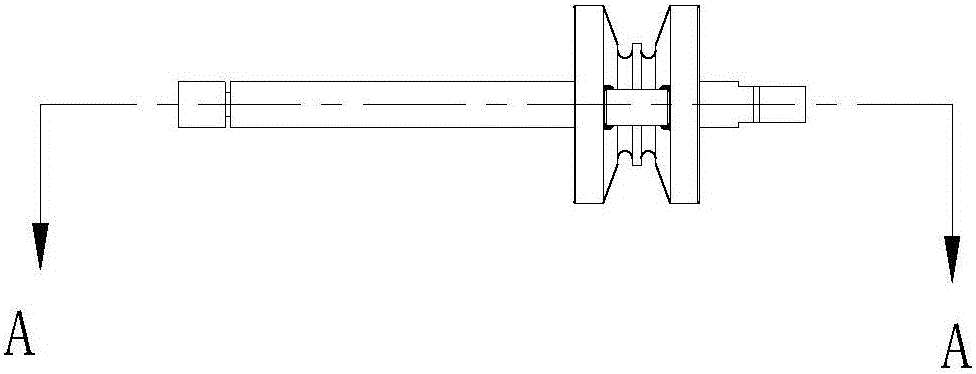

Numerical control polycrystalline silicon diamond wire high-speed cutting-off machine

The invention relates to a numerical control polycrystalline silicon diamond wire high-speed cutting-off machine which comprises a lathe bed and taking-up and paying-off chambers installed at the twoends of the lathe bed. An electric box is fixedly installed on the upper portion of each taking-up and paying-off chamber. Stand columns are installed on the four corners of the lathe bed correspondingly. Two working tables are installed between the two stand columns located on the two sides of the lathe bed through guide rail supports correspondingly. The guide rail supports and the working tables are connected through short steel guide rails. Sliding plates are installed on the two stand columns located on the rear side through linear guide rails correspondingly. The sliding plates drive a cutting wire frame fixed to the lower portions of the sliding plates to move up and down. A first datum motor and a second datum motor are installed at the two ends of the cutting wire frame correspondingly. Multiple diamond wire passing wheels are installed on the two sides of the cutting wire frame. Multiple diamond wire cutting wheels are installed below the cutting wire frame. Diamond wires areguided out from the taking-up and paying-off chamber at one end and sequentially wound around the multiple diamond wire cutting wheels and the diamond wire passing wheels into the taking-up and paying-off chamber at the other end. According to the machine, the diamond wire taking-up, paying-off and distributing quality is improved, and the operation stability and the production efficiency of equipment are improved.

Owner:WUXI SHANGJI AUTOMATION

Clothes drying machine microswitch control device with roller

InactiveCN105862356AAffect normal workPrevent jumperOther drying apparatusTextiles and paperPulp and paper industry

The invention discloses a clothes drying machine microswitch control device with a roller. The device comprises a microswitch driving rod and further comprises a roller mechanism. The roller mechanism comprises a left roller wall, a right roller wall, the roller and a limiting mechanism, wherein the microswitch driving rod is sleeved with the left roller wall and the right roller wall, the roller is clamped between the left roller wall and the right roller wall and used for rotating around the microswitch driving rod under the friction action of a clothesline, and the limiting mechanism is used for preventing the clothesline from disengaging from the roller mechanism. The roller which rotates around the microswitch driving rod under the friction action of the clothesline can move back and forth along with the clothesline and rotate around the microswitch driving rod, and accordingly friction between the roller and the microswitch driving rod is effectively avoided. Besides, by means of the arrangement of the limiting mechanism, the situation that the clothesline disengages from the roller mechanism in the loose state can be effectively prevented, and accordingly normal work of a clothes drying machine is affected. The microswitch control device can effectively reduce friction between the clothesline and the microswitch driving rod, and jump of the clothesline can be effectively prevented.

Owner:GUANGDONG A OK TECH GRAND DEV CO LTD

Wire regulating device of multi-wire cutting machine steel wire

Owner:HUNAN YUJING MACHINE

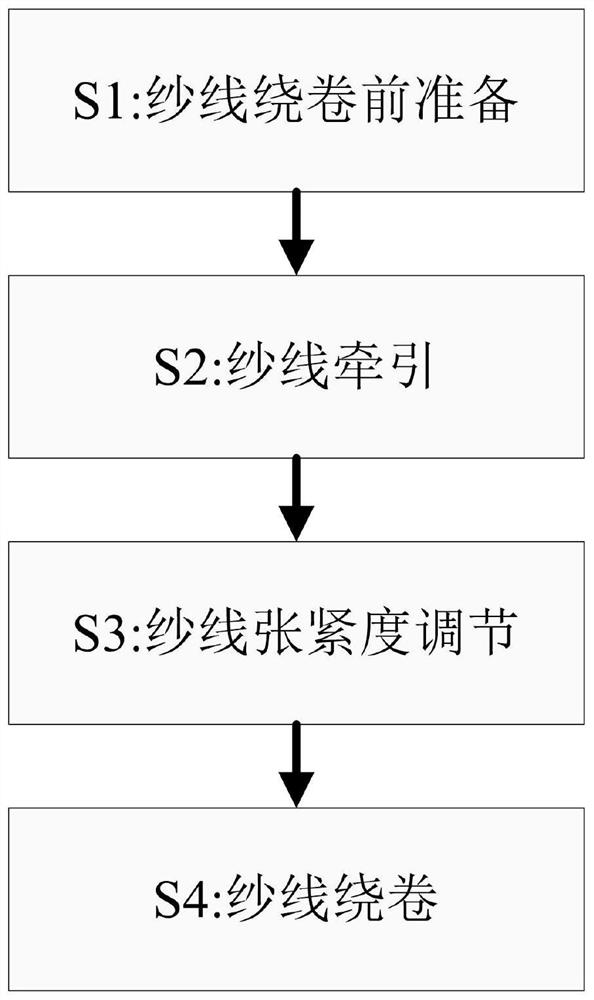

Textile yarn tensioning adjustment control method

InactiveCN112938646AGuaranteed winding effectPrevent yarn from looseningFilament handlingPackagingTextile yarnStructural engineering

The invention provides a textile yarn tensioning adjustment control method. A bottom plate, side plates, a tension limiting device, tensioning devices, a guiding device and a take-up device cooperate to complete tensioning adjustment control over textile yarn. According to the method, the problems that in the process of winding and twisting spinning yarn into a fixed-length yarn coil at present, the yarn is prone to knotting and twisting in the later unwinding and using process due to the fact that the yarn wound on a winding column barrel is prone to loosening, when the yarn is tensioned by adopting an existing tensioning wheel, the yarn is easy to break due to poor toughness, and in the process of tensioning the yarn through the tensioning wheel, too large force is applied to the yarn, the periphery of the yarn is lack of corresponding limitation, thus, yarn jumping occurs in the yarn winding process, and then, the yarn winding effect is affected are solved.

Owner:义乌市云翰纺织科技有限公司

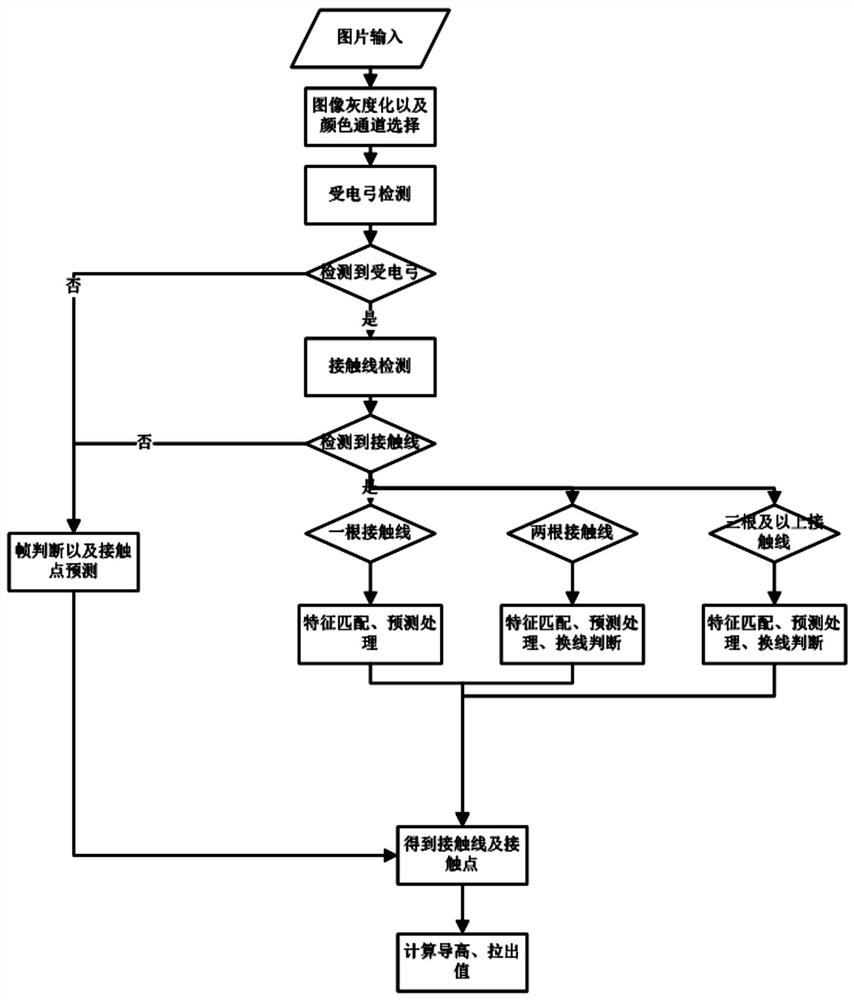

Catenary tracking method and system in pantograph-catenary system

ActiveCN109697709BAccurate trackingPrevent jumperImage enhancementImage analysisAlgorithmEngineering

The invention discloses a catenary tracking method and system in a pantograph catenary system. The catenary tracking method comprises the following steps: S1, acquiring a video frame image of the pantograph catenary system; S2, determining position information of the pantograph through image recognition; S3, identifying all suspension lines in the image, and calculating and determining parametersof the suspension lines; And S4, calculating and determining the contact line according to the parameters of the suspension line and the position information of the pantograph. The method has the advantages that the contact line can be identified from multiple suspension lines and tracked, line changing identification and processing of the contact line can be carried out at the anchor section joint, the accuracy is high, and the stability is good.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

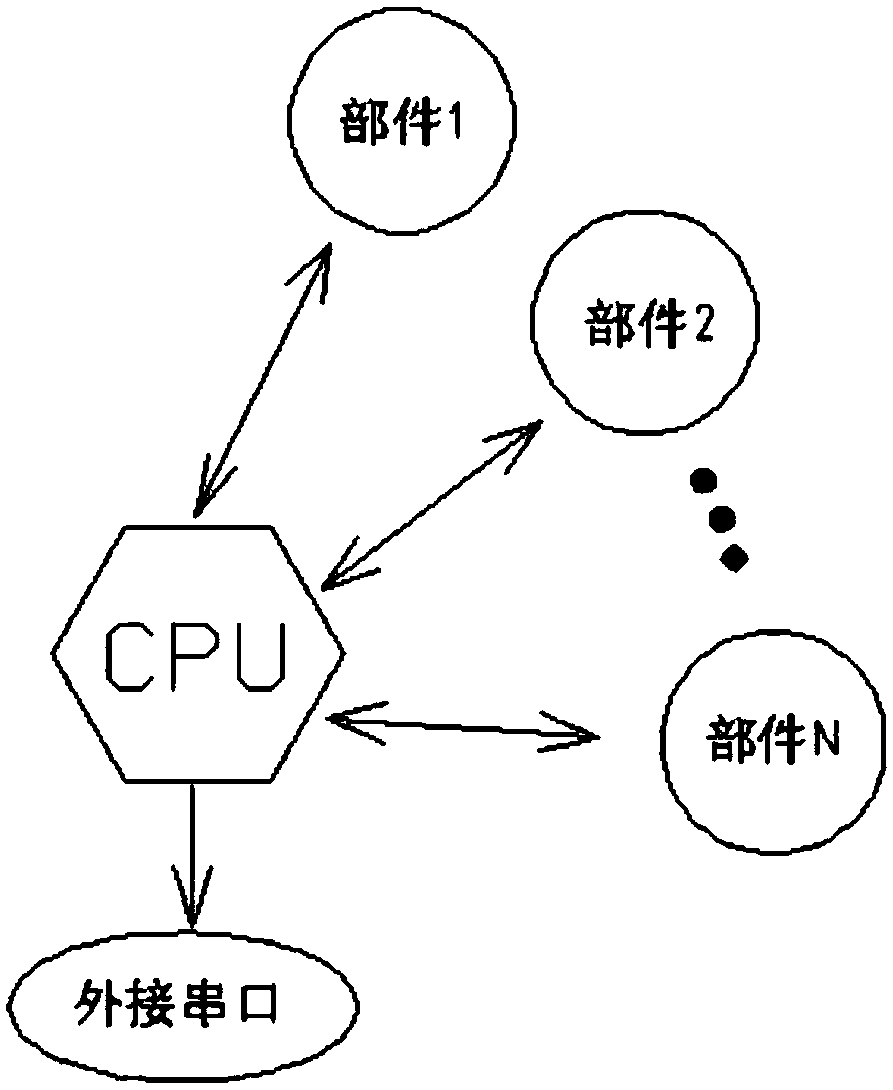

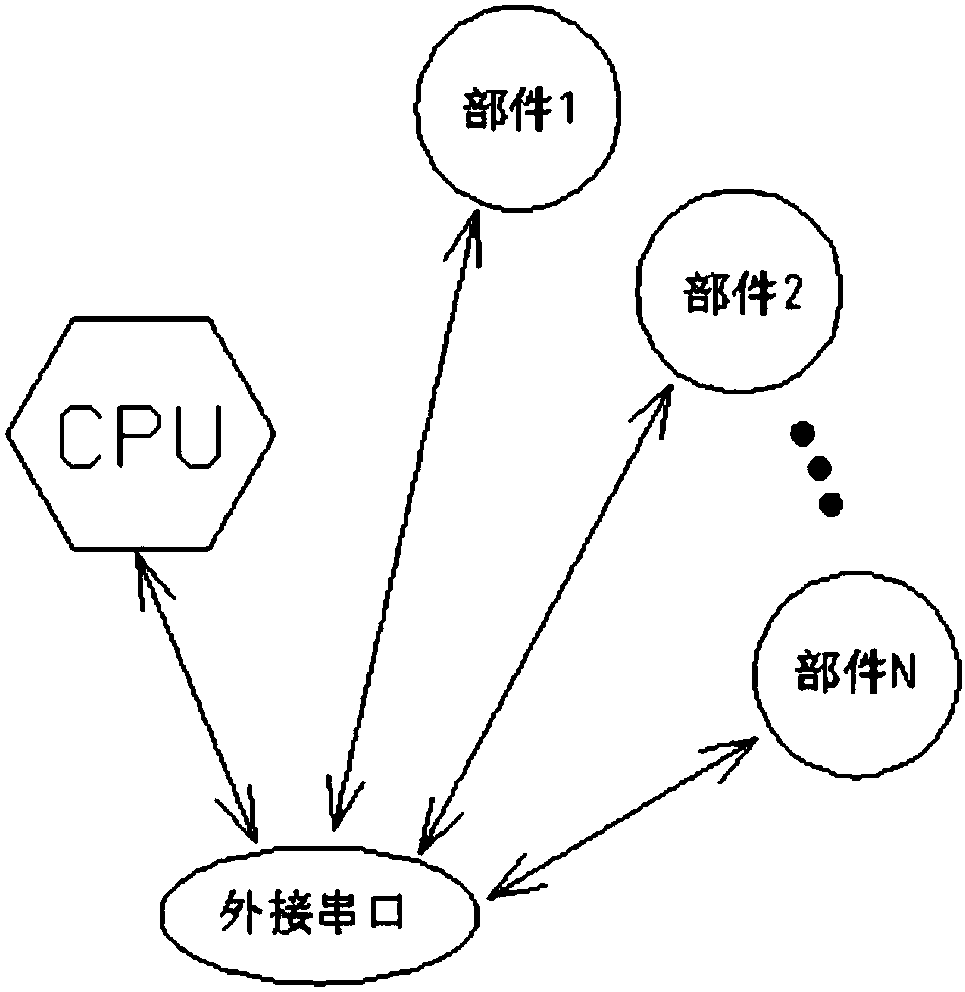

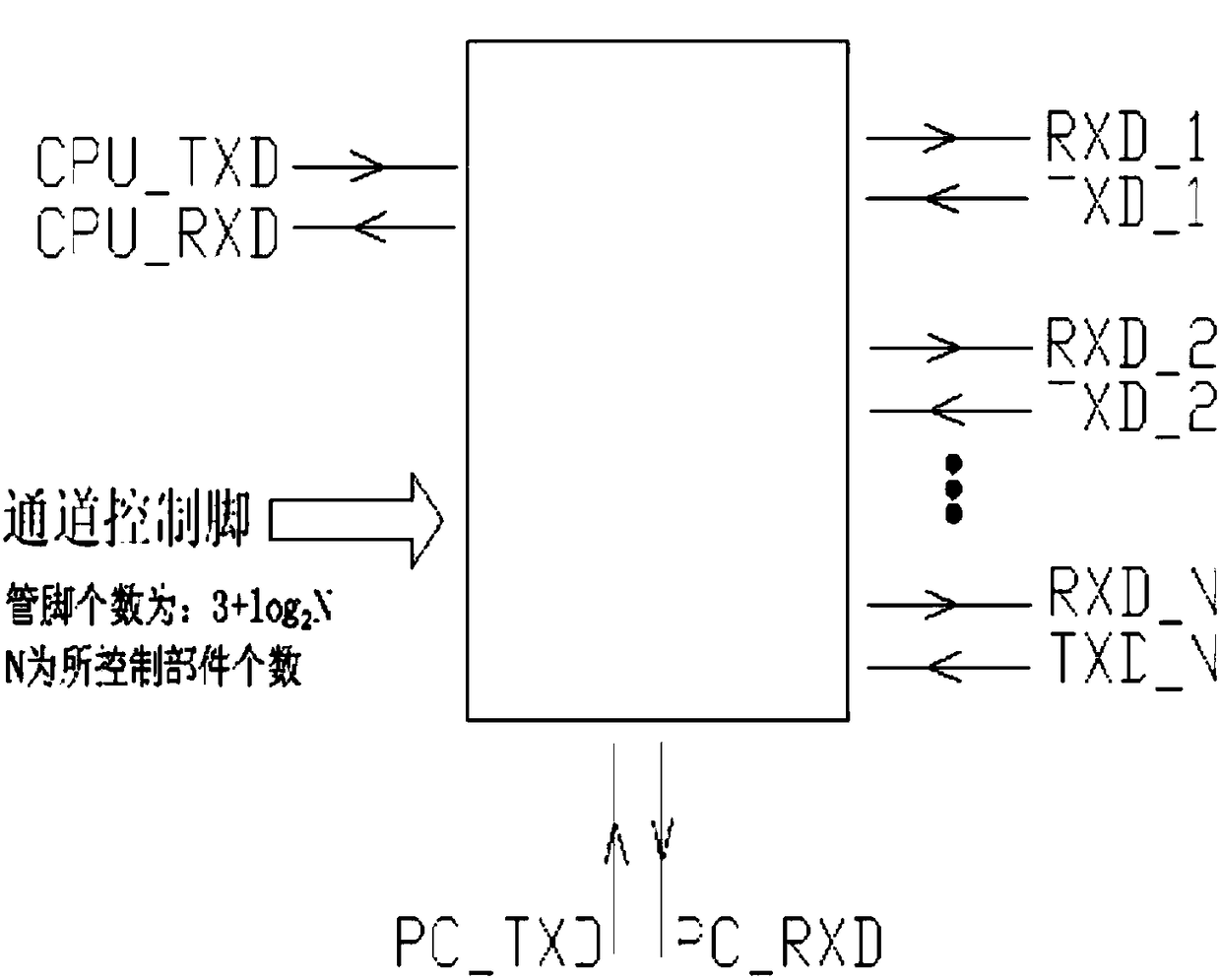

A method for realizing multi-serial device connection and monitoring

ActiveCN105955908BLow costPrevent openingHardware monitoringElectrical resistance and conductanceSwitching signal

The invention discloses a method for realizing multi-serial port device connection and monitoring. The method comprises setting special topological positions of a main CPU and external serial port sending-receiving signals in a network, setting a resistor in a special signal path to ensure level equalization when switching signals, to prevent mutual interference of annular signals formed by big delta connection. A CPU is provided to communicate with any functional component, and through external serial ports (connected with a computer), data sent and received by the CPU is monitored, and a monitoring function can be switched off. The external serial port communicates with any functional component or the CPU, to realize functions of independent debugging or program download. The method prevents a problem that a conventional method uses an electronic switch box internal jumper cap, and effectively solves inconvenience of design and maintenance, and gets rid of manual error caused by opening a cover and cutting off a power supply required by connecting the jumper cap. The method effectively reduces design manufacturing cost, and improves equipment operation reliability.

Owner:BEIJING GUOWANG SHENGYUAN INTELLIGENT TERMINAL SCI & TECH CO LTD

Wire winding structure and clothes hanger hand cranking device

PendingCN110983730AEasy to wrap in orderExtend your lifeOther drying apparatusTextiles and paperClothes hangerEngineering

The invention discloses a wire winding structure and a clothes hanger hand cranking device. The wire winding structure comprises a wire winding wheel and a steel wire rope, wherein an accommodating groove with an outward opening is formed in the peripheral wall of the wire winding wheel, and a guide groove communicating with the accommodating groove is formed in the side wall of the wire winding wheel; the steel wire rope enters the accommodating groove in the depth direction of the guide groove, and one end of the steel wire rope is rotationally connected with the wire winding wheel; a limiting structure is further arranged on the wire winding wheel and is used for limiting the steel wire rope from being disengaged from the wire winding wheel from the guide groove; and when the wire winding wheel rotates, the wire winding wheel is released or rolled. According to the winding structure and the clothes hanger hand cranking device, the service life of the steel wire rope can be prolonged, winding of the steel wire rope is smoother and more natural, and the use experience of a user is good.

Owner:九牧智能厨卫(安徽)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com