Patents

Literature

42results about How to "Avoid glue residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printing strippable protective ink, and preparation method and application thereof

The invention discloses a printing strippable protective ink, and a preparation method and application thereof. The ink comprises the following components in parts by weight: 50-80 parts of thermoplastic film-forming resin, 20-50 parts of low-viscosity plasticizer, 1-10 parts of filler and pigment, and 1-3 parts of functional assistant. The printing strippable protective ink has 100% solid rate, does not volatilize any solvent, is a green environment-friendly material, and satisfies the increasingly higher ecological environmental requirements. The ink has the advantages of no irritating smell, moderate viscosity and no voids, is not sticky to the printing screen, and is easy for printing operation; the ink can form a film by thermosetting at medium / low temperature, so the energy consumption is low; the thermosetting film has high flexibility, favorable heat resistance, favorable insulativity and favorable acid / alkali resistance, and effectively solves the influence on the resistance when etching the circuit on a transparent conductive film with acid and alkali in the touch screen manufacturing process; and after the conductive film protecting technique is finished in the touch screen manufacturing process, the protective ink layer can be easily stripped, and does not leave any residue, thereby effectively solving the problem of protection of the conducting film in the existing touch screen manufacturing process.

Owner:PANYU NANSHA YAN TIN CHEM

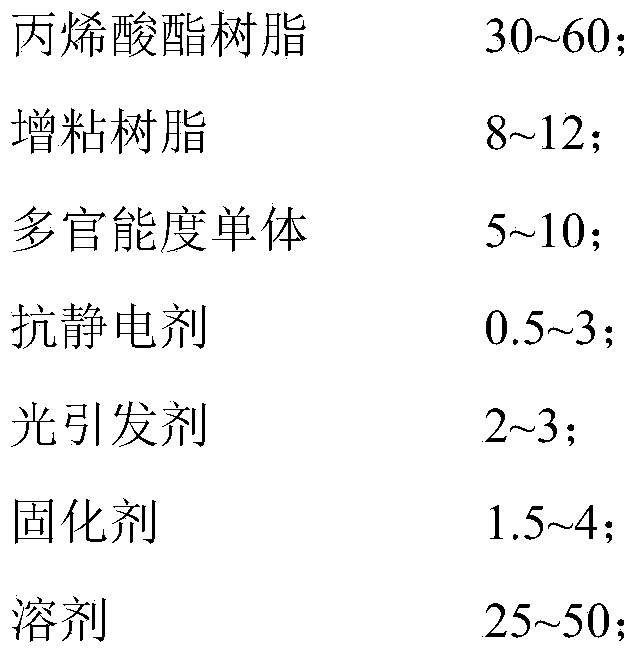

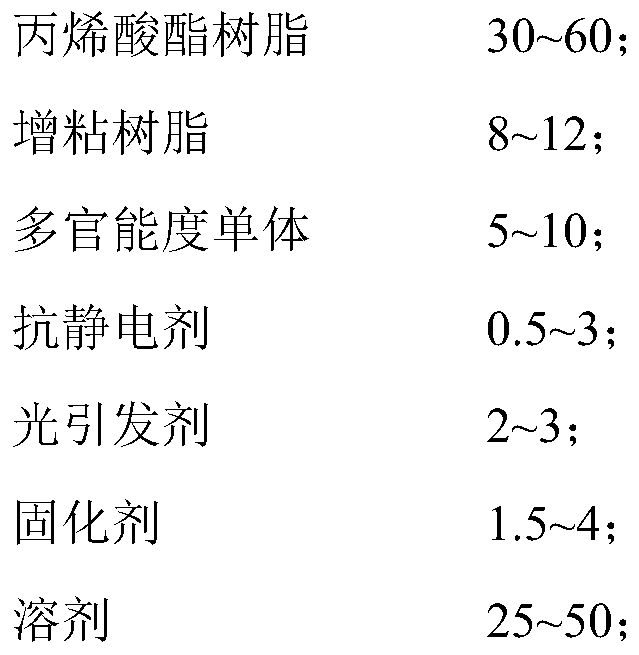

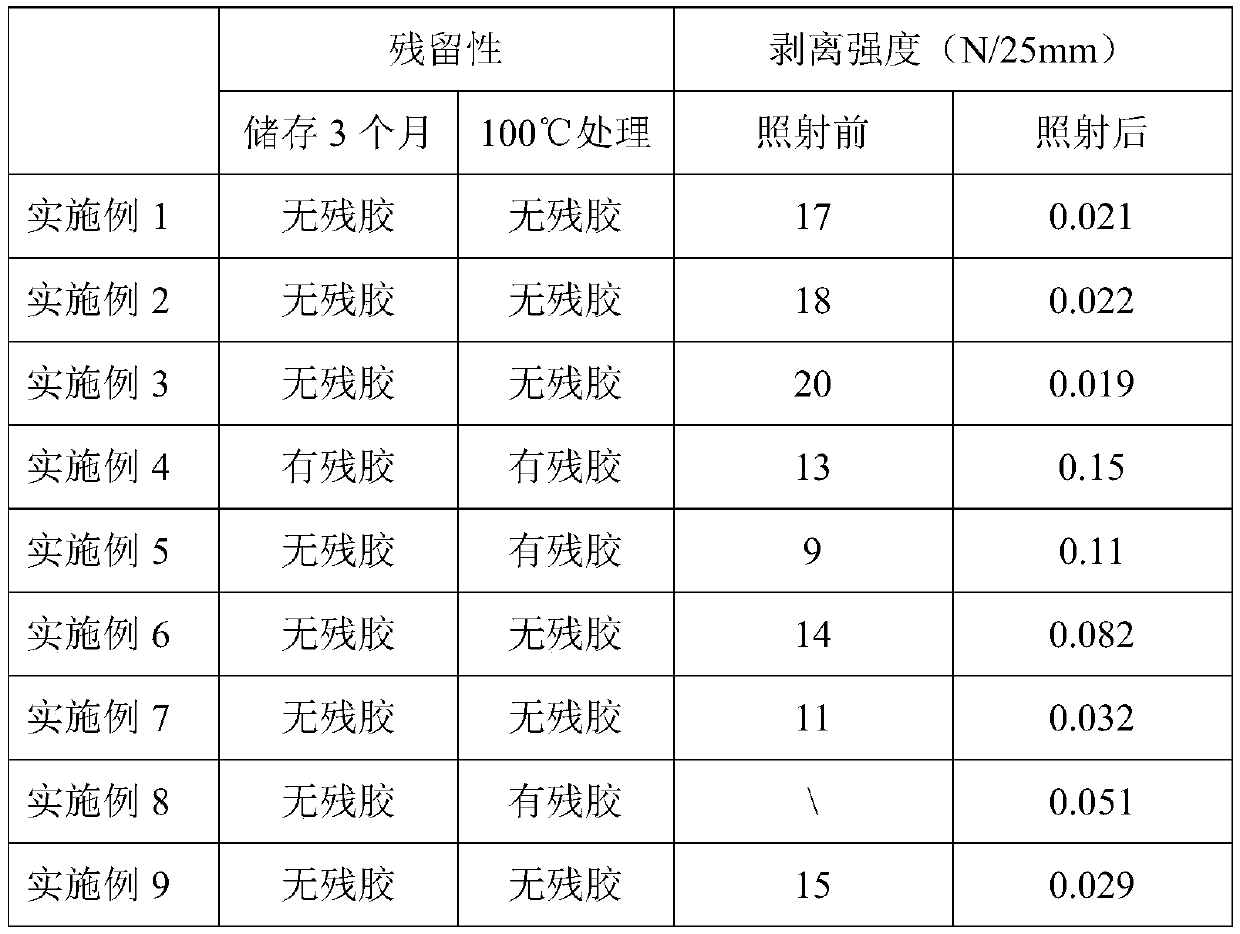

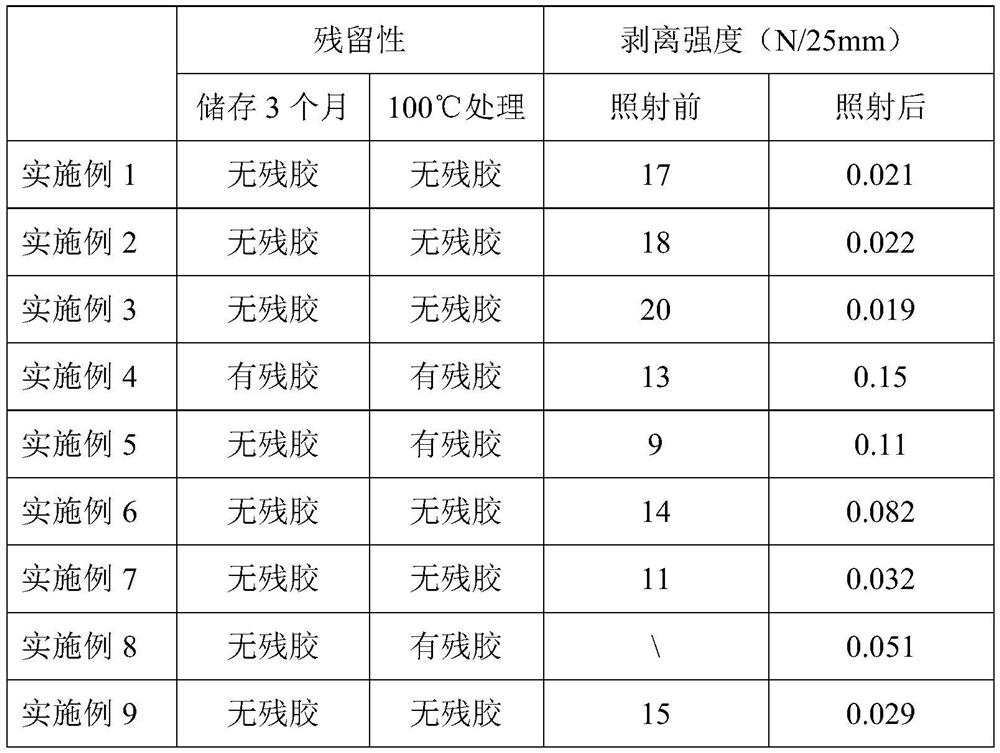

Adhesive for UV viscosity-reducing film and UV viscosity-reducing film thereof

InactiveCN111057474AAdd space network structureHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPhotoinitiatorPolymer chemistry

The invention discloses an adhesive for a UV viscosity-reducing film and the UV viscosity-reducing film thereof. The adhesive is prepared from the following raw materials in parts by mass: 30-60 partsof acrylate resin, 8-12 parts of tackifying resin, 5-10 parts of a polyfunctional monomer, 0.5-3 parts of an antistatic agent, 2-3 parts of a photoinitiator, 1.5-4 parts of a curing agent and 25-50 parts of a solvent. According to the UV viscosity-reducing film, the stripping force before UV illumination is larger than 25 N / 25 mm, the stripping force after UV illumination is lower than 0.1 N / 25 mm, no residual adhesive is left, the viscosity-reducing film has excellent antistatic performance, and the resistance of the adhesive layer is 109 ohms or below.

Owner:HEFEI LUCKY SCI & TECH IND

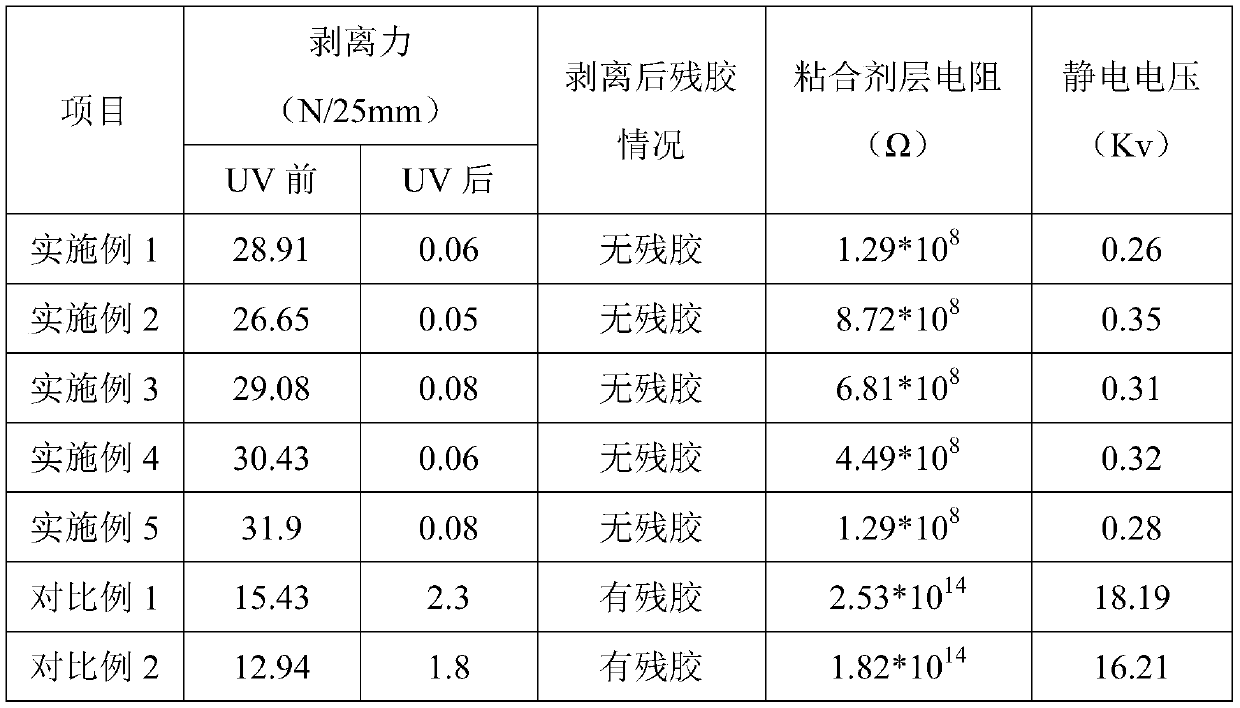

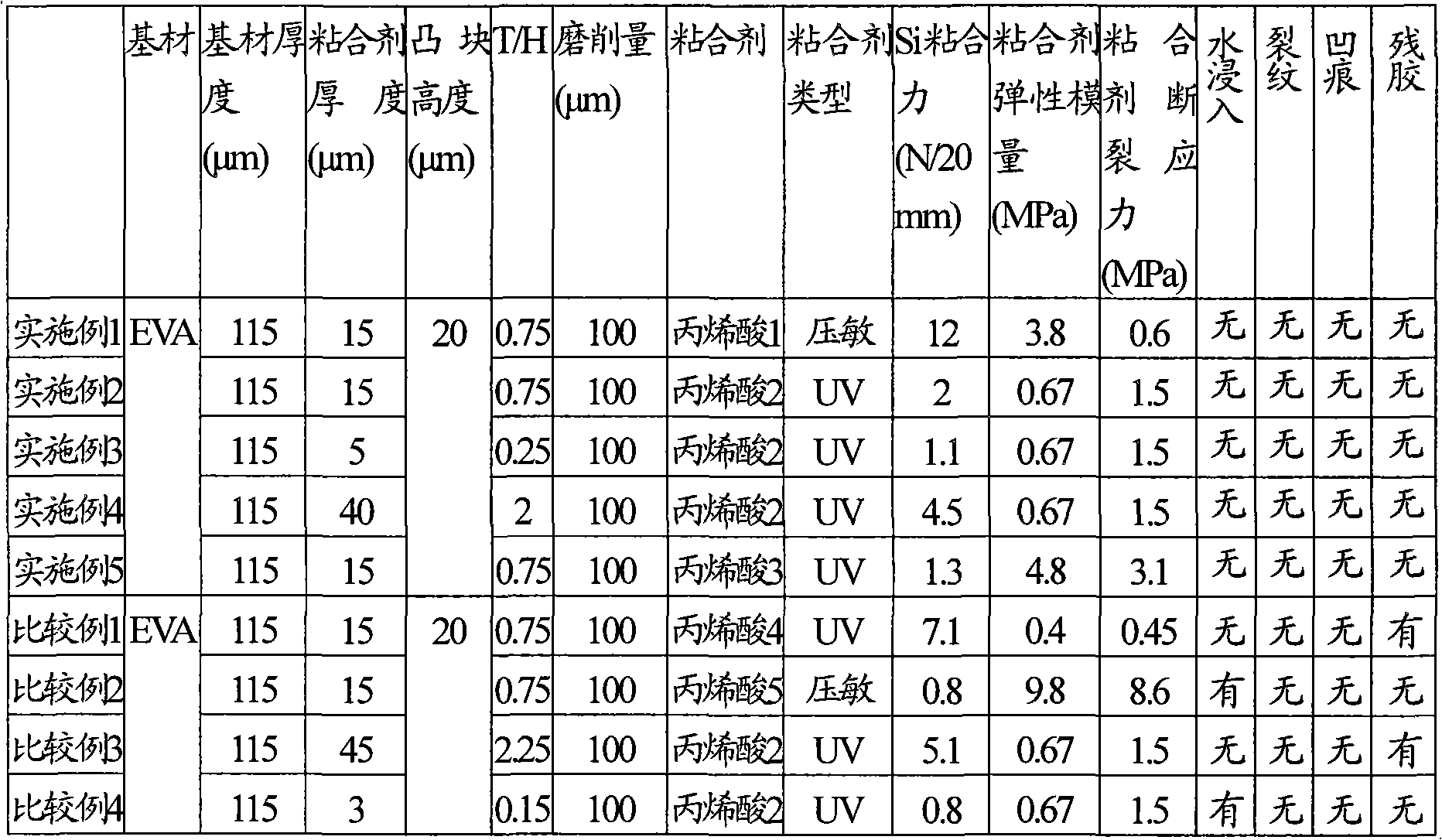

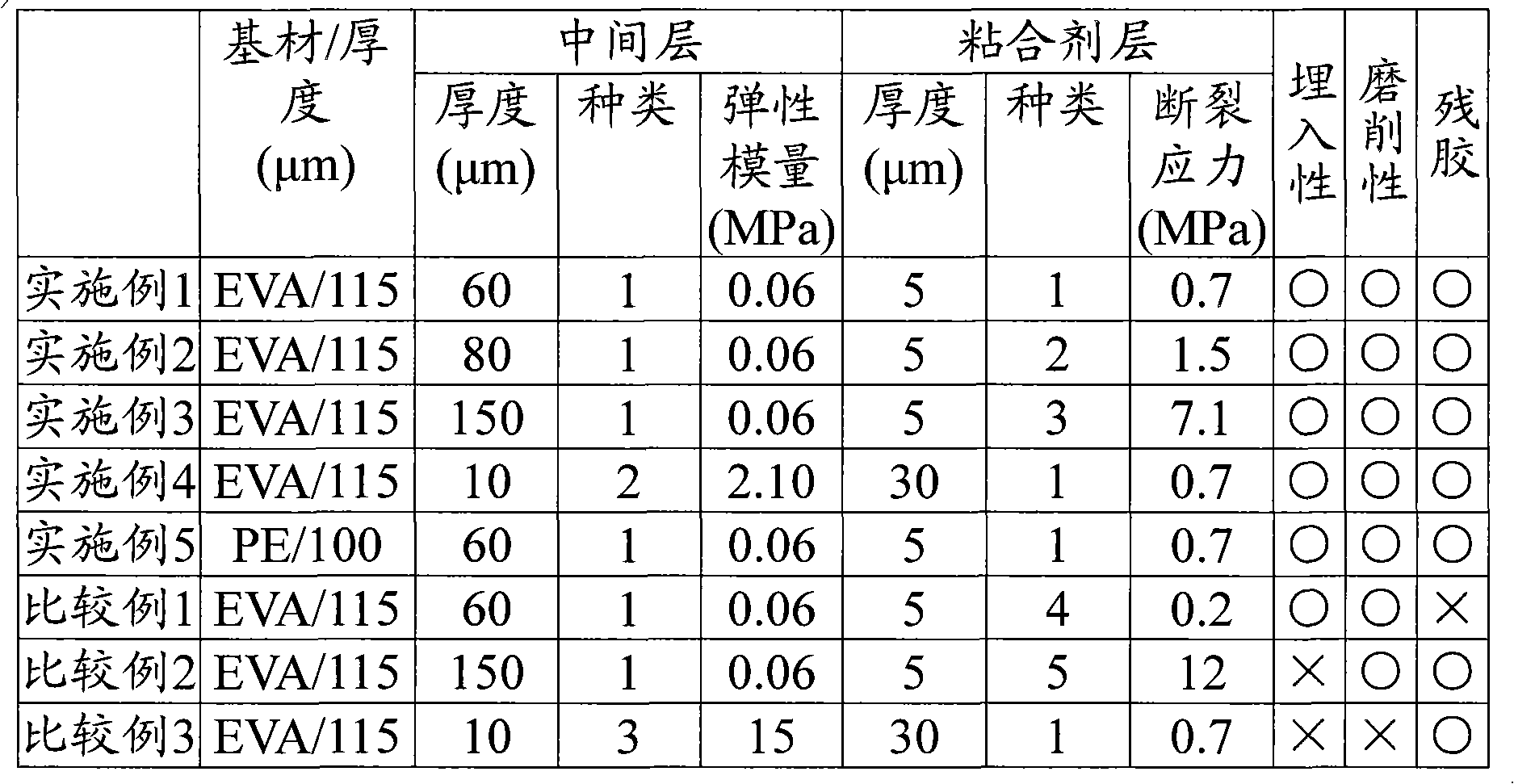

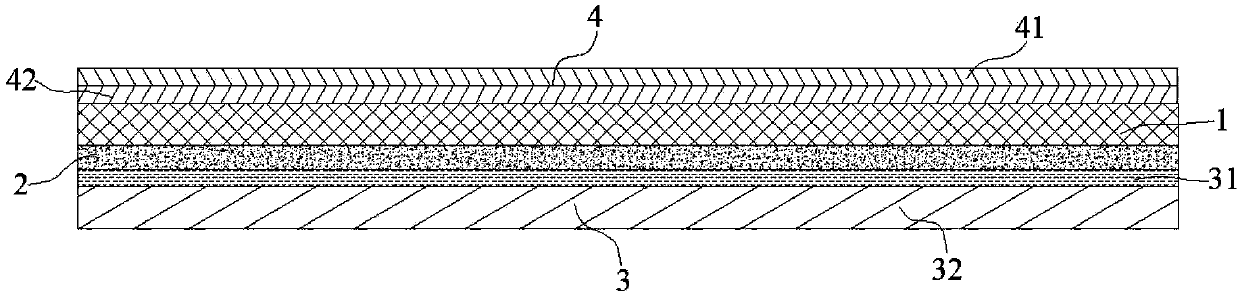

Adhesive sheet for supporting and protecting semiconductor wafer, back grinding method for semiconductor wafer

InactiveCN101993668AAvoid glue residueReduce generationFilm/foil adhesivesSolid-state devicesEngineeringSemiconductor

Owner:NITTO DENKO CORP

Novel easily-peeled pressure-sensitive adhesive

ActiveCN103160213AAvoid glue residueResidual glueOrganic non-macromolecular adhesiveMethacrylatePolymer science

The invention discloses a novel easily-peeled pressure-sensitive adhesive. The novel easily-peeled pressure-sensitive adhesive comprises, by weight, 2 to 10 parts of methyl acrylate, 1 to 5 parts of butyl acrylate, 3 to 15 parts of vinyl acetate, 10 to 30 parts of 2-ethylhexyl acrylate, 30 to 40 parts of 2-ethylhexyl methacrylate, 5 to 10 parts of glycerol, 3 to 7 parts of a cross-linking agent, 30 to 50 parts of an organic solvent and 5 to 10 parts of rosin. The novel easily-peeled pressure-sensitive adhesive is mainly used as a bonding layer between two films, can be easily peeled from a base, has good transparency and no residues, can be processed easily and is convenient for use. When a film with the novel easily-peeled pressure-sensitive adhesive is pasted on a base and especially on clothes and caps, the top layer and the bottom layer can be separated easily and the bottom layer is still pasted on the base. Therefore, the novel easily-peeled pressure-sensitive adhesive can be used for various double-layer film pasting.

Owner:张家港市杨舍镇美捷配饰设计工作室

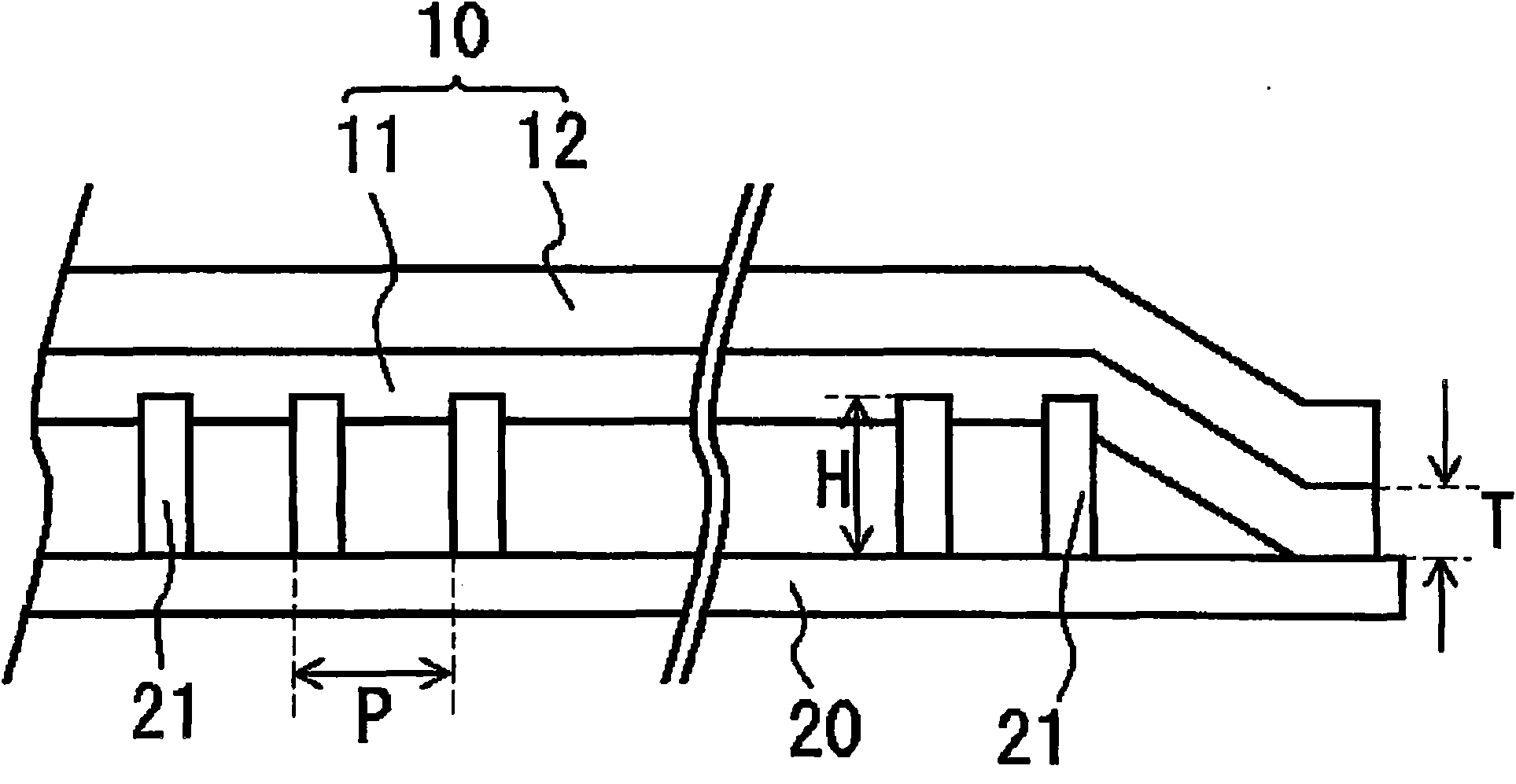

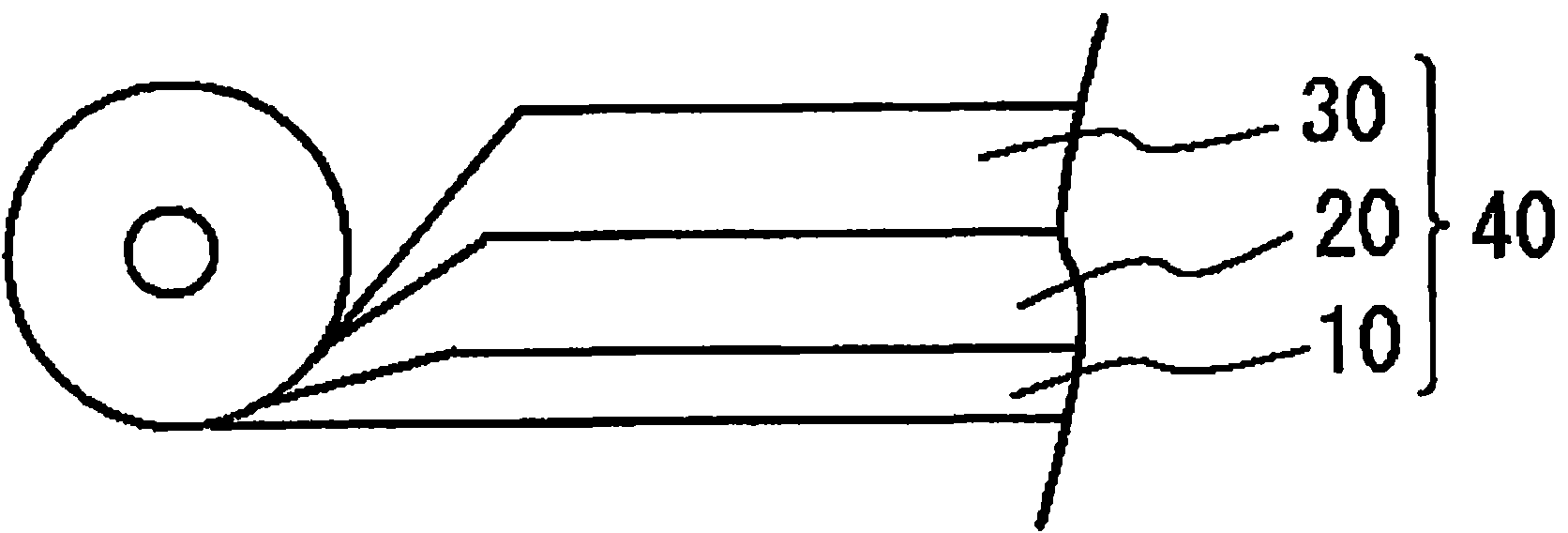

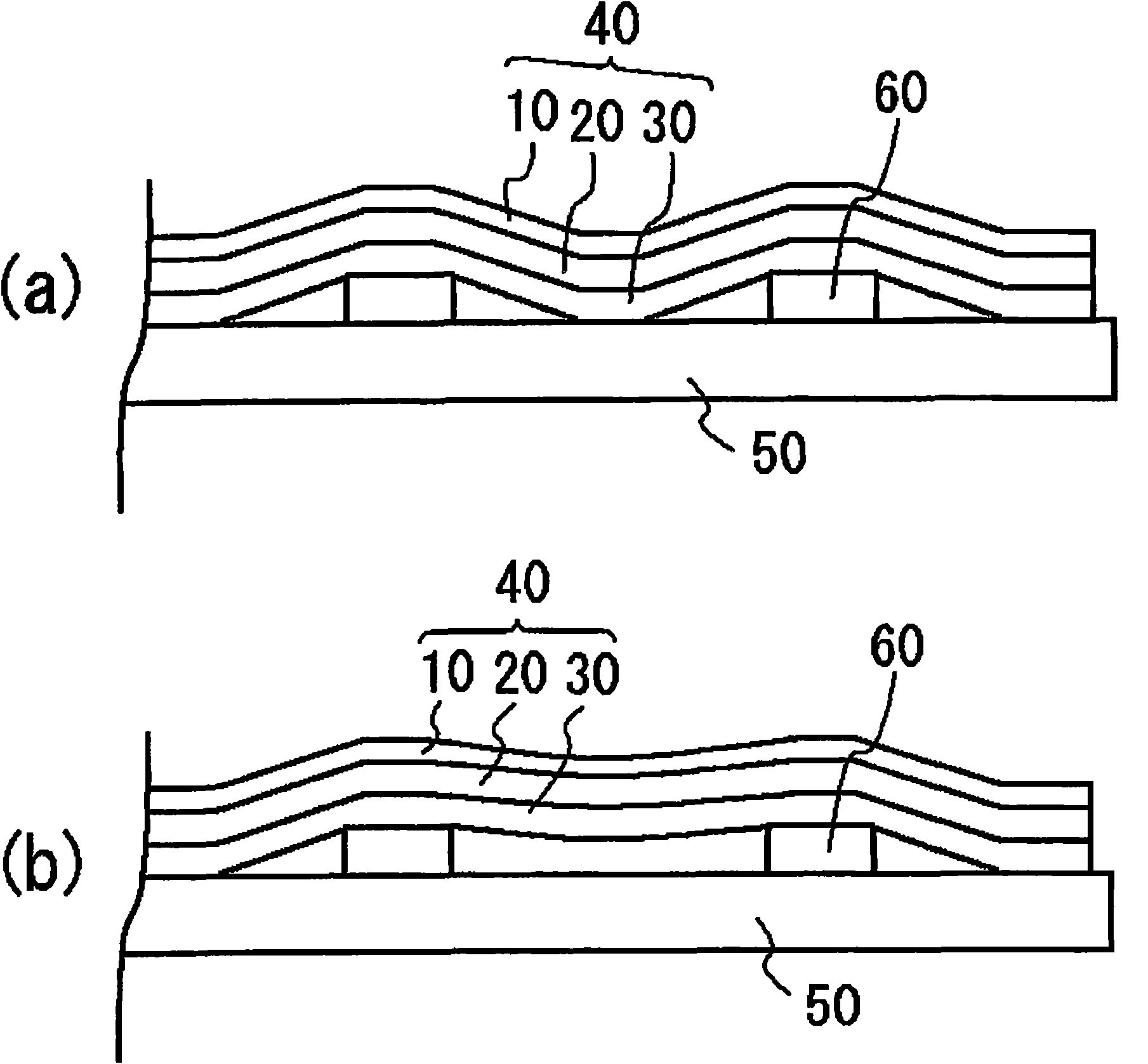

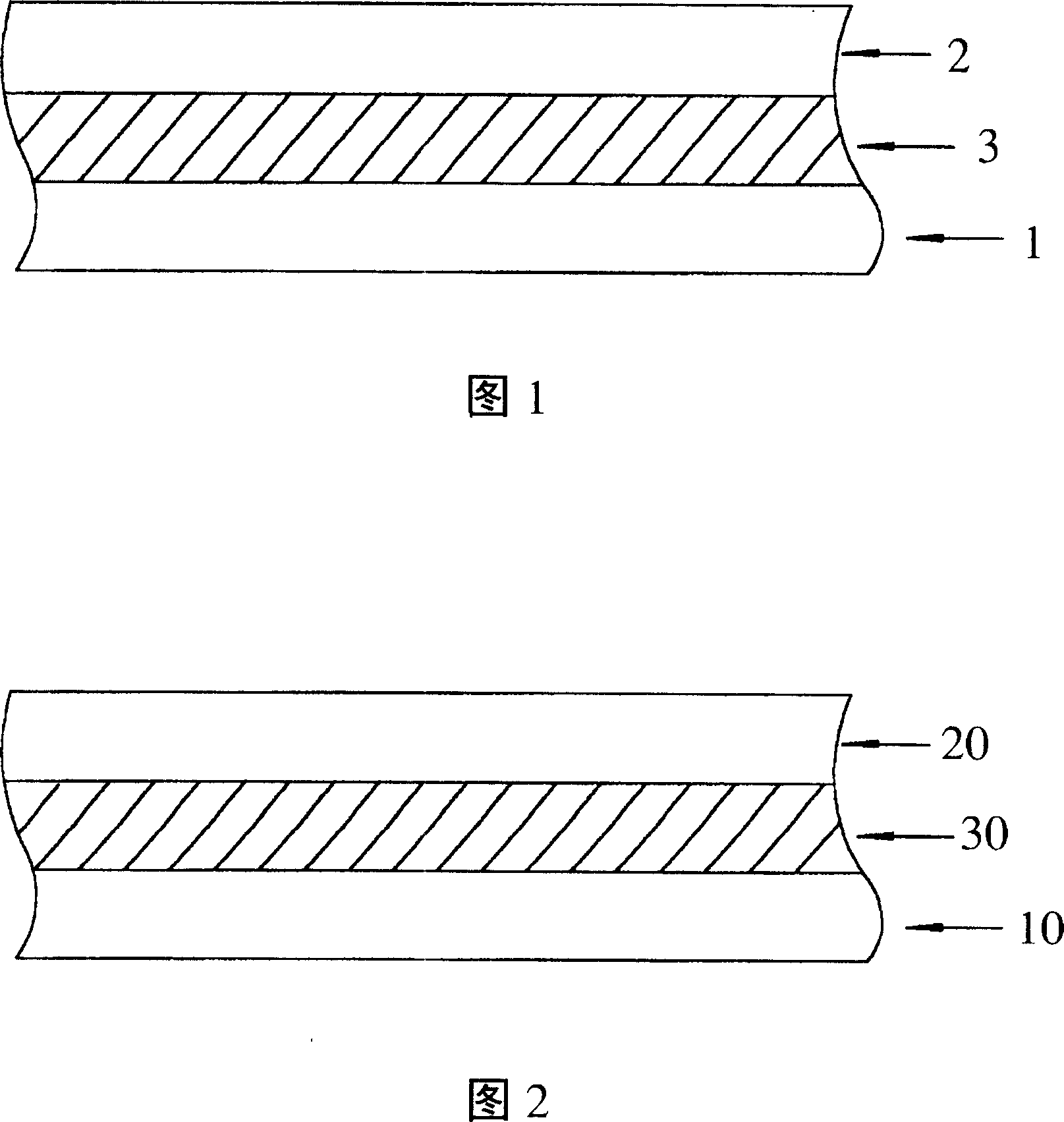

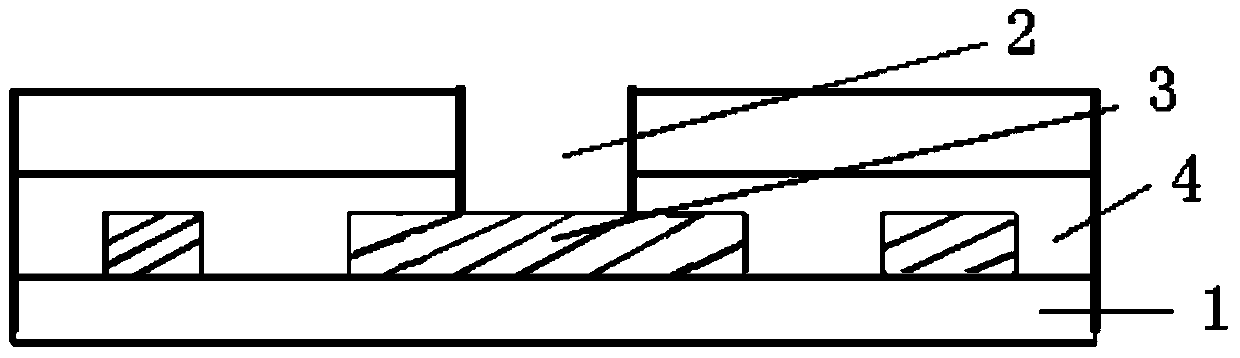

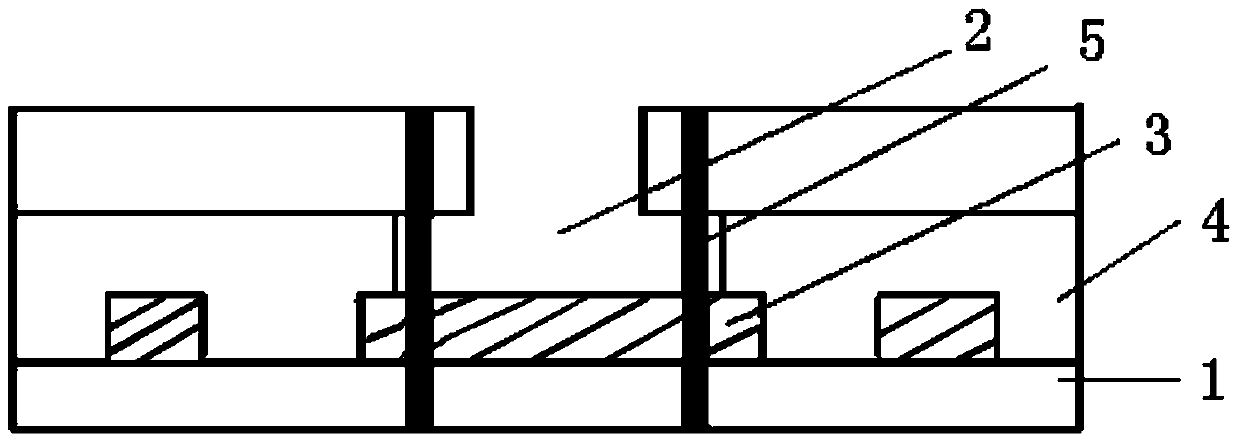

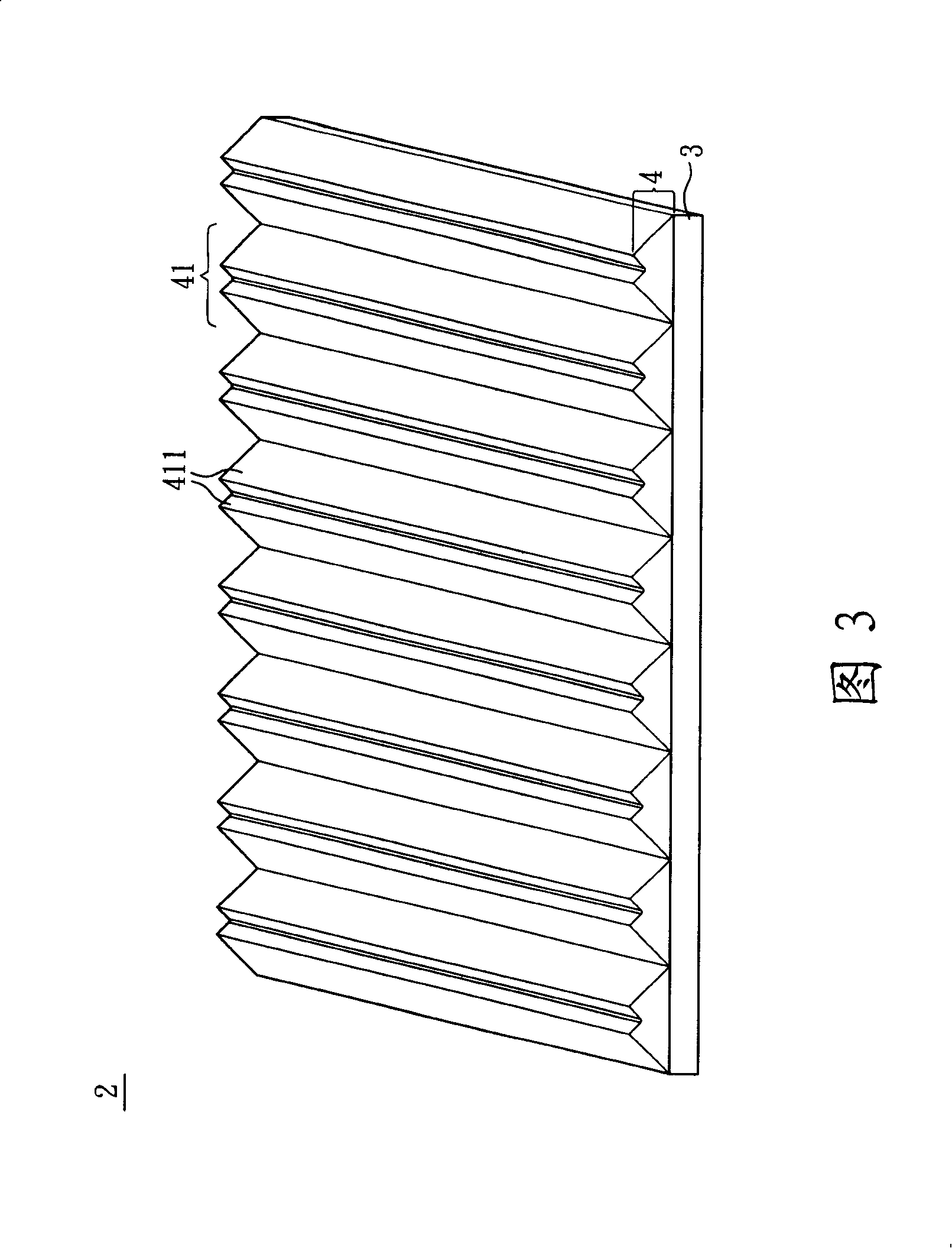

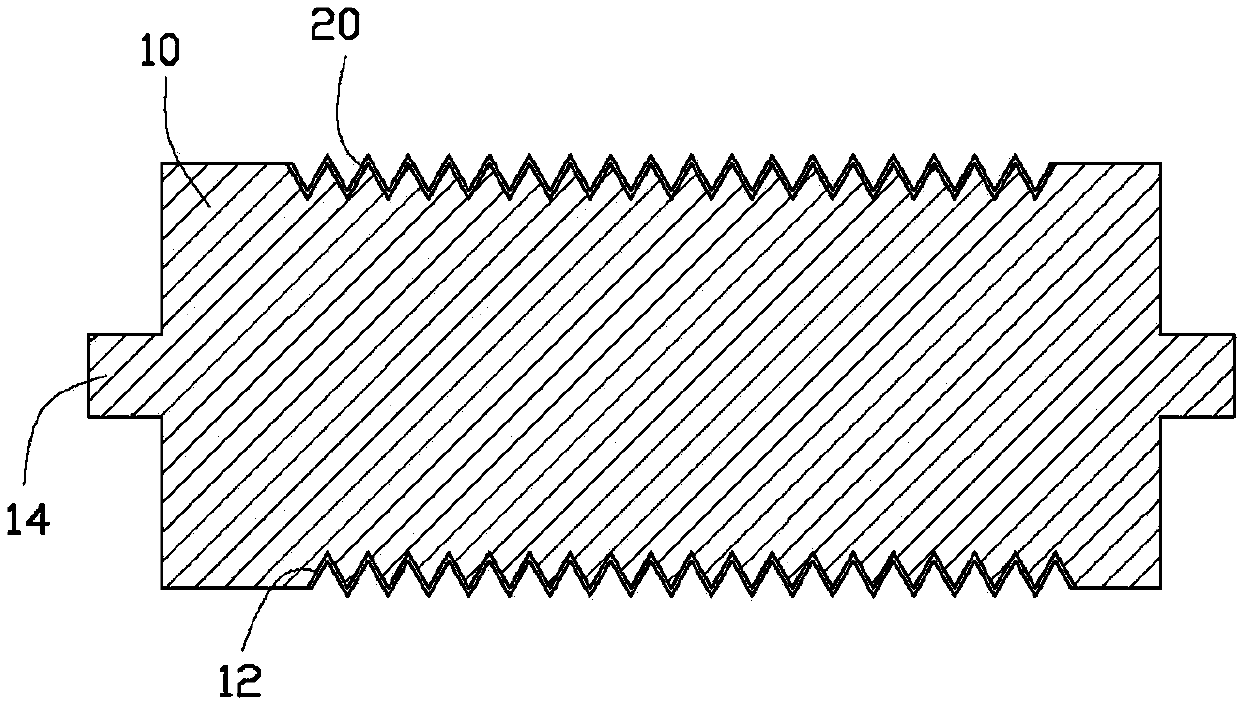

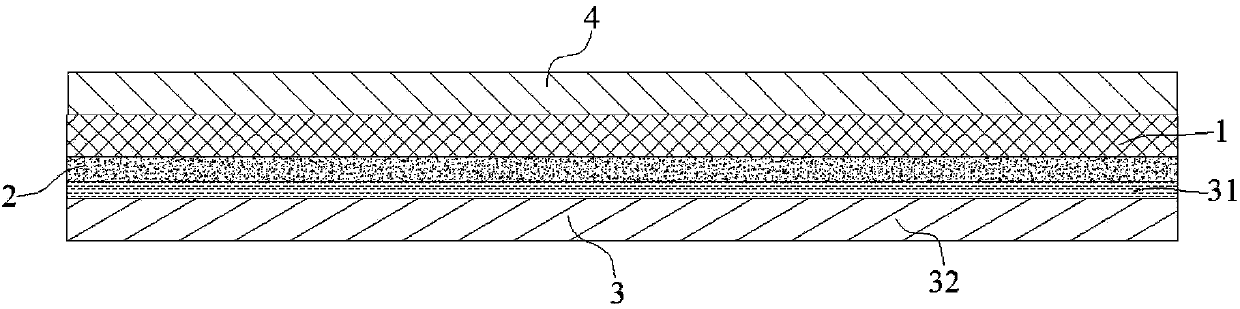

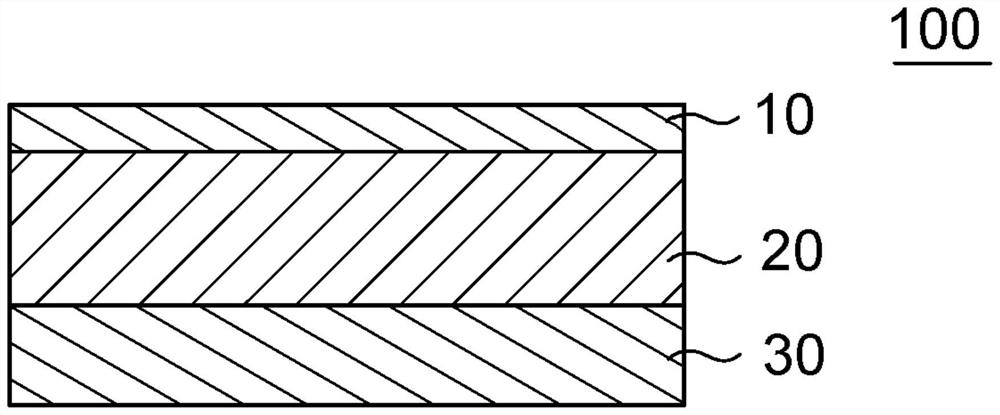

Adhesive sheet for supporting and protecting semiconductor wafer, back grinding method for semiconductor wafer

InactiveCN101993667AAvoid glue residueReduce generationLamination ancillary operationsLayered product treatmentShear stressAdhesive

The invention aims at providing an adhesive sheet for supporting and protecting a semiconductor wafer, and a back grinding method for the semiconductor wafer. The adhesive sheet can effectively prevent adhesive residue caused by concave-convex parts in a forming surface of circuit patterns and the like of the semiconductor wafer in recent years. The adhesive sheet for supporting and protecting the semiconductor wafer (40) is used for being adhered to a surface of a semiconductor wafer to support and protect the semiconductor wafer, an intermediate layer (20) and an adhesive layer (30) are formed on a one side of a substrate in this order, the adhesive layer (30) is made of a radiation curing type adhesive, and has a thickness of 1 to 50 mum and a shear stress of 0.5 to 10 MPa, the intermediate layer (20) has a thickness of 10 to 500 mum and an elastic modulus of 0.01 to 3 MPa.

Owner:NITTO DENKO CORP

Trade mark paper and its preparing method

InactiveCN1986964AHeat shrinkableAvoid glue residueMechanical working/deformationSpecial paperTrademarkPulp and paper industry

A label paper with high stability is composed of a thermoshrinkable plastic film, a pressure-sensitive adhesive layer and a parting paper layer. Its preparing process is also disclosed.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

Adhesive film with dicing sheet and method of manufacturing the same

ActiveCN102002323AGood adhesivenessImprove balanceSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

The present invention provides an adhesive film with a dicing sheet and a method of manufacturing the same. The adhesive film with the dicing sheet has a pressure-sensitive adhesive layer on a base material and also has a peelable adhesive film on the pressure-sensitive adhesive layer, that has an excellent peeling property when peeling a semiconductor chip obtained by dicing and an adhesive filmattached thereto together without impairing the holding power even during dicing a thin semiconductor wafer, and a method of manufacturing the same. The adhesive film with a dicing sheet of the present invention is formed by sequentially laminating a pressure-sensitive adhesive layer and an adhesive layer on a base material, in which the intensity of an Si-K[alpha] ray on at least one region on asurface of the pressure-sensitive adhesive layer to be pasted onto the adhesive layer is 0.01 to 100 kcps.

Owner:NITTO DENKO CORP

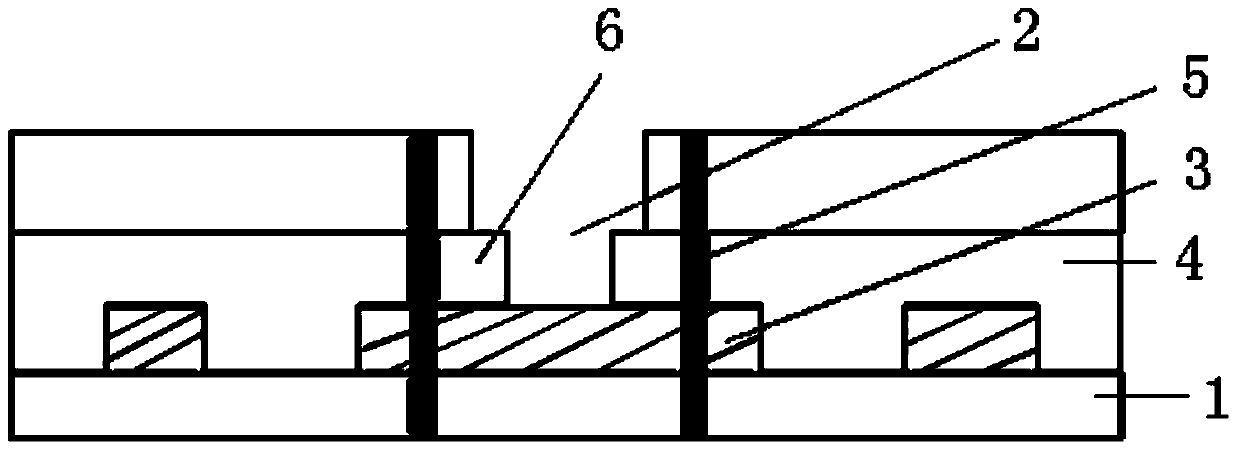

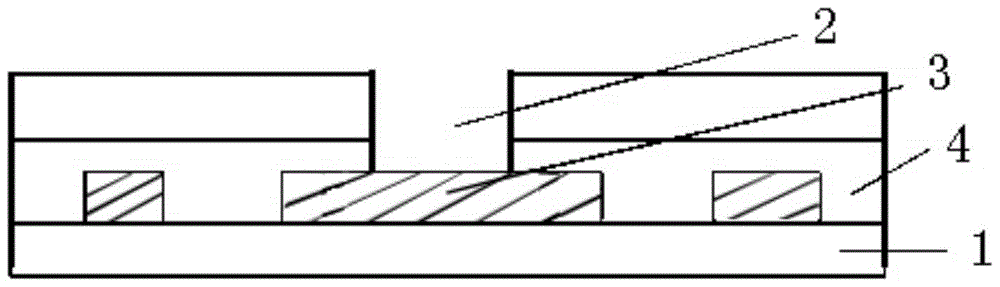

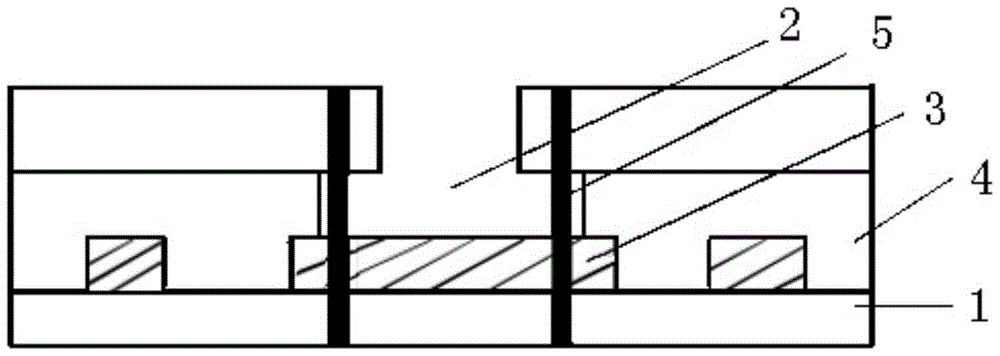

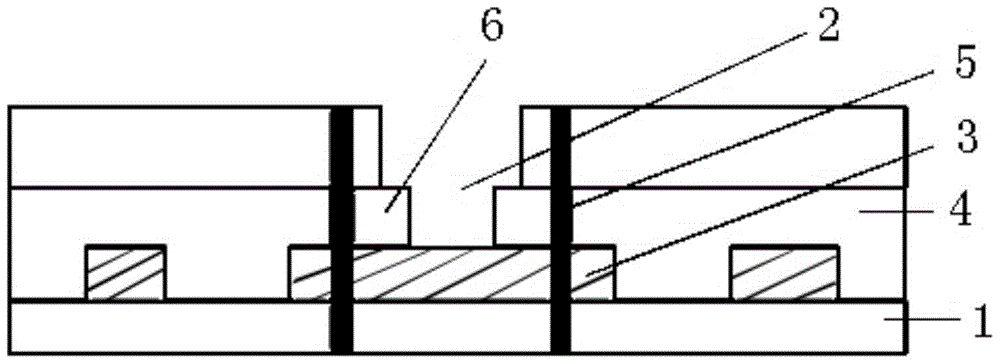

Glue control method of step package substrate

ActiveCN103779242AHave the effect of controlling glueGuaranteed effective sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAcid washing

The invention provides a glue control method of a step package substrate. The glue control method comprises the following steps that firstly, acid washing is conducted on an inner single chip of a package structure with a groove, and the groove is provided with a layer of peelable glue in a silk printing mode; secondly, the structure provided with the peelable glue in the silk printing mode is baked, so that the peelable glue is solidified and shaped; thirdly, after the peelable glue is solidified and shaped, brown oxidation is conducted on the inner single chip, and lamination is conducted on the inner single chip so as to form a multilayer board; fourthly, before a finished product is milled, the peelable glue is removed, so that a conductor under the peelable glue is exposed. The glue control method of the step package substrate can effectively prevent the situation that flow glue remains on the exposed conductor in the groove.

Owner:JIANGNAN INST OF COMPUTING TECH

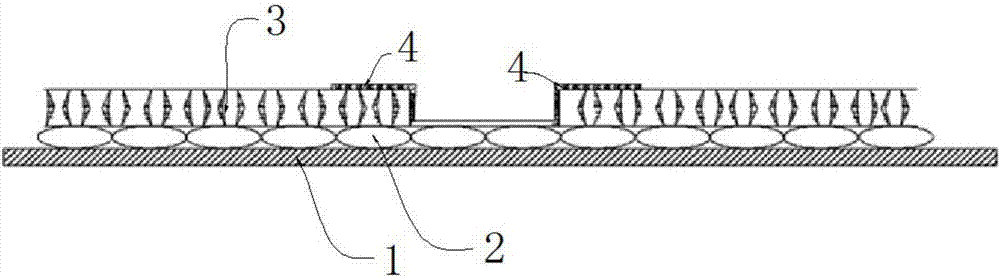

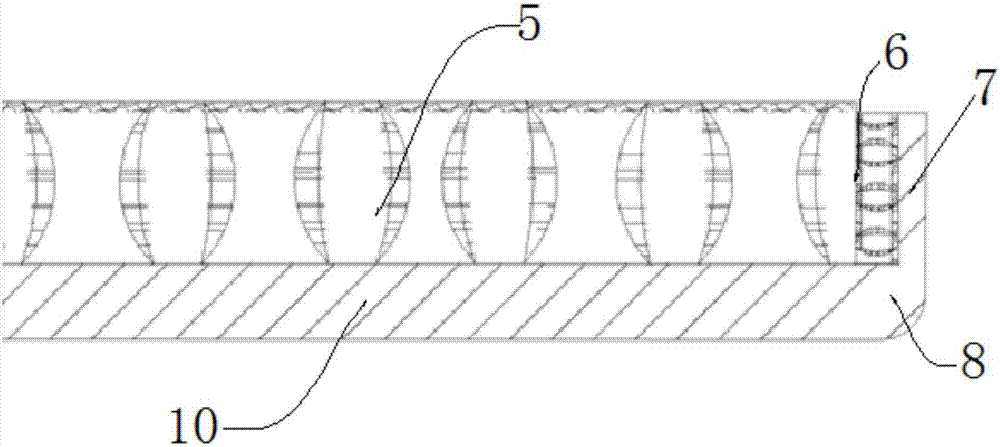

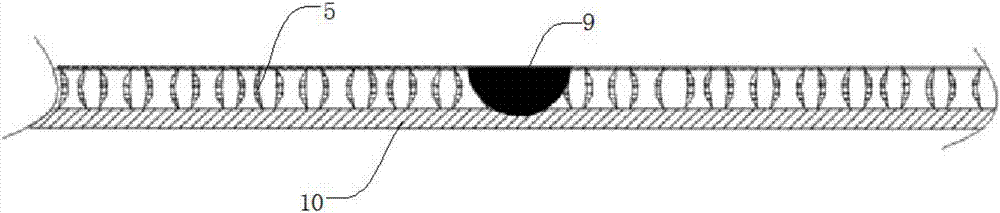

Tail end and hinge structure of PP cellular board and treatment process thereof

ActiveCN106945372AWon't leakReduce harmSynthetic resin layered productsLaminationAdhesiveEngineering

The invention discloses a tail end and hinge structure of a PP cellular board and a treatment process thereof. The structure comprises a cellular board layer (5) and an epidermal layer (10) fixedly covering the lower surface of the cellular board layer, wherein the epidermal layer coats the end surface (6) of the cellular board layer of the cellular board layer and forms an epidermal layer folding face (7) on the end surface of the cellular board layer; a semi-arc-shaped hinge port (9) is formed in the cellular board layer. By means of a reversing technology, the rim of the cellular board layer is coated, so that the cellular board layer is not leaked while the strength is increased, and the commodity is enhanced; the cellular board layer is compounded and bonded to the epidermal layer while a PP material is extruded, so that a solvent adhesive is solved, the damage on the environment and human is reduced, and meanwhile, the residue of the solvent adhesive is also solved, and the commodity is enhanced; the hinge is heated and thermally pressed through the cellular board layer to overturn at 180 degrees, so that a non-woven fabric is not used, and the material cost is lowered.

Owner:武汉林骏汽车饰件有限公司

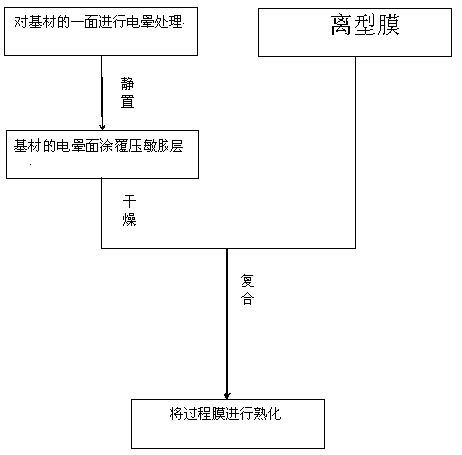

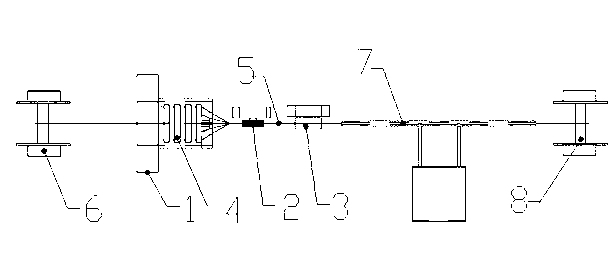

Process film production method for process of stable adhesion after high temperature, and product thereof

InactiveCN110437760ASolve the problem of sharp increase in peeling forceStable peel forceNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesLength wavePhotoinitiator

The invention discloses a process film production method for a for process of stable adhesion after a high temperature, and a product thereof. A substrate in the process film is a PET, PO, PVC or PP optical film with a thickness of 25-200 [mu]m, and one side of the optical film is subjected to corona treatment; and a pressure-sensitive adhesive layer is a UV viscosity reducing adhesive layer, andcomprises 0.1-5% of a photoinitiator having an absorption wavelength of 200-400 nm and 0.5-10% of nanocrystall beads, and the pressure-sensitive adhesive is applied to the corona surface of the substrate, and is covered with a release film, the peeling strength before UV is 500-5000 g / 25 mm, and the peeling strength after UV is 0-100 g / 25 mm. The peel strength is stable when the process film is used in a high temperature environment, so the problem that the peeling strength of the UV viscosity reducing adhesive film in the high temperature environment is greatly increased is solved, the residual glue phenomenon is avoided, the stability of the technology process is increased, and the yield and the efficiency are improved. The product is mainly applied to the processing process of a film group at present.

Owner:上海精珅新材料有限公司

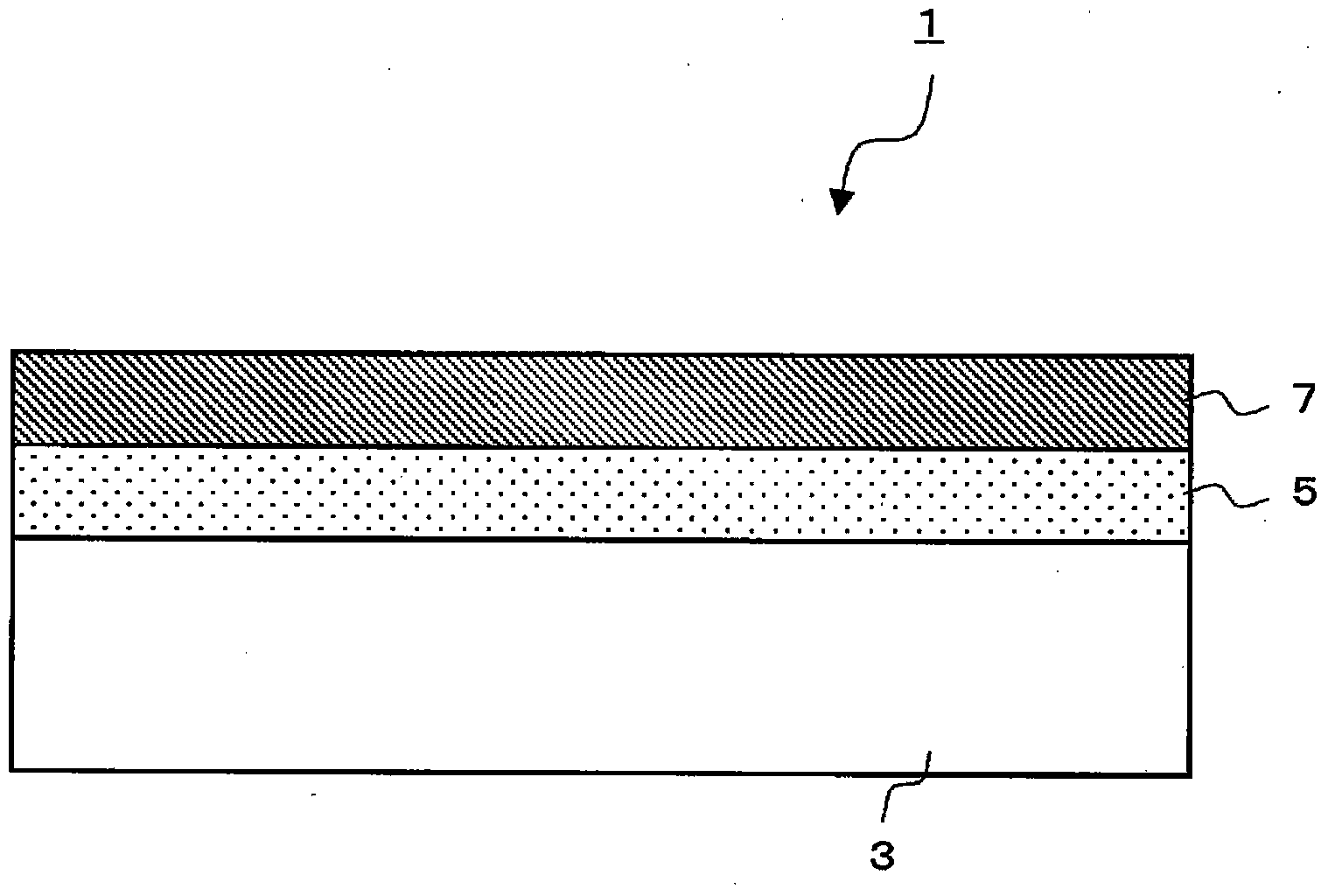

Dicing tape for processing semiconductor

ActiveCN103620743AReduce pollutionAvoid glue residueFilm/foil adhesivesSolid-state devicesDicing tapeEngineering

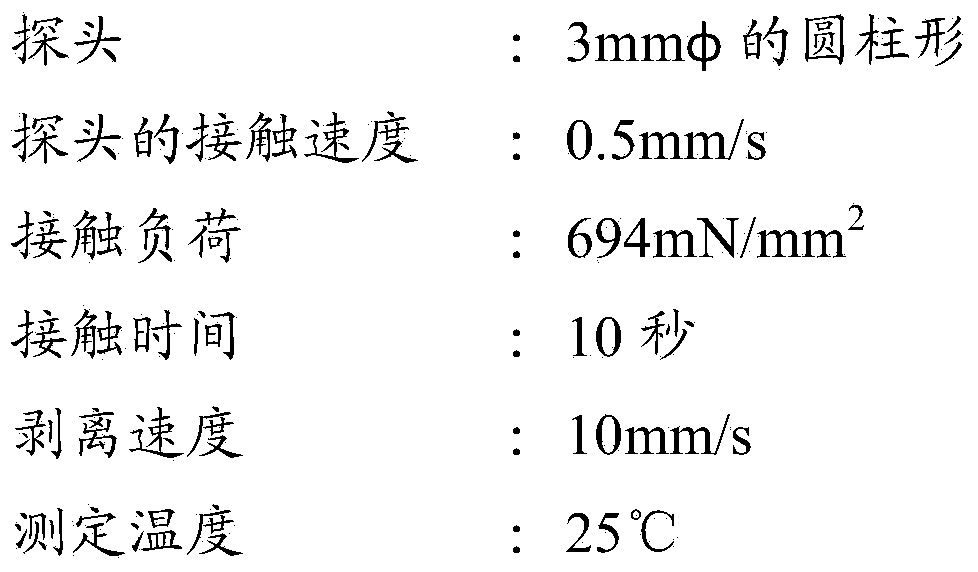

The purpose of the present invention is to provide a dicing adhesive tape for processing semiconductors, the tape having adhesive strength to sufficiently hold a semiconductor wafer during the process of performing dicing on the wafer, without causing problems such as adhesion to the device or the tray of packages that have been fragmented after the package dicing. The present invention provides a dicing tape for processing semiconductors, characterized in that: a radiation-curing adhesive layer is formed on at least one surface of a substrate film; the adhesive film comprises a resin composition containing, as a base polymer, an acrylic-based polymer; the thickness of the adhesive film is 10 to 30 mum; the adhesive strength of the adhesive layer, after irradiation of an SUS304 with radiation based on JIS Z0237, is 1.0 to 2.0N / 25 mm tape width when a 90 DEG peel test is performed; and the peak intensity of a probe tack of the adhesive layer after irradiation with radiation under air atmospheric conditions is 50 to 150 mN / mm2.

Owner:FURUKAWA ELECTRIC CO LTD

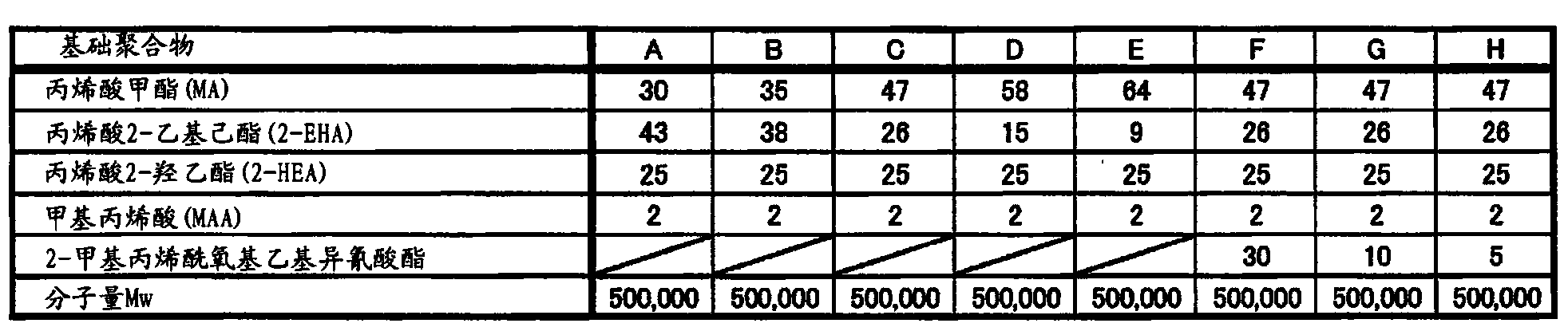

Protective film for automotive wheel

InactiveCN102414018AEasy to peelPrevent rustPolyureas/polyurethane adhesivesSynthetic resin layered productsMeth-Engineering

A protective film for automotive wheels which has excellent performances including the following. The protective film has excellent weatherability, and even when the motor vehicle is stored for a long period from completion to delivery, the protective film can be sufficiently prevented from decreasing in adhesive force. The protective film for automotive wheels comprises a base layer and a pressure-sensitive adhesive layer, and is characterized in that the pressure-sensitive adhesive layer has been formed from a pressure-sensitive adhesive composition comprising at least a (meth)acrylic polymer and a crosslinking agent, the (meth)acrylic polymer comprising 40-90 wt.% (meth)acrylic monomer having an alkyl group with 1-14 carbon atoms and, as other constituent monomer ingredient, at least a hydroxylated monomer, and the crosslinking agent being contained in an amount of 0.1-6 parts by weight per 100 parts by weight of the acrylic polymer, and that the pressure-sensitive adhesive layer has a gel content of 60-95 wt.%.

Owner:NITTO DENKO CORP

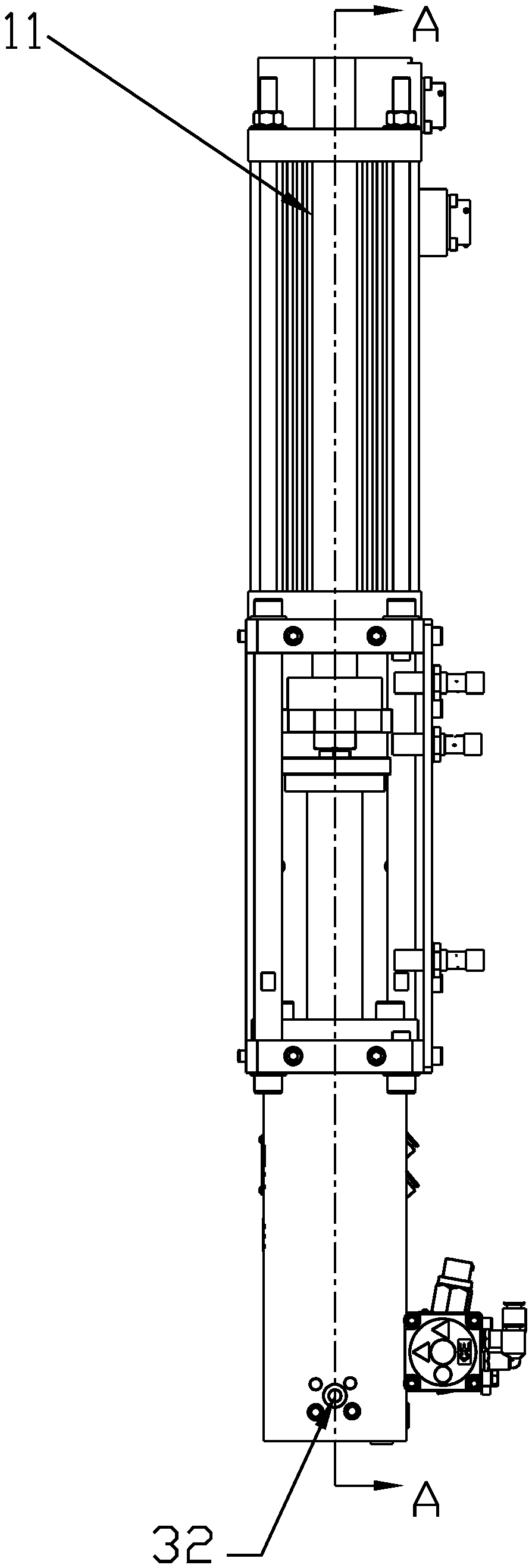

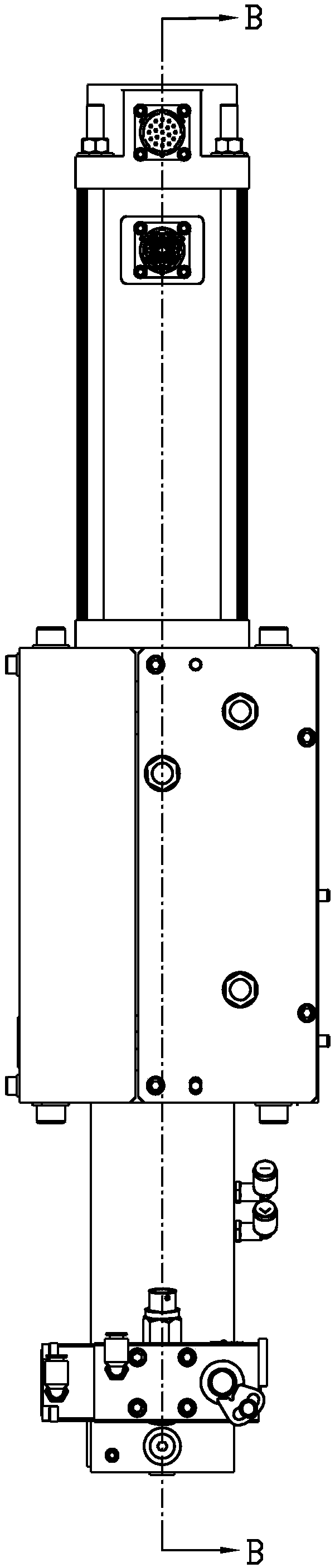

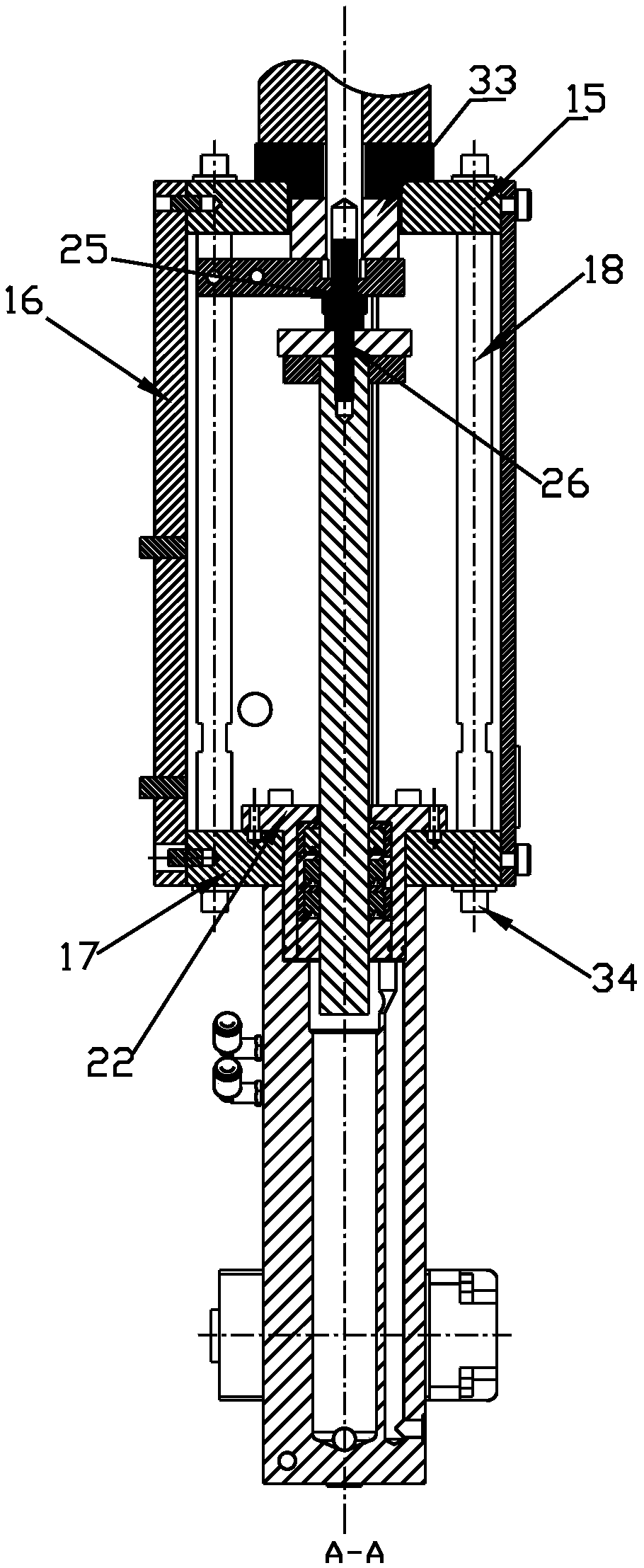

Servo gluing quantification machine

InactiveCN109382279APrevent glue accumulationAvoid glue residueLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a servo gluing quantification machine. The servo gluing quantification machine comprises a servo electric cylinder, a support and a glue cylinder, wherein the servo electric cylinder is fixedly connected with the glue cylinder through the support; the glue cylinder is provided with a glue feeding cavity with an upper opening; a throat sealing metal piece is mounted at the upper part of the glue feeding cavity in a sealed manner and provided with a vertical shaft hole; a piston rod is mounted in the vertical shaft hole; a dynamic sealing piece for sealing a gap between the piston rod and the vertical shaft hole is mounted in the vertical shaft hole; the diameter of the piston rod is smaller than the inner diameter of the glue feeding cavity; a glue feeding port communicated with the glue feeding cavity is formed in the bottom of the glue cylinder; a glue feeding valve is mounted in the glue feeding port; a push rod of the servo electric cylinder is coaxially arranged above the piston rod; a glue discharging cavity is formed in the glue cylinder, and the upper part of the glue discharging cavity is communicated with the glue feeding cavity through communicating holes; a glue discharging port communicated with the glue discharging cavity is formed in the bottom of the glue cylinder; a glue discharging valve is mounted in the glue discharging port. The servogluing quantification machine has beneficial effects as follows: first-in first-out of glue is guaranteed by adopting an isovolumetric replacement principle, and the problem of glue stacking or glueresidues in the glue cylinder is solved.

Owner:YANTAI KEPAI INTELLIGENT TECH CO LTD

Preparation method of adhesive tape

ActiveCN106497446AImprove adhesionReduce incidenceNon-macromolecular adhesive additivesChemical industryHeat sensitivePressure sensitive

The invention provides a preparation method of adhesive tape. The preparation method is characterized by comprising the following steps that a first release film is coated with a thermosenstive adhesive, and drying is conducted to form a release film layer and a thermosensitive adhesive layer; a second release film is coated with the thermosensitive adhesive to form a pressure-sensitive adhesive layer fit with the second release film, drying is conducted, and a base material and the pressure-sensitive adhesive layer are fit; the second release film is stripped from the pressure-sensitive adhesive layer and fit with the thermosensitive adhesive layer, and the adhesive tape on which the release film layer, the thermosensitive adhesive layer, the pressure-sensitive adhesive layer and the base material layer are sequentially fit is formed. According to the preparation method, the adhesive tape which can reduce bubbles or marks generated when a shell is wrapped can be obtained, the manufacture procedure protection effect is improved, and the problem that adhesive residues exist after the thermosensitive adhesive layer is fit through heating and stripped through cooling is avoided.

Owner:宁波启合新材料科技有限公司

Polarizer with TAC layer arranged on one side and preparation method thereof

The invention discloses a polarizer with a TAC layer arranged on one side, and the polarizer comprises a protective layer, a first PSA layer, a PVA layer and the TAC layer, which are disposed in a stepwise fitting manner. The invention also discloses a preparation method of the above polarizer. The polarizer with the TAC layer arranged on one side provided by the invention can meet the performance requirements of the polarizer to make the polarizer thinner and lighter, and can save the production cost and improve the competitiveness of the enterprise. The preparation method of the polarizer with the TAC layer arranged on one side provided by the invention is simple, and can effectively solve the problem of warpage and shrinkage of the polarizer provided with the TAC layer on one side, and also solve the problem that the glass substrate is bent after the polarizer is attached to the glass substrate.

Owner:SHENZHEN SUNNYPOL OPTOELECTRONICS

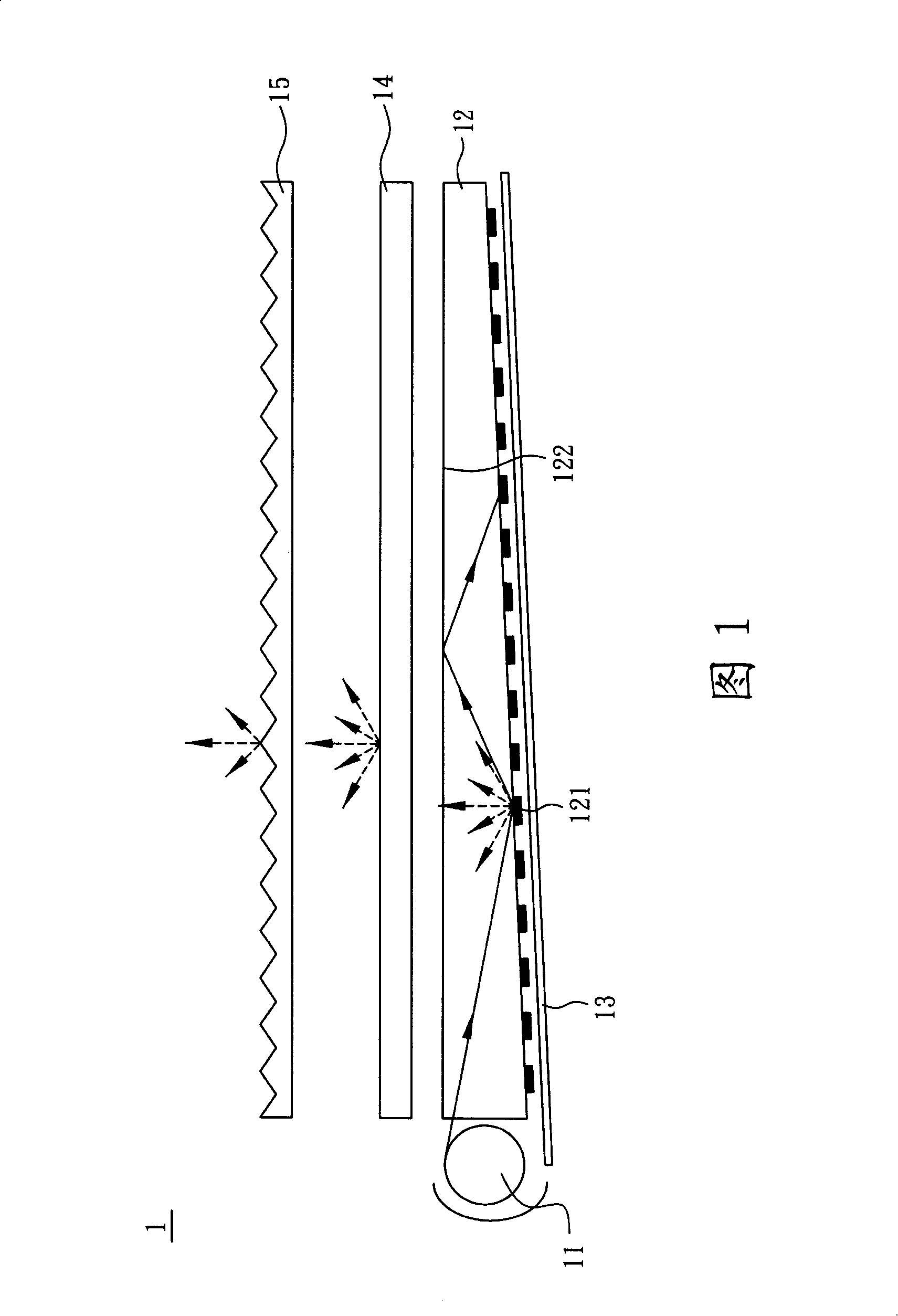

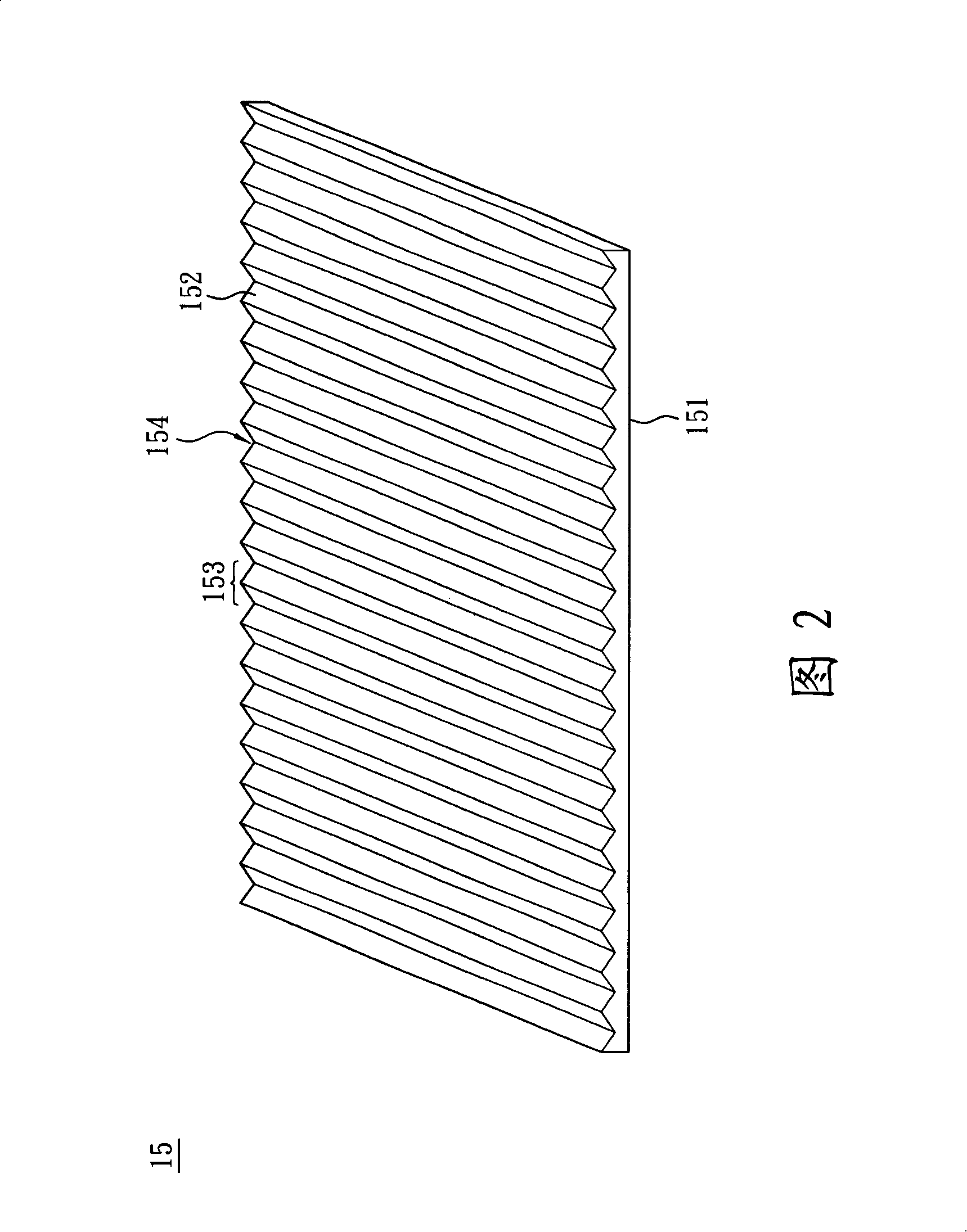

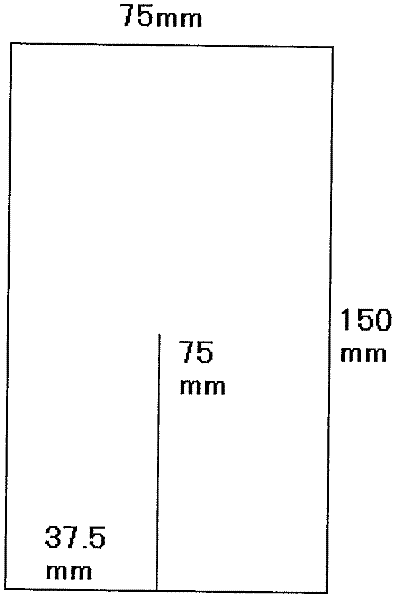

Optical thin film of back light module group

InactiveCN101206337ADisrupt regularityAvoid it happening againPrismsNon-linear opticsOptical thin filmEngineering

An optical thin film of backlight module comprises a basal plate and a prism sheet. The prism sheet is arranged on one side of the basal plate and comprises a plurality of prism patterns in periodic arrangement. The prism patterns respectively have a plurality of triangular prisms, wherein, a round angle is formed between at least two adjacent triangular prisms. The present invention can reduce residual glue of roller wheels.

Owner:PRODISC TECH INC

Anti-static protective film for wafer cutting and preparation method thereof

ActiveCN111303789AHigh peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesWaferFilm material

The invention provides an anti-static protective film for wafer cutting. The anti-static protective film sequentially comprises a first anti-static layer, a substrate layer, a second anti-static layer, a viscosity reduction layer and a release film layer. According to the invention, the protective film for wafer cutting is prepared by combining the double-sided antistatic layers and a viscosity reducing film material containing an antistatic filler, so the phenomenon of residual glue easily occurring in long-term storage or under a high-temperature condition is avoided; and meanwhile, the peeling strength of the protective film for wafer cutting before viscosity reduction can be improved, and the peeling strength of the protective film after viscosity reduction can be reduced, so accuratefixing and picking efficiency are improved.

Owner:广东硕成科技股份有限公司

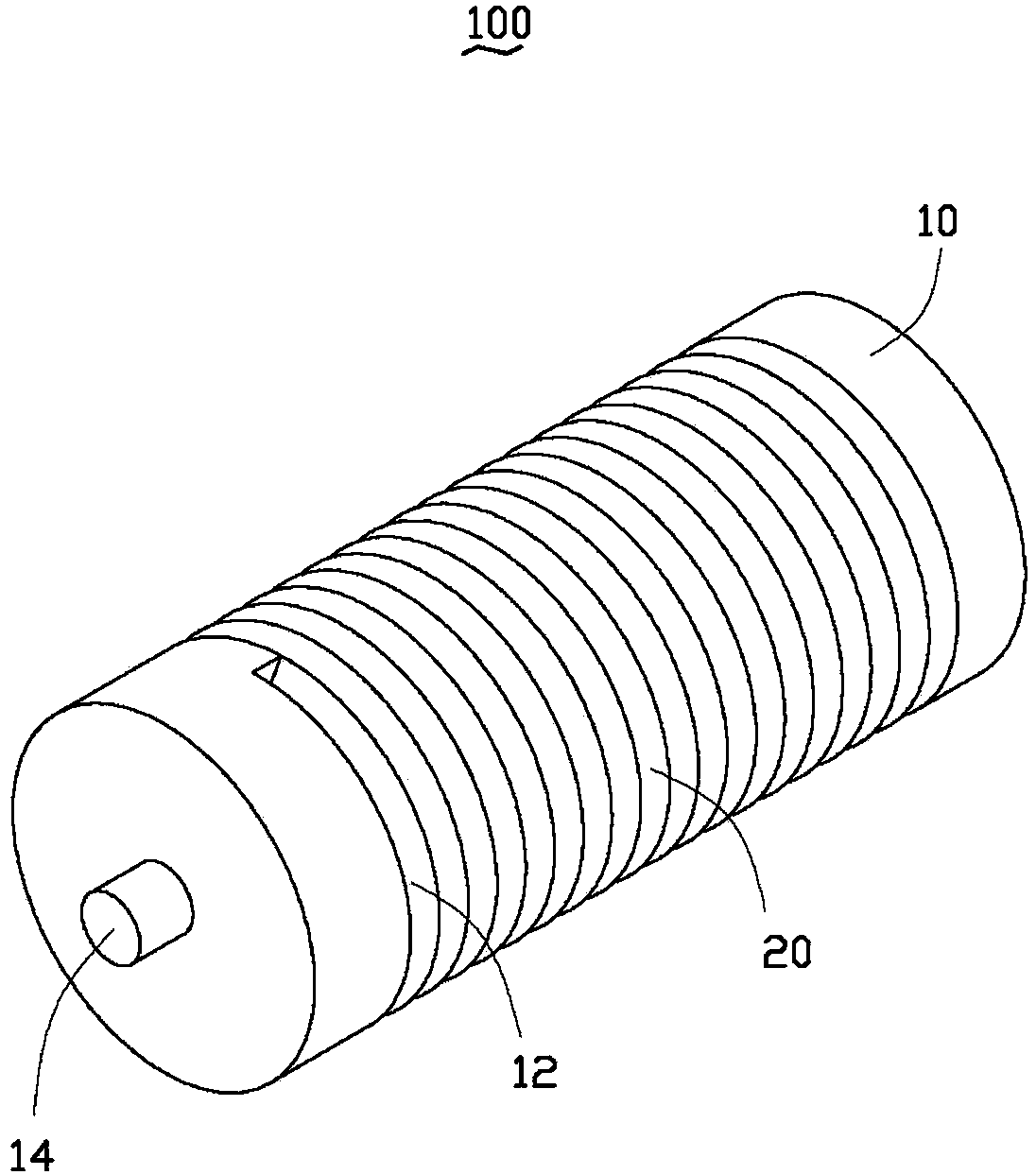

Roller die core and manufacturing method thereof

InactiveCN104175425AImprove antioxidant capacityOvercome the deficiency of being easily oxidizedOptical articlesCarbon filmMaterials science

The invention relates to a roller die core. The roller die core is used for molding an optical film. The roller die core comprises a roller, microstructures formed on the outer circumferential surface of the roller and a diamond-like carbon film formed on the surfaces of the microstructures. The invention also relates to a manufacturing method of the roller die core.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

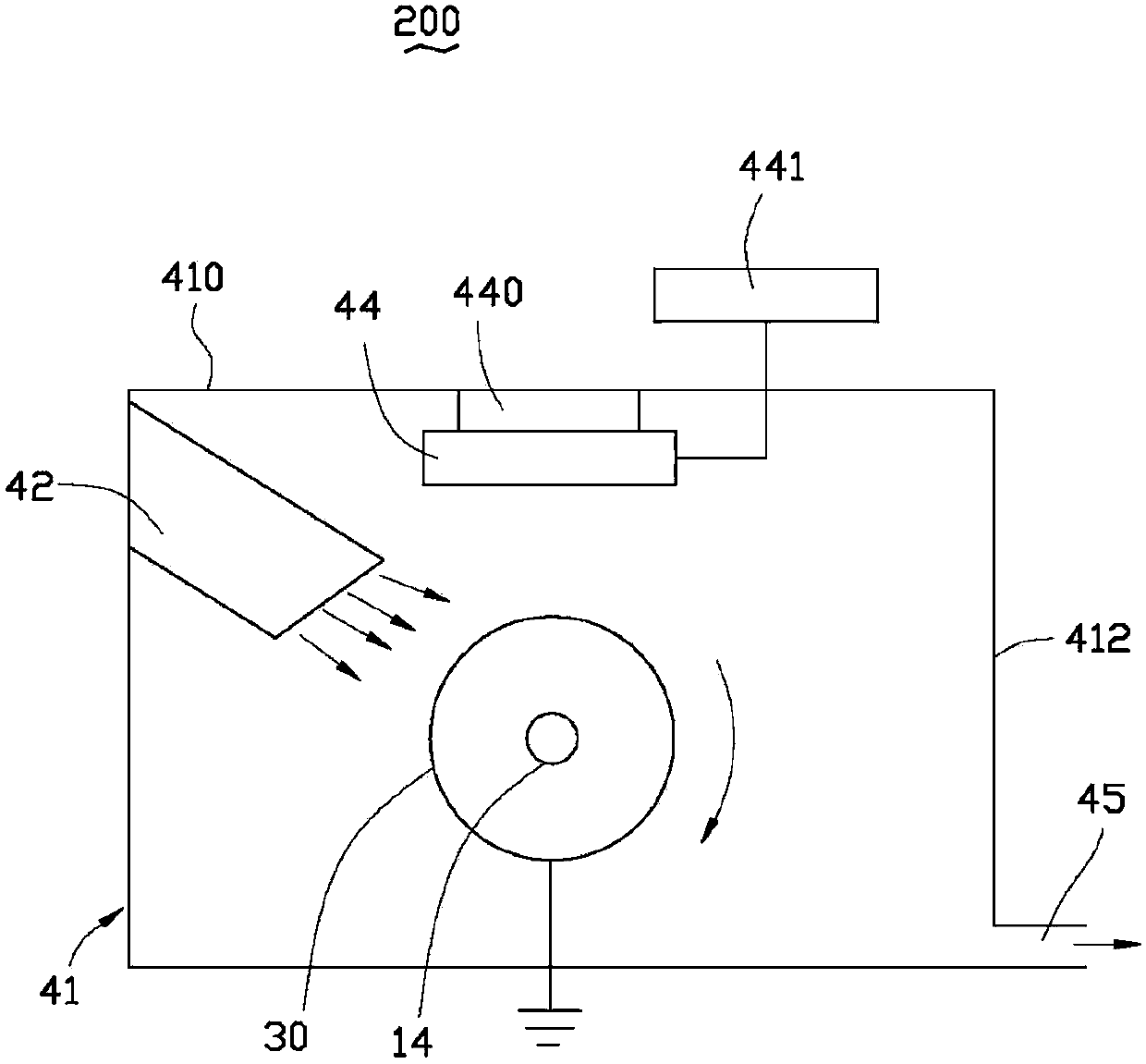

Processing apparatus and processing method for flocking flexible shaft

InactiveCN102913535AAvoid glue residueAvoid sticking inFlexible shaftsEngineeringUltimate tensile strength

The invention discloses a processing apparatus for a flocking flexible shaft. The processing apparatus comprises a material stack bin, a heating device and a traction wheel, wherein a wool spool coiled with wool is arranged in the material stack bin; the to-be-flocked flexible shaft used as a core wire is coiled on the flexible shaft wool spool; one end of the flexible shaft penetrates the material stack bin and the heating device to be connected to the traction wheel; and the wool is coiled on the flexible shaft. The processing apparatus adopts a hot melting method to realize mechanical automatic production, thereby reducing work intensity of operation staff and dependence on the manual technology, allowing processing technology to realize reel production of the flocking flexible shafts, and improving the processing efficiency. The produced flocking flexible shaft has universality.

Owner:SUHNER SUZHOU IND TECH

A kind of antistatic wafer cutting protective film and preparation method thereof

ActiveCN111303789BHigh peel strengthLow peel strengthNon-macromolecular adhesive additivesFilm/foil adhesivesPhysical chemistryWafer dicing

The first aspect of the present invention provides an antistatic wafer dicing protection film, which sequentially includes a first antistatic layer, a substrate layer, a second antistatic layer, an adhesion-reducing layer and a release film layer. The invention adopts the double-sided antistatic layer combined with the anti-adhesive film material containing antistatic performance filler to prepare the wafer cutting protective film, which avoids the phenomenon of residual glue that is easy to appear under long-term storage or high temperature conditions, and can also improve the quality of the wafer. Cutting the peel strength of the protective film before detackification and reducing the peel strength of the protective film after detackification, so as to improve the accuracy of fixing and picking efficiency.

Owner:广东硕成科技股份有限公司

A step packaging substrate glue control method

ActiveCN103779242BHave the effect of controlling glueGuaranteed effective sizeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorAcid washing

A glue control method of a step package substrate comprises: the first step, acid washing is conducted on an inner single chip of a package structure with a groove, and the groove is provided with a layer of peelable glue in a silk printing mode; the second step, the structure provided with the peelable glue in the silk printing mode is baked, so that the peelable glue is solidified and shaped; the third step, after the peelable glue is solidified and shaped, brown oxidation is conducted on the inner single chip, and lamination is conducted on the inner single chip so as to form a multilayer board; the fourth step, before a finished product is milled, the peelable glue is removed, so that the conductor under the peelable glue is exposed. The glue control method of the step package substrate can effectively prevent the situation that flow glue remains on the exposed conductor in the groove.

Owner:JIANGNAN INST OF COMPUTING TECH

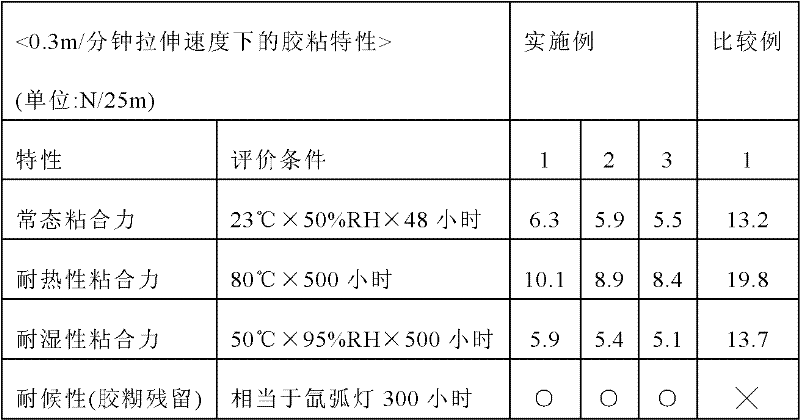

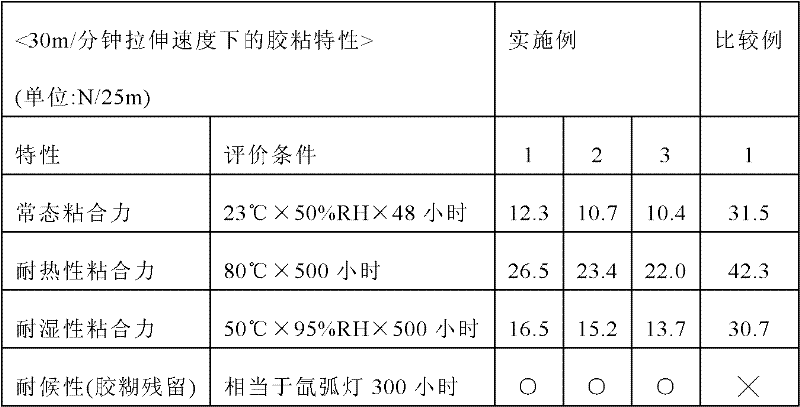

Protective film for automotive wheel

InactiveCN102414285AEasy to peelPrevent rustFilm/foil adhesivesPolyureas/polyurethane adhesivesEngineeringUltimate tensile strength

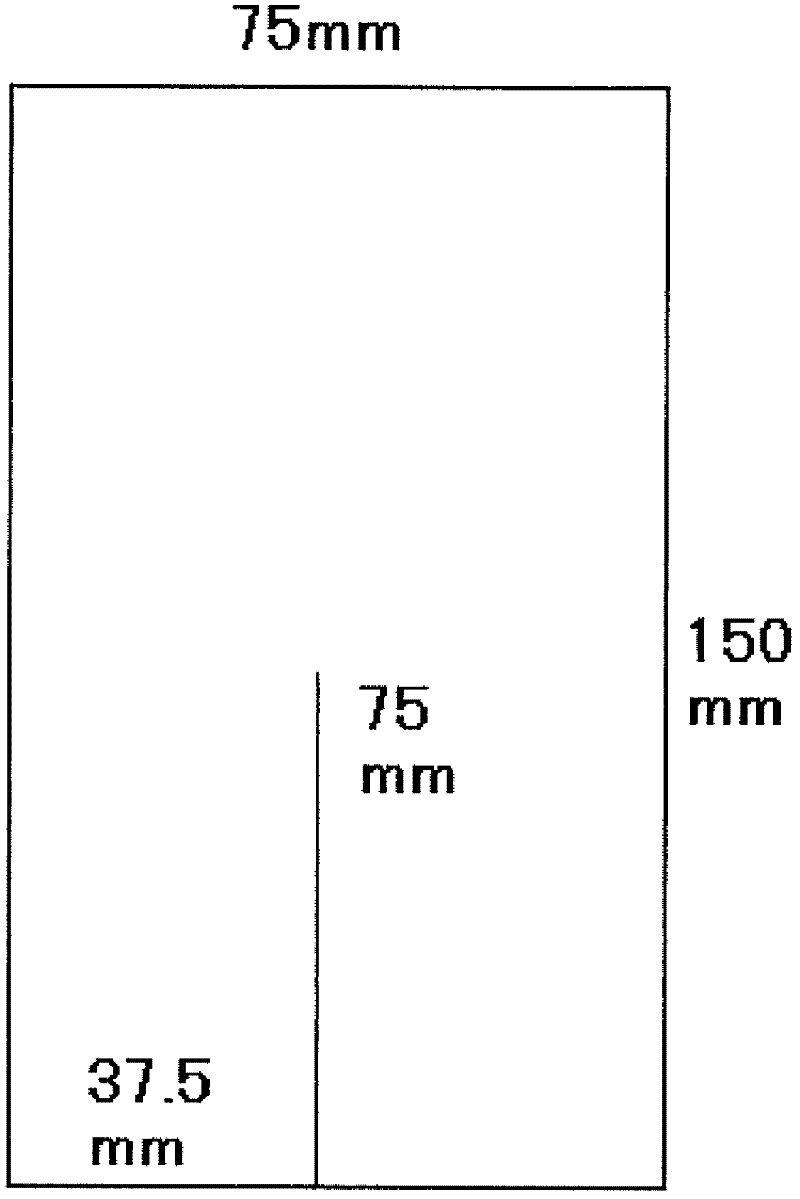

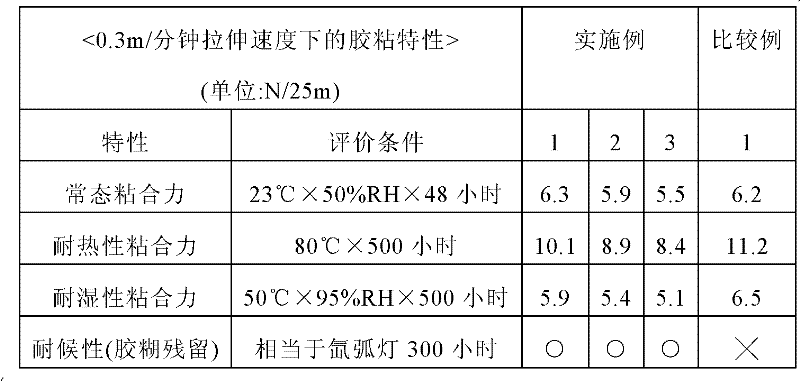

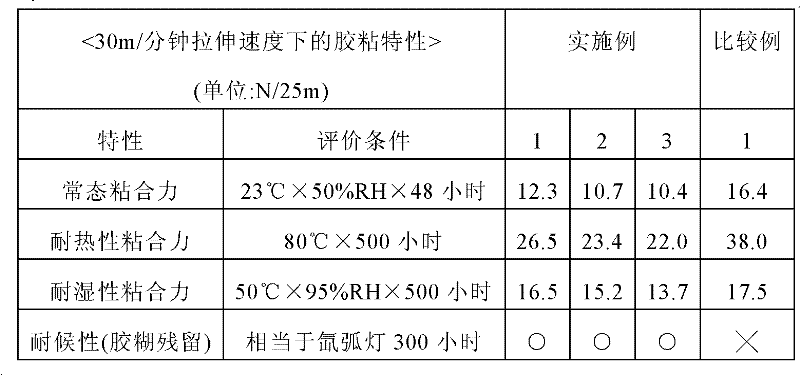

A protective film for automotive wheels which comprises a base layer and a pressure-sensitive adhesive layer, characterized in that the protective film has a trouser tear strength in the machine direction (MD) of 3 N or higher and that the protective film has adhesive forces (adherend, a panel coated with acrylic clear coating; after 48-hour standing at 23 C and 50% RH) of 4.9 N / 25 mm or higher at a pulling rate of 0.3 m / min. and of 19.6 N / 25 mm or lower at a pulling rate of 30 m / min.

Owner:NITTO DENKO CORP

High-heat conductivity coefficient graphite heat-radiation adhesive tape

ActiveCN103059761BAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesAdhesiveGraphite

Owner:斯迪克新型材料(江苏)有限公司

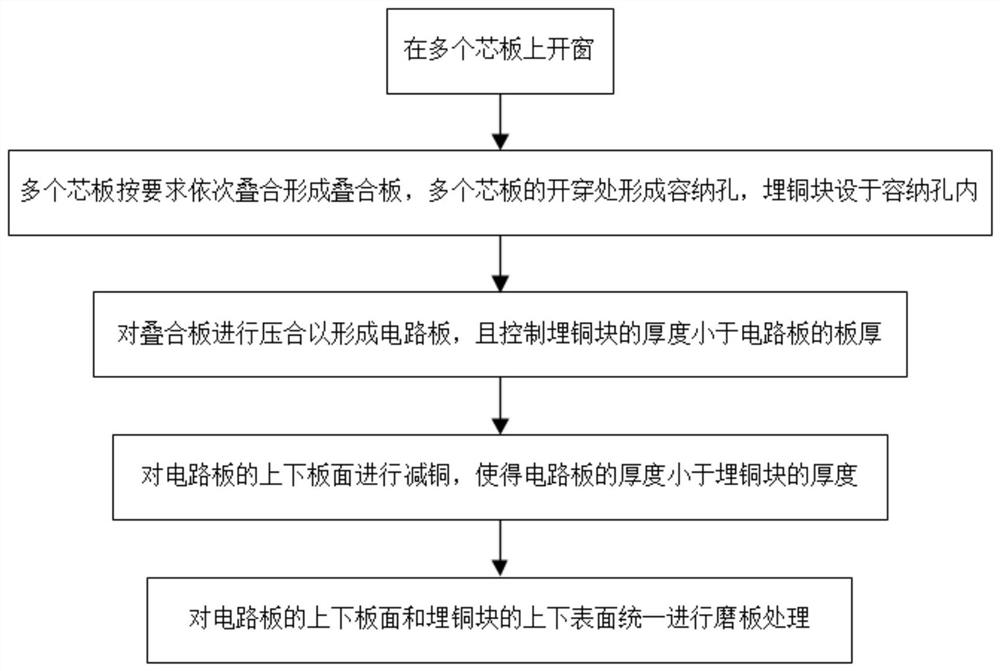

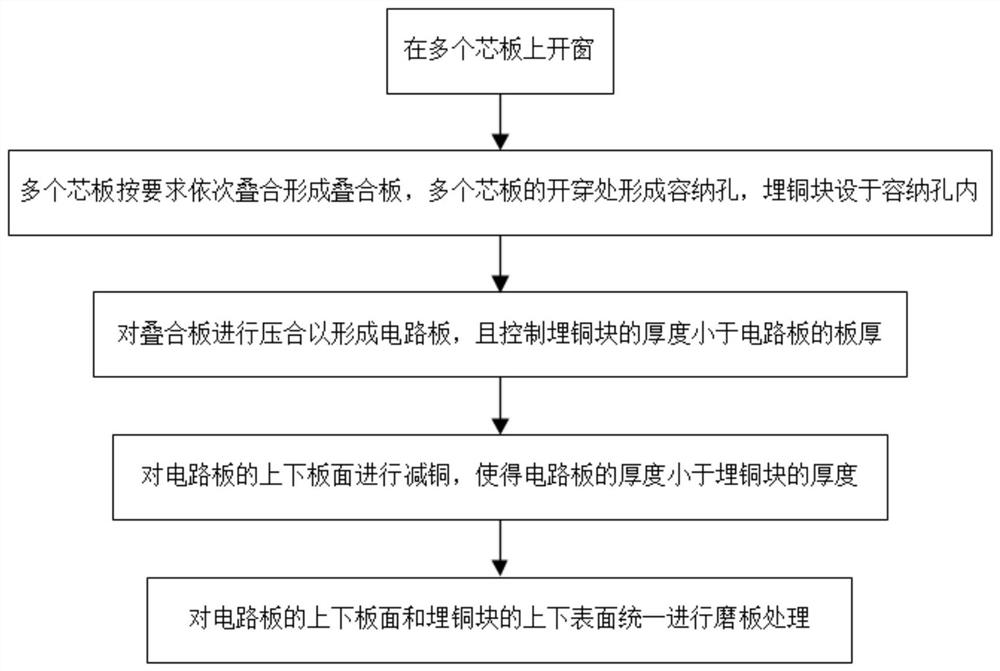

Manufacturing method of copper block-embedded circuit board

ActiveCN113194636AAvoid damage and deformationAvoid glue residuePrinted element electric connection formationMechanical engineeringPrinted circuit board

The invention discloses a manufacturing method of a copper-block-embedded circuit board, and relates to the technical field of printed circuit board manufacturing. The thickness of the embedded copper block is controlled to be smaller than that of the circuit board, the height difference prevents glue from flowing to the board surface of the circuit board after lamination, and the phenomenon of residual glue on the board surface is avoided; copper reduction treatment is carried out on the upper and lower surfaces of the circuit board, so that the thickness of the circuit board is smaller than that of the embedded copper block, and the height difference enables the upper and lower surfaces of the embedded copper block to protrude out of the circuit board, so that the upper and lower surfaces of the embedded copper block are subjected to glue removal; finally, the upper and lower board surfaces of the circuit board and the upper and lower surfaces of the embedded copper block are subjected to board grinding treatment to remove colloid on the upper and lower surfaces of the embedded copper block, and meanwhile it is guaranteed that the upper and lower board surfaces of the circuit board are flush with the upper and lower surfaces of the embedded copper block. According to the manufacturing method, the glue removing efficiency is improved, and meanwhile, the board surface of the copper block embedded circuit board is prevented from being deformed and damaged.

Owner:DONGGUAN SHENGYI ELECTRONICS

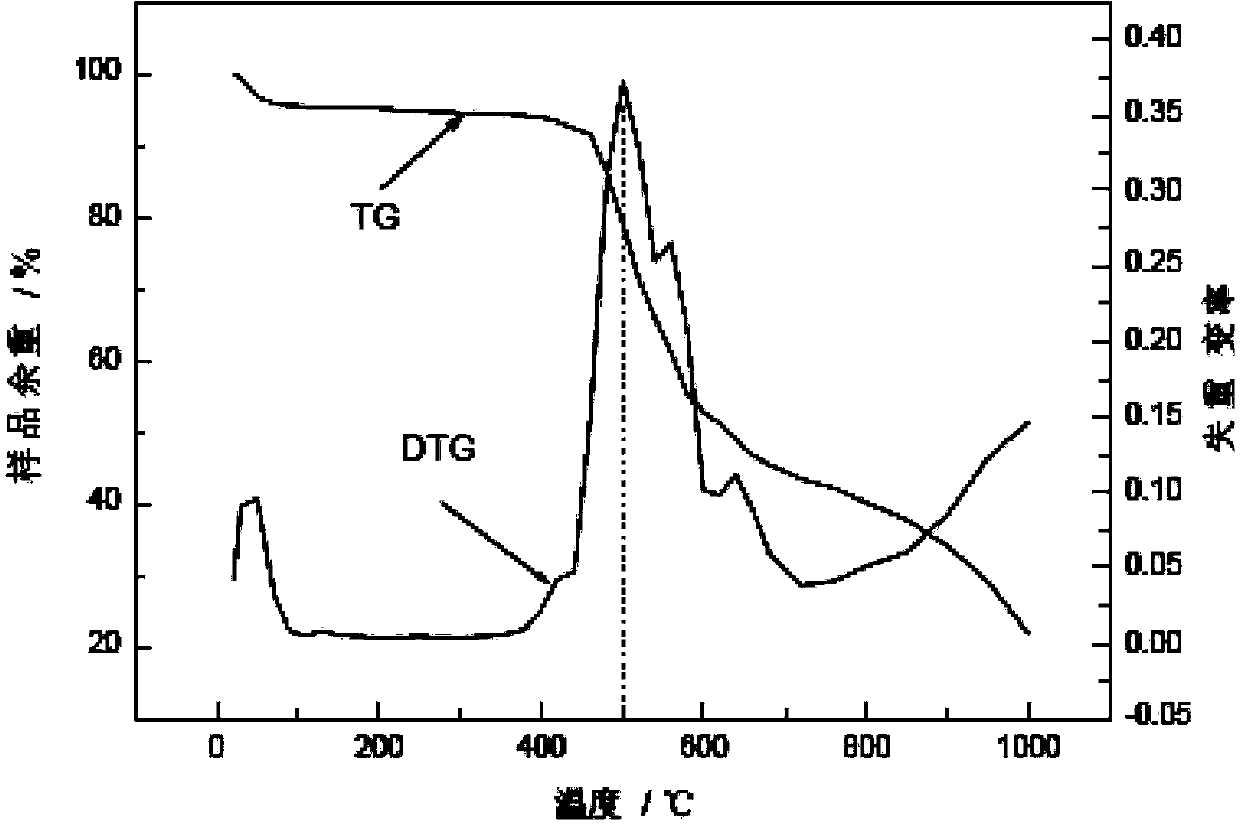

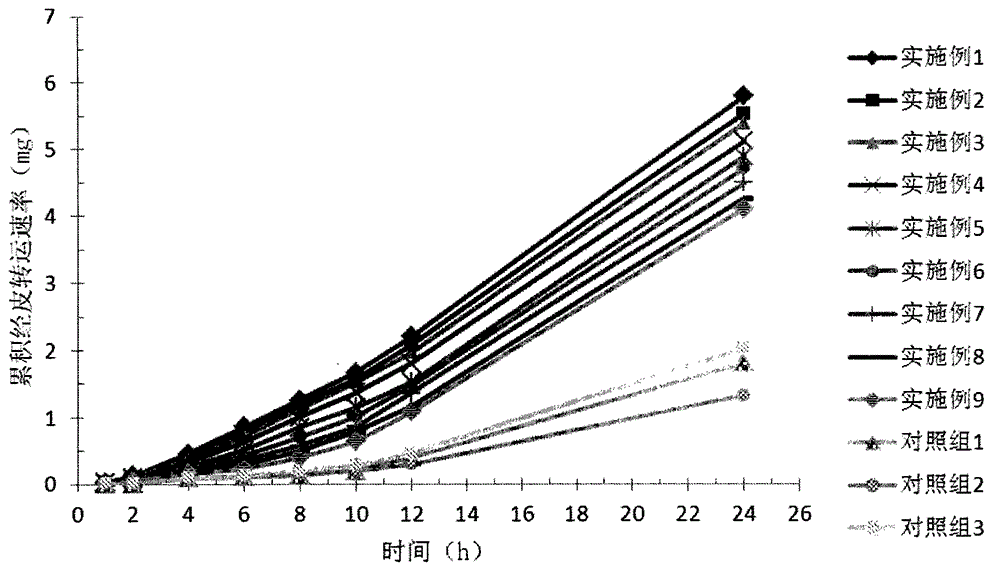

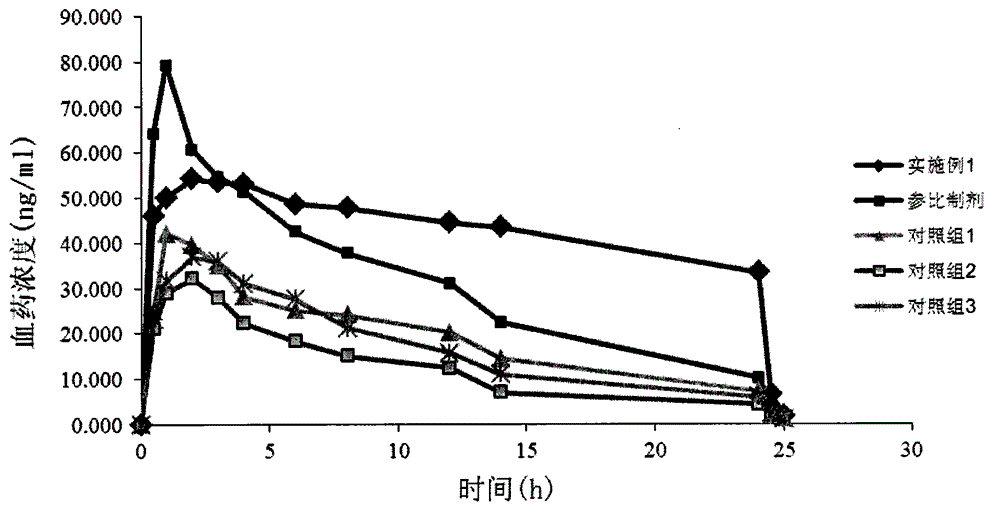

testosterone transdermal patch

ActiveCN103301093BGood skin permeabilityStrong synergyOrganic active ingredientsPharmaceutical non-active ingredientsSkin permeabilityAdditive ingredient

The invention relates to a testosterone transdermal absorbent patch which consists of an anti-sticking layer, a drug-containing glue layer and a liner layer structure, and in particular relates to a compound type modifier formed by the combined action of a plurality of ingredients, so that the skin permeability and the medicine stability of the testosterone can be improved, and the prepared drug-containing glue layer is uniform and stable, more stable in a drug release process, and better in safety. The patch provided by the invention hardly falls off, and is easy to remove, and free from the phenomenon of glue residue during use process, thereby being good in clinic application prospect.

Owner:CHINA RESOURCES ZIZHU PHARMA

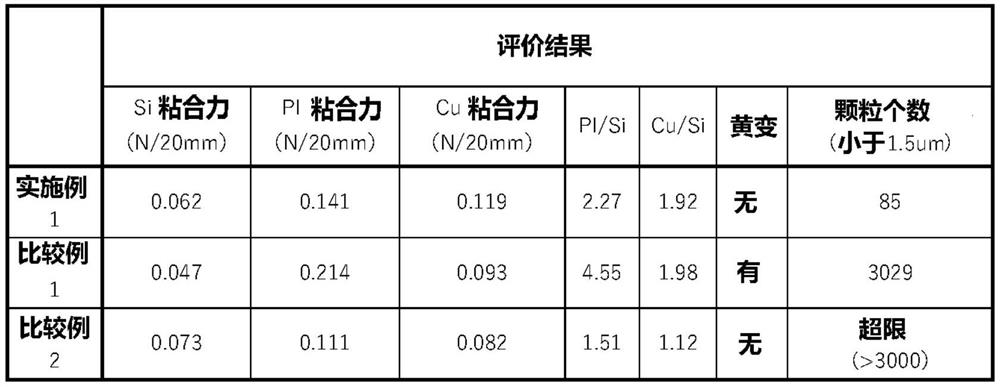

Ultraviolet curable adhesive sheet

PendingCN113214756AAvoid pollutionAvoid glue residueNon-macromolecular adhesive additivesFilm/foil adhesive primer layersOrganic chemistryMaterials science

Provided is an ultraviolet-curable adhesive sheet having low contamination to the surface of an adhered object. The ultraviolet-curable adhesive sheet according to the present invention comprises a substrate and an adhesive layer. The number of particles having a particle size of less than 1.5 [mu] m on the surface of the silicon wafer to which the adhesive layer is attached after the ultraviolet-curable adhesive sheet has been peeled off after the ultraviolet irradiation test is less than 100.

Owner:NITTO DENKO CORP

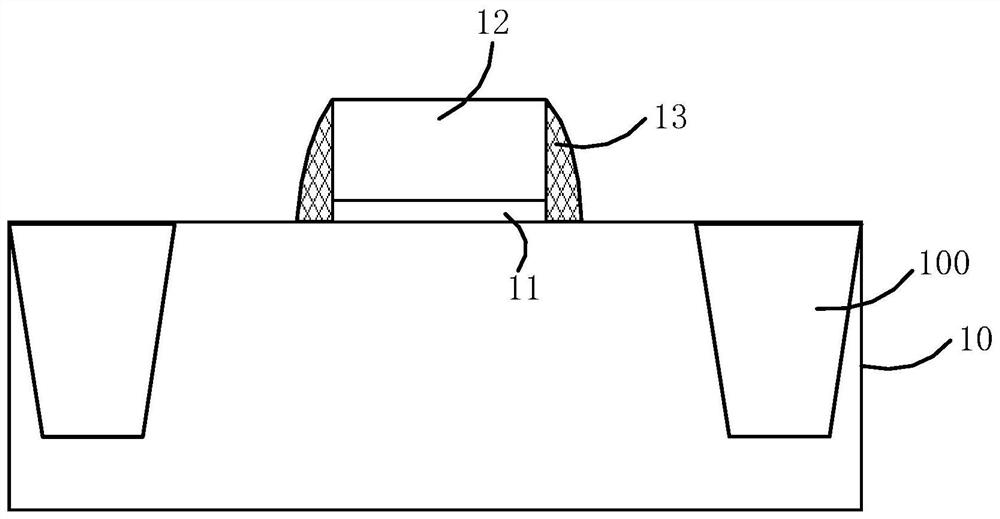

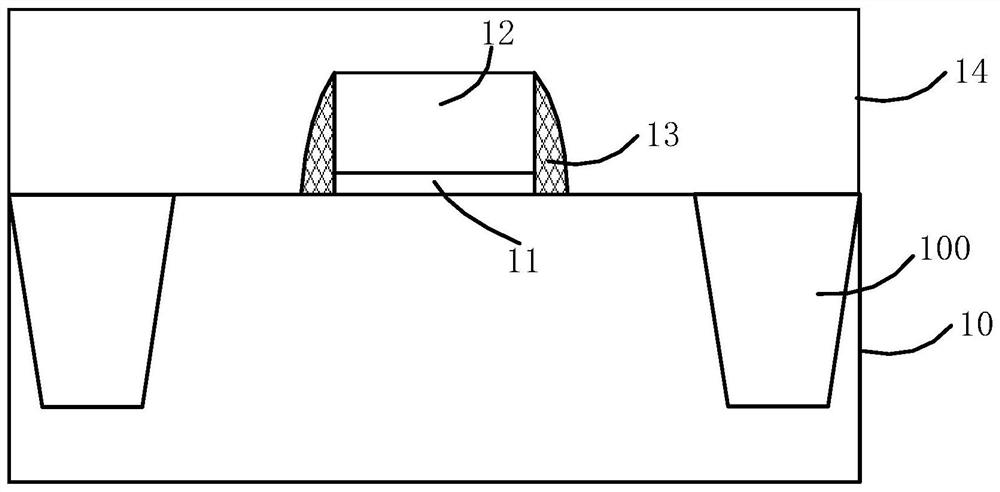

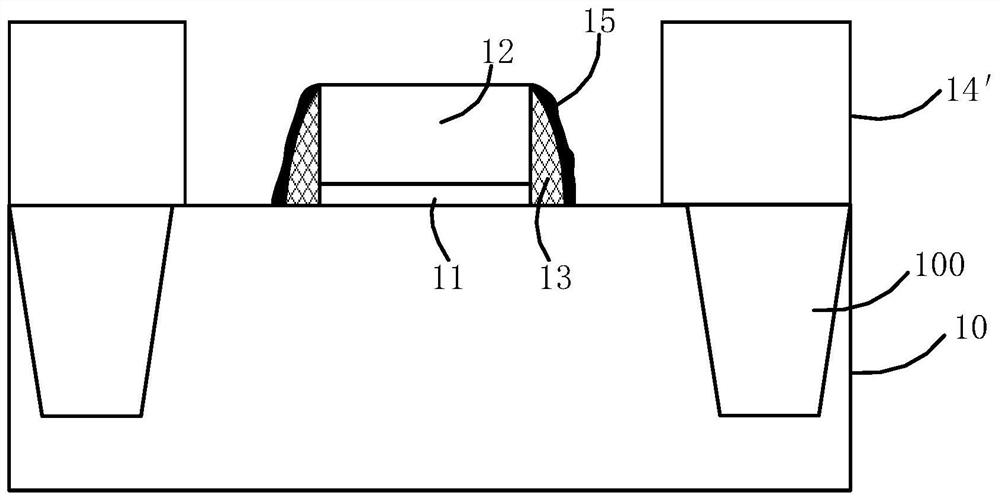

Semiconductor structure and fabrication method thereof

ActiveCN108666222BAvoid it happening againCD stableSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structurePhotoresist

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

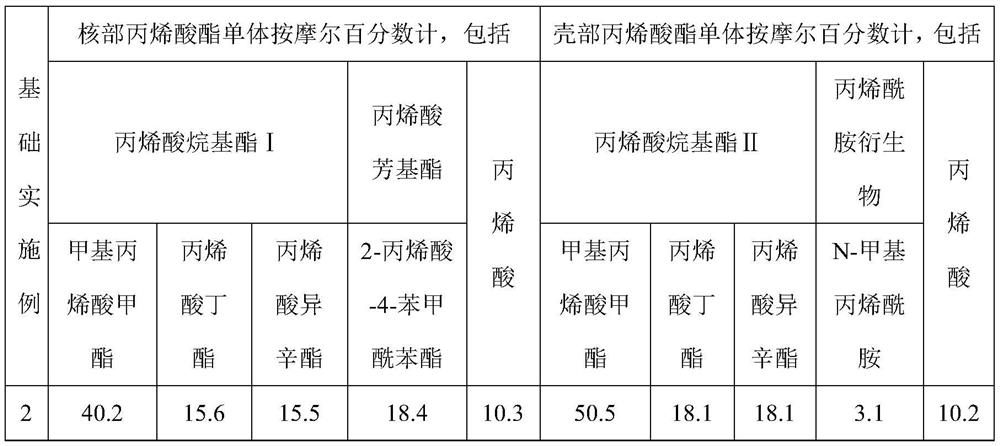

Acrylate prepolymer as well as preparation method and application thereof

ActiveCN114507320AReduce dosageHigh elongation at breakFilm/foil adhesivesOrganic non-macromolecular adhesivePolymer scienceOrganic synthesis

The invention provides an acrylate prepolymer as well as a preparation method and application thereof, and belongs to the technical field of organic synthesis. The acrylate prepolymer is prepared from the following raw materials: a core acrylate monomer and a shell acrylate monomer; the core acrylate monomer comprises alkyl acrylate I, aryl acrylate and acrylic acid; the shell acrylate monomer comprises alkyl acrylate II, an acrylamide derivative and acrylic acid; the molar ratio of the alkyl acrylate I to the alkyl acrylate II is 1: (9-19). According to the invention, by reasonably controlling the raw material components and proportion of the acrylate prepolymer, the obtained acrylate prepolymer has excellent performance, and the OCA optical cement prepared from the acrylate prepolymer can be better suitable for a soft screen and has excellent elasticity, flexibility and use performance.

Owner:嘉兴金门量子材料科技有限公司

A kind of manufacturing method of buried copper block circuit board

ActiveCN113194636BAvoid damage and deformationAvoid glue residuePrinted element electric connection formationEngineeringStructural engineering

The invention discloses a method for manufacturing a copper-buried circuit board, and relates to the technical field of printed circuit board manufacturing. The present invention firstly controls the thickness of the buried copper block to be smaller than the thickness of the circuit board, and the height difference prevents the colloid from flowing to the board surface of the circuit board after lamination, avoiding the phenomenon of residual glue on the board surface; Copper reduction treatment makes the thickness of the circuit board smaller than that of the buried copper block, and the height difference makes the upper and lower surfaces of the buried copper block protrude from the circuit board, so as to facilitate the cleaning of the upper and lower surfaces of the buried copper block; finally, the upper and lower surfaces of the circuit board The board surface and the upper and lower surfaces of the buried copper block are uniformly ground to remove the colloid on the upper and lower surfaces of the buried copper block, and at the same time ensure that the upper and lower surfaces of the circuit board are flush with the upper and lower surfaces of the buried copper block. The above manufacturing method not only improves the glue removal efficiency, but also avoids the deformation and damage of the board surface of the buried copper circuit board.

Owner:DONGGUAN SHENGYI ELECTRONICS

Wafer processing method and wafer obtained by the wafer processing method

InactiveCN103811301AAvoid glue residueGood effectSemiconductor/solid-state device manufacturingAdhesiveEngineering

The present invention provides a wafer processing method and a wafer obtained by the wafer processing method. The wafer processing method comprises a solvent cleaning step before a random appropriate processing step is performed, wherein a wafer can be properly kept and residual adhesive after stripping of a binding sheet is prevented in the processing step. The wafer processing method of the invention comprises the steps of: a binding sheet binding step for binding the wafer on the binding strip which is provided with a substrate and an adhesive layer with radiating-ray curable adhesive; a radiating ray irradiating step of irradiating radiating ray on the adhesive layer of the binding sheet for processing the wafer; the cleaning step of cleaning the wafer by the solvent; and a processing step of processing the wafer. In the wafer processing method of the invention, the radiating ray irradiating step is performed before the cleaning step.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com